Table of Contents

Market Insight: Winding Strips

Market Analysis: Winding Wire in Transformer Applications

The global demand for high-performance winding strips in transformer manufacturing continues to grow, driven by the expansion of electrical infrastructure, renewable energy integration, and industrial automation. Winding strips—typically fabricated from high-purity aluminum or copper—are a core component in the construction of transformer windings, where they serve as conductive pathways for electromagnetic energy transfer. Among non-ferrous materials, aluminum winding strips have gained significant traction due to their favorable conductivity-to-weight ratio, corrosion resistance, and cost efficiency, particularly in large-scale power distribution and transmission systems.

Industrial demand for aluminum winding strips is especially pronounced in dry-type transformers, distribution transformers, and high-voltage power transformers used in utility substations. These applications require materials that maintain dimensional stability under thermal cycling, exhibit low electrical resistance, and support efficient heat dissipation. As grid operators prioritize energy efficiency and reliability, the performance of winding materials directly impacts transformer lifecycle costs and operational safety. This has led to tighter material specifications from OEMs and regulatory bodies, emphasizing the need for consistent metallurgical quality and precision in strip geometry.

Quality in winding strip production is not merely a manufacturing objective—it is a technical imperative. Variability in thickness, width, or edge burr control can result in uneven winding tension, interlayer shorting, or localized hotspots during operation. Similarly, impurities in the aluminum matrix or inconsistent annealing profiles can degrade electrical conductivity and mechanical formability, increasing the risk of in-service failure. At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in aluminum strip production, we recognize that high-reliability transformer applications demand more than compliance with nominal standards; they require process control at every stage, from billet homogenization to cold rolling and final slitting.

Our winding strips are manufactured under strict ISO-certified protocols, ensuring precise dimensional tolerances (typically ±0.02 mm in thickness) and superior surface finish. We utilize continuous casting and rolling technologies combined with controlled atmosphere annealing to minimize oxide inclusions and ensure uniform recrystallization. This results in strips with optimal ductility for tight-radius winding and high tensile strength to withstand electromagnetic forces during fault conditions.

As the energy sector transitions toward smarter, more resilient grids, the role of high-quality winding materials becomes increasingly critical. Transformers are expected to operate reliably for decades under fluctuating loads and environmental stressors. Substandard winding strips may lead to premature aging, increased no-load losses, and higher total cost of ownership. By partnering with a technically rigorous supplier, transformer manufacturers can ensure design integrity, meet IEC and IEEE performance benchmarks, and deliver products that support long-term grid stability.

Technical Specs: Winding Strips

Technical Specifications for Aluminum Winding Strips

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and wire processing expertise to deliver precision-engineered aluminum winding strips for demanding electrical applications. Our specifications are rigorously aligned with IEC 60317 and ASTM B354 standards, ensuring optimal performance in motor, transformer, and inductor windings. Critical parameters are validated through in-house testing and third-party certification to guarantee reliability under operational stress.

Insulation breakdown voltage defines the dielectric strength of the strip’s coating system, directly impacting equipment safety and longevity. We specify minimum values per IEC 60243-1, measured at 1 mm thickness under controlled humidity. Insufficient breakdown voltage risks catastrophic short circuits during voltage surges or thermal cycling. Our standard enamel systems achieve 8.5 kV minimum, with high-reliability grades exceeding 12 kV for aerospace and traction applications.

Elongation at break, measured per ASTM E8, is critical for winding integrity during coil formation. Excessive brittleness causes micro-cracks in insulation during tight-radius bends, while overly ductile strips compromise dimensional stability. Our aluminum alloy substrates (1060, 1070, or 1350 series) are cold-rolled to precise temper conditions (H14, H16, or H18), yielding 2.5–4.0% elongation. This balance ensures crack-free winding at mandrel diameters down to 2× strip width without compromising tensile strength (80–120 MPa).

Thermal class dictates continuous operating temperature limits per IEC 60085. Our strips support classes 130 (B), 155 (F), 180 (H), and 220 (C), validated via thermal endurance testing (10,000-hour life at rated temperature). Higher classes utilize advanced polyamide-imide or polyester-imide topcoats, resisting thermal degradation and maintaining adhesion at 220°C. Crucially, thermal class must align with the end-application’s cooling design; mismatched classes accelerate insulation embrittlement.

