Table of Contents

Market Insight: Transformer Wire Coating

Market Analysis: Winding Wire – Industrial Demand and Quality Imperatives for Transformer Wire Coating

The global demand for high-performance transformer winding wire continues to grow, driven by expanding electrical infrastructure, renewable energy integration, and industrial automation. At the core of reliable transformer operation lies the insulated winding wire, where the wire coating serves as a critical dielectric and mechanical barrier. Transformer wire coating is not merely a protective layer; it is an engineered component that directly influences thermal stability, electrical endurance, and long-term reliability of the transformer system. As the energy sector pushes toward higher efficiency and longer service life, the industrial demand for premium-grade coated aluminum and copper winding wires has intensified.

Transformers operate under continuous electrical stress, thermal cycling, and environmental exposure. The wire coating must maintain dielectric integrity under these conditions to prevent short circuits, partial discharges, and insulation breakdown. In power and distribution transformers, especially those used in utility grids and industrial plants, even minor insulation defects can lead to cascading failures, unplanned downtime, and significant financial loss. Therefore, manufacturers and end-users prioritize winding wires with coatings that exhibit high dielectric strength, excellent thermal class ratings (typically Class B, F, or H), and resistance to thermal aging.

The shift toward compact, high-efficiency transformers further amplifies the need for advanced wire coatings. Modern designs often operate at elevated temperatures and higher current densities, requiring insulation systems capable of withstanding temperatures up to 180°C or more. Polyurethane, polyester, polyester-imide, and polyamide-imide are among the most widely used coating materials, each offering distinct advantages in flexibility, thermal performance, and chemical resistance. For aluminum winding wire—our core product at Luoyang Xinzhaohe Aluminum Co., Ltd—achieving uniform, pinhole-free coating is particularly critical due to aluminum’s lower mechanical strength and higher thermal expansion compared to copper.

Quality in wire coating translates directly to transformer reliability. Poor adhesion, inconsistent thickness, or contamination during the coating process can result in delamination, cracking, or reduced breakdown voltage. These defects are often undetectable during initial testing but manifest as premature failures in the field. Reputable manufacturers implement rigorous process controls, including continuous在线 testing for dielectric strength, thermal shock resistance, and winding endurance. At Luoyang Xinzhaohe, with over two decades of specialization in aluminum winding wire production, we adhere to international standards such as IEC 60317 and GB/T 23639, ensuring that every coil meets the stringent demands of transformer OEMs.

In conclusion, the industrial market for transformer wire coating is defined by performance-driven specifications and zero tolerance for failure. As transformers become more integral to smart grids and sustainable energy systems, the role of high-quality insulated winding wire will only grow in strategic importance.

Technical Specs: Transformer Wire Coating

Technical Specifications for Transformer Wire Coating

Transformer winding wire insulation must deliver precise electrical, mechanical, and thermal performance to ensure reliability in demanding power applications. At Luoyang Xinzhaohe Aluminum Co., Ltd., our aluminum magnet wire coatings undergo rigorous process controls to meet or exceed international standards including IEC 60317, ASTM B354, and GB/T 23312. Critical parameters are non-negotiable for preventing insulation failure, maintaining coil integrity during winding, and sustaining operational life under thermal stress.

The following table details core specifications for our polyamide-imide (PAI), polyesterimide (PEI), and dual-coated aluminum transformer wires. All values represent minimum acceptance criteria after standard curing protocols and are validated per batch testing.

| Parameter | Thermal Class 130 (B) | Thermal Class 155 (F) | Thermal Class 180 (H) | Thermal Class 200 (R) | Thermal Class 220 (S) |

|---|---|---|---|---|---|

| Temperature Index (°C) | 130 | 155 | 180 | 200 | 220 |

| Min Breakdown Voltage (AC, 60Hz) | 4.5 kV | 6.0 kV | 8.0 kV | 10.0 kV | 12.0 kV |

| Min Elongation (%) | 25 | 22 | 18 | 15 | 12 |

| Applicable Standards | IEC 60317-13, GB/T 23312.3 | IEC 60317-15, GB/T 23312.5 | IEC 60317-17, GB/T 23312.7 | IEC 60317-44, GB/T 23312.15 | IEC 60317-45, GB/T 23312.16 |

