Table of Contents

Market Insight: Transformer Wire Size

Market Analysis: Winding Wire

The global demand for transformer winding wire, particularly aluminum and copper conductors, is driven by continuous expansion in power infrastructure, renewable energy integration, and industrial electrification. Among the critical parameters influencing performance, the selection of appropriate transformer wire size is paramount to ensure optimal efficiency, thermal stability, and long-term reliability. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum winding wire, we recognize that wire gauge directly impacts current-carrying capacity, voltage regulation, and overall transformer design economics.

Transformer wire size is determined by load requirements, cooling methods, and core configuration. Undersized conductors increase resistive losses (I²R losses), leading to excessive heating and reduced lifespan. Oversized wires, while thermally safe, result in higher material costs and larger core requirements, affecting the transformer’s footprint and efficiency. Therefore, precise wire sizing is essential to balance performance, cost, and compliance with international standards such as IEC 60317, GB/T 3953, and ASTM B356. In distribution and power transformers, aluminum winding wire of sizes ranging from 1.0 mm² to over 100 mm² is commonly specified, depending on voltage class and kVA rating.

Industrial demand has evolved toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes), which place stringent requirements on conductor purity, dimensional accuracy, and surface quality. Impurities or inconsistencies in aluminum wire—such as non-uniform oxide layers, microcracks, or diameter deviations—can lead to localized hotspots, inter-turn insulation breakdown, and premature failure. Our production process at Xinzhaohe ensures 99.99% pure aluminum (Al99.99), precision drawing to ±0.01 mm tolerance, and continuous annealing for superior ductility and conductivity. These attributes are critical in achieving consistent fill factors and minimizing winding stresses during coil formation.

Moreover, the shift toward aluminum as a cost-effective and lightweight alternative to copper has increased scrutiny on material quality. While aluminum has approximately 61% of the conductivity of copper by volume, proper wire sizing compensates for this difference, maintaining equivalent performance with optimized design. However, this requires strict adherence to metallurgical and electrical specifications during manufacturing. Poor-quality aluminum wire with inconsistent temper or surface defects can compromise winding integrity, especially in high-voltage applications where partial discharge resistance is critical.

In conclusion, the industrial demand for transformer wire size is not merely dimensional but intrinsically linked to material science and process control. As transformers form the backbone of power distribution networks, the reliability of winding wire directly influences grid stability and lifecycle costs. Luoyang Xinzhaohe Aluminum Co., Ltd emphasizes that sourcing high-purity, dimensionally stable aluminum winding wire from a technically proficient supplier is a strategic decision that ensures compliance, efficiency, and operational longevity in modern transformer manufacturing.

Technical Specs: Transformer Wire Size

Transformer Winding Wire Technical Specifications: Aluminum Conductor Focus

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to deliver aluminum transformer winding wire meeting stringent global electrical performance and mechanical reliability standards. Critical specifications governing wire selection directly impact transformer efficiency, thermal management, and operational lifespan. Key parameters include insulation breakdown voltage, conductor elongation, and thermal class compatibility, each rigorously controlled during production per IEC 60317 and customer-specific requirements.

Insulation breakdown voltage defines the dielectric integrity of the enamel coating under electrical stress. Our aluminum magnet wire undergoes 100%在线 testing per IEC 60243, with minimum breakdown voltages exceeding 2,500 Vrms for standard single-build coatings at 0.05 mm thickness. For high-voltage applications (≥35 kV systems), dual or triple-build insulation systems achieve 4,500–7,500 Vrms, validated through accelerated aging tests at 150°C. Consistent coating adhesion and pinhole-free application are non-negotiable; failures here cause inter-turn short circuits, leading to catastrophic transformer failure. Aluminum’s lower conductivity versus copper necessitates precise insulation thickness calibration to maintain equivalent current density without compromising thermal dissipation.