Key parameters are summarized below for rapid technical evaluation:

| Parameter | Test Standard | Minimum Requirement | Typical Value | Application Impact |

|---|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60243-1 | 8.5 kV | 10.5 kV | Prevents arcing during voltage transients |

| Elongation at Break | ASTM E8 | 2.5% | 3.2% | Enables tight-radius winding without cracks |

| Tensile Strength | ASTM E8 | 80 MPa | 105 MPa | Maintains dimensional stability under tension |

| Thermal Class | IEC 60085 | 130°C (Class B) | 220°C (Class C) | Determines max continuous operating temperature |

| Thickness Tolerance | IEC 60628 | ±0.015 mm | ±0.010 mm | Ensures consistent coil fill factor |

| Surface Roughness (Ra) | ISO 4287 | ≤0.8 µm | ≤0.5 µm | Minimizes insulation pinholes during coating |

Consistent parameter control is non-negotiable in high-volume production. Our integrated supply chain—from billet casting to annealing and insulation coating—ensures batch-to-batch repeatability within 3σ limits. We provide full material test reports (MTRs) with every shipment, including thermal aging data and adhesion peel strength (≥1.5 N/mm per IEC 60851-5). Partnering with Xinzhaohe guarantees winding strips that meet the exacting demands of modern electrification, where thermal management and dielectric resilience define product lifecycle.

Factory Tour: Manufacturing

Manufacturing Process of Aluminum Winding Strips at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum winding strips at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical insulation reliability, and dimensional precision. With over two decades of specialized experience in aluminum wire and strip manufacturing, our facility integrates advanced equipment and rigorous quality control protocols across each phase: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rods, typically conforming to GB/T 3954 standards, which undergo precision rod drawing. In this stage, the aluminum rod is progressively reduced in diameter through a series of tungsten carbide or diamond dies, achieving the target cross-sectional dimensions required for winding applications. The drawing operation is performed under controlled tension and lubrication conditions to minimize surface defects and maintain uniform elongation. Throughout this phase, real-time diameter monitoring ensures dimensional consistency, with laser micrometers providing continuous feedback to adjust drawing parameters.

Following drawing, the aluminum strip enters a continuous annealing furnace. This step is critical for restoring ductility and eliminating work hardening induced during drawing. The annealing process is conducted in a controlled nitrogen-purged atmosphere to prevent oxidation and ensure a clean, oxide-free surface, which is essential for subsequent enamel adhesion. Temperature profiles are precisely regulated based on alloy type and final mechanical specifications, typically ranging between 300°C and 450°C, to achieve a fully recrystallized microstructure with optimal tensile strength and elongation.

The next stage is enameling, where a thermosetting polymer coating—commonly polyester, polyamide-imide, or a dual-layer system—is applied via precision die coating. The coated strip then passes through a series of curing ovens where the enamel is polymerized under precisely controlled temperature gradients. Multiple enamel layers may be applied in succession to achieve enhanced dielectric strength and thermal class ratings (e.g., Class 130, 155, or 180). Coating thickness is continuously monitored using beta-gauge sensors to ensure compliance with IEC 60317 and other relevant international standards.

Final quality assurance is achieved through comprehensive inline testing. Each wound strip undergoes 100% electrical breakdown voltage testing at high potential (hipot), typically 3–6 kV depending on insulation class. Additional inline checks include continuity testing, dimensional verification, surface defect scanning via optical inspection systems, and tension-controlled winding to prevent coil deformation.

All process parameters are logged in our manufacturing execution system (MES), enabling full traceability from rod batch to finished coil. This integrated approach ensures consistent production of winding strips suitable for demanding applications in transformers, reactors, and high-efficiency motors.

Packaging & Logistics

Export Packaging Standards for Aluminum Winding Strips: Ensuring Integrity During Ocean Transit

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and supply chain expertise to engineer export packaging systems specifically designed for the demanding requirements of aluminum winding strip shipments via sea freight. Our protocols prioritize absolute product protection against the primary threats encountered during maritime transport: moisture ingress, mechanical shock, and salt-laden atmospheric exposure. This engineered approach mitigates corrosion risks and preserves dimensional stability, ensuring coils arrive in optimal condition for downstream processing.

Wooden pallets form the foundational structural element of our export packaging. We utilize only ISPM 15 compliant, kiln-dried coniferous timber pallets, certified for international shipment. These pallets are engineered to ISO 9001 standards with precise dimensional tolerances, typically featuring 100 mm x 100 mm stringers and robust top deck boards capable of supporting concentrated coil loads exceeding 5,000 kg without deflection. Critical to aluminum protection, the timber undergoes rigorous moisture content verification, maintained below 20% to prevent internal condensation within the pallet structure during temperature fluctuations at sea. Pallet design incorporates reinforced corners and edge protection to withstand repeated handling by port equipment and resist deformation under stack pressure in container holds.

The primary defense against marine atmospheric corrosion is our multi-layer moisture barrier system. Each aluminum coil is hermetically sealed within a custom-fitted, co-extruded moisture-proof film meeting ISO 11607 specifications. This film features a minimum 3-layer structure: an outer LDPE layer for puncture resistance, a central high-barrier EVOH layer blocking oxygen and moisture vapor transmission, and an inner sealant layer compatible with aluminum surfaces. Crucially, we integrate Volatile Corrosion Inhibitor (VCI) technology directly into the inner film layer, providing active molecular protection to the coil surface. This is supplemented by strategically placed desiccant packs (minimum 500g per tonne of aluminum) within the sealed envelope, actively absorbing residual humidity and maintaining internal relative humidity below 40% throughout the voyage. Visual humidity indicator cards are included for non-invasive verification upon receipt.

