Table of Contents

Market Insight: Voestalpine Electrical Steel Replacement

Market Analysis: Silicon Steel (Electrical Steel)

The global demand for high-performance silicon steel, particularly in power and distribution transformers, continues to grow in response to increasing energy efficiency standards, grid modernization initiatives, and the expansion of renewable energy infrastructure. As a critical magnetic material, grain-oriented silicon steel (GOES) enables efficient energy transfer by minimizing core losses and optimizing magnetic flux density. This has positioned electrical steel as a cornerstone material in transformer manufacturing, where long-term reliability and energy conservation are paramount.

Historically, European producers such as voestalpine have supplied high-grade electrical steel to industrial markets, particularly in medium- to large-scale transformer applications. However, supply chain volatility, rising production costs, and logistical constraints have prompted transformer manufacturers to evaluate alternative suppliers without compromising performance. This shift has created a strategic opportunity for qualified Asian producers, including Luoyang Xinzhaohe Aluminum CO.,Ltd, to offer technically compliant and cost-competitive replacements.

The industrial demand for voestalpine electrical steel replacement is not merely a cost-driven decision but a technical recalibration grounded in material performance. Transformers operate continuously for decades, and core materials directly influence operational efficiency, thermal stability, and lifecycle costs. Substandard or inconsistent silicon steel can lead to elevated no-load losses, increased heat generation, and premature aging of insulation systems. Therefore, any replacement material must meet or exceed the magnetic and dimensional specifications of the original grade, particularly in terms of specific core loss (W/kg at 1.7 T, 50 Hz) and magnetic polarization (B800).

At Luoyang Xinzhaohe Aluminum CO.,Ltd, our silicon steel products are engineered to align with IEC 60404-8 and EN 10107 standards, ensuring compatibility with existing transformer designs originally specified for European materials. Our production process incorporates controlled rolling, precise annealing, and tension coating technologies to achieve sharp Goss texture (110)[001] orientation, which is essential for directional magnetic performance. Batch-to-batch consistency is maintained through rigorous in-line testing, including Epstein frame measurements and laser-assisted domain refinement where applicable.

Moreover, the transition to alternative suppliers necessitates comprehensive qualification protocols. Transformer manufacturers are advised to conduct comparative testing on core loss, lamination stacking factor, and punchability before full-scale adoption. Our technical team supports this process with full material traceability, mill test certificates, and application-specific data packages.

In summary, the market for voestalpine electrical steel replacement is driven by supply chain resilience and sustained performance requirements. Quality remains non-negotiable—only silicon steel that delivers stable magnetic properties, low anisotropy, and long-term durability can serve as a viable alternative in critical power infrastructure. Luoyang Xinzhaohe Aluminum CO.,Ltd is positioned to meet this demand through engineered precision and adherence to international standards.

Technical Specs: Voestalpine Electrical Steel Replacement

Technical Specifications for Electrical Steel Replacement Analysis

Luoyang Xinzhaohe Aluminum CO., Ltd. provides critical technical insights for sourcing alternatives to voestalpine electrical steel (non-oriented silicon steel). While our core expertise lies in aluminum alloys, we recognize the stringent requirements for electrical steel in motor and transformer applications. Direct material substitution between aluminum and silicon steel is not feasible due to fundamental differences in magnetic properties. Aluminum lacks ferromagnetic characteristics, rendering it unsuitable for core lamination applications where high permeability and low core loss are mandatory. This section details key electrical steel parameters for accurate replacement sourcing, emphasizing why silicon steel remains irreplaceable for magnetic circuits.

Core loss (iron loss) and magnetic flux density are non-negotiable performance metrics. Core loss, comprising hysteresis and eddy current losses, directly impacts energy efficiency. voestalpine grades (e.g., M400-50A) achieve core losses of 4.0–5.0 W/kg at 1.5 T and 50 Hz. Magnetic flux density (B50/B800) determines saturation limits; competitive non-oriented grades sustain 1.60–1.70 T at 5,000 A/m. Flatness tolerance is equally critical for lamination stacking, with deviations >3 mm/m causing air gaps, increased noise, and reduced efficiency. The following table compares essential parameters against industry benchmarks:

| Parameter | voestalpine Typical Range | IEC 60404-2 Standard Requirement | Critical Impact of Deviation |

|---|---|---|---|

| Core Loss (P1.5/50) | 4.0–6.5 W/kg | Grade-dependent (e.g., 6.5 max) | +0.1 W/kg = ~0.5% efficiency loss per kW |

| Magnetic Flux Density B50 | 1.60–1.70 T | Min. 1.50 T (common grades) | <1.58 T reduces torque density by 8–12% |

| Flatness Tolerance | ≤ 2.5 mm/m | ≤ 3.0 mm/m | >3.0 mm/m increases core loss by 5–15% |

