Table of Contents

Market Insight: Winding Wire

Market Analysis: Winding Wire for Transformer Applications

Global demand for transformer winding wire is intrinsically linked to the expansion and modernization of electrical infrastructure. Driven by renewable energy integration, aging grid replacements, and industrial electrification, the transformer market is projected to grow at 6.2% CAGR through 2030. Distribution transformers constitute the largest segment, where aluminum winding wire has gained significant traction due to its optimal balance of conductivity, weight reduction (35% lighter than copper), and cost efficiency. This shift is particularly pronounced in utility-scale projects across Asia and Latin America, where lifecycle cost optimization outweighs marginal conductivity differences. However, the criticality of winding wire quality cannot be overstated; it directly dictates transformer efficiency, thermal stability, and operational lifespan.

Substandard winding wire introduces systemic risks that compromise transformer integrity. Impurities or inconsistent metallurgical structure in aluminum conductors elevate electrical resistance, accelerating joule heating and reducing energy efficiency by up to 2.5% per 0.5% conductivity deviation. Surface defects—such as scratches, pits, or oxide inclusions—act as stress concentrators during winding, increasing the likelihood of insulation puncture and partial discharge under operational voltage stress. Furthermore, inadequate dimensional control (e.g., ovality exceeding 0.05mm tolerance) creates uneven magnetic flux distribution, exacerbating eddy current losses and localized hotspots. These failures manifest as premature insulation degradation, reduced overload capacity, and in severe cases, catastrophic dielectric breakdown. Industry data indicates that 22% of field failures in distribution transformers originate from conductor-related defects, incurring costs 8–10x higher than initial material savings.

Technical specifications governing aluminum winding wire quality are non-negotiable for reliable transformer operation. Adherence to IEC 60228 Class 2 conductivity standards (≥61% IACS minimum) ensures baseline electrical performance, while tight tolerances on diameter (±0.01mm) and roundness (<0.03mm) guarantee uniform winding tension and interlayer insulation integrity. Surface smoothness, measured via profilometry (Ra ≤ 0.8μm), prevents insulation damage during coil fabrication. Crucially, batch-to-batch consistency in mechanical properties—tensile strength (80–110 MPa) and elongation (≥5%)—is essential to withstand winding stresses without microcracking. At Luoyang Xinzhaohe Aluminum, our 20+ years of metallurgical expertise ensures these parameters are rigorously controlled through in-line conductivity monitoring, laser micrometry, and ASTM B557 tensile testing. This precision engineering translates to transformers achieving DOE 2016 Tier 2 efficiency levels with 30+ year service lives, directly supporting client objectives of grid resilience and total cost of ownership reduction.

The strategic selection of winding wire is not a commodity decision but a foundational element of transformer reliability. As grid demands intensify, only materials meeting exacting technical benchmarks will sustain the efficiency and durability required for next-generation power systems.

Technical Specs: Winding Wire

Technical Specifications for Winding Wire – Insulation Breakdown Voltage, Elongation, and Thermal Class

Winding wire, also known as magnet wire, is a critical component in the construction of electromagnetic coils used in motors, transformers, generators, and inductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and manufacturing expertise, we ensure our aluminum winding wire products meet stringent international performance benchmarks. Key technical parameters governing reliability and performance include insulation breakdown voltage, elongation, and thermal class. These specifications directly influence the wire’s electrical safety, mechanical durability, and thermal stability under operational loads.

Insulation breakdown voltage is a measure of the dielectric strength of the wire’s insulation coating. It indicates the maximum voltage the insulation can withstand before electrical failure occurs. For industrial-grade winding applications, a minimum breakdown voltage of 3 kV is typically required, with high-performance variants exceeding 6 kV. This parameter is tested using standardized methods per IEC 60317 and NEMA MW 1000, where voltage is applied between the conductor and a conductive liquid bath. Consistent insulation integrity ensures long-term reliability in high-voltage environments and prevents short circuits in tightly wound coil configurations.

