Table of Contents

Market Insight: Transformer Wire Insulation

Market Analysis: Winding Wire for Transformer Insulation Systems

Global demand for high-performance transformer winding wire, particularly aluminum alloy variants, is driven by sustained expansion in electrical infrastructure, renewable energy integration, and industrial electrification. Utilities and Original Equipment Manufacturers (OEMs) face escalating pressure to deploy transformers with extended operational lifespans exceeding 30 years under increasingly demanding grid conditions. This necessitates winding wire insulation systems capable of withstanding thermal, electrical, mechanical, and environmental stresses throughout the asset lifecycle. The shift towards compact, high-efficiency transformer designs further intensifies thermal loads on the winding assembly, placing critical reliance on the integrity of the wire insulation. Failure within this component propagates catastrophically, leading to dielectric breakdown, short circuits, and potentially destructive transformer failure, resulting in significant financial losses from equipment replacement, grid instability, and extended downtime. Consequently, the market prioritizes insulation materials and application processes that guarantee long-term reliability over initial cost minimization.

The technical rationale for stringent insulation quality centers on mitigating key failure mechanisms. Thermal aging is paramount; insulation must maintain dielectric strength and mechanical flexibility after prolonged exposure to operating temperatures, typically classified under IEC 60317 standards (e.g., Class 180, 200, 220). Inadequate thermal endurance accelerates polymer chain degradation, leading to embrittlement, cracking, and reduced voltage withstand capability. Simultaneously, partial discharges (PD) at insulation voids or defects erode material over time, creating conductive paths. High-quality enamel application ensures void-free, uniform coating thickness to suppress PD inception. Mechanical robustness during winding operations and thermal cycling is equally critical; the insulation must resist abrasion, pin-holing, and delamination when subjected to conductor movement and differential thermal expansion between aluminum and the insulation layer. Moisture resistance prevents hydrolysis and ionic contamination ingress, which degrade dielectric properties. Consistent insulation thickness and adhesion directly impact the transformer’s ability to pass rigorous factory acceptance tests (FAT), including impulse voltage and induced overvoltage tests, and ensure stable performance in service.

Quality parameters for transformer winding wire insulation are non-negotiable for reliable operation. The following table outlines critical performance indicators and their operational significance:

| Parameter | Standard Requirement | Operational Consequence of Failure |

|---|---|---|

| Thermal Class Rating | IEC 60317 (e.g., Class 200) | Premature thermal degradation, reduced MTBF |

| Dielectric Strength | > 30 kV/mm (min) | Internal short circuits, catastrophic fault |

| Partial Discharge Inception | > 1.5 x U0 (min) | Progressive insulation erosion, failure |

| Abrasion Resistance | IEC 60851-5 (Min. cycles) | Pin-holes during winding, localized faults |

| Thermal Shock Resistance | IEC 60851-6 (Pass/Fail) | Cracking during thermal cycling |

| Adhesion to Conductor | IEC 60851-3 (No delamination) | Delamination under stress, void formation |

Supply chain resilience for premium insulation materials hinges on rigorous supplier qualification, batch traceability, and adherence to certified manufacturing processes. Variability in enamel composition or application thickness introduces unacceptable risk into the transformer manufacturing process and final product reliability. Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise and stringent process controls to deliver aluminum winding wire with insulation systems engineered for the highest reliability demands, ensuring compatibility with modern transformer design requirements and minimizing total cost of ownership through extended service life and reduced failure rates. Quality is not an incremental cost but a fundamental investment in grid stability and asset integrity.

Technical Specs: Transformer Wire Insulation

Transformer wire insulation is a critical component in the performance and reliability of electrical transformers, particularly in high-stress industrial and power distribution environments. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wire solutions, we emphasize the integration of precise technical parameters to ensure insulation integrity under thermal, electrical, and mechanical loads. The insulation system must exhibit consistent dielectric strength, mechanical flexibility, and thermal endurance to prevent premature failure and support long operational life.