Insulation Breakdown Voltage is measured per IEC 60243-1 using a 1 mm electrode gap at 500 V/s ramp rate. This parameter directly correlates with dielectric strength and resistance to partial discharge. Values scale with thermal class due to increased polymer cross-linking density required for higher-temperature stability. Our PAI topcoats achieve 12.0 kV minimum at Class 220 through proprietary resin formulation and multi-stage curing, eliminating pinholes even at ultra-thin build dimensions (0.05–0.15 mm).

Elongation reflects mechanical resilience during wire drawing, coil winding, and thermal cycling. Tested per ASTM D4683, minimum values decrease incrementally with rising thermal class as higher-performance resins inherently exhibit reduced flexibility. Xinzhaohe mitigates this trade-off via optimized aluminum substrate temper (O-1/2H) and interfacial adhesion promoters, ensuring 12% elongation at Class 220—critical for avoiding microcracks in toroidal or complex-shaped windings.

Thermal Class validation follows IEC 60216-2 aging protocols, where insulation life is extrapolated to 20,000 hours at the rated temperature. Our Class 220 (S) wires utilize thermally conductive ceramic modifiers in the basecoat to reduce hotspot degradation, achieving 220°C continuous operation while maintaining 90%+ retention of initial breakdown voltage after 1,000 hours at 240°C.

These parameters are interdependent; for instance, excessive elongation can compromise thermal stability, while ultra-high breakdown voltage may reduce flexibility. Xinzhaohe’s 20-year expertise in aluminum wire metallurgy and coating chemistry enables precise balancing of these properties. All specifications are traceable to batch-specific test reports, with production adhering to ISO 9001 and IATF 16949 frameworks. Sourcing decisions must prioritize certified conformance to these metrics—not nominal class labels—to prevent premature transformer failure in grid or industrial applications.

