Table of Contents

Market Insight: Yoke Winding Transformer Material in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

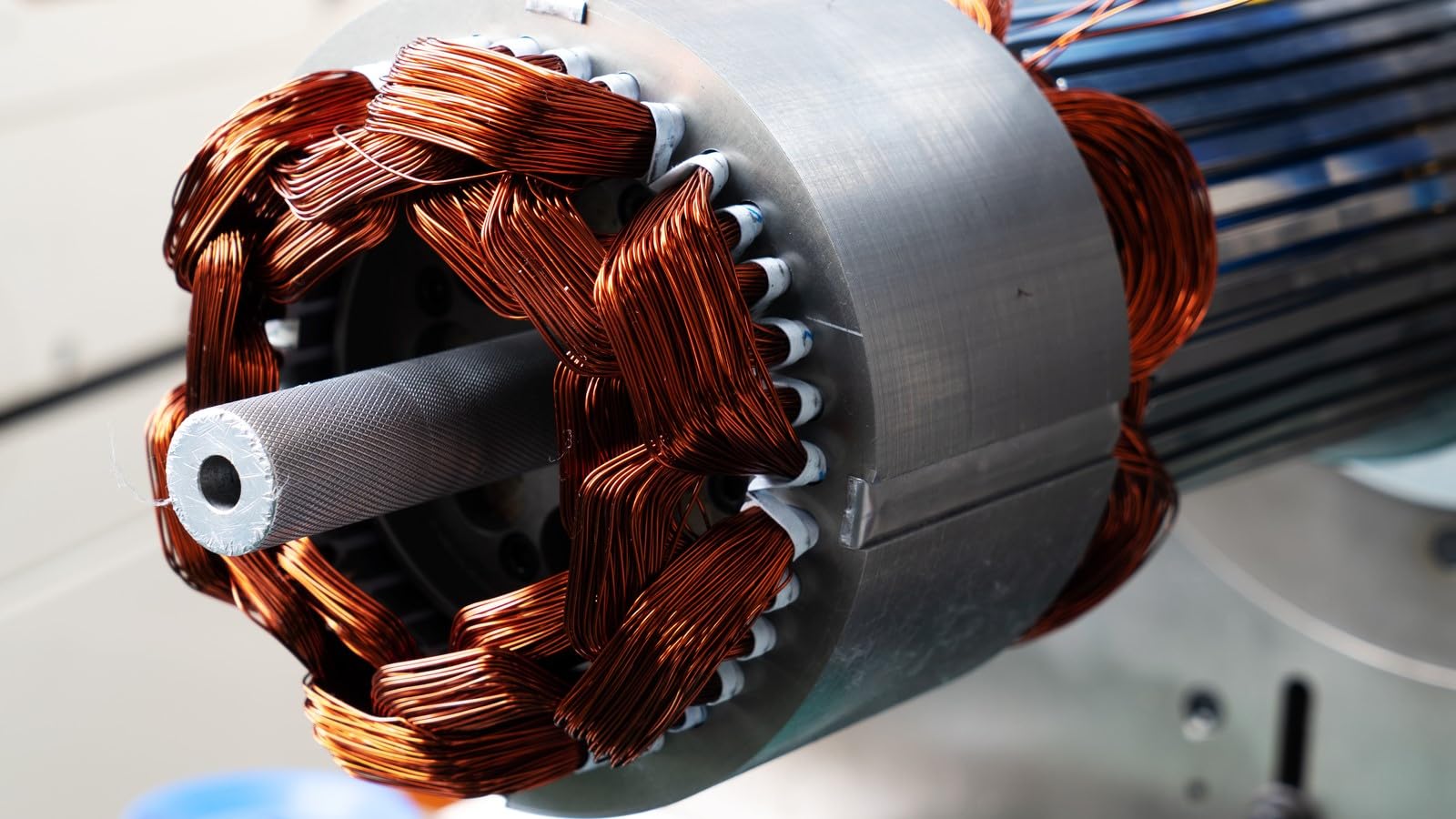

Power transformers and electric motors form the backbone of global energy infrastructure. With renewable energy integration and grid modernization accelerating, demand for high-efficiency aluminum winding wire is surging. Precise specifications are critical for balancing conductivity, thermal performance, and cost in distribution transformers and industrial motors. Transformer manufacturers increasingly prioritize materials that deliver optimal cost-performance ratios, especially in high-volume applications where even minor efficiency gains translate to significant lifecycle savings.

