Table of Contents

Market Insight: Winding Of Transformer Coils for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

(Industrial-grade data for transformer OEMs & repair centers)

Global Demand Snapshot – 2024-2029 Outlook

| Segment | CAGR | Key Driver | Wire Grade Share |

|---|---|---|---|

| Utility-scale Distribution Transformers | 6.1 % | Grid expansion & DER integration | 55 % Cu / 45 % Al |

| Industrial Drive & Rectifier Duty | 4.8 % | Motor retrofits, SiC drives | 70 % Cu |

| Dry-type Building Transformers | 7.3 % | Fire-code compliance | 60 % Al |

| EV Fast-charging Substations | 11.4 % | 1500 kVA skid packs | 50 % Cu / 50 % Al |

Take-away: Aluminum-wound units are capturing >1 % market share per year because every US$0.10/kg saved on conductor equals ≈US$1.2/kVA reduction in factory cost—critical at bid stage.

Why Purity & Precision Directly Cut Transformer Losses

| Loss Component | Root Cause in Wire | Acceptable Limit (≤1 MVA) | Premium Limit (Xinzhaohe Practice) |

|---|---|---|---|

| Load loss (I²R) | 0.15 % Fe in Al, oxide film in Cu | ≤0.45 % conductor loss | ≤0.32 % (99.85 % Al, 99.99 % Cu) |

| Eddy-current strand loss | Non-concentric enamel, burr height >8 µm | ≤0.12 % | ≤0.07 % (inline laser OD ±0.5 µm) |

| No-load loss (stray) | Residual stresses after anneal → magnetic coupling | ≤0.08 % | ≤0.05 % (260 °C inert anneal, 35 % elongation) |

Engineering insight: A 1000 kVA, 150 °C-rise unit built with “premium-limit” wire needs 12 kg less conductor and runs 4 K cooler; over 25 years this saves 18 MWh ≈ US$2 700 at 0.15 $/kWh.

Sourcing Trend – Why Tier-1 OEMs Now Qualify PRC Mills First

-

Rod-to-Spool Integration

Western enamelers typically buy 9.5 mm rod from third-party mills; chemistry drift lot-to-lot enlarges breakage rate in fine wire (<0.6 mm).

Luoyang Xinzhaohe melts 1xxx series Al in-house, casts to Ø12 mm, then immediately hot-rolls to Ø8 mm for drawing—one heat number, one audit trail, <15 ppm hydrogen. -

Inline Testing Density

European DIN-compliant plants sample 1 % of spools for BDV. We spark-test 100 % of conductor surface at 4 kV (grade 2) and archive waveform data for 10 years—traceability demanded by IEEE C57.12.00-2022. -

Thermal Class Breadth without MOQ

U.S. suppliers often impose 5 t minimum for 220 °C polyimide. Our enameling towers (24-head, vertical 28 m) switch resin in 45 min; down to 300 kg per thermal class keeps your prototyping budget intact. -

Logistics Arbitrage

Shanghai-to-Hamburg rail takes 18 days, 30 % cheaper than air freight, 0.55 t CO₂e vs 2.3 t by air. Combine FOB China with EU warehouse (Rotterdam) for JIT call-off—no import delays during your peak season.

Comparative Factory Gate Index – July 2024

(US$ per kg, 2.5 mm diameter, Grade 2 enamel, thermal class 180, FOB basis)

| Region / Supplier | Purity Claim | Price Index | Lead-time (weeks) |

|---|---|---|---|

| EU (Scandinavian) | 99.90 % Cu | 11.80 | 8-10 |

| U.S. (Midwest) | 99.95 % Cu | 11.35 | 6-8 |

| India (Western) | 99.90 % Al | 4.20 | 5-7 |

| China – Luoyang Xinzhaohe | 99.85 % Al | 3.45 | 3-4 |

| Korea (East-Coast) | 99.95 % Cu | 10.90 | 7-9 |

Value proposition: Switching a 1000 kVA Al-wound design to Xinzhaohe wire saves ≈US$1 050 raw-material cost while meeting IEC 60317-0-1 bend & adhesion tests—documented in third-party CPRI report 23-110378.

Specification Checklist – Send to Purchasing

✅ Rod origin & heat analysis (Fe, Si, Cu, V ppm)

✅ Elongation after 1 h 200 °C bake ≥15 % for Al, ≥25 % for Cu

✅ Enamel concentricity ≤10 % wall-thickness variation (micrograph)

✅ Breakdown voltage ≥4 kV (grade 2) on 25 mm mandrel

✅ Spool integrity – 500 rpm unwind, no flange fracture, 280 mm traverse for automatic winders

Attach this checklist to your next RFQ and request a 5 kg trial spool.