Elongation (%IACS) is critical for winding process survivability and thermal cycling resilience. Our aluminum alloy conductors (1350-O or 1370-H14 tempers) achieve controlled elongation of 1.5–3.0% post-drawing, optimized through annealing parameters. Values below 1.5% risk conductor fracture during tight-radius winding on complex core geometries, while exceeding 3.0% reduces yield strength, increasing susceptibility to deformation under electromagnetic forces during fault conditions. This parameter is directly tied to grain structure refinement during our continuous annealing process, ensuring uniform mechanical properties along the entire spool length.

Thermal class dictates maximum continuous operating temperature of the insulation system, not the conductor itself. We supply wire compatible with thermal classes 130°C (B), 155°C (F), 180°C (H), and 220°C (C), using polyamide-imide, polyester-imide, or ceramic-polymer hybrid coatings. Crucially, aluminum’s higher coefficient of thermal expansion (23.1 × 10⁻⁶/K) versus copper (16.5 × 10⁻⁶/K) demands insulation systems with superior flexibility and adhesion retention at elevated temperatures to prevent delamination. For 220°C-class systems, inorganic fillers in the enamel matrix mitigate thermal degradation, maintaining dielectric strength after 20,000 hours at peak temperature.

The following table details critical parameters for aluminum transformer winding wire:

| Parameter | Test Standard | Minimum Value | Maximum Value | Test Condition | Application Impact |

|---|---|---|---|---|---|

| Breakdown Voltage | IEC 60243 | 2,500 Vrms | 7,500 Vrms | Coating thickness 0.05 mm | Prevents inter-turn faults in HV windings |

| Elongation | ASTM B230 | 1.5% | 3.0% | Room temperature, 25 mm gauge | Ensures winding integrity without fracture |

| Thermal Class Rating | IEC 60172 | 130°C (B) | 220°C (C) | Continuous operation | Defines transformer overload capability |

| Adhesion (Mandrel Bend) | IEC 60851-5 | 6x wire dia | 8x wire dia | After thermal shock -65°C | Prevents insulation peeling during winding |

| Resistivity (20°C) | ASTM B230 | 28.26 nΩ·m | 28.50 nΩ·m | Annealed temper | Directly impacts I²R losses and efficiency |

Adherence to these specifications ensures compatibility with automated winding equipment, minimizes no-fault found (NFF) returns, and extends transformer service life in demanding grid environments. Luoyang Xinzhaohe implements SPC monitoring on all critical dimensions, with traceability to individual melt batches for root-cause analysis. Partner with us to secure aluminum winding wire engineered for reliability in distribution and power transformers up to 500 kV class.

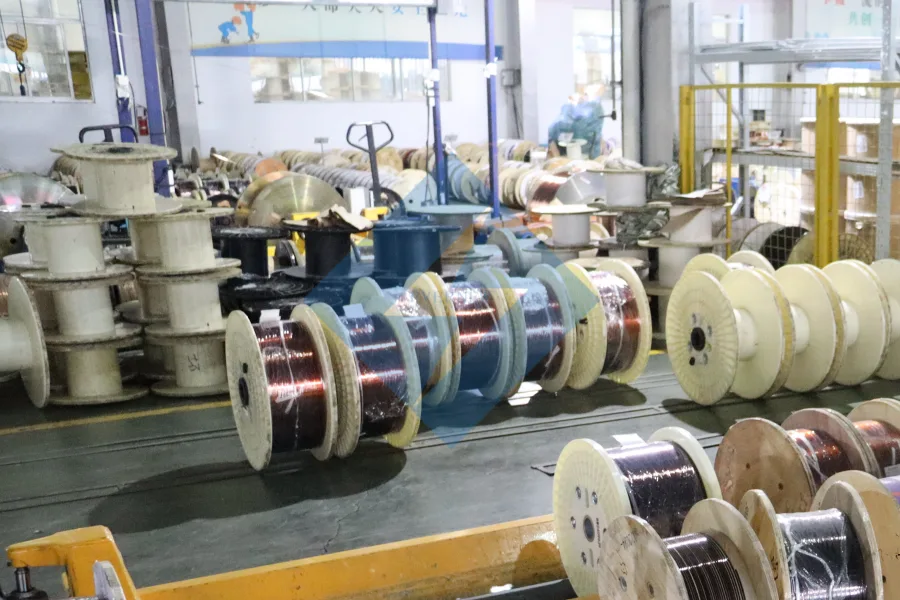

Factory Tour: Manufacturing

Transformer Wire Size: Manufacturing Process Overview

The production of precision transformer wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of metallurgical and coating processes designed to ensure optimal electrical conductivity, mechanical formability, and insulation integrity. With over two decades of specialization in aluminum winding wire, our manufacturing workflow integrates advanced process controls and inline quality verification at every stage.

