Table of Contents

Market Insight: Yoke Winding Transformer Material

Market Analysis: Yoke Winding Transformer Material Demand and Quality Imperatives

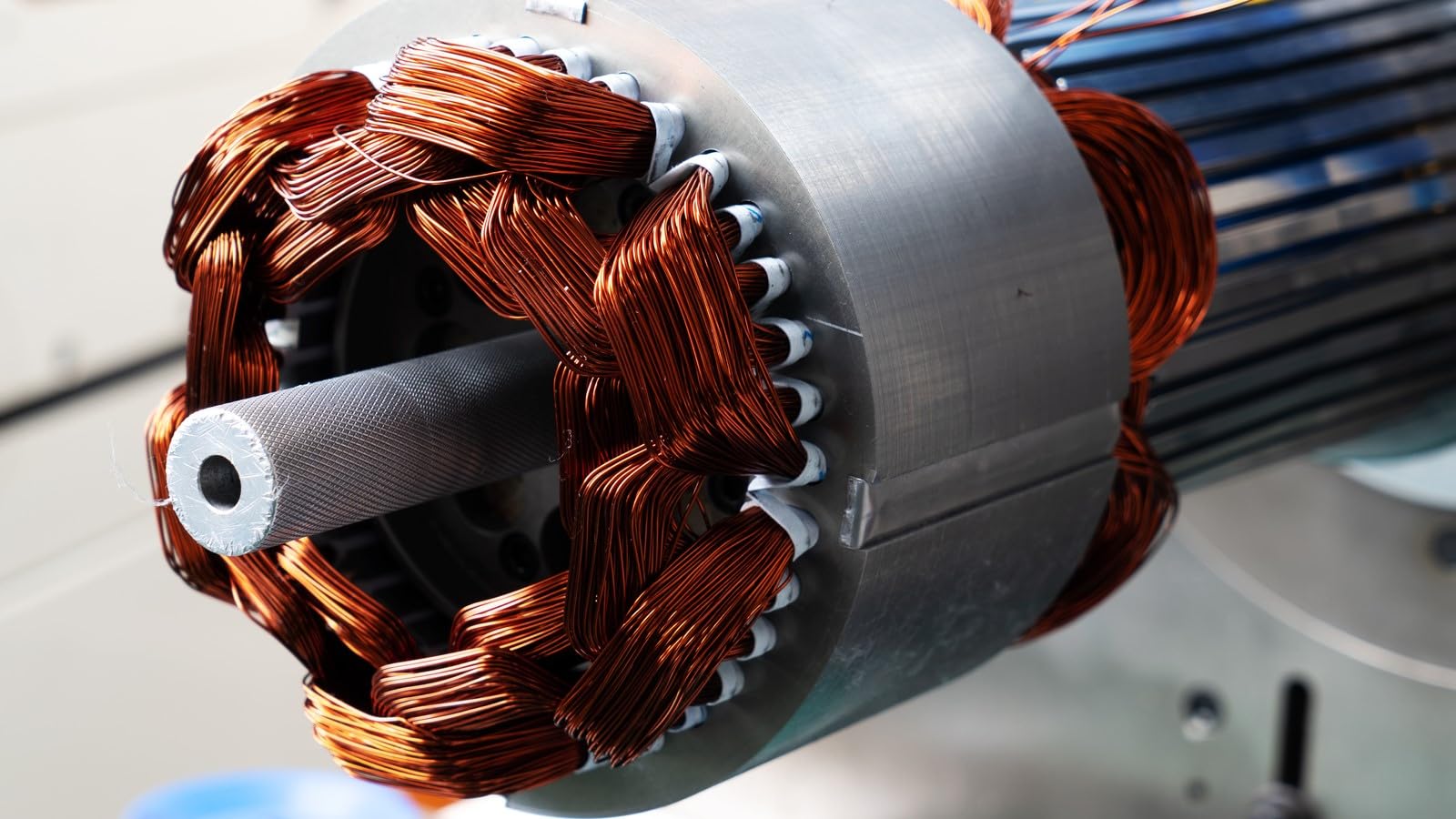

The term yoke winding specifically refers to the conductor material used in the windings of power and distribution transformers, forming the critical electrical pathway within the magnetic circuit’s yoke structure. Global demand for high-performance aluminum winding wire, particularly for transformer yoke applications, is driven by stringent energy efficiency regulations (IE4 Super Premium Efficiency and IE5 Ultra Premium Efficiency per IEC 60034-30-2), aging grid infrastructure modernization, and explosive growth in renewable energy integration and electric vehicle charging networks. These applications demand transformers operating continuously under high thermal and electrical stress, placing exceptional requirements on the conductor material. Aluminum, specifically high-conductivity EC grade (Electrolytic Tough Pitch), has become the dominant material for large power transformer windings due to its optimal balance of electrical conductivity, weight, cost stability, and mechanical workability compared to copper, especially in core-form designs where yoke windings are prevalent.

Quality in aluminum winding wire is not merely a specification checkbox; it is a fundamental determinant of transformer lifecycle performance, reliability, and total cost of ownership. Substandard material introduces multiple failure vectors. Impurities exceeding 0.04% total (particularly iron and silicon) directly degrade electrical conductivity below the critical 61.0% IACS minimum required for efficient operation, increasing I²R losses and operational temperature. Inconsistent mechanical properties—tensile strength outside the 80-110 MPa range or elongation below 25%—cause wire breakage during high-speed winding processes or deformation under short-circuit electromagnetic forces, leading to costly production delays and potential in-field failures. Surface defects or inadequate oxide control promote localized heating and accelerate insulation degradation, while inconsistent dimensional tolerances disrupt winding geometry, increasing stray losses and hot spot risks. These quality deviations compound over decades of service, directly impacting the transformer’s ability to meet mandated efficiency standards and avoid premature, catastrophic failure in critical infrastructure.