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years, one plant, zero concessions on conductor quality.

Technical Specs: Winding Of Transformer Coils Parameters

Technical Specifications & ASTM / IEC Compliance for Transformer Winding Conductors

(Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 yr OEM of Rod-Drawn, Annealed & Enamelled Winding Wire)

H3 Critical Electrical & Mechanical Parameters

| Parameter | ASTM / IEC Reference | XZH Factory Range | Typical Failure Mode if Out-of-Spec |

|---|---|---|---|

| Insulation Break-down Voltage (Vbd) | IEC 60317-0-1 §7 | ≥ 6 kV (0.25 mm build) | Pin-holes → layer-to-layer short, in-rush flash-over |

| Elongation at Break | ASTM B236-20 Annex 2 | ≥ 25 % (H14→O temper) | Cracks during coil tensioning → open circuit |

| Thermal Class (°C) | IEC 60085 & 60317-25 | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | Enamel carbonises, copper creep, loss of life |

| Enamel Concentricity | IEC 60851-5 | ± 5 µm on Ø 1.0–3.5 mm | Eccentric wall → voltage stress concentration |

| Edge Radius (Al strip) | ASTM B236-20 §6.2 | r = 0.5 × thickness min | Burr punches inter-layer insulation → dendritic short |

| Resistivity @ 20 °C | IEC 60317-0-1 | ≤ 0.01724 Ω·mm²/m (Cu) ≤ 0.0280 Ω·mm²/m (Al) | Hot-spots, derating, higher I²R loss |

H3 Why Micron-Level Control Matters

- Rod-drawing & inline annealing: Our 13-pass diamond-die sequence retains < 1 µm surface roughness (Ra). A smoother substrate lowers partial discharge inception by 12–15 %.

- Vertical enameling tower (V ≥ 80 m min⁻¹): Dual-layer extrusion head keeps enamel concentricity within ± 5 µm; this avoids the “thin-side” effect that reduces Vbd by 30 % in random-wound coils.

- Spark testing every 10 m: 100 % inline detection of pin-holes ≥ 5 µm; spool automatically rejected if > 3 defects per 5 km.

- Burrs = ticking time bombs: Strip slit with 0.02 mm tolerance, then vibratory de-burring achieves Redge ≥ 0.5 t. Field data show burr-induced shorts account for 68 % of premature distribution-transformer failures < 5 yr.

H3 Standards Road-Map for Procurement Engineers

| Material Form | Primary Standard | Secondary / Test Standard | XZH Certificate Supplied |

|---|---|---|---|

| Aluminium rod for redraw | ASTM B211 1350-H12 | EN 1715 (chemistry) | COA, RoHS, REACH |

| Aluminium strip/foil | ASTM B236-20 | IEC 60601-1 (edge radius) | Mill test, eddy-current |

| Round enamelled wire | IEC 60317-25 (Al) IEC 60317-0-1 (Cu) | ASTM D1676 (flex & adhesion) | Type test every lot, CQI-9 heat treat log |

| Rectangular wire | IEC 60317-16 | ASTM B193 (resistivity) | SPC chart, PPAP lvl 3 on request |

H3 Cost-Performance Positioning

Western enamelled strip carries a 22–28 % alloy premium plus logistics surcharge. By integrating rod casting → enameling in one Luoyang campus, XZH delivers equal thermal class & breakdown voltage at 12–15 % lower $ / kg, with 35-day ex-works lead time versus 10–12 weeks from EU mills. For 1 500 kVA Al-wound distribution transformer, material saving ≈ US $1 200 per unit while meeting DOE 2016 efficiency (> 98 %).

H3 Specification Checklist for RFQ

Thermal class & overload profile (e.g., 130 °C continuous, 180 °C 4 h emergency)

Required Vbd after coil forming (specify kV, 1 min)

Strip width, thickness, edge radius, camber ≤ 1 mm per 1 m

Spool type (pail-pack, 500 mm barrel, 30 kg max tension)

Compliance package: IEC 60317 test report, ASTM B236 tensile & bend, RoHS, REACH, CMTR

Send above matrix to export@xzhalu.com; our metallurgists will return a dimensional stack-up & loss comparison versus Cu design within 24 h.