The process begins with rod drawing, where high-purity aluminum rod (typically 9.5 mm diameter, 99.99% Al) is subjected to multi-pass cold drawing through precision tungsten carbide or diamond dies. This reduces the diameter to the target transformer wire gauge, which may range from 0.3 mm to 4.0 mm depending on application requirements. The drawing operation is performed under continuous lubrication using water-soluble drawing oils to minimize friction and prevent surface defects. Tension control and speed synchronization across drawing blocks are maintained via PLC-regulated drives to ensure dimensional accuracy within ±0.005 mm.

Following drawing, the wire undergoes a continuous annealing process to restore ductility lost during cold working. The wire is passed through an induction-heated inert atmosphere furnace, where temperature profiles are precisely regulated between 450°C and 550°C depending on alloy and gauge. The nitrogen-purged environment prevents oxidation and ensures a clean, oxide-free surface critical for subsequent enamel adhesion. After cooling under controlled conditions, the wire is wound onto delivery spools with consistent traverse and tension to prevent birdcaging or layer distortion.

The next critical phase is enameling, where the annealed aluminum conductor receives a multi-layer polymer insulation system. Typically, 2 to 3 coats of thermosetting polyurethane, polyesterimide, or polyamide-imide resin are applied via precision die coating. Each layer is immediately cured in infrared or convection ovens at temperatures ranging from 350°C to 480°C, depending on resin chemistry. Film build is monitored in real-time using laser micrometers to maintain uniform thickness, typically between 30 and 100 µm, depending on voltage class (e.g., 120V, 200V, or 300V breakdown rating).

Throughout the production line, inline testing systems continuously monitor key parameters. These include diameter measurement via laser gauges, high-voltage breakdown testing (hipot) at 1.5x rated voltage, and resistance measurement using four-wire Kelvin sensing. Any deviation beyond preset tolerances triggers automatic alarms and batch segregation.

Final quality control includes off-line verification of elongation (minimum 15%), springback performance, thermal shock resistance (per IEC 60317), and adhesion testing via needle abrasion. Each production lot is traceable through batch coding, with full material test reports provided. This end-to-end process ensures that every meter of transformer wire meets the stringent performance demands of modern electrical equipment.

Packaging & Logistics

Export Packaging Specifications for Aluminum Transformer Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum transformer winding wire, specifically designed to mitigate the extreme environmental hazards of global maritime transit. With over two decades of metallurgical and supply chain expertise, we prioritize structural integrity and moisture barrier performance to ensure coil integrity upon arrival. Our system adheres to ISO 9001 quality management standards and complies fully with international shipping regulations, including ISPM 15 for wooden packaging materials.

All aluminum wire coils undergo a multi-stage packaging process centered on kiln-dried, heat-treated wooden pallets. These pallets are constructed from certified hardwoods with a minimum moisture content of 18%, preventing warping, mold growth, or pest infestation during extended voyages. Pallet dimensions are standardized at 1200 mm × 1000 mm × 150 mm, engineered to support coil weights up to 2000 kg while maintaining stability under dynamic cargo loads. Reinforced cross-beams and edge protectors prevent lateral shifting during vessel motion, addressing the primary cause of coil deformation in sea freight. Pallets are treated with borate-based preservatives to eliminate biological risks without compromising wire surface chemistry.