Insulation breakdown voltage is a primary indicator of dielectric performance, representing the maximum electric field the insulation can withstand before electrical puncture occurs. For transformer-grade winding wires, this value must exceed operational peak voltages with a significant safety margin. Our insulation systems are engineered to achieve breakdown voltages starting from 4,000 V for thin-film coatings and scale up to 12,000 V for heavy build or multi-layer insulation, depending on wire diameter and application requirements. Testing is conducted per IEC 60317 and ASTM D2307 standards using immersed electrode configurations to simulate real-world conditions.

Elongation at break is another vital mechanical property, reflecting the insulation’s ability to endure winding stresses during coil fabrication. Excessive brittleness can lead to micro-cracking, compromising dielectric performance. Our insulation formulations maintain elongation values between 50% and 120%, depending on thermal class and polymer chemistry. This ensures compatibility with tight winding radii and complex coil geometries without delamination or cracking, particularly during automated winding processes.

Thermal class defines the maximum continuous operating temperature the insulation can endure while maintaining electrical and mechanical integrity over a 20,000-hour service life. We offer insulation systems rated from Class B (130°C) up to Class H (180°C), with specialized formulations extending to 220°C for extreme environments. These ratings are achieved through the use of advanced polymer materials such as polyamide-imide (PAI), polyesterimide (PEI), and silicone-based coatings, applied via precision solvent or powder coating systems. Each thermal class undergoes rigorous thermal aging tests per IEC 60216 to validate life expectancy and thermal index.

The following table summarizes key technical parameters for our transformer wire insulation systems:

| Parameter | Test Standard | Class B (130°C) | Class F (155°C) | Class H (180°C) | High-Temp (220°C) |

|---|---|---|---|---|---|

| Breakdown Voltage (min) | IEC 60317, ASTM D2307 | 4,000 V | 6,000 V | 8,000 V | 12,000 V |

| Elongation at Break | IEC 60851-5 | ≥50% | ≥60% | ≥80% | ≥100% |

| Thermal Class | IEC 60085 | 130°C | 155°C | 180°C | 220°C |

| Thermal Index (RTI) | IEC 60216 | 130 | 155 | 180 | 220 |

| Dielectric Strength | ASTM D149 | ≥80 kV/mm | ≥90 kV/mm | ≥100 kV/mm | ≥110 kV/mm |

These specifications are validated through in-house and third-party testing to ensure compliance with global standards. Luoyang Xinzhaohe Aluminum Co., Ltd maintains strict process controls to deliver winding wire insulation with repeatable performance, supporting reliability in transformers used across energy, rail, and industrial sectors.