Mechanical security during vessel motion is achieved through a dual-strapping protocol. Coils are first secured to the pallet base using galvanized steel strapping (minimum 19mm width, 15kN tensile strength) applied at four points with tension calibrated to 25% of breaking load. A secondary perimeter restraint system employs weather-resistant PET strapping encircling the entire sealed coil-pallet unit, preventing lateral shift during rolling or pitching. All strapping anchors utilize heavy-duty steel edge protectors to prevent film penetration and localized pressure points on the coil edges. Final container loading adheres strictly to CTU Code guidelines, with dunnage placement verified to eliminate point loading and ensure even weight distribution.

Our quality control process mandates 100% verification of seal integrity via vacuum decay testing prior to containerization. This systematic packaging methodology, refined through 20+ years of global shipments, consistently achieves moisture ingress rates below 0.1 g/m³ during transoceanic voyages, directly safeguarding the surface quality and metallurgical properties essential for precision winding applications. This commitment to packaging science underpins our reliability as a strategic supplier for critical industrial supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Winding Strips

With over two decades of specialized expertise in aluminum processing and conductor manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading supplier of precision-engineered winding strips for global industrial applications. Our deep-rooted experience in the transformer, inductor, and electric power equipment sectors enables us to deliver materials that meet the most stringent performance and reliability standards.

Our manufacturing facility integrates advanced rolling technology, precision slitting lines, and in-line quality monitoring systems to ensure dimensional consistency and metallurgical integrity across every batch. We specialize in producing aluminum winding strips in alloys 1060, 1070, 1350, and 8011, with thicknesses ranging from 0.1 mm to 6.0 mm and widths from 10 mm to 600 mm, tailored to customer specifications. Each strip undergoes controlled atmosphere annealing to achieve optimal conductivity and ductility, essential for high-efficiency winding operations and thermal stability under load.

We maintain strict adherence to international quality benchmarks, including ISO 9001:2015 certification and ASTM B418 compliance for electrical conductivity. Our in-house metallurgical laboratory conducts routine testing on mechanical properties, surface finish, edge quality, and resistivity, ensuring full traceability and repeatability in production. This technical rigor supports OEMs and tier suppliers in minimizing winding defects, reducing material waste, and enhancing the performance of final electromagnetic components.

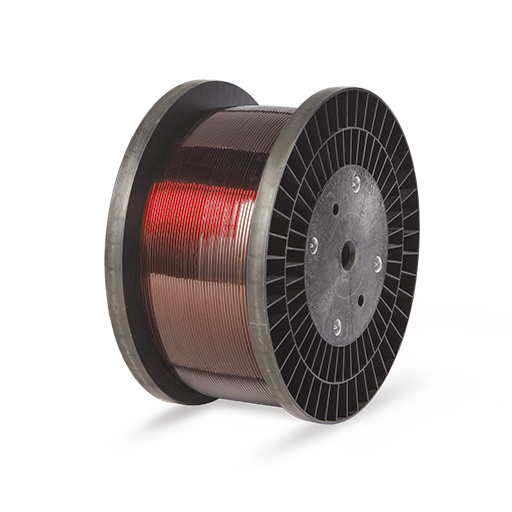

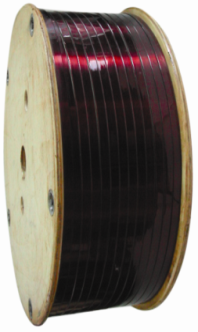

Our production capacity exceeds 20,000 metric tons annually, supported by automated warehousing and a responsive logistics network that enables just-in-time delivery to Asia, Europe, and North America. We offer both bare and insulated strip configurations, with options for carrier reels, anti-corrosion packaging, and custom labeling to streamline integration into automated winding lines.

As a vertically integrated manufacturer, we control the entire value chain—from billet homogenization to final slitting—ensuring consistent alloy purity and mechanical performance. Our R&D team collaborates closely with clients to develop application-specific solutions, including customized tempers (O, H14, H16, H18), surface treatments, and edge deburring for high-speed coil winding.

For engineers and procurement managers seeking a reliable, technically capable partner in winding strip supply, Luoyang Xinzhaohe delivers proven performance, scalable capacity, and long-term supply chain resilience. We are committed to supporting our clients with responsive technical service, rigorous quality assurance, and continuous process innovation.

Contact us today to discuss your winding strip requirements.

Cathy Zhang | Sales Director

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Established 2003 | ISO 9001 Certified | Global Exporter

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing winding strips directly from China.