Elongation, expressed as a percentage, reflects the ductility of the aluminum conductor. It is determined through tensile testing and represents the extent to which the wire can be stretched before fracture. For aluminum winding wire, elongation values typically range from 18% to 30%, depending on the alloy temper and drawing process. Higher elongation improves the wire’s ability to withstand mechanical stresses during coil winding, especially in complex geometries or automated winding systems. Our proprietary annealing process ensures uniform microstructure and optimal elongation characteristics, minimizing breakage and enhancing processability.

Thermal class defines the maximum continuous operating temperature at which the insulation system retains its dielectric and mechanical properties over a 20,000-hour service life. Winding wires are classified into thermal classes such as 130°C, 155°C, 180°C, 200°C, and 220°C, corresponding to their temperature index. The thermal class is determined by thermal endurance testing per IEC 60172, where insulation life is extrapolated from accelerated aging data. Higher thermal classes utilize advanced insulation materials such as polyimide, polyesterimide, or aromatic polyamide, offering superior thermal stability and resistance to thermal degradation.

The following table summarizes the typical technical parameters for aluminum winding wire products manufactured by Luoyang Xinzhaohe Aluminum Co., Ltd.:

| Parameter | Test Standard | Typical Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, NEMA MW 1000 | 3 kV – 6 kV (at 1x turn) | Measured in water bath, 1 turn method |

| Elongation (Aluminum Core) | ASTM B566 | 18% – 30% | Depends on temper and diameter |

| Thermal Class | IEC 60172 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system |

| Conductor Material | GB/T 8170 | Electrical Grade Aluminum (EC Al) | ≥ 99.99% purity, low oxide content |

| Diameter Tolerance | IEC 60122 | ±0.01 mm to ±0.03 mm | Tight tolerance for precision winding |

These specifications are rigorously maintained through in-line quality control, automated testing, and adherence to ISO 9001 standards. Custom configurations are available to meet specific application requirements in energy, automotive, and industrial sectors.

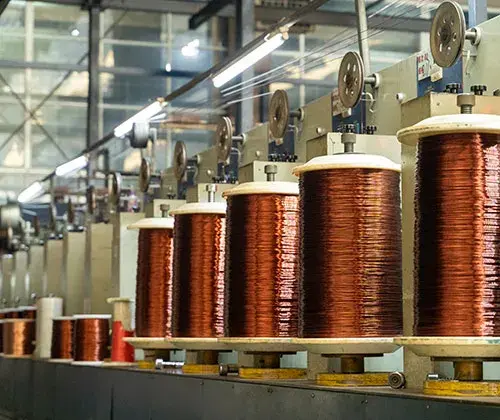

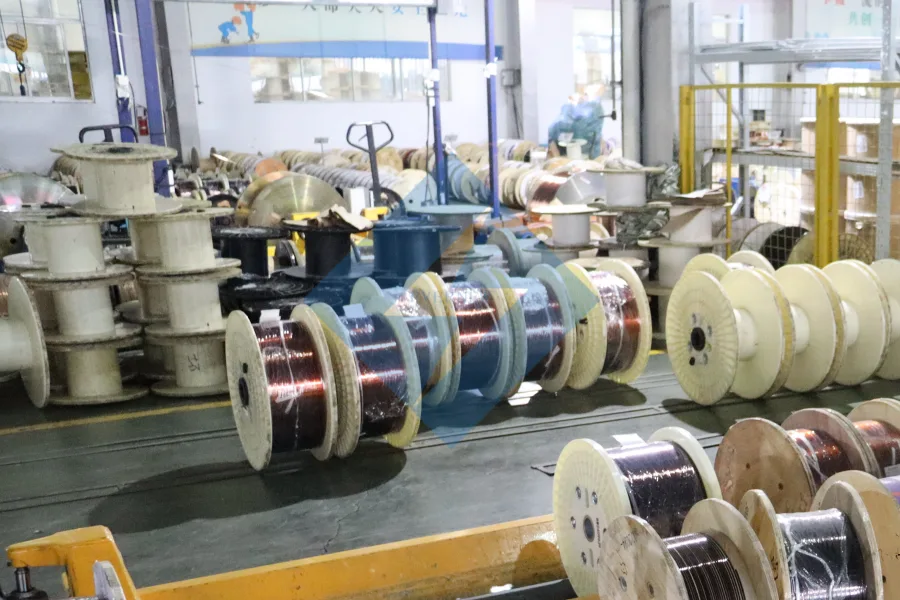

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Winding Wire

The production of high-performance aluminum winding wire at Luoyang Xinzhaohe Aluminum CO., Ltd. follows a rigorously controlled sequence: Rod Drawing, Annealing, Enameling, and Inline Testing. Each stage integrates metallurgical precision and continuous quality verification to ensure compliance with IEC 60317 and ASTM B230 standards for electrical conductivity, mechanical integrity, and dielectric strength.