Factory Tour: Manufacturing

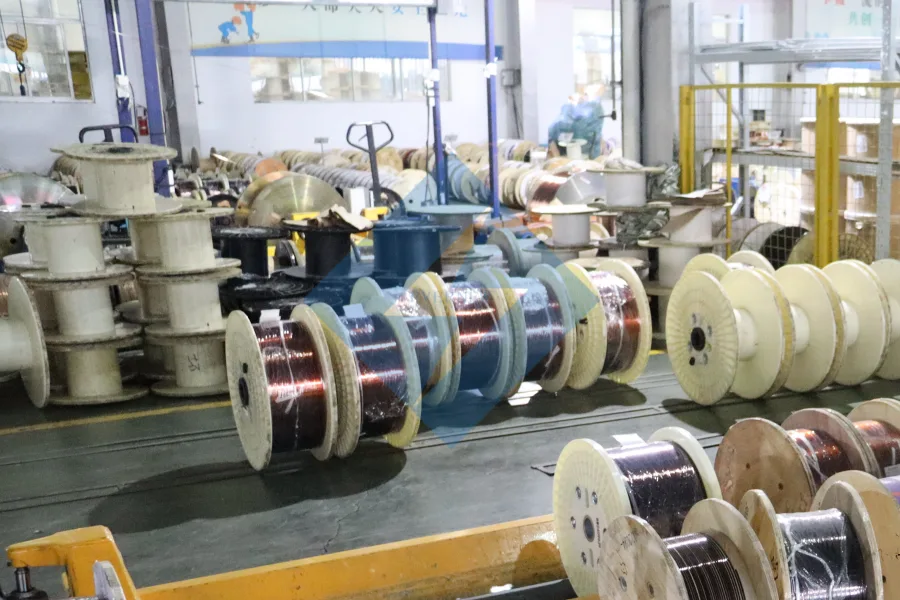

Transformer Wire Coating Manufacturing Process

The production of high-performance transformer wire coating at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure mechanical integrity, electrical reliability, and long-term service stability. With over two decades of specialized experience in winding wire technology, our process integrates precision engineering with rigorous quality control at every phase: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity aluminum rod conforming to GB/T 3954 standards, selected for optimal conductivity and ductility. The rod undergoes multi-pass cold drawing through precision tungsten carbide dies to achieve the target wire diameter, with tolerances maintained within ±0.005 mm. Drawing is performed under continuous lubrication to minimize surface defects and ensure dimensional consistency. Each drawing line is monitored in real time using laser micrometers to detect diameter deviations, ensuring compliance with IEC 60122-1 dimensional specifications.

Following drawing, the wire enters a continuous annealing system utilizing indirect resistance heating in a controlled nitrogen atmosphere. This softens the work-hardened structure, restoring optimal electrical conductivity (≥61.0% IACS) and elongation (≥25%). The annealing temperature profile is precisely regulated to prevent grain coarsening or oxidation, with exit cooling rates optimized to maintain metallurgical homogeneity. Oxygen content in the furnace zone is maintained below 10 ppm to prevent surface oxidation.

The annealed wire then proceeds to the enameling section, where a multi-layer polymer coating is applied via precision die coating. Typically, a dual-layer system is employed: a base layer of polyurethane (PU) for excellent thermal shock resistance and windability, followed by an overcoat of polyesterimide (PEI) or polyamide-imide (PAI) for enhanced thermal class (up to 200°C) and chemical resistance. Coating thickness is controlled within ±5 µm per layer using closed-loop viscosity and tension management systems. Each layer is cured in a series of vertical ovens with zoned temperature control up to 450°C, ensuring complete cross-linking and solvent removal.

Inline quality control is integral to the process. After each curing stage, the wire passes through high-voltage spark testing at 3 kV to detect pinholes or insulation defects. A final spark test at full rated voltage (up to 8 kV depending on diameter) is conducted post-coiling. Additional inline monitoring includes continuous diameter measurement, coating concentricity analysis via laser scanning, and tension control to prevent mechanical damage.

Final quality verification includes off-line testing per IEC 60317 standards: thermal endurance (20,000-hour extrapolation), thermal shock at 200°C, solderability at 380°C, and dielectric breakdown voltage. All batches are traceable through serialized lot coding, with material test reports provided upon shipment. This end-to-end control ensures that every spool of transformer wire coating meets the stringent demands of modern electrical equipment manufacturing.

Packaging & Logistics

Export Packaging Specifications for Transformer Wire Coating

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure transformer winding wire integrity during global maritime transit. With over two decades of metallurgical expertise, we recognize that improper packaging directly compromises coating adhesion, electrical performance, and core material stability. Our system prioritizes moisture exclusion and mechanical resilience, addressing the unique vulnerabilities of aluminum and copper-based winding wires exposed to prolonged sea freight conditions.

All export shipments utilize ISPM 15-compliant wooden pallets constructed from kiln-dried, heat-treated hardwood. Pallet dimensions adhere strictly to ISO container standards (1200 mm × 1000 mm or 1100 mm × 1100 mm) to maximize space utilization while preventing load shift. Each pallet incorporates reinforced stringers and deck boards rated for 1,500 kg static load capacity, with corner posts and edge protectors to absorb impact forces during handling. Critical to wire protection is the elimination of hygroscopic materials; pallet wood moisture content is maintained at 12–18% pre-assembly to prevent residual humidity migration into the coil core.