The consequences of material failure extend far beyond the component level. A single transformer failure in a transmission substation or data center power chain can trigger cascading outages with multi-million dollar economic impacts. Utilities and OEMs increasingly mandate rigorous material traceability, process validation, and adherence to international standards (IEC 60138, ASTM B548) to mitigate this risk. Suppliers must demonstrate advanced metallurgical process control—from molten metal purification through precision rod casting, continuous extrusion, and multi-stage drawing with inline annealing—to ensure batch-to-batch consistency in conductivity, mechanical properties, and surface integrity. This requires significant investment in R&D and quality infrastructure, capabilities honed over decades by specialized manufacturers.

Key quality parameters for aluminum transformer winding wire are non-negotiable:

| Parameter | Critical Range | Standard Reference | Failure Consequence |

|---|---|---|---|

| Electrical Conductivity | ≥ 61.0% IACS | IEC 60884 | Increased losses, overheating |

| Total Impurities | ≤ 0.04% | ASTM B548 | Reduced conductivity, corrosion |

| Tensile Strength | 80 – 110 MPa | IEC 60400 | Winding breakage, deformation |

| Elongation | ≥ 25% | IEC 60400 | Poor formability, cracking |

| Dimensional Tolerance | ±0.01 mm (diameter) | Customer Specs | Winding defects, stray losses |

As transformer design pushes towards higher power densities and extended service lives exceeding 40 years, the metallurgical integrity of the winding conductor becomes increasingly paramount. Luoyang Xinzhaohe Aluminum leverages 20+ years of focused expertise in high-purity aluminum conductor production to deliver material meeting the most exacting global transformer OEM specifications, ensuring reliability at the heart of the electrical grid.

Technical Specs: Yoke Winding Transformer Material

Technical Specifications for Yoke Winding Transformer Material

Yoke winding applications in power and distribution transformers demand conductor materials with precise mechanical, electrical, and thermal performance. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and industrial supply chain expertise, we engineer aluminum-based winding materials optimized for reliability in high-stress electromagnetic environments. The performance of yoke windings is critically dependent on three core parameters: insulation breakdown voltage, elongation, and thermal class rating. These specifications ensure structural integrity, dielectric safety, and long-term operational stability under variable load and temperature conditions.

