Table of Contents

Market Insight: Voestalpine Electrical Steel Replacement in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel for Voestalpine Replacement

Industrial Demand Drivers

Global energy efficiency regulations (EU Ecodesign, China GB 20052-2020) drive demand for high-performance electrical steel in power transformers and motors. With renewable energy infrastructure expanding at 5% CAGR, reliable supply chains are critical. Key applications include grid transformers, EV motors, and industrial drives requiring optimized magnetic properties. Supply chain disruptions have intensified the need for proven alternatives to global brands like voestalpine.

Material Quality Impact on Efficiency

Core loss (P1.5/50) and magnetic induction (B50) directly dictate transformer efficiency. Core loss constitutes 60-70% of no-load losses; a 0.1 W/kg reduction improves efficiency by ~1.5%. Over a 20-year lifespan, this saves 10,000+ kWh per transformer. Substandard materials cause excessive heating, reducing lifespan and increasing maintenance costs. Failure to meet core loss specifications risks non-compliance with regional efficiency standards, leading to market access barriers.

Luoyang Xinzhaohe’s Strategic Positioning

As a 20+ year manufacturer, we deliver consistent, ISO 9001-certified silicon steel meeting IEC 60404-8-1 standards. Our vertically integrated production ensures traceability and quality control through automated testing and strict process parameters.

| Parameter | Voestalpine (M12-30) | Luoyang Xinzhaohe (XZ-30) | Advantage |

|---|---|---|---|

| Core Loss (W/kg @1.5T/50Hz) | 1.10 | 1.08 | -1.8% |

| Magnetic Induction (B50, T) | 1.85 | 1.86 | +0.5% |

| Cost Premium | +20% | Baseline | -20% |

Exported to 30+ countries, our factory-direct model guarantees supply chain resilience and on-time delivery. For transformer manufacturers, Xinzhaohe offers premium performance at competitive pricing with zero design modifications required, ensuring optimal total cost of ownership.

Technical Specs: Voestalpine Electrical Steel Replacement Parameters

Technical Specifications & Standards for Voestalpine Replacement

Luoyang Xinzhaohe Aluminum CO., Ltd. has supplied high-quality electrical steel to global transformer manufacturers for over two decades. Our Luoyang facility operates under ISO 9001:2015 certification, with advanced production lines capable of producing grain-oriented (GO) and non-oriented (NO) silicon steel grades tailored to specific application requirements. We deliver Voestalpine-grade electrical steel with a 15-20% lower total cost of ownership (TCO), strictly adhering to IEC 60404 and ASTM A876 standards. Leveraging our localized manufacturing base, we minimize logistics lead times while maintaining rigorous quality control for consistent performance.

Critical Parameter Specifications

| Parameter | Specification (Voestalpine Equivalent) | IEC/ASTM Standard | Compliance Method |

|---|---|---|---|

| Core Loss (W/kg) | 1.05 @ 1.7T, 50Hz (M4) | IEC 60404-2 | IEC 60404-3 testing |

| Magnetic Flux Density (T) | 1.70-1.75 @ 800 A/m (M4) | IEC 60404-2 | ASTM A876 hysteresisgraph |

| Lamination Flatness | ≤0.3 mm/m deviation (M4) | ASTM A876, IEC 60404-11 | Laser scanning + automated |

| Insulation Coating | Phosphate + C6 (1.5-2.5μm) (M4) | IEC 60404-8-5 | ASTM D3359 adhesion test |

Quality Assurance Protocol

Our quality assurance protocol employs a multi-stage verification process to maintain consistency across all production batches:

Raw Material Screening: XRF spectrometry for precise chemical composition analysis (ISO 17025 certified), ensuring silicon content within 2.8-3.2% for GO steel and precise control of impurities like sulfur and carbon to minimize core loss. All incoming coils undergo batch-wise testing to guarantee material consistency.

Rolling & Annealing: Controlled atmosphere furnaces with ±2°C temperature precision and real-time monitoring, optimizing grain structure per IEC 60404-2 requirements to achieve uniform magnetic properties. Advanced annealing processes reduce internal stresses and enhance magnetic permeability.

Coating Application: Automated roll-coating systems with 1.5-2.5μm thickness control and adhesion testing per ASTM D3359, preventing delamination during stacking and ensuring insulation integrity under high-voltage conditions. Coating uniformity is verified via eddy current testing for each coil.

Final Inspection: 100% automated testing for core loss (using Epstein frame per IEC 60404-3), magnetic flux density (ASTM A876), and lamination flatness (laser scanning), with traceable quality certificates for each coil. Data is stored in our ERP system for full traceability and customer access.

This rigorous process ensures our electrical steel consistently meets or exceeds Voestalpine specifications, providing transformer manufacturers with a reliable, cost-efficient alternative without compromising performance.

Factory Tour: Manufacturing Voestalpine Electrical Steel Replacement

Precision Manufacturing & Rigorous Quality Control for Consistent Performance

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers voestalpine-grade electrical steel performance at 15-20% lower costs through optimized production and stringent QC. Our factory-direct approach eliminates middlemen while maintaining ISO 9001-certified processes for transformer-grade silicon steel.

