Table of Contents

Market Insight: Transformer Wire

Market Analysis: Transformer Wire Demand and Quality Imperatives

Transformer wire constitutes the electromagnetic core of power and distribution transformers, directly influencing energy conversion efficiency, thermal management, and operational lifespan. Global demand remains robust, driven by critical infrastructure imperatives. Accelerated grid modernization programs, particularly in emerging economies, necessitate vast quantities of distribution transformers to expand access and reliability. Concurrently, the integration of renewable energy sources like solar and wind farms requires specialized step-up transformers at generation sites and grid interconnection points, demanding high-performance winding wire capable of handling fluctuating loads and harmonic distortions. Industrial electrification trends, including the proliferation of electric vehicle charging networks and data center expansions, further strain existing infrastructure, spurring replacement cycles and new transformer installations. This sustained demand underscores transformer wire as a non-discretionary component within the electrical supply chain, with procurement strategies directly impacting project timelines and grid stability.

The operational environment of transformers imposes extreme stresses on winding wire. Continuous electrical current generates significant heat, while electromagnetic forces induce mechanical vibration during fault conditions. Substandard wire introduces critical failure vectors. Inadequate electrical conductivity, often resulting from impurities or improper alloy composition in aluminum conductors, necessitates larger conductor cross-sections to achieve target efficiency, increasing material costs and transformer size. More critically, conductivity variations create localized hotspots within the winding, accelerating insulation degradation and potentially triggering catastrophic thermal runaway. Mechanical properties are equally vital; insufficient tensile strength or elongation after annealing leads to wire breakage during the precise winding process or under operational stress, causing immediate production delays or latent field failures. Surface defects, such as scratches or oxide inclusions, compromise the integrity of the enamel or paper insulation system applied over the conductor, creating pathways for partial discharge and eventual insulation breakdown. Adherence to stringent international standards like IEC 60282 is non-negotiable, as deviations directly correlate with reduced transformer efficiency (increasing lifetime energy losses), shortened service life, and heightened risk of unplanned outages with significant financial and safety repercussions.

Aluminum transformer wire, a specialty focus for manufacturers with deep metallurgical expertise, offers compelling advantages in weight and cost for distribution applications. However, its successful deployment hinges on precise control over the alloy system, thermal treatment, and surface quality. Aluminum’s lower inherent conductivity compared to copper demands exacting process control to maximize conductivity within the alloy constraints. Achieving the optimal balance of ductility for winding and sufficient strength to resist deformation under short-circuit forces requires sophisticated annealing profiles. Surface cleanliness is paramount, as aluminum oxides form rapidly and can interfere with insulation adhesion. Procurement based solely on lowest initial cost ignores the total cost of ownership; a minor conductivity deficit or surface imperfection can compound into substantial energy waste over a transformer’s 30+ year lifespan or precipitate premature failure. Rigorous quality assurance protocols, including batch traceability, certified conductivity testing, and mechanical property verification, are essential investments safeguarding grid reliability and operational economics. The transformer wire specification is not merely a material purchase; it is a fundamental engineering decision impacting the core performance and longevity of critical power infrastructure.

Technical Specs: Transformer Wire

Transformer Winding Wire – Technical Specifications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance aluminum winding wire engineered for reliable operation in power and distribution transformers. With over two decades of metallurgical and manufacturing expertise, our transformer wire meets stringent international standards for electrical insulation integrity, mechanical ductility, and thermal endurance. The following technical specifications outline the critical performance parameters for our aluminum transformer winding wire, ensuring compatibility with demanding electrical applications.

The insulation system of our winding wire is designed to withstand high electrical stress, with a minimum insulation breakdown voltage of 6 kV AC at standard test conditions. This ensures dependable dielectric performance under normal operating voltages and transient overloads. The enamel insulation is applied using precision coating technology to maintain uniform thickness and eliminate weak spots, contributing to long-term reliability in high-voltage environments. Breakdown voltage consistency is verified through 100%在线 testing during production, guaranteeing compliance across all spools.