Rod Drawing initiates the process, where high-purity aluminum rod (99.7% min. Al) undergoes multi-pass reduction through tungsten carbide dies. This stage achieves precise diameter tolerances (±0.003 mm for 0.8–2.5 mm wire) while maintaining uniform ovality (<0.005 mm). Critical process parameters include controlled draw speed (8–12 m/s), lubricant viscosity (15–20 cSt), and tension management to prevent surface defects. In-process QC employs laser micrometers for real-time diameter monitoring and surface inspection systems detecting scratches or pits exceeding 5 µm depth.

Annealing follows immediately in a continuous inert-atmosphere furnace (N₂/H₂ mix, <10 ppm O₂). The wire is heated to 300–400°C to achieve full recrystallization, optimizing ductility (Elongation >15%) and electrical conductivity (≥61% IACS). Precise temperature profiling prevents grain coarsening, which would compromise mechanical stability during winding. Conductivity is verified via eddy-current testing at 100% inline rate, with deviations triggering automatic process correction.

Enameling applies multiple polymer layers (typically polyester-imide or polyamide-imide) via precision capillary applicators. The wire traverses a multi-zone oven (320–380°C) where solvent evaporation and polymer curing occur under strict humidity control (<40% RH). Layer thickness is maintained at 25–120 µm per IEC specifications, with viscosity (25–30 sec Ford Cup #4) and solid content (38–42%) monitored hourly. Automated optical inspection detects pinholes, bubbles, or thickness variations >5% tolerance, rejecting non-conforming sections before spooling.

Final Inline Testing validates electrical and mechanical performance. Every meter undergoes:

High-Voltage Testing: 3× operating voltage + 1500 V AC for 2 minutes (IEC 60317-0-2)

Thermal Shock Resistance: 200°C bake for 30 minutes followed by cold bend test

Scrape Abrasion Test: Withstanding 1000 cycles at 500 g load

Critical Testing Parameters and Acceptance Criteria

| Test Parameter | Standard Requirement | Xinzhaohe Control Limit |

|————————-|———————-|————————-|

| Dielectric Strength | ≥3000 V AC | ≥3500 V AC |

| Thermal Class Rating | 180°C (Class H) | 200°C validated |

| Elongation at Break | ≥12% | ≥15% |

| Conductivity | ≥61% IACS | ≥61.5% IACS |

This integrated manufacturing system—refined over 20 years of production—ensures zero-defect delivery for demanding applications like EV traction motors and industrial transformers. All process data is logged to blockchain-enabled traceability systems, providing customers with full material pedigree from rod to finished coil. Statistical process control (SPC) charts for critical parameters are available upon request for supply chain transparency.

Packaging & Logistics

Export Packaging for Winding Wire – Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we recognize that the performance and reliability of winding wire begin long before it reaches the production floor. Proper export packaging is a critical component in maintaining product integrity, particularly during extended sea freight transit, where environmental and mechanical stresses are significant. Our packaging protocols are engineered to meet international logistics standards, ensuring that every coil arrives at its destination in optimal condition.

All winding wire shipments are secured on high-strength wooden pallets constructed from kiln-dried, ISPM-15 certified timber. This certification guarantees that the wood has undergone heat treatment to eliminate pests and pathogens, meeting global phytosanitary requirements for cross-border transport. The pallets are designed with structural reinforcement to support the full weight of tightly wound aluminum coils, which can range from several hundred kilograms to multiple metric tons per shipment. Each coil is precisely centered and mechanically fastened to prevent lateral or axial displacement during handling and ocean transit.