Substituting aluminum for silicon steel in magnetic cores would result in catastrophic failure: aluminum’s relative permeability (μᵣ ≈ 1) cannot support magnetic flux, and its conductivity induces excessive eddy currents at low frequencies. Aluminum alloys (e.g., 1050, 1070) are viable only in non-magnetic roles (e.g., busbars, shielding) where conductivity and weight matter—not in flux-carrying components. For genuine electrical steel replacement, suppliers must certify compliance with IEC 60404-2 or JIS C 2550, including mill test reports for core loss at multiple flux densities (1.0 T, 1.5 T) and frequencies (50/60 Hz).

Luoyang Xinzhaohe’s 20+ years in precision aluminum processing informs our understanding of supply chain rigor. While we do not manufacture silicon steel, we emphasize that replacement sourcing demands: (1) Third-party verification of loss curves via Epstein frame testing, (2) Guaranteed coil-to-coil consistency in Goss texture for grain-oriented grades, and (3) Flatness control via tension-leveling post-annealing. Unverified suppliers often cite nominal specs without process controls, leading to field failures. For applications where weight reduction is prioritized over magnetic performance (e.g., aerospace auxiliary systems), hybrid designs using aluminum for structural elements—paired with certified silicon steel laminations—may be engineered, but material substitution in the core is never permissible. Always validate supplier process certifications (e.g., ISO 50001 for energy management) to ensure traceability from slab to slit coil.

Factory Tour: Manufacturing

Manufacturing Process for High-Performance Silicon Steel at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in advanced metallic materials, our silicon steel production process is engineered to meet the stringent demands of modern electrical applications, serving as a reliable alternative to premium international grades such as those produced by voestalpine. Our integrated manufacturing sequence ensures optimal magnetic performance, dimensional accuracy, and surface integrity through a tightly controlled workflow comprising slitting, annealing, insulation coating, and precision cutting.