Mechanical elongation is a critical factor in winding processability and resistance to cracking during coil formation. Our aluminum transformer wire exhibits a minimum elongation of 25% as measured over a 200 mm gauge length in accordance with GB/T 4909.3 and IEC 60468 standards. This high ductility enables tight bending radii without fracturing the conductor or insulation, essential for complex winding geometries in modern transformer designs. The elongation performance is achieved through controlled annealing processes that optimize grain structure while maintaining tensile strength within the range of 80–110 MPa.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation can endure without significant degradation. Our product portfolio covers thermal classes from 130°C to 220°C, allowing selection based on transformer loading profiles and cooling methods. Each class is constructed with thermally stable polyamide-imide, polyesterimide, or dual-layer systems, providing excellent resistance to thermal aging, softening, and dielectric loss at elevated temperatures. All thermal class ratings are validated through accelerated aging tests per IEC 60172 and UL 1446.

The following table summarizes the key technical parameters:

| Parameter | Value / Range | Test Standard |

|---|---|---|

| Conductor Material | Aluminum (Al 99.7% min) | GB/T 3190, ASTM B233 |

| Insulation Breakdown Voltage | ≥ 6 kV AC (1 min, 50 Hz) | IEC 60317-0-1, GB/T 23312 |

| Elongation (min) | 25% | GB/T 4909.3, IEC 60468 |

| Tensile Strength | 80–110 MPa | GB/T 4909.3 |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60172, UL 1446 |

| Insulation Type | Polyesterimide, Polyamide-imide | IEC 60317 series |

| Diameter Tolerance | ±0.02 mm (standard) | GB/T 23312, IEC 60122-1 |

These specifications reflect our commitment to delivering aluminum winding wire that supports efficient, durable, and safe transformer operation across industrial, utility, and renewable energy sectors.