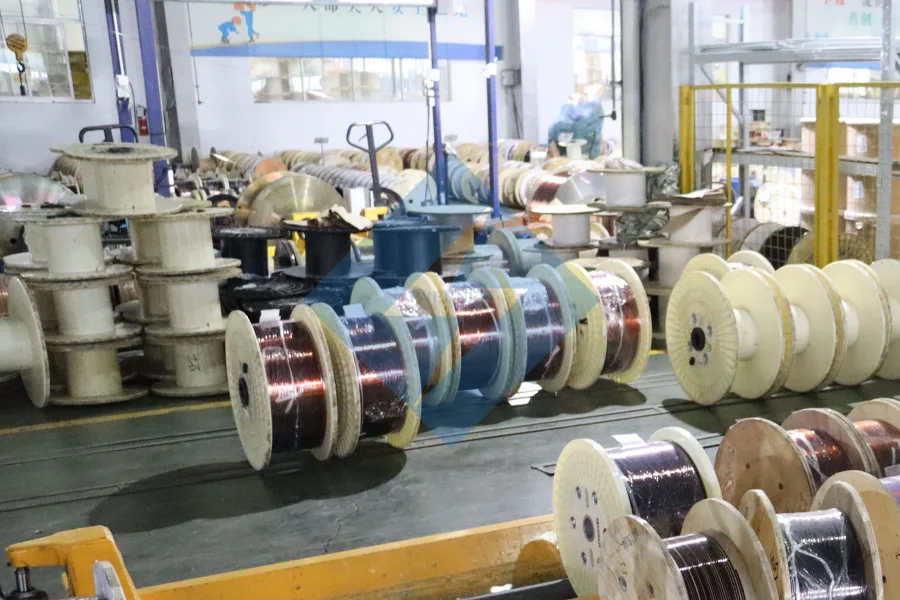

Factory Tour: Manufacturing

Transformer Wire Insulation Manufacturing Process: Aluminum Conductor Production

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise in aluminum conductor production for high-reliability transformer winding wire. Our stringent manufacturing sequence ensures the conductor substrate meets exacting electrical and mechanical specifications prior to insulation application, forming the foundation for superior enamel performance. The core process flow comprises four critical, interdependent stages: Rod Drawing, Annealing, Enameling, and Inline Testing, each incorporating defined quality control checkpoints.

Rod Drawing initiates the process using high-purity aluminum rod (typically ASTM B230 1350-H19 or equivalent). The rod undergoes precision cold drawing through a series of tungsten carbide or diamond dies within controlled lubrication systems. This reduces the diameter to the target wire gauge while inducing work hardening. Critical QC parameters monitored continuously include dimensional accuracy (diameter tolerance ±0.002 mm via laser micrometers), surface finish (absence of scratches, pits, or scoring), and mechanical property consistency (tensile strength and elongation per ASTM E8). Any deviation triggers immediate process adjustment or material rejection.

The drawn wire then enters the continuous annealing furnace. This stage is vital for restoring optimal ductility and electrical conductivity (minimum 61.0% IACS per ASTM E100) degraded during cold drawing. Our in-line annealing systems utilize precise temperature profiling (typically 350-550°C range) in an inert or reducing atmosphere to prevent oxidation, coupled with controlled cooling rates. Real-time monitoring of furnace temperature uniformity, atmosphere composition (oxygen levels < 50 ppm), and wire speed ensures consistent metallurgical recrystallization. Post-anneal QC verifies conductivity, grain structure (microscopic examination per ASTM E3/E112), and mechanical properties to guarantee the wire possesses the necessary flexibility for tight winding without fracture.