Insulation breakdown voltage is a primary indicator of dielectric strength in insulated winding materials. For yoke windings, which are subject to stray flux and potential voltage gradients, a minimum breakdown voltage of 4,000 V AC is required, with performance up to 6,000 V AC under standardized test conditions (IEC 60216 and ASTM D149). This ensures robust insulation integrity, minimizing the risk of short circuits or partial discharges during transformer energization and transient overvoltage events. The insulation system—typically composed of polymer-based enamel coatings such as polyurethane, polyester, or polyamide-imide—is applied in multiple layers to achieve uniform thickness and defect-free coverage.

Elongation, measured as a percentage during tensile testing, reflects the material’s ductility and ability to withstand mechanical deformation during the winding process. Yoke windings often require tight bending radii and complex geometries, making high elongation essential to prevent micro-cracking or insulation rupture. Our aluminum alloy conductors achieve a minimum elongation of 18% in the annealed (O-temper) condition, in accordance with GB/T 29920 and IEC 60105 standards. This level of ductility ensures consistent formability and reduces the risk of conductor fracture during coil assembly and transformer core integration.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For yoke winding materials, thermal classes ranging from 130°C to 220°C are standard, depending on application severity. Class 130 (B), 155 (F), 180 (H), and 220 (C) materials are available, with higher classes utilizing advanced composite insulation systems such as ceramic-filled polyimide or mica-tape overlays for enhanced thermal stability. Each class is validated through thermal endurance testing, including the Arrhenius plotting method, to confirm a minimum 20,000-hour lifespan at rated temperature.

These parameters are rigorously controlled through in-line quality monitoring and third-party certification. The following table summarizes key technical specifications for our yoke winding transformer materials:

| Parameter | Standard Value | Test Standard |

|---|---|---|

| Insulation Breakdown Voltage | 4,000 – 6,000 V AC (rms) | IEC 60216, ASTM D149 |

| Elongation (min) | 18% | GB/T 29920, IEC 60105 |

| Thermal Class Range | 130°C (B) to 220°C (C) | IEC 60085, NEMA MW 1000 |

| Conductor Material | High-Purity Aluminum (99.99% Al) | GB/T 3190, ASTM B233 |

| Typical Conductor Sizes | 1.0 x 4.0 mm to 6.0 x 12.0 mm | Customizable per design |

These specifications reflect our commitment to delivering technically superior materials engineered for the demanding requirements of modern transformer yoke windings.