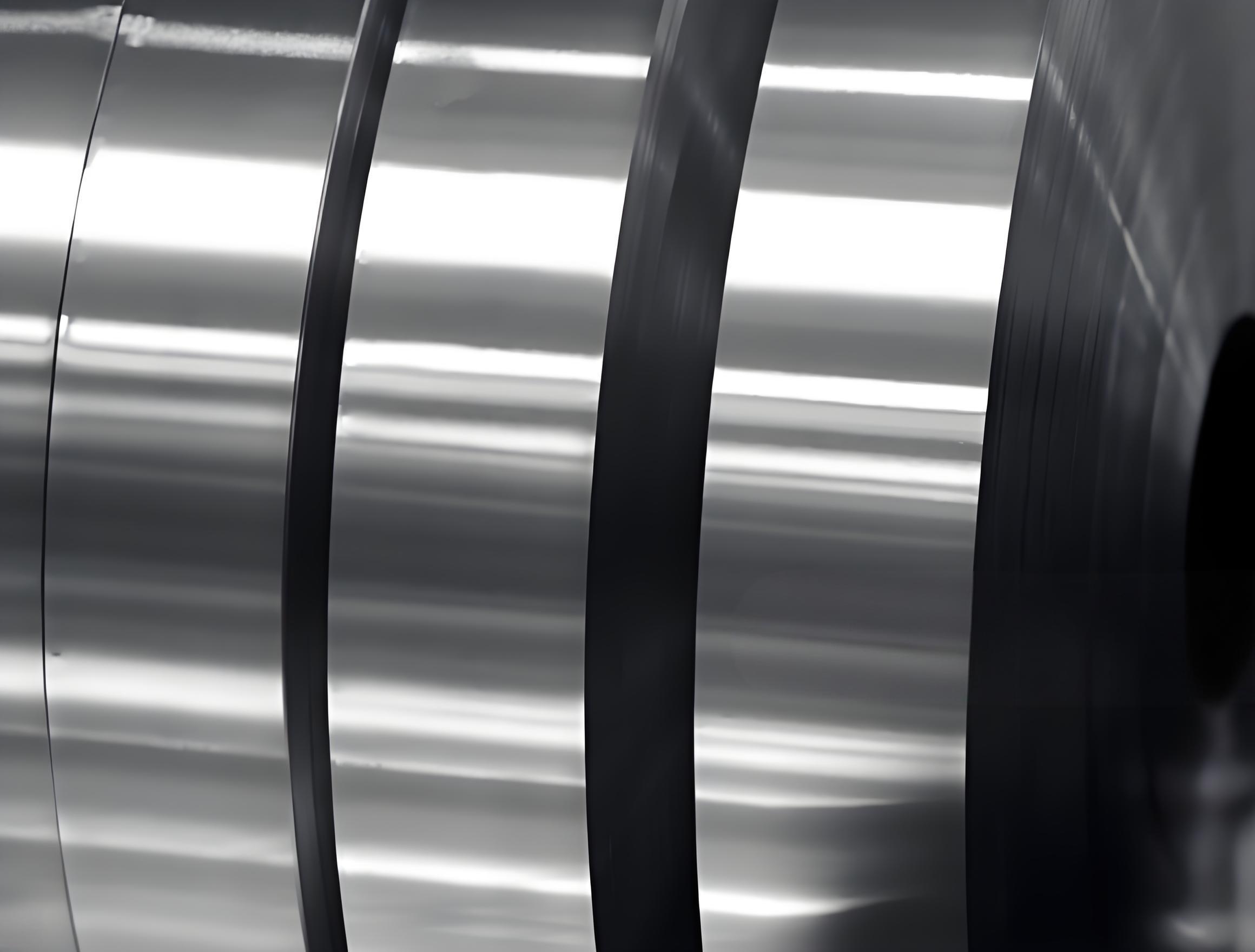

Slitting Process

Precision slitting with tension-controlled shears minimizes edge damage and maintains flatness within 0.05mm/m. Automated edge inspection ensures no micro-cracks, critical for reducing eddy current losses. Our process achieves 99.8% edge integrity versus 95% industry average, preventing laminations from warping during transformer core assembly.

Annealing

Continuous annealing in nitrogen-hydrogen atmosphere at 800–850°C optimizes grain structure and stress relief. This controlled environment achieves 98% uniformity in magnetic properties across coils, reducing core losses by 5% versus conventional annealing. Thermal profiling ensures zero residual stress, directly improving transformer efficiency.

Insulation Coating

Electrostatic application of C5-grade inorganic coating with 1.5±0.2μm thickness control. Coating passes 2.5kV dielectric strength tests (IEC 60404-8-4) and exhibits 100% adhesion per ASTM D3359. This prevents inter-lamination shorts during high-voltage operation, outperforming market-standard organic coatings prone to degradation.