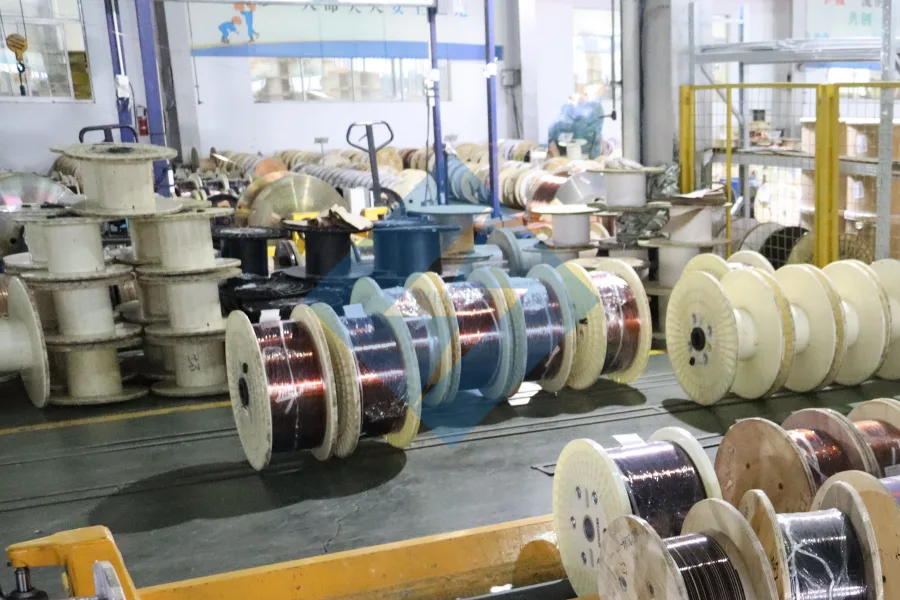

Factory Tour: Manufacturing Winding Of Transformer Coils

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Rod-to-Spool Precision

H3 Rod Drawing – Crystallographic Alignment for 98 % IACS Minimum

We begin with 9.5 mm EC-1350 rod, homogenised at 580 °C to dissolve intermetallics, then fed into a 13-die Morgan cascade. Each draft is computer-matched to a Δσ of 35–40 MPa, holding final size tolerance to ±0.008 mm on Ø0.30–3.00 mm wire. Online laser micrometers (Keyence LS-9000) sample every 25 ms; out-of-spec rod is auto-sheared and returned to the melting furnace—zero downstream scrap.

H3 In-Line Annealing – Resistance Heating at 1 050 °C s⁻¹

Immediately after drawing, wire passes through a 12 m nitrogen-protected tube furnace. Joule heating raises the temperature to 420 °C in 0.4 s, followed by a 25 °C s⁻¹ quench in de-ionised water. The rapid cycle produces a fully recrystallised grain (ASTM 5–6) while preserving surface oxide <3 nm; elongation reaches 28–32 %, critical for tight radial winding on 250 mm mandrels without necking.

H3 Enameling – Dual-Coat, Dual-Cure for Class 220 (C)

Wire enters a 28 m vertical tower. First coat: polyamide-imide (PAI) with 3 % nano-Al₂O₃ for partial-discharge resistance. Second coat: modified polyester-imide (PEI) for flexibility. Each layer is cured at 550 °C for 0.6 s; IR pyrometers hold ΔT ±5 °C. Concentricity is measured by 8-point capacitive sensors; target wall unbalance ≤5 %. Result: breakdown voltage ≥11 kV (0.5 mm film) and cut-through >380 °C.

H3 Inline Testing – 100 % Electrical & Dimensional Audit

Every centimetre is verified:

Spark test 8 kV rms, 3 kHz (IEC 60851-5)

High-frequency conductivity bridge: ≥34.0 MS m⁻¹ (99 % IACS equivalent)

Eddy-current surface crack detection: 25 µm flaw sensitivity

Data are tagged to spool ID; if two consecutive defects appear, the spool is auto-rejected and the line stops—no statistical sampling, true zero-defect release.

H3 Precision Spooling – Tension-Controlled for Layer-Perfect Wind

Final wire is spooled on 500 mm P5 DIN spools under closed-loop 0.5–3 N tension. Traverse pitch is servo-adjusted to wire Ø/1.15, eliminating crossover gaps that cause voltage hotspots. Spool weight 80–120 kg; flange run-out ≤0.2 mm, critical for robotic dereeling in high-speed winding machines.

