Table of Contents

Market Insight: Winding Of Transformer Coils

Market Analysis: Winding Wire for Transformer Coils

Global demand for transformer winding wire, particularly aluminum alloy variants, is intrinsically linked to the expansion and modernization of electrical infrastructure. Driven by renewable energy integration, grid resilience initiatives, and industrial electrification, the transformer market exhibits sustained growth, directly escalating requirements for high-performance winding conductors. Utilities and original equipment manufacturers (OEMs) prioritize aluminum due to its favorable conductivity-to-weight ratio, cost efficiency versus copper, and compatibility with modern core designs. However, this demand is not merely volumetric; it is increasingly defined by stringent performance specifications across transmission, distribution, and specialty transformers. The operational environment of transformers—characterized by high electrical stress, thermal cycling, and long service lifespans exceeding 30 years—demands winding wire that consistently meets exacting metallurgical and dimensional criteria. Compromised material quality directly translates to elevated operational risks and lifecycle costs.

The criticality of winding wire quality cannot be overstated. Conductivity, measured against the International Annealed Copper Standard (IACS), is paramount. Aluminum wire must achieve minimum 61.0% IACS to ensure efficient energy transfer and minimize resistive (I²R) losses. Impurities such as iron or silicon beyond controlled limits significantly degrade conductivity and accelerate thermal aging. Surface integrity is equally vital; microscopic scratches or protrusions act as initiation points for partial discharges under high voltage stress, leading to progressive insulation degradation and eventual dielectric breakdown. Precise dimensional tolerances—diameter, ovality, and lay length in stranded conductors—are non-negotiable for achieving optimal coil packing density and mechanical stability during winding and operation. Inconsistent dimensions cause uneven stress distribution, increasing susceptibility to vibration fatigue and short-circuit forces. Furthermore, controlled mechanical properties, including yield strength and elongation post-annealing, ensure the wire withstands the rigors of high-speed winding processes without deformation or breakage, while maintaining structural integrity under electromagnetic forces during fault conditions.

Consequently, substandard winding wire introduces severe failure modes. Poor conductivity increases operational losses, directly impacting efficiency compliance and total cost of ownership. Surface defects or dimensional inaccuracies compromise the inter-turn insulation system, accelerating aging and risking catastrophic inter-winding faults. Inadequate mechanical properties lead to coil deformation during short circuits, causing immediate transformer failure. The financial repercussions extend far beyond replacement wire costs, encompassing transformer repair/replacement, extended downtime, grid instability penalties, and reputational damage. For discerning B2B buyers, sourcing from suppliers with rigorous in-house metallurgical control, continuous casting and rolling capabilities, and adherence to international standards (IEC 60138, ASTM B230/B354) is not an option but a fundamental requirement. Luoyang Xinzhaohe Aluminum’s two decades of专注 in aluminum electromagnetic wire manufacturing underscores our commitment to delivering material where every batch meets the uncompromising quality benchmarks demanded by the global transformer industry, ensuring reliability and optimal asset performance.

Technical Specs: Winding Of Transformer Coils

Transformer coil winding demands precision-engineered winding wire with stringent performance characteristics to ensure long-term reliability, dielectric integrity, and thermal stability. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and industrial manufacturing experience, we produce high-purity aluminum winding wire engineered specifically for demanding transformer applications. Our wire meets or exceeds international standards for electrical insulation performance, mechanical ductility, and thermal endurance. The following technical specifications are critical for ensuring optimal performance during the winding process and throughout the operational life of the transformer.

Insulation breakdown voltage is a primary determinant of dielectric reliability in transformer windings. This parameter measures the maximum electric field the insulation layer can withstand before electrical failure occurs. For medium to high-voltage transformers, a minimum breakdown voltage of 6 kV is required, with premium-grade wires achieving up to 9 kV depending on insulation thickness and material uniformity. Consistent insulation integrity prevents short circuits between turns and layers, especially under transient overvoltages or thermal cycling. Our enamel-coated aluminum wires utilize multi-layer insulation systems, including polyesterimide and polyamide-imide, to achieve superior dielectric strength and resistance to partial discharge.

Elongation, expressed as a percentage, reflects the material’s ductility and ability to withstand plastic deformation during the winding process. Aluminum wire used in transformer coils must exhibit controlled elongation to prevent cracking or necking under tension. The minimum elongation for our aluminum winding wire is 18%, with typical values ranging between 20% and 24% in the fully annealed (O-temper) condition. This ensures smooth coiling, tight layer-to-layer packing, and resistance to mechanical stress during handling and impregnation. Consistent elongation across spool lengths is maintained through precise annealing control and metallurgical homogenization during rod casting and wire drawing.