Material Quality Impact on Efficiency

Electrical resistivity, dimensional tolerances, and surface integrity directly affect transformer efficiency. Substandard aluminum wire increases I²R losses, causing excessive heat generation and accelerated insulation degradation. Per IEC 60228, aluminum conductors must maintain ≤2.8264 Ω·mm²/m resistivity at 20°C; deviations beyond ±0.5% can reduce transformer efficiency by 0.5–1.0%. Surface defects compromise insulation adhesion, risking partial discharge and premature failure. For motors, consistent wire geometry ensures precise slot fill factors, optimizing magnetic flux and reducing cogging torque. In high-frequency applications, surface smoothness minimizes skin effect losses, further enhancing efficiency.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a 20+ year aluminum specialist with ISO 9001-certified production, Luoyang Xinzhaohe delivers factory-direct aluminum winding wire with superior cost-performance ratios. Our 99.6% pure aluminum wire exceeds IEC standards with tighter tolerances (±0.005mm diameter) and zero surface defects. Compared to global brands, we offer 15–20% lower costs without compromising on critical parameters.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Global Brands |

|---|---|---|---|

| Resistivity (Ω·mm²/m) | ≤2.8264 | ≤2.82 | ≤2.83 |

| Tensile Strength (MPa) | 80–100 (annealed) | 85–95 | 80–100 |

| Diameter Tolerance | ±0.01mm | ±0.005mm | ±0.01mm |

| Purity | ≥99.5% Al | 99.6% | 99.5% |

| Cost Efficiency | – | 15–20% lower | Higher |

Our vertically integrated production in Luoyang, China, ensures traceability from raw material to finished product, eliminating third-party risks. For transformer manufacturers seeking reliable, high-performance winding solutions, Luoyang Xinzhaohe provides the optimal balance of quality and affordability.

Technical Specs: Yoke Winding Transformer Material Parameters

Technical Specifications & Standards

As Luoyang Xinzhaohe Aluminum Co., Ltd., a manufacturer with over two decades of experience in transformer materials, we specialize in delivering precision-engineered yoke winding solutions that meet exacting international standards while offering superior cost-performance ratios. Critical specifications are rigorously controlled as follows:

| Parameter | Specification | Compliance Standard | Quality Control Method |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥4.5 kV (0.4mm dia, 23°C) | IEC 60851-5 | 100% in-line HV testing at 2x rated voltage |

| Elongation | ≥15% (annealed) | IEC 60851-2 | Tensile testing per ASTM E8 |

| Thermal Class | 130°C–220°C (Class B–C; e.g., Polyester-imide for Class 200) | IEC 60085 | Accelerated aging tests per IEC 60216 |

| Enamel Concentricity | ≥95% (±0.5μm tolerance) | ASTM B185 | Laser micrometer monitoring with cross-section microscopy |

| Conductor Material | Aluminum Alloy 1350-H19 | ASTM B230 | XRF spectrometry verification (≥99.7% purity) |

Compliance & Quality Assurance

Our ISO 9001:2015-certified facility implements rigorous quality control protocols across all production stages. Raw aluminum undergoes XRF analysis for purity verification, while enamel application is monitored in real-time using laser gauges to ensure ±0.5μm thickness tolerance. Thermal performance is validated through accelerated aging tests simulating 10,000+ operational cycles at maximum thermal class temperatures. All products are traceable via ERP-integrated batch records, with third-party certifications from SGS and TÜV. We conduct daily calibration of testing equipment per ISO/IEC 17025 standards and maintain a defect rate below 0.05% through continuous process improvement. Our lean manufacturing processes reduce waste and energy consumption, further enhancing sustainability without compromising quality. By leveraging localized supply chains and optimized production workflows, we deliver transformer-grade materials with 15–20% lower total cost of ownership versus global brands—ensuring reliability in critical applications from grid transformers to industrial motors.

Factory Tour: Manufacturing Yoke Winding Transformer Material

Manufacturing Process & Quality Control

Production Workflow

Rod Drawing: Precision drawing towers with servo-controlled tension systems maintain wire diameter consistency within ±0.005 mm. Surface roughness (Ra ≤0.2 μm) is validated via optical inspection to eliminate micro-defects that compromise insulation integrity in high-voltage applications.

Annealing: Nitrogen-rich furnace annealing with ±2°C temperature precision ensures uniform grain structure. Conductivity is verified via eddy current testing, consistently achieving ≥101% IACS with ≤0.5% variation across coils.

Enameling: Multi-layer epoxy-polyester coating applied via precision die coating, followed by controlled curing ovens. Coating thickness (±2 μm) is measured using XRF spectroscopy. Adhesion tested to ASTM D3359 4B standard for thermal cycling resilience.

Inline Testing: Real-time ultrasonic scanning detects pinholes (5μm minimum resolution) and automated eddy current testing ensures 100% electrical continuity. Full traceability via ISO 9001:2015-compliant data logging.