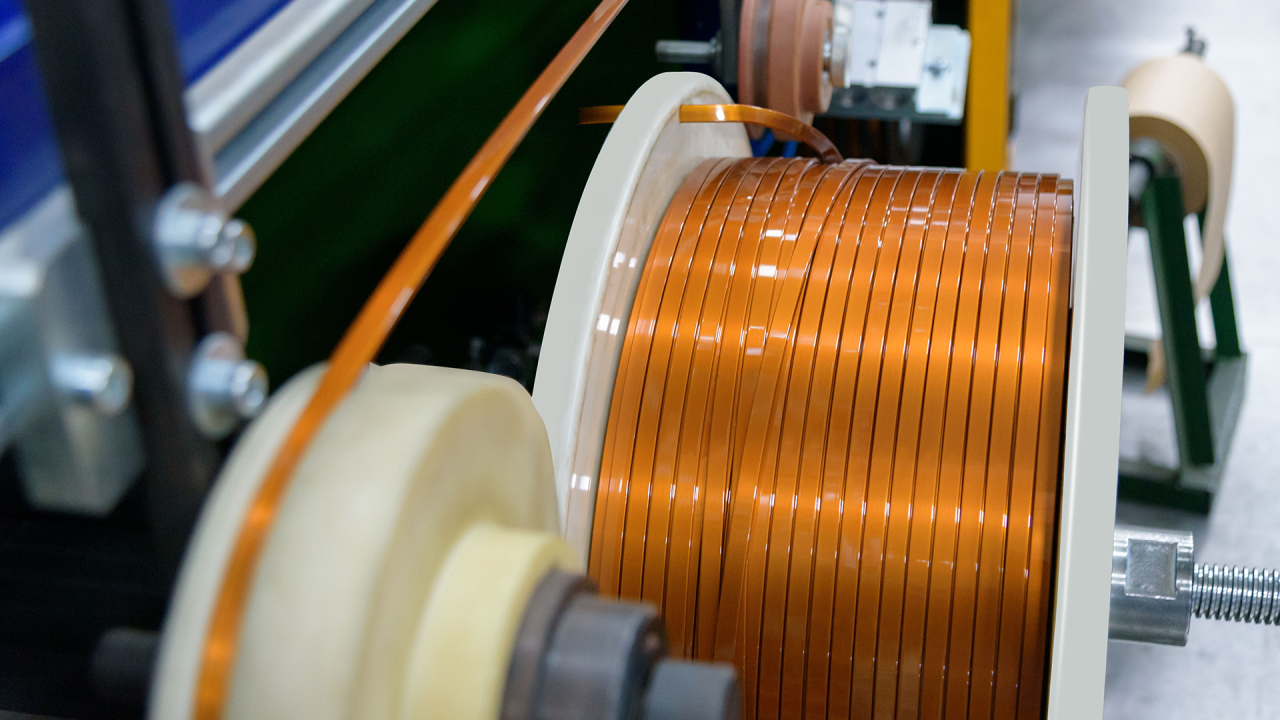

Enameling applies the critical insulating layer. The annealed aluminum conductor passes through a precision applicator (dip, roll, or spray) to coat it with formulated polymer resin (e.g., polyesterimide, polyamide-imide). The coated wire then traverses multi-zone curing ovens where controlled thermal profiles (typically 350-500°C) polymerize the resin into a continuous, adherent film. Key process controls include resin viscosity, coating thickness (micron-level precision via beta-gauge), oven temperature stability (±5°C), and line speed synchronization. QC at this stage is paramount, measuring insulation thickness uniformity (ASTM D2305), adhesion (mandrel wrap test per NEMA MW 1000), and visual defects (pinholes, bubbles, discoloration).

Final verification occurs during Inline Testing. Every meter of finished wire undergoes 100% non-destructive electrical testing. High-voltage spark testing (typically 1500-3000V AC) detects microscopic insulation flaws (pinholes) by monitoring leakage current. Breakdown voltage testing on sample segments validates dielectric strength (exceeding NEMA MW 1000 Class 200 requirements). Simultaneously, diameter and ovality are reconfirmed. Comprehensive data logging ensures full traceability from rod batch to finished spool. The table below summarizes critical inline QC checkpoints.

| Process Stage | Key QC Parameter | Measurement Standard | Critical Tolerance |

|---|---|---|---|

| Rod Drawing | Diameter | ASTM B263 | ±0.002 mm |

| Annealing | Electrical Conductivity | ASTM E100 | ≥61.0% IACS |

| Enameling | Insulation Thickness | ASTM D2305 | ±5% nominal |

| Inline Testing | Spark Test Voltage | NEMA MW 1000 | 0 defects/m |

This integrated, QC-driven manufacturing sequence, refined over 20+ years, ensures Luoyang Xinzhaohe delivers aluminum transformer winding wire with unparalleled insulation integrity, dimensional precision, and electrical performance, meeting the most demanding global transformer specifications. Traceability and real-time data capture underpin our commitment to zero-defect supply.

