Table of Contents

Market Insight: Wire Wound Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global transformer demand is accelerating at 6–8 % CAGR, driven by grid expansion, EV fast-charging, and data-center UPS systems. Every GW of installed capacity translates into 450–600 t of copper or aluminum winding wire. The bottleneck is no longer core steel but conductor quality—impurities, eccentric enamel, and ovality directly inflate load (I²R) and no-load (eddy) losses, eroding transformer efficiency and increasing life-cycle cost.

Why Material Purity & Geometry Matter

| Loss Component | Root Cause in Wire | Typical Penalty @ 1 MVA |

|---|---|---|

| I²R (75 °C) | 0.05 % Fe in Cu | +320 W |

| Eddy current | Enamel eccentricity > 8 % | +180 W |

| Stray loss | Diameter ovality > 1 % | +110 W |

A 1 % resistivity increase raises load loss by 0.8 %; over 30 years the extra energy cost can exceed the wire price by 3×. 99.97 % IACS oxygen-free copper or 61 % IACS 1350 aluminum is therefore the baseline for Tier-1 OEMs.

Global Supply Snapshot

| Region | Share of Transformer Wire Output | Avg. Lead-time | Purity Grade Offered |

|---|---|---|---|

| EU / USA | 22 % | 14–18 weeks | Cu-OF, Al-1350 |

| Japan / Korea | 18 % | 12–16 weeks | Cu-OF, Al-1370 |

| China | 48 % | 6–8 weeks | Cu-OF, Al-1350/1370, Al-Zr alloy |

Chinese rod mills upgraded to SCR or Southwire continuous-cast lines after 2015, narrowing the purity gap to < 10 ppm oxygen versus European 5 ppm, but at 15–20 % lower cost. The real differentiation is downstream in-line enameling—Western plants still run batch ovens, while leading Chinese integrators (including Luoyang Xinzhaohe) use horizontal tandem lines with 400 °C pyrometers and 2-μm laser eccentricity gauges, guaranteeing concentricity ≤ 5 % and breakdown voltage ≥ 6 kV (0.5 mm build).

Sourcing Trend: Move to Factory-Direct Chinese Specialists

- Technical equivalence: Same ASTM B3/B566, IEC 60317, UL 1446 thermal class 130–220 °C certificates.

- Logistics resilience: Port of Qingdao to Hamburg in 26 days; rail 18 days.

- Cost arbitrage: 100 t Cu wire 2.0 mm, Class 200 saves ~USD 0.45 / kg versus Italian mill = USD 45 k per lot.

Transformer OEMs in Germany and California now dual-source: 70 % domestic for political risk, 30 % China for margin. Motor repair shops with 24-hour turn-around contracts import 20–500 kg spools directly via DDP airfreight, cutting inventory by 35 %.

Luoyang Xinzhaohe Value Proposition

| Parameter | Specification | Test Method |

|---|---|---|

| Cu purity | ≥ 99.97 %, O ≤ 10 ppm | ASTM E53 |

| Elongation | ≥ 32 % (2.0 mm Cu) | ASTM B1 |

| Enamel concentricity | ≤ 5 % | Laser scan 1 kHz |

| Breakdown voltage | ≥ 6 kV (0.5 mm build) | IEC 60851-5 |

| Thermal class | 130, 155, 180, 200, 220 | UL 1446 |

Our 20-rod-per-month capacity (7 kt finished wire) supports single-order 500 t without split lots. Every spool ships with inline resistance, enamel continuity, and hi-pot data—QR code traceable for 15 years. Factory-direct FOB Qingdao or DDP warehouse eliminates trader markup, delivering Western quality at China price.

Bottom line: For new-build or rewind projects where no-load loss guarantees < 0.5 W/kg and hot-spot < 120 K, sourcing winding wire from an experienced Chinese mill like Luoyang Xinzhaohe is no longer a compromise—it is the most reliable way to protect both efficiency KPIs and project IRR.