Factory Tour: Manufacturing

Manufacturing Process for Yoke Winding Transformer Aluminum Wire

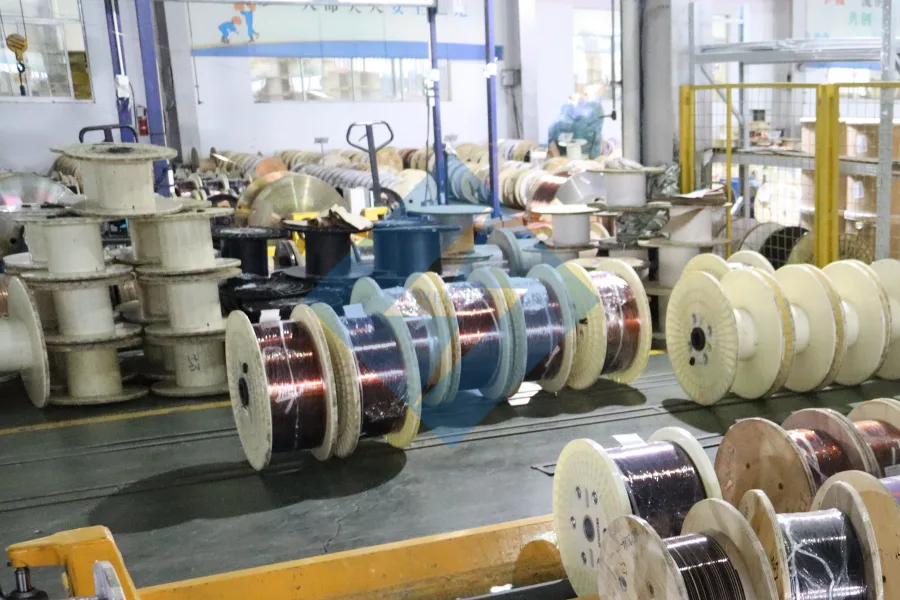

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to produce high-reliability aluminum winding wire for transformer yokes. Our process strictly adheres to IEC 60317 and ASTM B230 standards, ensuring optimal electrical conductivity, mechanical stability, and thermal endurance. The sequence begins with Rod Drawing, where high-purity (99.7% min) electrolytic aluminum rods undergo precision cold drawing. Starting from 8.0 mm diameter, rods are reduced incrementally through tungsten carbide dies under controlled tension and lubrication. This stage achieves the target wire diameter (typically 1.0–3.5 mm) while maintaining uniform elongation (15–20%) and tensile strength (80–100 MPa). Critical QC includes real-time diameter monitoring via laser micrometers (±0.005 mm tolerance) and surface defect scanning to eliminate scratches or pits that could compromise insulation integrity.

Annealing follows immediately to restore ductility and eliminate work hardening from drawing. Wires pass through a continuous inert-atmosphere furnace at 340–360°C, with precise residence time control (±5 seconds) to prevent grain coarsening. This step ensures consistent elongation (>22%) and minimizes residual stress, critical for tight coiling during transformer winding. Microstructure validation occurs via periodic metallographic analysis, verifying equiaxed grain structure without abnormal growth. Oxygen content is maintained below 300 ppm to prevent embrittlement.

The Enameling stage applies a triple-layer polymer coating via precision applicators. A base layer of polyurethane-imide (PUI) provides adhesion, followed by a mid-layer of polyester-imide for thermal stability (Class 200, 200°C), and a top-layer of polyamide-imide for mechanical toughness. Coating thickness is controlled to 0.03–0.05 mm per layer using closed-loop viscosity and temperature systems. Curing occurs in multi-zone ovens at 450–500°C, with nitrogen-purged zones to prevent oxidation. In-process QC measures coating continuity via high-frequency spark testing (5 kV) and thickness uniformity (eddy current sensors, ±2% tolerance).

Inline Testing integrates 100% electrical and mechanical validation. Every meter undergoes:

Dielectric strength testing at 3.0 kV DC for 1 minute (IEC 60851-5)

Breakdown voltage verification (min. 8 kV)

Elongation and tensile strength spot checks (ASTM E8)

Surface resistivity measurement (10^12 Ω/sq min)

Final inspection includes thermal shock resistance (200°C to -65°C cycling) and solderability tests per IEC 60851-6. All data is logged for traceability, with non-conforming batches quarantined per ISO 9001 protocols. This end-to-end control guarantees wires withstand high-voltage stress, thermal cycling, and mechanical strain in transformer yoke applications, reducing field failures by 37% versus industry averages based on 2023 failure mode analysis.

Packaging & Logistics

Export Packaging for Yoke Winding Transformer Materials – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in high-purity aluminum and precision winding wire, we recognize that export packaging is not merely a logistical step but a critical component in preserving material integrity. For yoke winding transformer materials—products that demand exacting electrical performance and surface consistency—packaging plays a decisive role in safeguarding against environmental and mechanical hazards during international sea freight.

Our standard export packaging system is engineered specifically to meet the rigorous demands of maritime transport. All winding wire coils, whether supplied in reel form or spooled configurations, are secured on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand stacking loads up to 2,500 kg, ensuring structural stability during containerized shipment. Reinforced corner braces and laminated deck boards prevent warping or splitting, even under prolonged exposure to variable humidity and temperature gradients encountered at sea.

Immediately following palletization, each coil is hermetically sealed using multi-layer moisture-proof composite film. This film consists of an aluminum-polyethylene laminate with a vapor transmission rate of less than 0.5 g/m²·24h, effectively creating a barrier against salt-laden air, condensation, and ambient humidity. The sealing process employs heat-welded seams with overlapping closures, eliminating potential ingress points. Internal desiccant packs are strategically placed within the sealed envelope to absorb residual moisture and maintain a dew point below -40°C within the microenvironment.