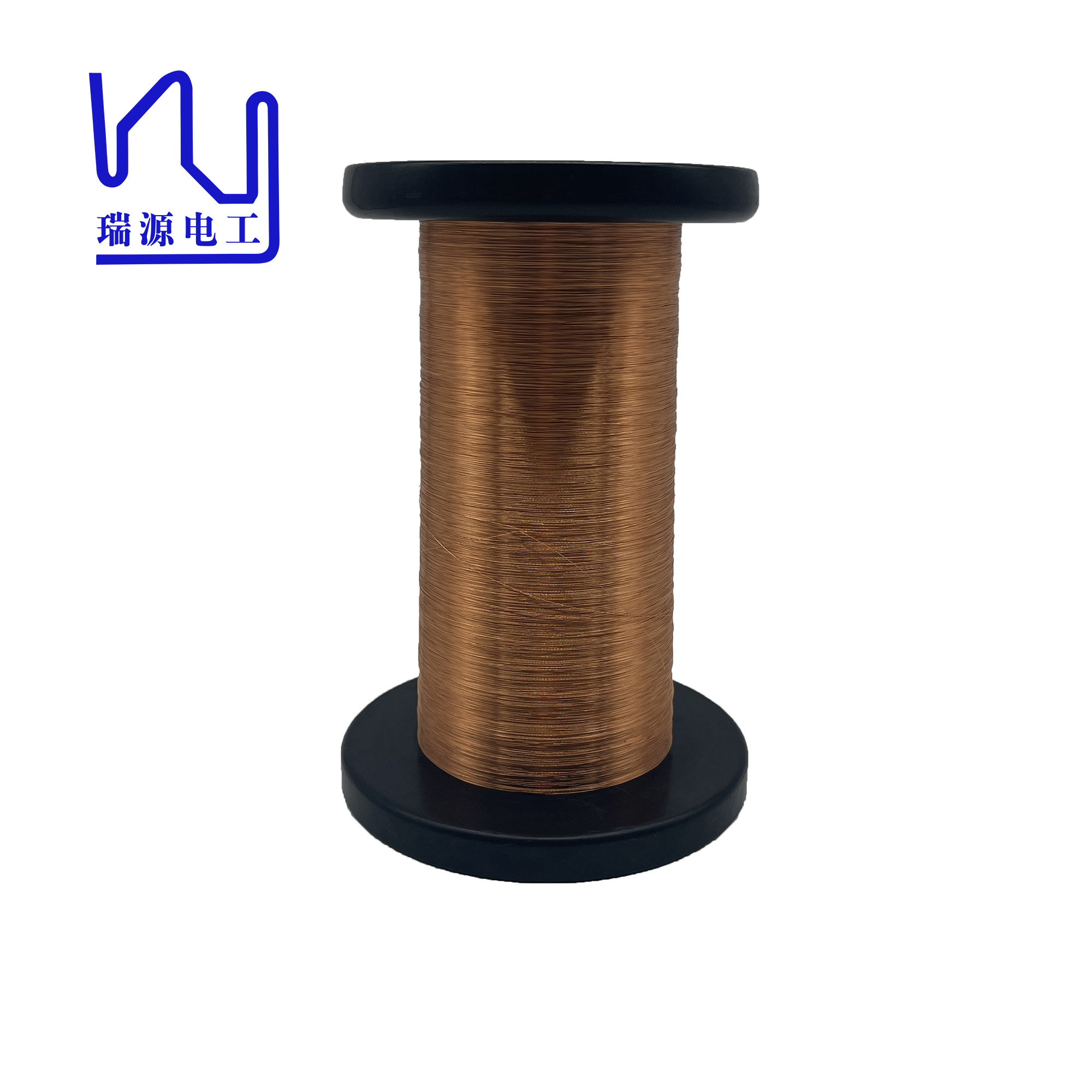

Packaging & Logistics

Export Packaging for Transformer Wire Insulation – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized expertise in the production of high-performance winding wires, we recognize that the integrity of transformer wire insulation must be preserved throughout the entire supply chain. Export packaging is not merely a logistical consideration—it is a critical technical component in safeguarding product quality, particularly during prolonged sea freight operations where environmental exposure is significant.

All export shipments of our transformer wire insulation products are systematically prepared using industrial-grade wooden pallets that meet international phytosanitary standards (ISPM 15). These pallets are constructed from durable, kiln-dried hardwoods to ensure structural rigidity and load stability. Each coil is securely fastened to the pallet using high-tensile steel strapping, minimizing movement during transit and reducing the risk of mechanical deformation or edge damage to the wound aluminum or copper conductors. The use of wooden pallets provides superior shock absorption compared to plastic or metal alternatives, a vital attribute when navigating the variable handling conditions common in global port operations.