Factory Tour: Manufacturing

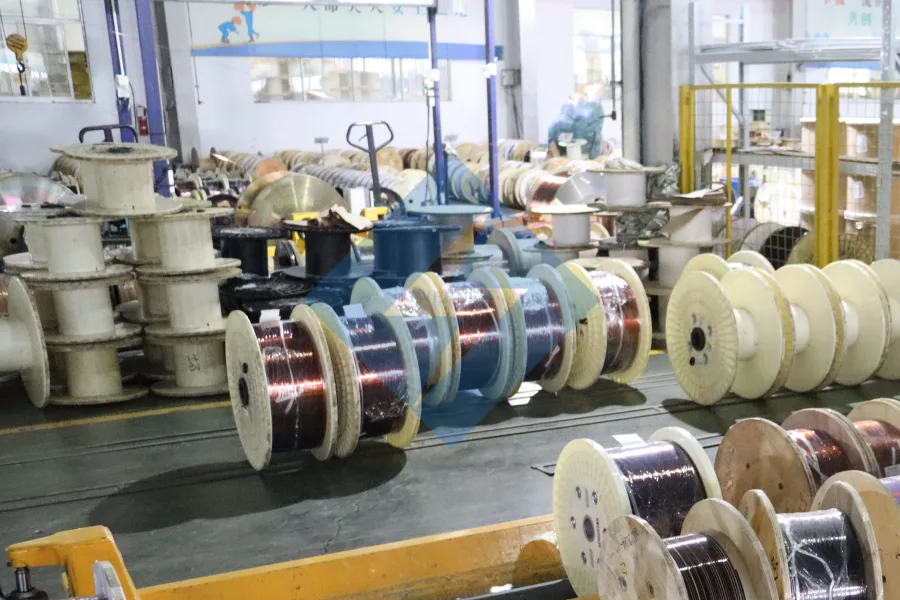

Transformer Wire Manufacturing Process: Precision Engineering for Critical Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver high-reliability aluminum transformer winding wire. Our production process integrates stringent material science protocols with inline quality control, ensuring compliance with IEC 60284 and ASTM B355 standards. The sequence begins with Rod Drawing, where high-purity aluminum rod (99.7% min. Al) undergoes continuous casting and homogenization. Rods are cleaned via acid-alkali degreasing to eliminate surface oxides prior to cold drawing. Multi-die reduction sequences achieve precise diameters (0.15–3.00 mm) with controlled reduction ratios (15–25% per pass), maintaining tensile strength at 80–120 MPa and elongation ≥3%. Surface roughness is held to Ra ≤0.8 μm through diamond-coated dies and tension-controlled capstans, preventing micro-cracks that compromise enamel adhesion.

Annealing follows immediately post-drawing in a continuous vertical furnace under inert nitrogen atmosphere (O₂ < 50 ppm). Temperature profiles are calibrated to 380–420°C with ±5°C precision, optimizing recrystallization while minimizing grain growth. This step restores ductility (elongation ≥30%) and achieves target conductivity of 59.0–61.0% IACS. In-process verification includes real-time conductivity monitoring via eddy current sensors and periodic metallurgical cross-sections to confirm uniform equiaxed grain structure (ASTM E3/E112).

Enameling applies thermosetting polymer insulation in a multi-layer coating system. Aluminum wire traverses precision applicators for solvent-based polyurethane or polyester-imide resins, with dry film thickness controlled to ±2 μm per layer. Curing occurs in segmented ovens (280–420°C) with oxygen-limited zones to prevent carbonization. Critical parameters—viscosity (20–50 cP), solids content (35–45%), and line speed (8–15 m/min)—are automated via PLC feedback loops. Adhesion is validated through 180° bend tests over mandrels per IEC 60851-5, with no cracking or peeling permitted.

Inline testing ensures zero-defect delivery at every production stage. Key checks include:

| Test Parameter | Standard Method | Tolerance | Frequency |

|---|---|---|---|

| Diameter | IEC 60122 | ±0.003 mm | Continuous |

| Elongation | ASTM E8 | ≥30% | Every 2 hours |

| Dielectric Strength | IEC 60851-3 | ≥3.5 kV AC (1 min) | Every 30 min |

| Spark Test | IEC 60851-5 | 0 defects/1000 m | Continuous |

| Conductivity | ASTM E1004 | 60.5–61.0% IACS | Every batch |

Final inspection includes thermal shock testing (-40°C to 155°C cycles) and solderability verification. All data logs are traceable to individual wire reels via QR codes, enabling full supply chain transparency. This integrated approach—combining metallurgical precision, atmospheric control, and real-time QC—delivers transformer wire with exceptional thermal class (180–220°C), mechanical resilience, and electrical integrity for mission-critical power applications.

Packaging & Logistics

Export Packaging for Aluminum Transformer Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum winding wire for power and distribution transformers, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity throughout international supply chains. Our export packaging system is engineered to meet the rigorous demands of global maritime transport, ensuring that aluminum transformer wire arrives at its destination in optimal condition, free from mechanical damage, environmental exposure, or moisture-related degradation.

All export shipments of aluminum winding wire are secured on robust, ISPM-15 compliant wooden pallets. These pallets are constructed from high-density, kiln-dried hardwood, designed to support the substantial weight of coiled conductors while maintaining structural stability during multi-modal handling. The use of nailed hardwood frames ensures torsional rigidity, minimizing coil deformation during lifting, stacking, and long-haul transit. Each coil is centered and mechanically fastened to the pallet base using steel strapping anchored at multiple points, preventing lateral shift or vibration-induced abrasion during ocean freight.

To address the primary environmental threat during sea transport—humidity—we implement a multi-layer moisture barrier system. Each wound coil is first wrapped in heat-sealed, metallized moisture-proof polyethylene film, providing a vapor transmission rate of less than 0.5 g/m²/24h under standard conditions. This primary wrap is then overlaid with a secondary layer of industrial-grade polypropylene scrim-reinforced film, enhancing puncture resistance and providing additional protection against condensation in tropical and high-humidity shipping zones. The entire palletized unit is then hermetically sealed using automated stretch hooding technology, creating a fully enclosed micro-environment that resists salt-laden air and temperature fluctuations common in containerized marine logistics.