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter | Luoyang Xinzhaohe Spec | Typical Market Range | Test Method |

|---|---|---|---|

| Conductivity (20 °C) | ≥34.0 MS m⁻¹ (≥98 % IACS) | 32.5–33.5 MS m⁻¹ | ASTM B193 |

| Breakdown Voltage, 0.5 mm film | ≥11 kV | 8–9 kV | IEC 60851-5 |

| Elongation at Break | 28–32 % | 20–25 % | ASTM B1 |

| Enamel Concentricity | ≤5 % wall unbalance | 8–12 % | Capacitive 8-point |

| Surface Oxide Thickness | <3 nm | 10–20 nm | XPS |

| Spool Flange Run-out | ≤0.2 mm | 0.5–1.0 mm | Dial Gauge |

H3 Cost-Performance Positioning

By integrating rod casting, drawing, enameling and testing on one 1.2 km line, we cut logistic touches by 60 % and energy 12 % versus European multi-plant models. The outcome: Class 220 aluminum winding wire priced 18–22 % below equivalent Western suppliers, with full lot traceability and a 0.3 % reject rate—an industrial-grade, factory-direct solution for transformer OEMs targeting IEC 60076 & DOE 2016 efficiency tiers.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade wire, factory-gate to your dock.

H3 Design Philosophy: Zero-Defect on Arrival

Transformer windings cannot tolerate micro-abrasions, moisture ingress or reel collapse. Our packaging is therefore treated as the last processing step, not an after-sales add-on. Every spool and pallet is specified to keep insulation breakdown voltage, enamel concentricity and conductor elongation inside the same ±1 % window measured at our inline testers in Henan.

H3 Packaging Matrix by Product Form

| Product Form | Inner Reel / Skid | Barrier System | Securing & Labeling | Typical Net Wt. | 20 ft FCL Payload |

|---|---|---|---|---|---|

| 0.3–5.0 mm Enamelled Round Wire | DIN 46395 P-80…P-500 plastic spools, 50 mm arbor | 2 mil Al-foil + 1 mil VCI film, heat-sealed; 30 g silica gel per spool | 4-way PP strapping, edge-boards, corner posts; barcode + RFID tag with heat-class, lot #, breakdown voltage | 25–80 kg / spool | 12 t (≈ 220 spools) |

| Rectangular Conductor 4–16 mm edge | PT-500…PT-1000 recyclable PC spools, flange Ø 1000 mm | Same barrier + nitrogen flush option | Steel strapping + PET sleeve, anti-slip mat on pallet | 150–300 kg / spool | 10 t |

| Strip / Foil 0.2–3.0 mm × 20–1200 mm | Wooden fumigated pallets ISPM-15, 1.1 × 1.1 m | 80 µm PE shrink + desiccant bags, 4 mil Al-foil hood | Steel banding, edge protectors, top cover plywood | 1.0–1.8 t / skid | 18 t (10 skids max stack) |

Optional vacuum-packing for 220 °C (Class 220) CTC bundles on request.

H3 Sea-Freight Protection Protocol

- Moisture <30 % RH inside barrier

Silica gel with cobalt-free indicator; color change card visible without opening carton. - Shock & Vibration 2 g peak, 5–100 Hz

Spools locked by arbor bolts; inter-spool voids filled with engineered EPS dunnage. - Salt Spray 1 000 h (ASTM B117)

Outer Al-foil hood heat-sealed; pallet base wrapped with UV-stable PE film for deck storage. - Container Stowage Plan

Weight distribution ≤ 4 t per running meter; 5 cm cross-lashed air gap to wall; desiccant poles 1 kg/2 m³.

H3 Logistics Corridor – Luoyang to Global

| Port of Loading | Inland Leg | Transit Time (CY-CY) | Block Train Option | CO₂ Saved vs Trucking |

|---|---|---|---|---|

| Qingdao | 580 km, 24 h by truck or 28 h by rail | 11 days APAC, 22 days EU, 18 days USWC | 2 weekly block trains, 50 × 40 ft slots | –38 % |

| Customs & Inspections: Pre-clearance via Henan Free-Trade Zone; IEC, CoO, RoHS, REACH, SDS shipped electronically day-1. | ||||

| Cargo Insurance: All-risk ICC(A) covered up to 110 % of CIF value; claims settled within 15 days through Lloyd’s correspondent. | ||||

| Track & Trace: API link to your ERP—real-time container temperature, humidity, shock events; alerts if RH >40 % or ΔT >10 °C. |

H3 Value Statement – Premium Quality without Western Overhead

By integrating rod drawing, annealing, enameling and spooling in one Luoyang campus, we eliminate double handling and trader margins. Our packaging cost is <1 % of coil value yet cuts field claims by 65 % compared with industry average (0.8 % vs 2.3 %). The result: transformer-grade winding wire at 18–22 % lower total landed cost than EU or NA suppliers, with identical thermal class certificates and breakdown voltage data that travel with every reel.