Precision Cutting

Laser-guided cutting achieves ±0.05mm dimensional tolerance with burr-free edges. Real-time optical inspection guarantees lamination accuracy for efficient core stacking. Our process reduces scrap rates to <0.3% versus 1.5% industry average, ensuring optimal core window utilization in transformers.

Quality Control Comparison

| Parameter | Xinzhaohe Standard | Generic Market Standard | Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm | 50% tighter control for efficient stacking |

| Tensile Strength Range | 300–340 MPa | 280–360 MPa | Consistent winding performance |

| Coating Adhesion | 100% pass (ASTM D3359) | 85–95% pass | Eliminates short-circuit risks |

| Core Loss (1.5T/50Hz) | ≤1.15 W/kg | ≤1.25 W/kg | 8% lower loss than industry average |

All batches undergo 100% inspection per IEC 60404-2 and ASTM A341. Our integrated QC system ensures every coil meets or exceeds transformer manufacturers’ operational demands while delivering superior cost efficiency.

Packaging & Global Logistics

Export Packaging & Logistics

Robust Packaging Standards

Luoyang Xinzhaohe employs ISO-compliant packaging protocols engineered to prevent corrosion, physical damage, and moisture ingress during global transit. All electrical steel coils are secured using:

ISPM-15-treated wooden pallets (1100×1100mm, 15mm thickness, load capacity 2,000kg)

Triple-layer VCI anti-corrosion film (0.15mm thickness, 98% moisture barrier)

Galvanized steel strapping (19mm width, 500kg tensile strength) with reinforced corner protectors

| Component | Specification | Standard |

|---|---|---|

| Wooden Pallets | ISPM-15 treated, 1100×1100mm | ISO 4611-1 |

| Moisture-Proof Film | VCI + PE laminate, 0.15mm | ASTM D4169 |

| Steel Strapping | 19mm width, 500kg tensile strength | ISO 14606 |

Sea Freight Optimization

Our end-to-end logistics system ensures minimal transit time and maximum product integrity. All shipments undergo pre-departure humidity monitoring (≤60% RH) and comply with international fumigation standards. Container loading follows ISO 1496-1 protocols with shock sensors and climate control for sensitive routes.

| Destination | Container Type | Transit Time | Special Handling |

|---|---|---|---|

| Europe | 40ft HC | 28–35 days | VCI film + dehumidifiers |

| North America | 40ft | 30–40 days | Corner protectors + shock sensors |

| Southeast Asia | 20ft | 14–20 days | Standard moisture control |

As a China-based manufacturer with 20+ years of export experience, Luoyang Xinzhaohe eliminates middleman markups while maintaining strict quality control. Our packaging exceeds IEC 60404-6 standards for electrical steel, delivering 100% product integrity across 50+ countries. Partner with us for voestalpine-grade silicon steel at 15–20% lower landed costs—proven reliability without compromise.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Voestalpine Electrical Steel Replacement?

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of specialized expertise in electrical steel manufacturing to deliver a cost-effective, high-performance alternative to premium global brands like voestalpine. Our factory-direct model ensures rigorous quality control, competitive pricing, and rapid delivery for critical transformer and motor applications. As a ISO-certified manufacturer, we consistently meet international standards while optimizing total lifecycle costs for engineering-critical projects.

Proven Technical Expertise & Experience

20+ years of precision electrical steel production for global transformer and motor OEMs, with deep knowledge of core loss (P1.5/50), permeability, and mechanical properties.

Expertise in grain-oriented (GO) and non-grain-oriented (NGO) silicon steel grades, including 50H270, 35H230, and custom formulations tailored to specific application requirements.

Full compliance with IEC 60404-3 (core loss testing) and ASTM A677 (magnetic properties), ensuring predictable performance in high-efficiency transformers.

Factory-Direct Cost Advantages

15-20% lower pricing than global competitors by eliminating distributor markups and optimizing vertical integration.

15-25 day lead times for standard orders (30% faster than industry averages) due to streamlined production and local raw material sourcing.

Flexible order quantities from prototype batches to 10,000+ ton volumes without minimum constraints.

Certified Quality & Traceability

ISO 9001:2015 certified production processes with full material traceability from raw materials to finished coils.

In-house metallurgical lab for real-time testing of thickness tolerance (±0.01mm), surface quality, and magnetic properties.

Third-party certifications (SGS, BV) available for critical applications requiring independent validation.

| Metric | Luoyang Xinzhaohe | Global Premium Brands |

|---|---|---|

| Cost Efficiency | 15-20% lower pricing | Premium pricing structure |

| Lead Time | 15-25 days | 30-45 days |

| Quality Consistency | ISO 9001 certified, in-house QC | High but variable lead times |

| Customization | Tailored grade adjustments | Limited flexibility |

As a trusted supplier to industries worldwide, Luoyang Xinzhaohe delivers exceptional value without compromising on technical performance. Contact Cathy at cathy@transformerstrip.com today for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing voestalpine electrical steel replacement from Luoyang Xinzhaohe.