Thermal class defines the maximum continuous operating temperature the wire insulation system can endure without significant degradation. Transformer windings generate heat under load, and insulation must maintain dielectric and mechanical properties across a wide thermal range. Our winding wire is available in thermal classes from 130°C to 220°C, with common grades including 155°C (Class F), 180°C (Class H), and 200–220°C (high-temperature polyamide-imide systems). Higher thermal classes enhance overload capacity and extend service life, particularly in dry-type transformers operating in high ambient environments.

The table below summarizes key technical parameters for our aluminum winding wire used in transformer coil applications.

| Parameter | Test Standard | Typical Value Range | Unit |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, ASTM D4355 | 6.0 – 9.0 | kV |

| Elongation (min) | IEC 60266, GB/T 4910 | 18 – 24 | % |

| Thermal Class | IEC 60172, NEMA MW | 130, 155, 180, 200, 220 | °C |

| Conductor Resistivity | IEC 60889 | ≤ 0.028264 | Ω·mm²/m |

| Tensile Strength | GB/T 4910 | 60 – 90 | MPa |

All parameters are validated through in-house and third-party testing to ensure compliance with global transformer manufacturing requirements. Consistency in these specifications enables reliable automation in winding lines and supports high-efficiency transformer designs.

Factory Tour: Manufacturing

Transformer Coil Winding Wire Manufacturing Process

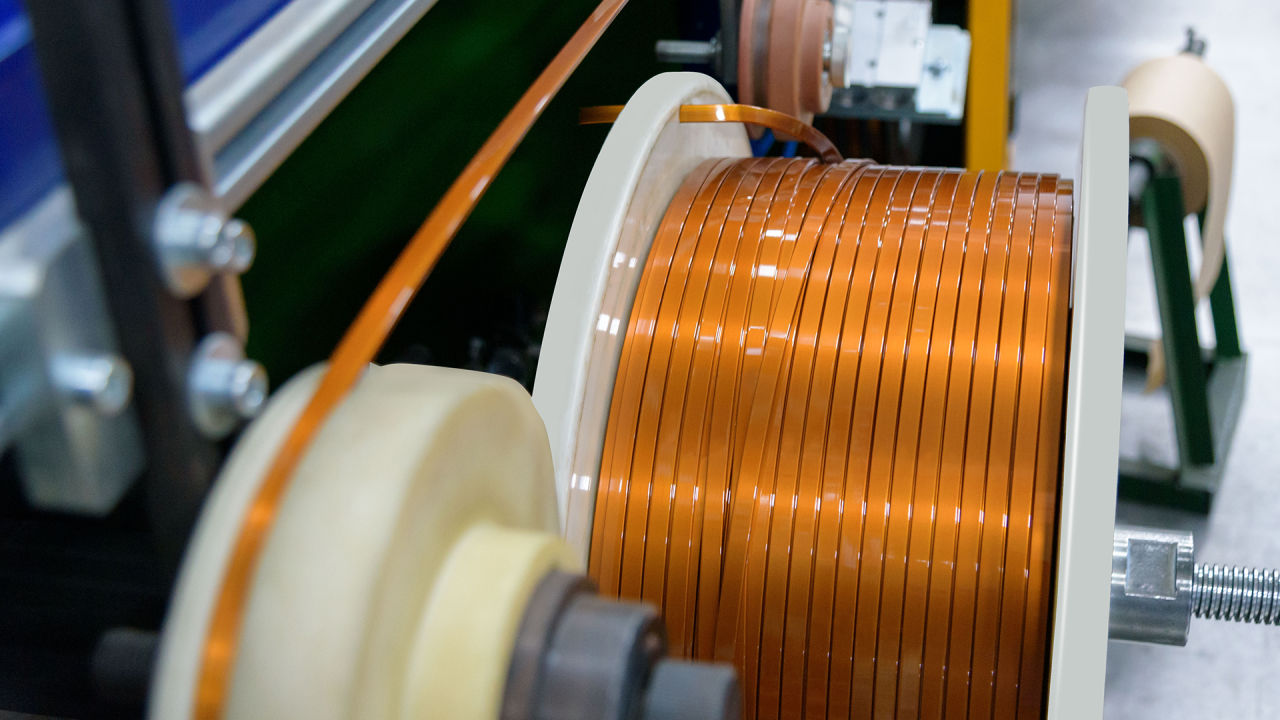

Luoyang Xinzhaohe Aluminum Co., Ltd employs a rigorously controlled production sequence for aluminum magnet wire, ensuring optimal electrical performance and mechanical reliability in transformer coil applications. The process begins with high-purity aluminum rod (99.99% min) subjected to precision rod drawing. Utilizing multi-die reduction systems under strict tension control, the rod is drawn to exact diameters ranging from 0.35 mm to 4.00 mm. Diameter tolerance is maintained within ±0.002 mm through real-time laser micrometer feedback, critical for consistent coil layering and minimized void spaces. Surface integrity is preserved via ceramic die technology, eliminating micro-scratches that could compromise enamel adhesion.

