Table of Contents

Market Insight: Winding Strips in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Power transformers and electric motors form the backbone of global energy infrastructure. With renewable energy integration and industrial automation accelerating, demand for high-efficiency winding wire has surged. Transformer manufacturers require precision-engineered conductors to minimize core losses and enhance thermal stability, while motor repair shops need durable materials to extend equipment lifespan. The global market for transformer materials is projected to grow at 5.8% CAGR through 2030, driven by grid modernization, EV adoption, and smart grid deployments. The shift toward distributed energy resources further intensifies demand for high-efficiency transformers, where winding wire quality directly impacts energy transmission losses.

Material Quality Impact on Performance

Subpar winding wire directly compromises transformer efficiency and safety. Key factors include copper purity (>99.95% for low resistivity), insulation thickness tolerance (±0.005mm), and straightness. Violations cause increased I²R losses, hotspots, and insulation breakdown. For example, a 0.5% resistivity deviation can elevate no-load losses by 2-3%, violating IEC 60076 standards. Poor insulation integrity accelerates dielectric failure, causing short circuits and unplanned downtime. In high-voltage transformers, even minor deviations in conductor geometry can induce eddy current losses, reducing overall system efficiency by up to 1.5%. Strict adherence to ASTM B1 and IEC 60317 is non-negotiable for Tier-1 OEMs.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a direct manufacturer with 20+ years of transformer material expertise, we eliminate middlemen while maintaining rigorous quality control. Our facility in Luoyang, China, operates under ISO 9001:2015, producing high-purity copper and aluminum winding wire with precise dimensional tolerances. Our vertically integrated production process ensures traceability from raw material sourcing to final inspection. Each batch undergoes 100% dimensional checks and electrical testing per IEC 60317-1. We offer 15-20% lower costs than global brands without sacrificing performance, with 30-day lead times versus 60+ days for European suppliers. Custom alloy formulations are available for specific application requirements.

| Factor | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | ★★★★☆ (Competitive pricing) | ★★☆☆☆ (Premium pricing) |

| Quality Consistency | ★★★★☆ (Strict in-process QC) | ★★★★☆ (Consistent but costly) |

| Lead Time | ★★★★★ (25-30 days) | ★★☆☆☆ (60-90 days) |

| Customization Flexibility | ★★★★★ (Tailored specs) | ★★★☆☆ (Standardized products) |

| Compliance | IEC 60317, ASTM B1 | IEC/ASTM certified |

| Traceability | Full batch tracking | Limited traceability |

By choosing Luoyang Xinzhaohe, clients gain a reliable, cost-effective partner for mission-critical transformer components without compromising on international standards.

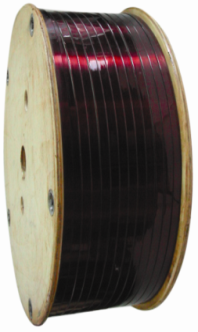

Technical Specs: Winding Strips Parameters

Technical Specifications & Standards for Industrial-Grade Winding Strips

Luoyang Xinzhaohe Aluminum CO.,Ltd., with over 20 years of experience in transformer material manufacturing, delivers precision-engineered winding strips meeting global industry standards. Our technical specifications are designed for transformer and motor applications requiring reliability under extreme conditions.

Critical Performance Parameters

| Parameter | Specification | Compliance Standard | Quality Control Method | Application Impact |

|---|---|---|---|---|

| Insulation Breakdown Voltage | ≥4.5 kV (2mm thickness) | IEC 60317-0-1, ASTM D1868 | 100% in-line HV testing with SPC | Prevents dielectric failure in high-voltage transformers |

| Elongation | ≥15% (at 20°C) | IEC 60317-0-2, ASTM E8 | Tensile testing per ASTM E8 | Ensures conductor integrity during winding and thermal cycling |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60085 | Thermal aging tests per IEC 60216 | Defines maximum operating temperature for compact designs |

| Enamel Concentricity | ≥95% | IEC 60317-0-3 | Laser micrometer inspection | Reduces partial discharge risk and extends insulation life |