To combat the primary threat to conductor performance—moisture exposure—we employ a multi-layer moisture-proof barrier system. The wound coil is first wrapped in industrial-grade, aluminum-laminated moisture-proof film, which provides a vapor-tight seal. This film exhibits low water vapor transmission rate (WVTR), effectively isolating the aluminum surface from ambient humidity. Overwrapping is applied using automated tension-controlled systems to ensure uniform coverage without compromising the dimensional stability of the coil edges. Additional desiccant packs are strategically placed within the sealed envelope to absorb any residual moisture and buffer against condensation during temperature fluctuations common in maritime environments.

The entire palletized unit is then stretch-wrapped with UV-resistant, high-tenacity polyethylene film to provide mechanical protection against abrasion, contamination, and handling impacts. Corner boards and edge protectors are added where necessary to reinforce vulnerable points, especially in stacked configurations within shipping containers. Each package is labeled with durable, weather-resistant markings indicating product specifications, batch numbers, handling instructions, and orientation indicators to ensure correct loading and unloading.

Our packaging methodology is validated through rigorous internal testing, including simulated salt spray exposure, vibration analysis, and drop testing, to replicate the conditions of intercontinental sea freight. These protocols align with ISO 11607 and IEC 60204 standards for packaging of electrical conductors. By integrating robust materials with precision engineering, Luoyang Xinzhaohe ensures that our winding wire maintains its surface quality, electrical properties, and dimensional accuracy from factory to final integration.

This systematic approach to export packaging underscores our commitment to delivering not just a product, but a fully secured, logistics-ready solution for global partners in the transformer, motor, and cable manufacturing industries.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Winding Wire Engineered for Performance

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and integrated manufacturing to deliver aluminum winding wire meeting the most stringent global electrical industry demands. Our vertically aligned production ecosystem, encompassing controlled alloying through to final annealing, ensures unparalleled consistency and performance in every coil shipped. This deep process mastery is fundamental for applications where electrical conductivity, mechanical stability, and thermal endurance are non-negotiable.

Our core strength resides in rigorous metallurgical control. Utilizing high-purity 1350-H19 aluminum billets (minimum 99.99% Al), we implement proprietary continuous casting and homogenization techniques to eliminate micro-segregation and ensure uniform grain structure. This foundational step is critical for achieving the target electrical conductivity of 61.0% IACS ±0.5% and consistent mechanical properties essential for high-speed winding operations without breakage. Precise temperature and atmosphere management during drawing and annealing prevent surface oxidation and hydrogen embrittlement, directly impacting the wire’s long-term reliability in transformers and motors.

Dimensional precision defines our manufacturing output. Advanced multi-die continuous drawing lines, coupled with laser micrometer feedback systems operating in real-time, maintain tight tolerances on diameter (±0.005mm for sizes 1.0mm to 5.0mm) and ovality (<0.01mm). This micron-level accuracy minimizes air gaps during coil winding, maximizing slot fill factor and thermal efficiency in the final electromagnetic component. Every production batch undergoes comprehensive in-process verification, including tensile strength (130-150 MPa), elongation (3-6%), bend test compliance per ASTM B566, and surface defect scanning. Full traceability from billet lot to finished coil is standard, supported by our ISO 9001-certified quality management system with integrated Statistical Process Control (SPC) protocols.

Supply chain resilience is engineered into our operations. We maintain strategic raw material inventories and dedicated production cells for winding wire, ensuring reliable lead times under 30 days for standard specifications without compromising quality. Our 30,000-ton annual capacity includes specialized lines for custom tempers (O, H14, H19) and diameters up to 6.0mm, accommodating both high-volume OEM contracts and agile prototyping needs. Global logistics partnerships guarantee secure, climate-controlled container shipping with documented handling procedures to prevent transit damage.

Partnering with Luoyang Xinzhaohe means securing a supplier whose technical depth matches your engineering requirements. We transcend commodity supply by providing metallurgical data packages, process capability studies, and collaborative engineering support to optimize your winding parameters and component performance. Our commitment is to deliver wire that performs predictably in your production environment and throughout the operational lifespan of your equipment.

Contact us to discuss your specific winding wire requirements and receive a technical quotation backed by 20 years of aluminum conductor excellence.

cathy@transformerstrip.com

Metallurgical Engineering Team

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing winding wire directly from China.