The primary moisture barrier consists of triple-layer coextruded polyethylene film with integrated vapor corrosion inhibitors (VCI). This film features a 125-micron thickness, providing superior puncture resistance against sharp wire edges during strapping. The inner layer releases non-toxic VCI molecules that form a molecular shield on metal surfaces, actively suppressing electrochemical corrosion at humidity levels up to 85% RH. Outer layers incorporate UV stabilizers and anti-fog agents to prevent condensation bridging during temperature fluctuations. Coils are hermetically sealed using industrial heat-sealing equipment, with seam integrity verified via vacuum decay testing at 0.5 bar differential pressure.

For ocean freight, we enforce multi-stage desiccant protocols. Calcium chloride desiccant units (minimum 1,200 g/m³ container volume) are strategically positioned within the palletized load to maintain internal relative humidity below 60% throughout voyages exceeding 30 days. Container pre-stowage inspection confirms floor moisture content ≤18% and absence of prior liquid cargo residues. All packages undergo salt spray testing per ASTM B117 for 96 hours to validate corrosion resistance under simulated marine environments.

Documentation accompanies each shipment with certified test reports for film permeability (WVTR ≤1.0 g/m²/day at 38°C, 90% RH) and desiccant saturation thresholds. This integrated approach—combining structural pallet integrity, active corrosion inhibition, and environmental monitoring—eliminates moisture-induced coating delamination and surface oxidation. Clients receive wire meeting IEC 60317 coating adhesion standards upon arrival, regardless of transit duration or route. Our packaging system is not merely protective but a metallurgical extension of wire quality assurance, reflecting our commitment to zero-defect delivery in transformer manufacturing supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Wire Coating Solutions

With over two decades of specialized experience in aluminum processing and winding wire manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for high-performance transformer wire coating solutions. Our vertically integrated production system, rooted in metallurgical precision and advanced surface treatment technologies, enables us to deliver consistent, high-purity aluminum winding wire tailored to the rigorous demands of power and distribution transformer applications.

Our manufacturing facility spans more than 50,000 square meters, housing fully automated production lines designed for high-efficiency coating application and tight dimensional control. We utilize continuous annealing and precision drawing systems to ensure uniform mechanical properties across all wire batches. The core of our technical capability lies in our proprietary polyurethane and polyester-imide coating formulations, which are applied using computer-regulated die systems to achieve coating thickness tolerances within ±2 µm. These coatings exhibit excellent dielectric strength, thermal stability up to Class 200 (200°C), and superior resistance to solvents and mechanical abrasion—critical parameters for long-term transformer reliability.

All raw materials are sourced from certified aluminum suppliers, with incoming billets undergoing spectrographic analysis to verify purity (minimum 99.7% Al). Our in-house R&D laboratory conducts ongoing quality validation, including adhesion testing per IEC 60317 standards, thermal shock evaluation, and breakdown voltage measurement. This ensures full compliance with international specifications and customer-specific technical requirements.

We operate under an ISO 9001-certified quality management system, with real-time process monitoring across all stages of wire drawing, coating, curing, and spooling. Our production capacity exceeds 15,000 metric tons annually, supported by automated warehousing and a dedicated logistics team enabling timely global delivery. Custom packaging options—including sealed moisture-proof reels and export-grade crates—ensure product integrity during transit.

As a manufacturer deeply embedded in the transformer supply chain, we prioritize technical collaboration with our clients. Whether supporting new product development, optimizing coating performance under extreme operating conditions, or scaling production for large-scale grid projects, our engineering team provides responsive, data-driven solutions.

Partnering with Luoyang Xinzhaohe means securing a reliable source of technically advanced, cost-effective aluminum winding wire with full traceability and consistent quality. Our long-standing relationships with transformer OEMs across Asia, Europe, and North America reflect our commitment to performance, innovation, and service excellence.

For technical inquiries or to initiate a sourcing partnership, contact us at cathy@transformerstrip.com. Our team is available to provide sample kits, material certifications, and engineering support to meet your project requirements.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer wire coating directly from China.