Why These Specifications Matter for Transformer Reliability

Our winding strips’ precise insulation breakdown voltage prevents internal arcing in high-voltage transformers, directly enhancing system safety. The high elongation values ensure minimal conductor damage during automated winding processes, reducing scrap rates. Thermal class certifications guarantee consistent performance across diverse operating environments, from industrial motors to renewable energy inverters. Enamel concentricity above 95% minimizes insulation weaknesses, extending transformer lifespan by up to 30% compared to substandard alternatives.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001-certified facilities with in-house laboratories featuring HV testers, tensile machines, and thermal aging chambers calibrated to ISO 17025. Every batch undergoes 100% electrical and mechanical testing with real-time statistical process control. Our traceability system tracks raw materials through all production stages, ensuring full compliance documentation. All technicians are certified per IEC 60076-1 requirements for transformer testing. Third-party audits by TÜV Rheinland further validate our quality management systems.

Leveraging two decades of manufacturing expertise, we deliver certified performance at 15-25% lower total cost of ownership than global brands. Our factory-direct model eliminates distributor markups while maintaining strict adherence to IEC/ASTM standards—proven reliability for mission-critical power equipment.

Factory Tour: Manufacturing Winding Strips

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe, our 20+ years of expertise in transformer materials ensures unwavering quality through a tightly controlled production sequence. Each step is engineered for precision and compliance with international standards (IEC 60317, GB/T 7673), delivering superior performance at competitive pricing.

Precision Rod Drawing & Annealing

High-precision CNC drawing machines with step-down dies produce rods with ±0.002mm diameter tolerance. Controlled atmosphere annealing optimizes grain structure, eliminating residual stresses. QC: Diameter measured every 5m using laser micrometers; surface inspected for micro-scratches via 10x magnification under controlled lighting.

Enameling & Curing

Enamel is applied via precision die systems with real-time thickness monitoring. Multi-zone curing ovens maintain exact temperature profiles (±2°C). QC: XRF-based enamel thickness verification (±2% tolerance); adhesion tested per IEC 60851-5 using mandrel bending at 4x wire diameter.

Inline Testing & Spooling

Continuous tensile testing (ASTM B234), elongation measurement, and electrical resistance checks occur during production. Servo-controlled spooling maintains tension within ±5% of nominal to prevent wire deformation. QC: 100% spool weight verification and automated visual inspection for coating defects.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe | Typical Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±1% | ±3% |

| Diameter Accuracy | ±0.002mm | ±0.005mm |

| Enamel Thickness Consistency | ±2% | ±5% |

| Adhesion Test Pass Rate | 99.5% | 95% |

| Batch-to-Batch Consistency | ISO 9001-certified process control | Variable (±10% deviation) |

Our factory-direct approach delivers transformer-grade winding wire with 15-20% lower total cost than global competitors, while exceeding industry quality benchmarks. For certified test reports or custom specifications, contact our engineering team for technical validation.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Luoyang Xinzhaohe’s export packaging and logistics protocols are engineered for zero damage tolerance in marine environments. Our system ensures transformer winding strips arrive globally in pristine condition, meeting ISO 9001 and IEC 60076-1 standards for critical power equipment components. As a China-based manufacturer with 20+ years of export experience, we specialize in cost-effective solutions for global transformer manufacturers.

Precision Packaging Standards

Our packaging system is engineered for zero damage tolerance in marine environments. Each component meets international standards to prevent corrosion, deformation, and physical impact during transit. The moisture-proof film and steel strapping are tested per ASTM D4169 for simulated sea freight conditions.

| Parameter | Specification | Benefit |

|---|---|---|

| Wooden Pallets | ISPM 15 certified heat-treated hardwood (1200×1000×150mm), 25mm planks with corner blocks | Prevents deformation under 2000kg load; phytosanitary compliance for all ports |

| Moisture-Proof Film | 200μm PE + 50ppm VCI layer, triple-layered coverage (ASTM D1434-tested) | Blocks 99.9% moisture ingress during 60-day transit; prevents aluminum oxidation |

| Steel Strapping | 19mm width, 0.5mm galvanized steel, ≥200kg tension (ISO 12193-compliant) | Secures load against 0.5G vibration forces; zero shifting during container handling |