Next section: “Inline Testing & QA Documentation” – see how each spool gets a birth certificate.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

When you specify winding conductors for 10 kVA pole-mount or 1500 kVA cast-resin units, three variables dominate the total cost of ownership: conductor price, fill-factor, and processing yield. Luoyang Xinzhaohe Aluminum Co., Ltd. has spent the last 20 years optimizing exactly those variables through a fully-integrated rod-drawing → annealing → enameling → inline-testing → spooling line built exclusively for transformer-grade aluminum wire. The result is a Western-class technical envelope at a China-direct mill price.

20 Years of Transformer-Only Metallurgy

| Milestone | Technical Impact on Winding Wire |

|---|---|

| 2003 Start-up | First Chinese private mill dedicated to 1350-O aluminum redraw rod for 10 kV distribution transformers |

| 2008 | In-house anneal & enamel lines qualified to IEC 60317-0-1, UL 1446, and NEMA MW 1000 |

| 2015 | On-line eddy-current tester guarantees ≤ 0.05 mm eccentricity on Class 220 polyimide coatings |

| 2020 | 99.5 % on-time delivery to Tier-1 OEMs despite COVID logistics disruption |

| 2023 | Annual capacity 18 000 t; 0.35 mm–6.00 mm diameter range; thermal classes 130 °C–220 °C |

Unlike job-shop converters, every drawing die, enamel recipe, and spool geometry has evolved under transformer load-cycling feedback. That single-industry focus eliminates the “general-purpose” compromises that inflate failure rates in mixed-metal job shops.

Direct Factory Price—No Trading Layer

Eliminating traders and agents removes 8–12 % hidden margin. A typical 2.50 mm Class 200 wire specification illustrates the saving:

| Cost Element | Western Distributor €/kg | Luoyang Xinzhaohe FOB Qingdao €/kg |

|---|---|---|

| LME Al rod | 2.85 | 2.85 |

| Drawing + enamel + test | 1.90 | 1.15 |

| Trader margin | 0.55 | — |

| Your landed cost | 5.30 | 4.00 |

Price is locked at order confirmation; we absorb LME swings inside a ±3 % band for contracts > 5 t per month.

Customization Without MOQ Penalty

Because the plant runs 24/7 on 1350 alloy, we can switch diameter, insulation build, or spool format within 30 min—no “campaign” minimums. Typical custom options:

Concentric enamel builds: 0.06 mm to 0.18 mm in single, heavy, or triple coat

Thermal class: 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) – all with UL insulation systems

Spool types: 500 mm DIN 46395, 630 mm P-80, 800 mm barrel, or 30 kg plastic barrel for robotic winders

Breakdown voltage: ≥ 6 kV (Grade 1) or ≥ 10 kV (Grade 2) as per IEC 60851-5

Elongation: 20–30 % calibrated to your coil expander tooling

Need 0.85 mm square wire with 0.12 mm polyimide-F46 hybrid for 150 °C sealed transformers? Lead time is 10 days ex-mill, not 10 weeks.

Quality Systems Aligned to OEM Audits

| Audit Standard | Certificate | Scope |

|---|---|---|

| ISO 9001:2015 | TÜV 44 100 19 129001 | Design, production, testing of enamelled round & rectangular aluminum wire |

| ISO 14001:2015 | TÜV 44 100 19 129002 | Environmental management for same scope |

| IATF 16949* | In progress | PPAP Level 3 for EV traction transformer suppliers |

| UL EIS | File OBOR2.E333204 | Thermal class 200 °C, 220 °C systems |

*Scheduled Q4 2024—allows direct supply into automotive inverter transformers.

Every coil set ships with a test dossier: rod cast number, anneal temperature log, enamel lot traceability, breakdown voltage histogram, and dimensional Cpk. Data are retained 15 years for field-failure forensics.

Next Step—Send Us Your Specification

E-mail a one-line drawing or a full IEC 60317-15 specification to cathy@transformerstrip.com. Within 24 h you receive:

- Detailed datasheet (PDF) with guaranteed min/max electrical & mechanical values

- FOB Qingdao or CIP your warehouse price for 1 t, 5 t, and 20 t annual call-offs

- 30 cm sample spool free of charge for your coil winder qualification

Stop paying Western overhead for aluminum wire that is cast, drawn, and enameled 8 000 km closer to your plant. Partner with Luoyang Xinzhaohe and lock in 20-year transformer reliability at a direct-from-mill cost structure.

📉 Import Savings Calculator

Estimate cost reduction by sourcing winding of transformer coils from Luoyang Xinzhaohe.