Our packaging protocol conforms to IEC 60204-1 and ISO 11607 standards for industrial electrical component handling and preservation. Each shipment includes desiccant packs with moisture indicators placed within the sealed envelope, enabling end-users to verify environmental integrity upon receipt. Batch-specific documentation, including coil identification tags and handling instructions, is affixed externally on weather-resistant polypropylene labels to ensure traceability without compromising the sealed barrier.

This engineered packaging solution has been validated across major trade routes, including trans-Pacific, Asia-Europe, and South Atlantic corridors, consistently demonstrating zero incidence of moisture ingress or coil deformation under standard container shipping conditions. By integrating structural resilience with advanced moisture control, Luoyang Xinzhaohe ensures that our aluminum transformer winding wire maintains dimensional accuracy, surface cleanliness, and electrical performance specifications upon delivery—supporting seamless integration into downstream winding operations at transformer manufacturing facilities worldwide.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Transformer Wire Manufacturer

With over two decades of specialized metallurgical expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers transformer winding wire engineered for uncompromising performance in critical power applications. Our vertically integrated production ecosystem, spanning raw material refinement to finished conductor, ensures granular control over the aluminum’s electro-physical properties. We exclusively utilize 99.85%+ high-purity aluminum ingot, processed through proprietary degassing and filtration protocols to eliminate hydrogen content below 0.10 ml/100g Al and non-metallic inclusions to Class B per ASTM E2084 standards. This foundational purity directly translates to consistent bulk resistivity of ≤ 0.02804 Ω·mm²/m at 20°C and superior thermal stability under sustained load cycles.

Our 50,000-ton annual production capacity leverages continuous casting-rolling technology with inline ultrasonic thickness monitoring, achieving dimensional tolerances of ±0.005 mm for rectangular cross-sections. All wire undergoes rigorous homogenization annealing in oxygen-controlled furnaces, ensuring uniform tensile strength (60–75 MPa) and elongation (≥ 35%) across every coil. Quality assurance is non-negotiable: 100% of output undergoes eddy current testing for subsurface defects, coupled with batch-level verification of conductivity, bend fatigue resistance, and adhesion to insulation systems per IEC 60172 and GB/T 3953 protocols.

Supply chain resilience is engineered into our operational model. Dual sourcing of primary aluminum feedstock from certified smelters, combined with on-site remelting capabilities, mitigates raw material volatility. Our just-in-sequence production system supports lean inventory models for global OEMs, with standard lead times of 15–20 days for 20-foot container quantities. All facilities maintain ISO 9001:2015 and IATF 16949 certification, with traceability extending from final coil to original smelter lot via blockchain-enabled digital logs.

Production Capabilities Summary

| Parameter | Specification | Standard Compliance |

|——————–|———————————–|———————|

| Purity | ≥ 99.85% Al | GB/T 863 |

| Resistivity | ≤ 0.02804 Ω·mm²/m (20°C) | IEC 60228 |

| Dimensional Tolerance | ±0.005 mm (width/thickness) | GB/T 3955 |

| Tensile Strength | 60–75 MPa | ASTM B230 |

| Annual Capacity | 50,000 metric tons | — |

For transformer manufacturers demanding metallurgical precision and supply chain certainty, Luoyang Xinzhaohe provides the technical partnership to optimize core efficiency and reduce field failure rates. Our engineering team collaborates directly with client R&D divisions to tailor temper profiles and surface treatments for specific lamination stacking or vacuum pressure impregnation processes. Contact Cathy Zhang, Technical Sourcing Manager, at cathy@transformerstrip.com to initiate material qualification or request certified test reports for your next high-efficiency transformer program. We respond to all technical inquiries within 4 business hours with actionable data.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer wire directly from China.