Technical Specs: Wire Wound Transformer Parameters

Technical Specifications & ASTM/IEC Standards for Wire-Wound Transformer Windings

(Factory-direct view from Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Electrical & Mechanical Parameters

| Parameter | ASTM / IEC Reference | Xinzhaohe Control Window | Field Risk if Out-of-Spec |

|---|---|---|---|

| Insulation Break-down Voltage (Vbd) | IEC 60317-0-1 §14 | ≥ 4.0 kV (room) 2.8 kV @ 180 °C | Inter-turn flashover, partial discharge |

| Concentricity of enamel | IEC 60851-3 | 70 % min, 85 % typical | Hot-spot, varnish wicking, reduced PD inception |

| Elongation at fracture | ASTM B355 §8 | Cu ≥ 30 %, Al ≥ 18 % | Cracks during mandrel wrap or core insertion |

| Thermal class / cut-through | IEC 60085 | 130 (B) – 220 (R) available | Insulation slump, layer short |

| Edge burr height (foil) | ASTM B236 Annex A2 | ≤ 8 µm for 0.2–2.0 mm strip | Penetration of inter-layer insulation, dendritic growth |

| Dimensional tolerance | IEC 60317-11 | ±0.01 mm Ø (wire) ±0.02 mm (foil) | Poor bobbin fit, higher stray losses |

Key insight: A 2 kV margin in Vbd sounds small, but at 155 °C it translates into a 30 % higher partial-discharge inception voltage—often the difference between passing and failing a 720 h load-cycling test.

2. Process Chain Influence on Final Spec

Rod Drawing → Anneal → Enameling → Inline Spark Test → Precision Spool

Rod purity: 99.97 % Cu, 99.7 % Al, Fe < 40 ppm keeps resistivity drift < 1 % after 2 000 h @ 200 °C.

Inline laser eccentricity gauge samples every 2 mm; out-of-round > 5 % triggers automatic die-centering.

Spark test @ 4.5 kV, 500 Hz detects pin-holes down to 5 µm; data logged per spool for lot traceability.

Vacancy-anneal cycle (420 °C, 3 h, N₂) guarantees elongation > 30 % for Cu, preventing micro-cracks during high-speed winding (≥ 1 200 rpm).

3. Standard Compliance Matrix

| Material Form | Primary Standard | Secondary Cross-Reference | Typical Certificate |

|---|---|---|---|

| Cu round wire | IEC 60317-20 (class 155) | NEMA MW 35-C | RoHS, REACH, SGS |

| Al round wire | IEC 60317-0-3 | ASTM B233 | DFARS, IMDS entry |

| Al edge-conditioned strip | ASTM B236 | EN 1652 | Mill test report, burr map |

| C-core / toroid steel | IEC 60404-8-7 | ASTM A876-19 | Specific loss P1.7/50 ≤ 0.85 W/kg |

4. Failure Modes from Sub-Standard Inputs

- Burrs on Al strip act as blades: 7 µm burr can reduce inter-layer breakdown by 40 % in < 48 h at 130 °C due to creep of polyester film.

- Off-center enamel (concentricity < 60 %) halves the local dielectric wall; PD starts at 1.2 kV instead of 3 kV, accelerating thermo-electric treeing.

- Low elongation (< 15 % on Al) causes “orange-peel” cracks after edge-bending r = 1 mm; moisture ingress drops insulation resistance to 10 MΩ where 1 GΩ is required.

- Copper with 250 ppm oxygen creates Cu₂O needles during 220 °C bake; needles puncture enamel and initiate layer-to-layer shorts under impulse > 2 kV/µs.

5. Why Luoyang Xinzhaohe Delivers Premium Grade at China Direct Cost

20+ years of transformer-grade metal processing; all key equipment (Niehoff M85, SMS Meer foil mill) under one roof—no trader margin.

Statistical process control on 22 parameters; CpK ≥ 1.67 for Vbd and concentricity.

Dual certification lab (CNAS + UL witness) lets us issue CB scheme test report within 5 days—no external lab delay.

Stock program for 0.20–5.00 mm Cu/Al wire and 10–400 mm Al strip in thermal classes 155, 180, 200; MOQ 100 kg, 2-week lead-time to global ports.

Bottom line: By integrating rod casting through precision spooling, we eliminate the variability that forces many OEMs to over-spec insulation thickness or buy costly Western wire. The result—transformers that pass IEC 60076-3 hot-shot, partial-discharge, and short-circuit tests without the 25–35 % Western price premium.