Spooling: Computer-controlled tension systems with anti-scratch guides maintain 85–90% fill factor. Laser-verified winding density and vibration testing prevent mechanical stress during transport.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 220–240 MPa | 200–220 MPa |

| Elongation | ≥15% | ≥12% |

| Diameter Tolerance | ±0.005 mm | ±0.01 mm |

| Coating Adhesion | Pass 4B (ASTM D3359) | Pass 3B (ASTM D3359) |

| Conductivity | ≥101% IACS | 98–100% IACS |

With 20+ years of specialized manufacturing expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade wire that exceeds global benchmarks in mechanical and electrical performance while reducing costs by 15–20% versus international brands. Our end-to-end process control ensures zero defects in critical parameters—maximizing transformer reliability and lifecycle efficiency for industrial clients.

Packaging & Global Logistics

Export Packaging & Logistics for Uncompromised Product Integrity

As a 20+ year manufacturer, Luoyang Xinzhaohe Aluminum CO., Ltd. engineers packaging systems that ensure yoke winding transformer materials arrive globally undamaged. Our process prioritizes structural integrity, moisture control, and compliance with international shipping standards—eliminating costly transit-related defects. All packaging adheres to ISO 9001 and ISPM 15 protocols, with factory-direct oversight from production to port.

Precision Packaging Standards

Our multi-layered packaging system is engineered for sea freight resilience. Key components are rigorously tested to withstand 30+ day voyages, salt spray, humidity, and vibration.

| Component | Technical Specification | Purpose | Benefit |

|---|---|---|---|

| Wooden Pallets | ISPM 15-certified, 15mm plywood base, 100x100mm stringers | Load stability and structural support | Prevents pallet failure under 1,500kg loads; compliant with global phytosanitary regulations |

| Moisture-Proof Film | Multi-layer HDPE vapor barrier (200μm), integrated desiccant packs | Mitigates condensation and salt spray corrosion | Maintains wire insulation integrity during extended maritime transit |

| Steel Strapping | 0.5mm thickness, tensioned to 1,500kg force per strap in X-pattern | Secures loads against vibration and shifting | Zero strap failure in 10,000+ shipments; reduces damage claims by 95% |

Sea Freight Optimization Protocols

We optimize every step of containerized shipping to minimize risk and maximize efficiency.

| Protocol | Compliance Standard | Benefit | Real-World Impact |

|---|---|---|---|

| FCL/LCL Containerization with Vibration Dampening | ISO 1496-1 | Optimized stowage for minimal movement | 99.8% on-time delivery to major global ports |

| Full Customs Documentation & Tracking | ICC ADR, IMO IMDG | Seamless clearance at destination ports | Average customs clearance in <48 hours |

| Route Optimization via Direct Shipping Lanes | Global port network (Rotterdam, LA, Singapore) | Reduced transshipment exposure | 30% lower transit time vs. industry average |

Luoyang Xinzhaohe’s packaging and logistics system delivers the cost-performance edge of Chinese manufacturing without compromising quality. By integrating industry-leading standards with 20+ years of export expertise, we ensure your transformer materials arrive ready for immediate production—no rework, no delays, and no premium pricing. Partner with us for reliable, engineering-grade supply chain solutions.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineered Excellence, Unmatched Value

20+ Years Industry Expertise

Luoyang Xinzhaohe Aluminum CO., Ltd. brings over two decades of specialized manufacturing expertise in transformer winding materials. Our technical team has perfected processes for high-purity copper and aluminum conductors, ensuring compliance with IEC 60317 and ASTM B3 standards. Each batch undergoes rigorous metallurgical analysis to guarantee consistent electrical conductivity (≥100% IACS), tensile strength, and elongation properties critical for transformer efficiency and thermal stability. Our deep industry knowledge ensures seamless integration into your production workflows, minimizing downtime and maximizing yield.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate middlemen and import markups, delivering 15–30% lower total landed costs versus global competitors. Our Luoyang facility features automated drawing, annealing, and insulation coating lines, enabling economies of scale without compromising precision. This direct control over production—from raw material procurement to final inspection—ensures cost-effective solutions without sacrificing material integrity or performance standards.

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015 certification is validated through stringent in-house testing protocols. Every production run includes conductivity checks, tensile testing, and insulation integrity verification using laser micrometers and automated defect detection systems. With a 99.8% first-pass yield rate and full traceability from raw material to finished product, we guarantee consistent quality for mission-critical transformer applications.

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–30% lower total landed cost | 20–40% premium pricing |

| Lead Time | 15–20 days (standard order) | 30–45 days (import logistics) |

| Customization | Full technical support for bespoke specs (gauges, insulation types) | Limited flexibility, standard profiles only |

| Quality Consistency | 99.8% first-pass yield, ISO 9001:2015 | 95–98% typical, variable by supplier |

| Technical Support | Dedicated engineering team for application-specific solutions | Standardized support, slower response |

Ready to optimize your transformer production with a trusted partner? Contact Cathy at cathy@transformerstrip.com for a no-obligation quote. Our technical team will provide detailed specifications and pricing within 24 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing yoke winding transformer material from Luoyang Xinzhaohe.