To mitigate the primary environmental threat during maritime transport—moisture—we employ a multi-layer moisture-proof packaging system. Each wound coil is first wrapped in a vapor-corrosion inhibiting (VCI) film, which actively prevents oxidation of the conductor surface. This is followed by an outer wrapping of high-density polyethylene (HDPE) moisture barrier film, heat-sealed to form a fully enclosed, water-resistant envelope. The sealed package is then affixed to the pallet, ensuring that the insulation layers—whether enamel, paper, or polymer-based—remain free from humidity ingress that could compromise dielectric strength or promote partial discharge over time.

This dual-layer moisture protection strategy is validated through accelerated climatic chamber testing, simulating 45-day sea voyages under 95% relative humidity and temperature cycling between 5°C and 40°C. Results consistently confirm the integrity of the insulation system post-exposure, affirming the robustness of our packaging protocol.

Labeling is executed in compliance with IMDG Code and international freight regulations. Each pallet bears UV-resistant, tamper-evident labels containing batch traceability data, insulation class, conductor specifications, handling instructions, and destination details in both Chinese and English. This ensures seamless customs clearance and warehouse identification across global logistics hubs.

Our packaging methodology reflects a systems-based approach to export logistics, integrating material science, environmental engineering, and supply chain best practices. By prioritizing structural stability and moisture exclusion, Luoyang Xinzhaohe ensures that every shipment of transformer wire insulation arrives at its destination with the same electrical and mechanical properties as when it left our facility. This commitment underpins our reputation as a reliable partner in the global electrical manufacturing supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Engineered Solution for Transformer Wire Insulation

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver aluminum winding wire engineered explicitly for demanding transformer insulation applications. Our factory operates at the intersection of precise material science and industrial-scale production, ensuring every coil meets the stringent electrical, thermal, and mechanical requirements critical for transformer reliability. With 20+ years focused exclusively on aluminum conductor technology, we understand that insulation performance begins with the foundational metallurgical integrity of the wire itself.

Our technical strength originates in tightly controlled production processes. We utilize continuous annealing lines with inert atmosphere processing to achieve optimal electrical conductivity (IACS ≥ 61.0%) while maintaining precise mechanical properties essential for winding integrity. The aluminum rod feedstock undergoes rigorous chemical analysis to ensure impurity levels remain below 0.03% Fe+Si, minimizing hot shortness and enhancing drawability. This metallurgical purity directly translates to smoother surface finishes, reducing the risk of insulation puncture during high-speed winding operations. Our proprietary surface treatment protocols further optimize adhesion for common insulation systems, including polyesterimide and polyamide-imide varnishes, ensuring robust dielectric strength and thermal endurance per IEC 60317 standards.

Quality assurance is embedded at every process stage through a certified management system compliant with ISO 9001 and IATF 16949. In-house laboratories conduct real-time monitoring of critical parameters:

| Parameter | Control Method | Target Specification |

|---|---|---|

| Diameter Tolerance | Laser micrometry (100% inline) | ±0.002 mm |

| Elongation | ASTM E8 tensile testing | 25-35% |

| Resistivity | Four-point probe measurement | ≤ 0.028264 Ω·mm²/m (20°C) |

| Surface Cleanliness | Optical microscopy & particle count | ≤ 5 particles/cm² (>10µm) |

This granular control mitigates risks associated with insulation delamination, partial discharge, and premature transformer failure. Our supply chain resilience is equally critical; we maintain strategic raw material buffer stocks and operate dual production lines with redundant annealing capabilities, guaranteeing on-time delivery continuity even during market volatility. This operational discipline has enabled consistent service to Tier-1 transformer manufacturers across Asia and Europe for 15+ years.

Partnering with Luoyang Xinzhaohe means accessing a supplier whose technical foundation aligns with the physics of transformer insulation performance. We do not merely supply wire; we deliver a validated component within your insulation system, backed by metallurgical data and process transparency. Request our full technical datasheet and production capability portfolio to validate our fit for your specific insulation architecture. Contact Cathy Zhang directly at cathy@transformerstrip.com to initiate a technical review of your requirements. Let our engineering team demonstrate how precise aluminum conductor control underpins your transformer’s longevity.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer wire insulation directly from China.