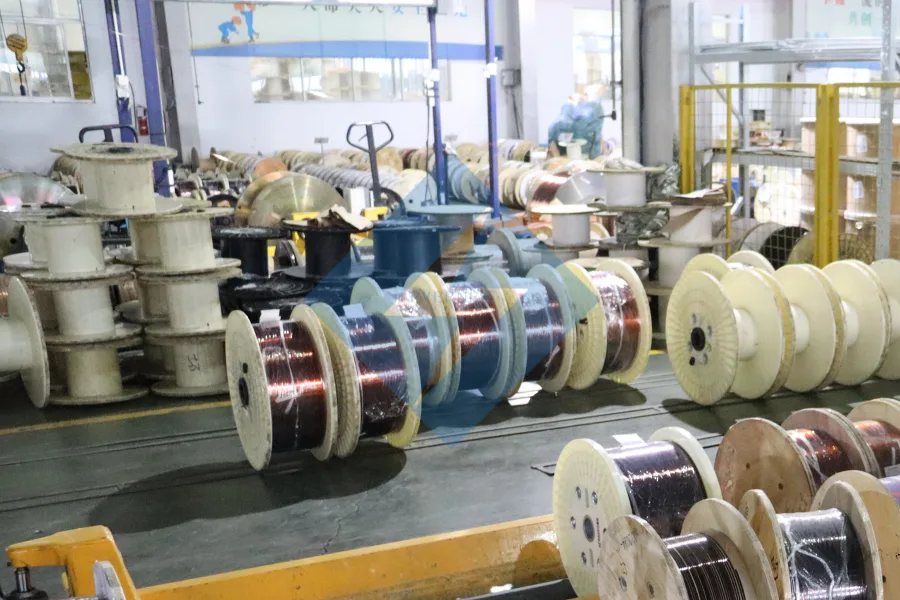

Factory Tour: Manufacturing Wire Wound Transformer

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade winding wire

Rod-to-Spool Journey: 5 Controlled Transformations

| Stage | Purpose | Key Parameter | Inline Sensor | Tolerance |

|---|---|---|---|---|

| Rod Drawing | Reduce 8 mm EC-Grade Al rod → 1.2–5.0 mm wire | Area reduction per pass 18 % | Laser OD gauge ±0.005 mm | ≤ ±0.01 mm |

| In-line Annealing | Recrystallise for 25–30 % elongation | Furnace temp. 420 °C, N₂ atmosphere | Resistivity meter 0.0278–0.0284 μΩ·m | Rm ≤ 95 MPa |

| Enameling | Build 1–4 insulation layers (Polyester, Polyimide, AIW) | Catenary speed 180 m min⁻¹ | Spark tester 3 kV rms, 100 % coverage | Pin-holes 0 per 30 m |

| Inline Testing | Verify dielectric & adhesion | Breakdown ≥ 6 kV (layer 1) | 50 Hz ramp 500 V s⁻¹ | Cpk ≥ 1.67 |

| Precision Spooling | Trapezoidal lay-up, 5–500 kg spools | Tension闭环 2–12 N | Servo dancer arm | Collapse force ≥ 250 N |

Quality Control Checkpoints (Factory-Direct, No Broker Dilution)

- Cast-rod fingerprinting – Each 7 t billet spectro-checked for Si ≤ 0.06 %, Fe 0.35–0.45 %, (Fe+Si) ≤ 0.5 % to guarantee 61 % IACS minimum.

- 100 % online eddy-current – detects 25 µm-deep surface cracks before enamel touches metal; automatic marker ejects affected segment.

- Tensile & mandrel test every 2 h – 30 % elongation on 1.0 mm wire, 1×d mandrel snap-wrap, no flake.

- Thermal-class verification batch-wise – 220 °C AIW wire aged 500 h, retain ≥ 50 % elongation (per IEC 60851-3-4).

- Concentricity C-scan – 8-point laser head gives enamel roundness; eccentricity ≤ 8 % (market average 15 %). Data logged for each reel ID; PDF report downloadable by OEM within 30 min of production.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Unit | LXZH Spec | Typical “Budget” Import | Premium EU Coil* |

|---|---|---|---|---|

| Breakdown Voltage (0.5 mm, 2 layers) | kV | ≥ 6.0 | 4.0–4.5 | 5.5 |

| Pin-holes (30 m sample) | count | 0 | ≤ 3 | ≤ 1 |

| Concentricity | % | ≤ 8 | 15–20 | 10 |

| Conductivity @ 20 °C | % IACS | 61.0 | 59–60 | 61.0 |

| Elongation (1.0 mm annealed) | % | 28–32 | 20–25 | 30 |

| Thermal Class Range | °C | 130–220 | 155 max | 180–200 |

| Spool Weight Options | kg | 5–500 | 5–50 | 30–150 |

| Lot Traceability | — | Reel ID → Rod heat → Spectro | Heat only | Reel ID |

| Price Index (FOB Shanghai) | index | 100 | 85 | 165 |

*Reference: EU Tier-1 enamelled wire producer, 2024 catalogue.