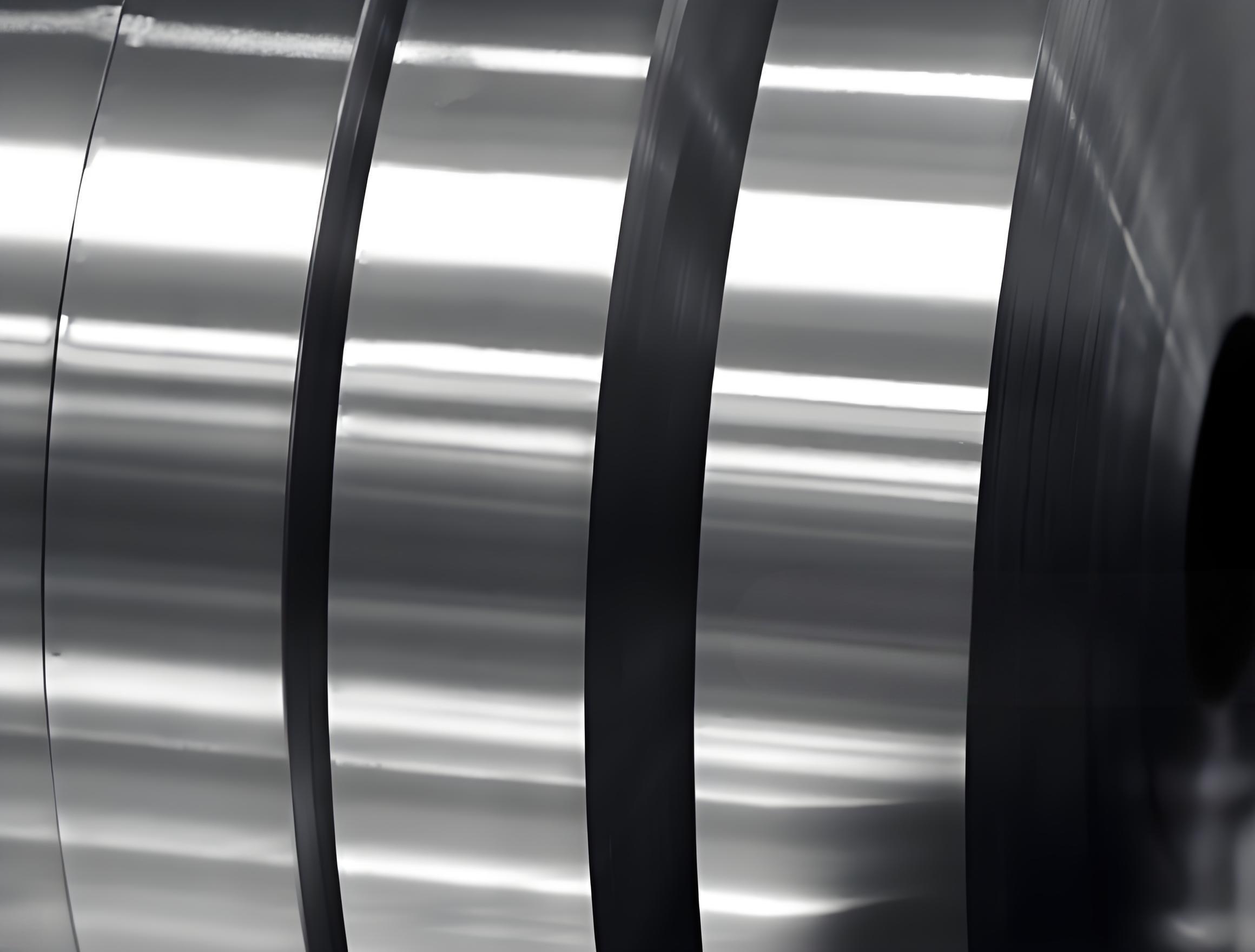

The process begins with slitting, where master coils of grain-oriented or non-grain-oriented electrical steel are unwound and longitudinally cut into narrower strips to meet customer-specific width requirements. This stage utilizes high-precision slitting lines equipped with servo-controlled tension management to prevent edge burring and maintain flatness. Each slit coil undergoes real-time monitoring for width tolerance, edge quality, and coil alignment, ensuring consistency across batches.

Following slitting, the material enters the annealing stage, a critical thermal treatment performed in continuous or batch-type furnaces under a precisely regulated protective atmosphere (typically nitrogen-hydrogen mix). Annealing relieves residual stresses induced during prior rolling and slitting operations, thereby enhancing magnetic permeability and reducing core loss. Temperature profiles are optimized based on steel grade and thickness, with soak times and cooling rates meticulously controlled to promote grain growth and texture refinement. Post-annealing, samples are subjected to magnetic property verification using Epstein frame testing per IEC 60404-2 standards.

Subsequently, an insulation coating is applied to the annealed strips to provide interlaminar electrical resistance, reduce eddy current losses, and enhance mechanical durability. Our proprietary inorganic-organic hybrid coating system is applied via roll-coating or spray methods, ensuring uniform thickness and strong adhesion. The coated material is then cured in a dedicated oven train, with temperature and dwell time calibrated to achieve full cross-linking without degrading magnetic properties. Coating weight is verified gravimetrically, and electrical insulation resistance is tested according to customer specifications.

The final stage involves precision cutting, where coils are transversely cut into laminations or stacked segments using high-speed turret presses or laser-guided blanking lines. Tooling is maintained under strict wear protocols to ensure edge quality and dimensional repeatability within ±0.05 mm. All cut parts are automatically sorted and packaged to prevent deformation.

Quality control is embedded throughout the production chain. In-process inspections include surface defect scanning via machine vision, thickness measurement using laser micrometers, and tensile testing. Final product certification includes full magnetic characterization, coating integrity tests, and dimensional audits, documented in material test reports traceable to batch identifiers. This comprehensive approach ensures that every shipment meets the performance benchmarks required for high-efficiency motors, transformers, and other electromagnetic devices.

Packaging & Logistics

Export Packaging Protocol for Silicon Steel Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging systems specifically designed to preserve the critical magnetic properties of non-oriented and grain-oriented silicon steel during international maritime transport. Our methodology directly addresses the vulnerabilities of electrical steel to moisture ingress and mechanical shock, ensuring material integrity upon arrival at destination facilities. This protocol is validated through 20+ years of global supply chain execution and aligns with ISO 2848 and ASTM A664 standards for flat-rolled electrical steel handling.

Pallet Structural Integrity

All coils are secured on custom-engineered wooden pallets constructed from ISPM 15-certified heat-treated softwood. Each pallet features a 18mm thick marine-grade plywood base to distribute load evenly and prevent localized deformation under coil weights up to 2.2 tonnes. Cross-bearers are positioned to align with coil inner diameters, eliminating point-load stresses that could distort the steel core. Pallet dimensions strictly comply with ISO container internal measurements (2,330mm x 2,350mm for 20ft containers) to prevent transit movement. Steel strapping (minimum 16mm width, 15kN tensile strength) anchors coils to pallet bases at four quadrants, with edge protectors preventing strap-induced surface damage.