Annealing follows drawing to restore ductility and achieve target electrical conductivity. Wires pass through a continuous hydrogen-nitrogen atmosphere furnace at 350–450°C, precisely regulated to prevent oxidation while ensuring uniform recrystallization. This step achieves a minimum conductivity of 61% IACS (0.028264 Ω·mm²/m) and tensile strength of 60–90 MPa. Hydrogen purity (99.995%) is monitored continuously to eliminate surface oxides, a prerequisite for enamel bonding. Post-annealing, wires undergo immediate quenching to stabilize metallurgical properties.

Enameling applies a thermosetting polyurethane-imide resin via precision die coating. Single or multiple coats are applied based on thermal class requirements (typically 150°C or 180°C), with intermediate curing at 300–450°C to volatilize solvents and crosslink the polymer. Film thickness is controlled to ±2 μm per coat using closed-loop viscosity and line-speed systems. Solvent recovery units maintain environmental compliance while ensuring consistent resin composition. The final enamel layer provides dielectric strength ≥3.5 kV/0.1mm and withstands 20+ winding mandrel bends without cracking.

Inline testing occurs at every critical stage. During drawing, diameter and ovality are verified via non-contact optical sensors. Post-annealing, conductivity and tensile properties are sampled hourly per ASTM B263. Enamel adhesion is confirmed via continuous spark testing at 2.5 kV, with automatic wire rejection for pinholes. Elongation (min 35%) and thermal shock resistance (200°C for 30 min) are validated per IEC 60317 standards. Final reels undergo 100% spark testing, dimensional checks, and visual inspection for surface defects.

Quality Control Verification Points

| Process Stage | Parameter Verified | Standard Tolerance | Test Method |

|———————|—————————–|——————–|——————-|

| Rod Drawing | Diameter | ±0.002 mm | Laser Micrometer |

| Annealing | Conductivity | ≥61% IACS | Eddy Current |

| Enameling | Film Thickness | ±2 μm | Optical Profilometer |

| Final Inspection | Dielectric Strength | ≥3.5 kV/0.1mm | IEC 60851-5 |

This integrated approach, refined over 20+ years, ensures metallurgical integrity from rod to finished wire. Statistical process control (SPC) tracks all parameters, with deviations triggering immediate corrective action. The result is aluminum winding wire meeting IEC 60216 and NEMA MW standards, engineered for high-efficiency transformer winding with minimal scrap rates and long-term operational stability.

Packaging & Logistics

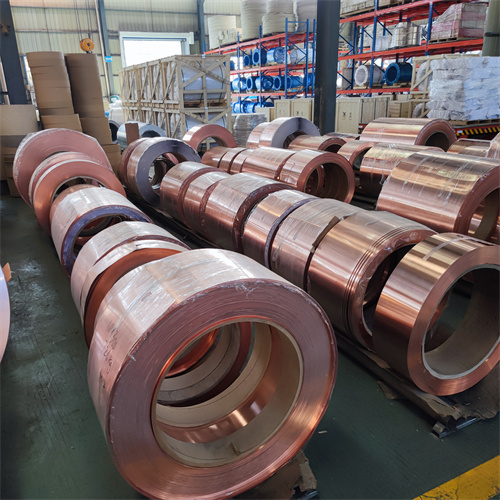

Export Packaging for Aluminum Winding Wire: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production of high-purity aluminum winding wire for transformer coil applications, we recognize that packaging is not merely a logistical necessity but a critical component of product integrity. Given the sensitivity of aluminum conductors to environmental exposure and mechanical stress—particularly during extended sea freight—we have engineered a robust export packaging system designed to ensure safe transit under global shipping conditions.

All aluminum winding wire reels are mounted on precision-engineered wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. These pallets are designed to meet international phytosanitary standards and provide structural stability under dynamic load conditions encountered during ocean transport. The use of hardwood ensures resistance to compression, impact, and deformation, even when stacked in containerized cargo holds. Each reel is securely fastened to the pallet using corrosion-resistant steel strapping and corner protectors, minimizing the risk of axial or radial displacement during handling and transit.