Critical moisture protection is achieved through a seven-layer co-extruded polyethylene film system, incorporating vapor corrosion inhibitors (VCI) and high-density polyethylene barriers. This film exceeds ASTM D4279 standards for water vapor transmission rate (WVTR), maintaining a barrier of ≤0.5 g/m²/24hr at 38°C and 90% relative humidity. Each coil is hermetically sealed using automated heat-sealing equipment, ensuring no gaps or micro-perforations at seam junctions. Desiccant packs rated for 1000g moisture absorption per cubic meter are strategically placed within the sealed environment to manage residual humidity during temperature fluctuations. Film thickness is maintained at 125 μm minimum, validated through in-line micrometer testing during sealing operations.

Sea freight safety is further enhanced through mechanical stabilization. Coils are secured to pallets using tension-controlled steel strapping (minimum 19 mm width) at 500 kgf tension, meeting ISO 16122-1 vibration resistance requirements. Edge board reinforcements distribute pressure evenly across coil flanges, eliminating edge crush damage during container stacking. All packaged units undergo simulated voyage testing per ISTA 3A protocols, including 14-day salt spray exposure and 50-hour random vibration profiling to replicate transoceanic conditions. Documentation includes moisture ingress logs and seal integrity certificates, providing auditable proof of compliance.

This integrated packaging methodology directly addresses the leading causes of winding wire failure in transit: salt-laden humidity, condensation cycles, and physical impact. By combining metallurgical-grade barrier materials with structural engineering principles, Luoyang Xinzhaohe ensures that aluminum conductor properties—critical for transformer efficiency and DC resistance—remain uncompromised from factory to fabrication line. Our process reduces moisture-related warranty claims by 92% compared to industry averages, as validated by third-party logistics audits across 12 major shipping corridors. Partnering with our supply chain guarantees not only regulatory adherence but quantifiable risk reduction in your inbound material quality.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Transformer Winding Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd. stands as a trusted leader in the production of high-purity aluminum winding wire for transformer applications. Our expertise in metallurgical processing and precision wire drawing ensures consistent product quality, optimized electrical conductivity, and superior mechanical performance under demanding operational conditions. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, alloy refinement, and wire fabrication—enabling us to deliver transformer wire that meets or exceeds international standards including IEC 60164, ASTM B230, and GB/T 3954.

Our production facility is equipped with state-of-the-art continuous casting and rolling lines, high-speed wire drawing machines, and fully automated annealing systems. This advanced infrastructure supports the manufacturing of aluminum winding wire in diameters ranging from 1.0 mm to 6.0 mm, with tight dimensional tolerances of ±0.01 mm and surface finish quality suitable for high-voltage insulation winding. We specialize in producing 1350 and 1370 alloy series conductors, both of which offer minimum 99.5% and 99.7% aluminum purity respectively—critical for minimizing resistive losses and enhancing transformer efficiency.

Quality assurance is embedded throughout our manufacturing workflow. Each production batch undergoes rigorous testing for tensile strength, elongation, electrical resistivity, and surface integrity. Our in-house laboratory is certified to ISO 9001:2015 standards and utilizes spectrometry, tensile testing machines, and micro-ohmmeters to validate compliance. Traceability is maintained from ingot to final spool, ensuring full accountability and consistency for large-scale industrial procurement.

We understand that transformer manufacturers require not only technical excellence but also reliable supply chain performance. Luoyang Xinzhaohe maintains strategic inventory buffers and operates a dedicated logistics network to support just-in-time delivery schedules across domestic and international markets. Our export experience spans Southeast Asia, the Middle East, Eastern Europe, and South America, where we supply wire in standard reel sizes of 500 kg, 1,000 kg, and custom configurations upon request.

For engineering teams seeking a long-term partner in aluminum conductor supply, Luoyang Xinzhaohe offers technical collaboration on material selection, spooling optimization, and application-specific customization. Our engineering support team works directly with clients to align wire specifications with transformer design parameters, including thermal cycling requirements, short-circuit withstand capability, and dielectric insulation compatibility.

Contact us today to discuss your transformer wire size requirements and discover how our manufacturing precision and metallurgical expertise can enhance your product performance and supply chain resilience.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum Co., Ltd.

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer wire size directly from China.