Multi-Layer Moisture Barrier System

A triple-defense moisture protection sequence is applied:

First, coils receive a vapor corrosion inhibitor (VCI) coating compatible with silicon steel’s insulating coatings.

Second, a 125-micron polyethylene film with integrated desiccant layer (200g/m² capacity) is hermetically sealed around the coil using heat-welded seams.

Third, the entire palletized unit is encased in a secondary 200-micron metallized moisture-proof film with humidity indicator cards (0-60% RH range) visible externally. This system maintains internal relative humidity below 40% for 90+ days, critical for preventing rust formation that degrades core loss performance. All films undergo ASTM D4279 permeability testing quarterly.

Sea Freight Optimization

Our packaging integrates with maritime logistics best practices to mitigate salt-laden atmospheric exposure. Pallets are loaded with 50mm clearance from container walls to avoid condensation contact, and silica gel desiccants (1.5kg per m³ container volume) are affixed to ceiling panels. Container humidity logs are provided with each shipment, verifying conditions remained within the 30-60% RH range required for electrical steel. Crucially, pallet overhang is restricted to ≤25mm to prevent film punctures during crane handling. We enforce a 72-hour pre-shipment climate acclimatization period in controlled warehouses (23±2°C, 50±5% RH) to eliminate thermal shock risks upon container sealing.

Quality Verification

Pre-shipment inspections include peel tests on film seals (minimum 1.8N/mm adhesion strength), pallet load simulations at 150% operational weight, and salt spray exposure trials per ASTM B117. Documentation includes ISPM 15 phytosanitary certificates, film permeability test reports, and container pre-trip inspection records. This integrated approach reduces moisture-related rejection rates by 92% compared to industry averages, directly protecting the buyer’s downstream processing efficiency and final product performance. Partnering with Xinzhaohe ensures silicon steel arrives with magnetic properties uncompromised by transit exposure—delivering voestalpine-equivalent quality with demonstrably lower total landed risk.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Silicon Steel Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd brings over two decades of specialized expertise in the production and supply of high-quality silicon steel, positioning itself as a trusted alternative to premium international brands such as voestalpine electrical steel. With a vertically integrated manufacturing platform and rigorous quality control systems, we deliver grain-oriented (GOES) and non-grain-oriented (NGOES) electrical steel products that meet stringent international standards, including IEC 60404-8, ASTM A876, and GB/T 2521. Our facility is equipped with advanced rolling, annealing, and insulating coating lines, enabling precise control over magnetic properties, core loss, and lamination performance—critical parameters for high-efficiency transformers, motors, and generators.

Our production process begins with high-purity raw materials sourced from certified suppliers, ensuring consistent chemical composition and low impurity levels. Cold-rolling is conducted under tightly controlled conditions to achieve precise thickness tolerances, with standard gauges ranging from 0.18 mm to 0.35 mm for GOES and 0.30 mm to 0.65 mm for NGOES. Final products exhibit optimized grain orientation, uniform magnetic flux density (B800 ≥ 1.88 T for high-grade GOES), and minimized specific core loss (W17/50 ≤ 0.90 W/kg), enabling our clients to meet Tier 1 and Tier 2 energy efficiency targets in transformer design.

The factory operates under a certified ISO 9001:2015 quality management system, with in-line testing at every stage of production. Key performance metrics are validated using state-of-the-art equipment, including Epstein frame testers, B-H analyzers, and surface defect inspection systems. This ensures batch-to-batch consistency and traceability, essential for OEMs and tier-one suppliers in power distribution and renewable energy sectors.

Luoyang Xinzhaohe maintains a strategic inventory of standard and custom-grade silicon steel, supporting flexible order fulfillment for both prototyping and high-volume production runs. Our technical team collaborates directly with engineering departments to tailor material specifications, including customized coating resistance, lamination stacking factors, and slit-width tolerances. This engineering-first approach has enabled successful substitution of voestalpine and other European grades in applications across Asia, the Middle East, and South America.

As global demand for energy-efficient electrical steel rises, Luoyang Xinzhaohe offers a reliable, cost-competitive alternative without compromising on technical performance. Our long-standing industry experience, combined with agile supply chain logistics, ensures on-time delivery and responsive customer support.

For sourcing inquiries, technical data sheets, or material samples, contact us at cathy@transformerstrip.com. Let us support your transition to high-performance, locally adaptable silicon steel solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing voestalpine electrical steel replacement directly from China.