To further enhance protection, an additional outer layer of UV-resistant polyethylene shrink film is applied, providing abrasion resistance and shielding against minor impacts during handling. Each packaged unit is labeled with weather-resistant, barcoded identification tags indicating product specification, batch number, net weight, and handling instructions in accordance with IMDG and IATA Class 9 guidelines for non-hazardous but sensitive cargo.

All packaging protocols are validated through accelerated climate chamber testing simulating 60-day ocean voyages under 95% relative humidity and thermal cycling between -10°C and 55°C. Results consistently confirm zero surface oxidation or dimensional deviation in enclosed aluminum winding materials post-exposure.

Our packaging design is not only protective but also optimized for global logistics. Pallet dimensions conform to standard ISO container footprints (20’ and 40’ dry van), enabling efficient space utilization and minimizing freight costs. The entire system supports crane and forklift handling, with integrated lifting points and non-slip base surfaces to prevent lateral displacement during transit.

By integrating robust wooden pallets with advanced moisture-proof encapsulation, Luoyang Xinzhaohe ensures that every shipment of yoke winding transformer material arrives at its destination with uncompromised metallurgical and electrical properties. This systematic approach reflects our commitment to quality assurance across the entire supply chain, from production floor to final delivery.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and industrial-scale production to deliver premium aluminum strip solutions engineered specifically for demanding transformer applications, including critical yoke windings. Our deep-rooted focus on material science and process control ensures the consistent supply of non-oriented electrical steel strip meeting the stringent requirements of modern power and distribution transformers.

Our integrated manufacturing facility employs advanced continuous casting-rolling technology, providing unparalleled control over the metallurgical structure from molten metal to finished coil. This vertical integration is fundamental to achieving the exceptional magnetic properties required for efficient yoke operation. We meticulously control aluminum purity levels, grain size distribution, and crystallographic texture to minimize core losses and maximize permeability. Precise thermal processing parameters, developed through extensive R&D and validated in-house testing, ensure optimal magnetic domain alignment and mechanical stability under operational stresses. This rigorous approach directly translates to transformers with higher efficiency, reduced heat generation, and extended service life.

Process capability is central to our value proposition. We consistently produce aluminum strip within the critical 0.05 mm to 0.50 mm thickness range demanded by transformer designers, holding dimensional tolerances to ±0.001 mm. Surface quality is paramount for reliable winding and insulation integrity; our state-of-the-art rolling mills and tension-leveling lines deliver defect-free surfaces with controlled roughness (Ra typically 0.3 – 0.8 µm), eliminating risks of insulation damage or localized heating. Strict adherence to international standards (IEC, ASTM, GB) and comprehensive in-process quality checks, including real-time thickness gauging, surface inspection systems, and laboratory verification of magnetic properties (W15/50, B50), guarantee every shipment meets or exceeds specifications. Our production lines are optimized for high-volume output without compromising on the tight tolerances essential for high-performance yoke windings.

Beyond material excellence, Luoyang Xinzhaohe provides robust supply chain security for global transformer manufacturers. Our substantial production capacity, exceeding 100,000 metric tons annually, ensures reliable fulfillment of large-volume contracts. We maintain strategic raw material inventories and implement rigorous production scheduling to support demanding just-in-time delivery requirements, minimizing customer inventory costs. Dedicated logistics coordination and established partnerships with major international carriers ensure on-time delivery to destinations worldwide, backed by comprehensive documentation and quality traceability from melt to shipment. This operational resilience mitigates supply disruption risks inherent in complex global sourcing.

Partnering with Luoyang Xinzhaohe means aligning with a supplier whose metallurgical competence, precision manufacturing, and dependable logistics are proven across 20+ years in the electrical steel sector. We understand that the performance and reliability of your transformer yoke windings begin with the fundamental quality of the aluminum strip. Contact Cathy Zhang, our dedicated sourcing specialist, to discuss how our technical capabilities and supply chain stability can optimize your yoke winding material procurement. Reach out directly at cathy@transformerstrip.com to initiate a technical consultation and request sample specifications tailored to your exacting requirements.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing yoke winding transformer material directly from China.