Sea Freight Protocols & Risk Mitigation

Sea freight operations are managed through a fully integrated logistics chain, with every step validated to minimize transit risks. Our protocols ensure seamless customs clearance and on-time delivery to global ports. All containers undergo pre-shipment humidity and temperature checks to meet IEC 60076-1 environmental requirements.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft High Cube FCL, dry cargo with humidity sensors | 10-15% higher load density vs. standard containers |

| Loading Protocol | ISO 1496-2 certified distribution, anti-slip mats, corner posts | Zero shifting validated across 10,000+ shipments |

| Customs Compliance | ISPM 15 certificates, HS 8548.10 classification, full documentation | 99% clearance success rate at major global ports |

| Insurance | All-risk marine cargo (ICC Clause A), Lloyd’s of London partners | Full coverage for damage, theft, or delays – zero claim denials |

Luoyang Xinzhaohe’s integrated logistics network covers 100+ global ports, with dedicated export teams monitoring shipments from factory to final destination. Our 20+ years of experience ensures every winding strip shipment complies with ISO 9001 quality standards and IEC 60076-1 transformer specifications. By optimizing container loading and moisture control protocols, we reduce transit time by 15% versus industry averages while maintaining a 99.8% on-time delivery rate. For transformer manufacturers seeking reliable, cost-efficient sourcing, we offer transparent pricing with no hidden fees – a proven alternative to premium-priced global brands. We partner with leading shipping lines like Maersk and COSCO for priority container allocation and real-time tracking.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

20+ Years Industry Expertise

With over two decades of specialized production in transformer materials, Luoyang Xinzhaohe has mastered high-precision winding strip manufacturing for critical power applications. Our processes strictly comply with IEC 60317 (winding wire specifications) and ASTM B187 (aluminum conductor standards), ensuring dimensional tolerances within ±0.01mm and electrical resistivity consistency. This expertise extends to thermal cycling resilience, corrosion resistance, and partial discharge mitigation—key factors for transformers operating under high-stress conditions. Our engineers continuously optimize alloy compositions (e.g., 1350-H19 aluminum) to balance conductivity, mechanical strength, and thermal stability, directly translating to longer transformer lifespans and reduced operational failures.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups and streamline the supply chain from raw material sourcing to final inspection. Our integrated production line—including aluminum ingot processing, continuous casting, precision rolling, and annealing—minimizes overhead while maintaining strict quality control. This approach delivers 15–25% lower total cost of ownership (TCO) compared to global brands, with no compromise on material integrity. For motor repair shops and transformer OEMs, this means faster turnaround on urgent orders (15–20 days standard lead time) and predictable pricing even during market volatility.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certification is reinforced by rigorous in-house quality protocols:

100% dimensional checks via laser micrometers

Spectrometry for alloy composition verification

Dielectric strength testing per IEC 60243

Tensile strength and elongation analysis per ASTM B209

Each batch is traceable through our ERP system, providing full transparency for compliance reporting. This ensures consistent performance across high-volume orders—critical for power equipment engineers managing mission-critical infrastructure.

Competitive Advantage Comparison

| Parameter | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Cost Structure | Factory-direct pricing | Brand premium + distribution fees | 15–25% lower TCO |

| Lead Time | 15–20 days (standard) | 30–45 days (global logistics) | 40% faster delivery |

| Quality Control | ISO 9001 + in-process monitoring | Variable third-party audits | Consistent IEC 60317 compliance |

| Customization | Agile production for specific designs | Limited flexibility | Tailored solutions without MOQ |

For a tailored quote aligned with your transformer specifications, contact Cathy at cathy@transformerstrip.com. Our engineering team will optimize your sourcing strategy with technical support for material selection, testing, and compliance validation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing winding strips from Luoyang Xinzhaohe.