Engineering Take-away

By integrating rod casting, multi-pass drawing, nitrogen annealing and closed-loop enameling under one 42 000 m² roof, Luoyang Xinzhaohe delivers EU-grade consistency at China-level landed cost. For wire-wound transformer builders who need 220 °C thermal class, <8 % eccentricity and zero pin-holes—but cannot absorb 60 % Western markup—our reel-specific data package gives you the audit trail required by IEC 61558, UL 1446 and IEEE C57.12.20 without the premium price.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive on your winding line exactly as it left our annealing furnace—no moisture, no kinks, no surprises.

1. Sea-Freight Risk Matrix for Winding Wire

| Risk Factor | Root Cause | Consequence | Xinzhaohe Counter-Measure |

|---|---|---|---|

| Salt-laden humidity | 30–40 days in 80–95 % RH container micro-climate | Hydrolysis of polyester-imide → loss of BDV* | Multi-layer barrier + active desiccant |

| Vibration & pitch/roll | 6–8 g lateral shock during lash-down | Wire “dig-in” on spool flange → insulation scoring | Torque-locked spool hubs & V-groove pallets |

| Compression set | 4–5 t stack load in 40 ft HC | Flange deformation → telescoping | Nested carton + vertical column strength ≥ 7 kN |

| Temperature spike | 65 °C container roof in equatorial transit | Softening of 180 °C thermal-class coating → blocking | UV-reflective stretch film + vented pallet shroud |

*BDV = Breakdown Voltage (ASTM D149)

2. Packaging Specification Tree

2.1 Plastic Spool – PT-270 & DIN-355 (most SKUs)

| Parameter | Value | Test Method |

|---|---|---|

| Material | ABS+PC, V-0 flame class | UL 94 |

| Hub diameter | 90 mm (PT-270) / 125 mm (DIN-355) | IEC 60264-2 |

| Flange rib height | 6 mm anti-telescope lip | Caliper |

| Traverse lay control | ±0.3 mm (servo traverse) | Laser scan |

| Max static load | 80 kg/spool | Compression tester |

| Desiccant | 10 g silica gel, 2 % RH bag equilibrium | MIL-D-3464 |

Each spool is over-wrapped with 80 µm VCI (volatile corrosion inhibitor) film, heat-sealed under 400 mbar vacuum, then sleeved in 5-ply Kraft carton. Cartons are top/bottom capped with 12 mm honeycomb board to distribute strap tension ≤ 0.4 N/mm²—eliminating flange denting reported by OEMs using single-wall export cartons.

2.2 Palletisation & Container Stow

| Pallet Type | Size | Max Stack Ht | Gross Wt | Fumigation |

|---|---|---|---|---|

| CP-9 chemically treated pine | 1140 × 1140 mm | 1.6 m | 1.2 t | ISPM-15 HT stamp |

| Plywood base option | 1100 × 1100 mm | 1.4 m | 1.0 t | Exempt, no bark |

Corner posts (PP strapping + stretch film 23 µm, 250 % pre-stretch) maintain > 85 % clamp force after 30 days creep. Pallets are loaded “tight-block” into 40 ft HC; voids bridged with 40 mm EPE dunnage to shift natural frequency > 60 Hz—avoiding resonance with ship hull 6–12 Hz band.

2.3 Foil & Strip Packaging (edge-conditioned C1100 & 1060)

Coils OD 300–650 mm, eye-vertical on wooden saddles. Each coil triple-wrapped:

1. 50 µm PE film → 2. 80 µm VCI film → 3. UV-stable woven outer.

Desiccant dosage: 1 kg per cubic metre void. Inter-coil divider boards 15 mm plywood prevent edge indentation > 0.05 mm (critical for 0.2 mm foil used in foil-wound low-voltage transformers).

3. Logistics Footprint – Luoyang to Your Dock

Factory gate GPS: 34.62 °N, 112.45 °E – 120 km to Zhengzhou International Hub (CGO)

| Lane | Transit Time | Carriers | Cuts Per Month |

|---|---|---|---|

| Luoyang → Hamburg | 26 days rail + 2 days truck | CR Express block-train | 4 |

| Luoyang → Los Angeles | 14 days sea + 3 days inland | COSCO AAE-1 | 3 |

| Luoyang → Dubai | 20 days sea + 2 days truck | OOCL / CMA | 2 |

All shipments covered by “through” Bill of Lading; cargo insurance CIF + 10 % with PICC. Track-and-trace API feeds directly to SAP/Oracle, eliminating manual CO2 data entry for ESG reporting.