A primary concern in maritime transport is moisture exposure, which can lead to surface oxidation and degradation of electrical performance in aluminum conductors. To mitigate this risk, each wound reel is hermetically sealed using multi-layer moisture-proof film. This film consists of an aluminum foil laminate barrier with low water vapor transmission rate (WVTR), effectively isolating the coil from ambient humidity. The sealing process is conducted in a climate-controlled environment to prevent entrapment of moisture during packaging. Additionally, desiccant packs are strategically placed within the sealed enclosure to absorb any residual humidity and maintain internal dew point below critical thresholds.

The entire packaged unit is then overwrapped with UV-resistant polyethylene outer film to protect against condensation, salt spray, and mechanical abrasion. This outer layer also provides defense against minor impacts and contamination during port handling and intermodal transfer. Each package is clearly labeled with handling instructions, moisture sensitivity indicators, and batch-specific traceability data, including alloy grade, temper, dimensions, and production date, ensuring full compliance with international supply chain documentation standards.

Our packaging protocol has been validated through accelerated climate testing and real-world shipping trials across major trade routes, including trans-Pacific and trans-Indian Ocean voyages. The system consistently maintains coil surface quality, dimensional stability, and electrical integrity upon arrival, even after prolonged exposure to high-humidity tropical zones and temperature fluctuations.

For transformer manufacturers and tier-1 suppliers relying on consistent material performance, our export packaging represents a calibrated integration of material science and logistics engineering. It reflects Luoyang Xinzhaohe’s commitment to delivering aluminum winding wire that meets exacting technical specifications—intact and ready for immediate processing upon delivery.

Sourcing from Luoyang Xinzhaohe

Strategic Partnership for Precision Transformer Winding Wire Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and process engineering expertise to deliver aluminum winding wire meeting the exacting demands of high-performance transformer coil manufacturing. Our vertically integrated production ecosystem, centered on advanced aluminum processing, ensures consistent material properties critical for efficient winding operations and ultimate transformer reliability. We understand that dimensional stability, surface integrity, and precise electrical characteristics are non-negotiable factors in coil winding speed, fill factor, and long-term dielectric performance.

Our core strength resides in rigorous metallurgical process control. Utilizing high-purity (99.70% min) aluminum ingot sourced under stringent supplier qualification protocols, we implement proprietary homogenization and continuous casting techniques to achieve optimal grain structure and eliminate internal stresses. This foundational control directly translates to superior wire drawability and consistent mechanical properties essential for high-speed, low-breakage winding. Our state-of-the-art rolling mills and drawing lines feature closed-loop tension control and real-time dimensional monitoring, guaranteeing tight tolerances on width, thickness, and edge contour critical for layer-to-layer stability in coil builds. The integrated continuous annealing system precisely controls temper (typically H14 to O temper), ensuring uniform elongation and tensile strength across every coil shipment, minimizing winding tension variations and core distortion risks.

Quality assurance is embedded at every process stage through our ISO 9001 and IATF 16949 certified systems. In-process testing includes 100% laser micrometer monitoring for dimensional conformance and automated surface defect detection. Final product verification encompasses rigorous electrical conductivity testing (IACS %), mechanical property validation (tensile strength, elongation), and meticulous surface inspection against industry standards. Typical key properties for our transformer strip are summarized below:

| Parameter | Typical Value | Standard Tolerance | Test Method |

|---|---|---|---|

| Conductivity (IACS) | ≥ 61.0% | ±0.5% | IEC 60468 |

| Thickness | 0.80 – 3.00 mm | ±0.01 mm | ISO 16630 |

| Width | 10.0 – 100.0 mm | ±0.10 mm | ISO 16630 |

| Tensile Strength | 85 – 115 MPa (O) | ±5 MPa | ASTM E8/E8M |

| Elongation | ≥ 35% (O) | ±3% | ASTM E8/E8M |

Supply chain resilience is engineered into our operations. We maintain dedicated production lines for transformer-grade aluminum strip, ensuring priority scheduling and batch traceability from melt to shipment. Strategic raw material inventory buffers and collaborative logistics planning with Tier-1 carriers guarantee >98.5% on-time delivery performance, even during peak industry demand cycles. Our technical service team, comprising experienced metallurgists and process engineers, provides direct support for material qualification, winding parameter optimization, and rapid root-cause analysis for any production interface challenges.

Partner with Luoyang Xinzhaohe to secure a reliable source of precision-engineered aluminum winding wire that enhances your coil winding efficiency and transformer performance. Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your specific technical requirements, request comprehensive material certification packages, or schedule a virtual production capability review. We are prepared to integrate seamlessly into your supply chain as a committed technical partner.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing winding of transformer coils directly from China.