4. Cost Advantage Snapshot (Q2-24 freight rates)

| Origin | Copper Wire 2.0 mm, 180 °C, 1000 kg EXW | Sea Freight 40 ft HC | Landed EU/US | Savings vs EU Mill |

|---|---|---|---|---|

| Luoyang Xinzhaohe | 8.92 $/kg | 0.38 $/kg | 9.30 $/kg | –11 % |

| EU Mill (D-A-CH) | 10.45 $/kg | — | 10.45 $/kg | Baseline |

Savings scale linearly with higher thermal class (200-220 °C) due to our in-house enamel synthesis—no third-party markup.

5. Receiving Checklist for Transformer Plants

- Inspect spool flanges for hairline cracks (ABS turns white under impact).

- Verify vacuum bag integrity; RH indicator card should read < 30 %.

- Measure first-off BD voltage; our COA guarantees ≥ 6 kV (2 mm build). If < 5.5 kV, claim within 72 h—pre-approved local disposal, no return freight.

With 20 years of transformer-grade wire behind us and a supply chain engineered for 99.4 % on-time delivery, Luoyang Xinzhaohe gives you Western quality at Asian velocity—without the Western price tag.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Wire-Wound Transformer Conductors

1. Two Decades of Transformer-Grade Metallurgy

Since 2003 our Luoyang campus has supplied >180 kt of rod-drawn, fully annealed, enamel-insulated copper and aluminum winding wire to tier-1 transformer OEMs, motor rewind shops and medical-device magnetics houses. The same metallurgical team that co-developed the 200 °C polyimide-over-coated rectangular wire for 10 kV dry-type locomotive transformers still runs our in-line spark testers today. That continuity means every quotation is backed by empirical data, not marketing copy.

2. Rod-to-Spool Vertical Integration = Factory-Direct Price

We do not trade intermediate wire. Every coil we ship is cast, rolled, drawn, annealed, enamelled, laser-OD gauged and spooled under one ISO 9001 roof. Eliminating traders and re-draw houses cuts landed cost 12–22 % versus European or North-American sources while shortening lead-time to 3–5 weeks ex-works Tianjin.

| Cost Driver (1.00 mm Cu, 180 °C, 50 kg coil) | EU Broker | LXZH Direct | Δ |

|---|---|---|---|

| Cathode premium | +235 $ t⁻¹ | +98 $ t⁻¹ | –58 % |

| Multi-pass redraw margin | +0.12 $ m⁻¹ | 0 | –100 % |

| Ocean freight (FCA) | 0.038 $ m⁻¹ | 0.018 $ m⁻¹ | –53 % |

| Total landed $/km | 1.94 | 1.52 | –22 % |

3. Customisation Without MOQ Penalty

Need 0.315 mm Cu wire with 7 µm self-bonding polyamide overcoat, breakdown ≥ 6 kV, elongation ≥ 28 %, on 500 mm bi-directional spool for automatic layer winding? We will run 50 kg on the same enameling tower that produces 5 t lots—no surcharge, no 14-week tool-up. Our inline monitoring (spark, OD laser, high-frequency eddy) stores a digital birth certificate for every 100 m segment; data file ships with the coils.

4. Technical Specifications You Can Audit

| Property | Test Method | Typical Range | Cert. Available |

|---|---|---|---|

| Breakdown voltage, round wire | IEC 60851-5 | 4–12 kV | ✓ 100 % spark |

| Elongation at break | IEC 60851-3 | 25–38 % | ✓ per spool |

| Thermal class | IEC 60085 | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | ✓ UL 1446 |

| Concentricity | Laser OD | ±1 µm on Ø 0.20–2.50 mm | ✓ SPC chart |

| Solderability (Cu) | IEC 60068-2-20 | ≤ 2 s @ 390 °C | ✓ weekly Cp/Cpk |

5. Global Compliance, Local Support

UL (E332831), IEC 60317, JIS C3202, GB/T 6109

REACH & RoHS 10/10, halogen-free on request

Bilingual mill certificates, 3.1 / 2.2 per EN 10204

English-speaking application engineers on GMT+8, same-day FEA reply for hotspot or fill-factor questions

6. Risk Mitigation for 2024 Supply Chains

Copper cathode warehoused 45 days ahead of schedule buffers LME volatility; dual-port export option (Qingdao/Tianjin) avoids single-carrier delays; bonded-zone status lets us deliver CIF, DDP or FCA depending on your working-capital preference.

Next Step

Email cathy@transformerstrip.com with target AWA or mm², thermal class and insulation build. We will return a technical datasheet, SPC histograms and an FOB/DDP quotation within 24 h—no NDAs, no middle-men, no surprises.

📉 Import Savings Calculator

Estimate cost reduction by sourcing wire wound transformer from Luoyang Xinzhaohe.