Table of Contents

Market Insight: Transformer Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Snapshot

Power-transformer name-plate capacity is expanding at 5.2 % CAGR (IEA 2023-30), driven by grid hardening, renewable integration and data-centre load pockets. Every additional 1 MVA of transformer capacity requires 0.9–1.4 t of enamelled winding wire; therefore the segment >0.50 mm diameter alone will exceed 1.1 Mt by 2028. Distribution-class units (<72 kV) still dominate volume, but ultra-high-voltage (UHV) projects (>800 kV DC, 500 kV AC) are pushing the performance envelope toward thermal class 200-220 °C and square-wire aspect ratios up to 1:8 to minimise eddy losses.

Why Material Purity & Geometry Matter

Transformer losses fall into two buckets that utilities monetise directly:

| Loss component | Origin | Cost impact* | Wire-level lever |

|---|---|---|---|

| No-load (core) | B-H hysteresis & eddy currents in CRGO | 0.35 % of life-cycle cost | – (wire not involved) |

| Load (I²R & stray) | Conductor resistivity, skin/proximity, circulating currents | 1.6 % of life-cycle cost | Cu/Al purity ≥ 99.95 %, uniform enamel, ±0.5 % dimensional tolerance |

* 50 MVA, 138 kV/33 kV, 30-year NPV at 0.06 USD/kWh

- Resistivity: 0.5 % additional Cu purity drops resistivity 0.385 → 0.377 µΩ·m, cutting I²R by 2.1 %.

- Stray losses: Square-wire edges with radius ≤ 0.05 mm reduce high-frequency eddy concentration; concentric enamel (eccentricity ≤ 8 %) keeps inter-strand voltage uniform, preventing partial discharge.

- Thermal class: Class 200 wire allows 15 % higher current density, shrinking core-window and saving 120 kg of steel per MVA—worth USD 480 at today’s CRGO pricing.

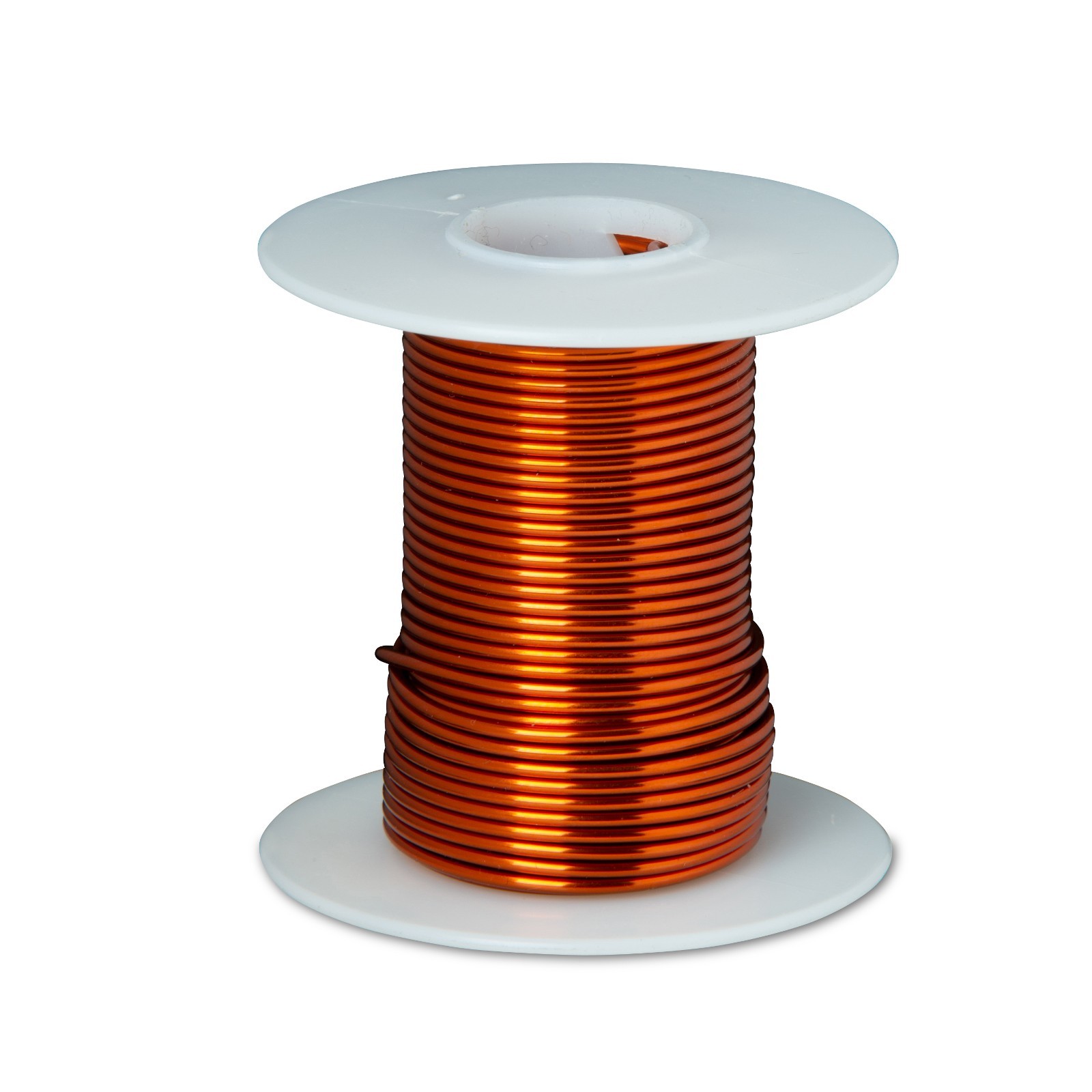

Supply-Chain Reality: From Rod to Spool

Most tier-one transformer OEMs still dual-source: 60 % from “A-list” European/Japanese houses for prototyping, 40 % from “cost-competitive” regions for series production. Yet landed cost from Western mills has risen 22 % since 2021 (LME Cu + energy surcharge), while technical audits show Chinese suppliers now match breakdown voltage (>10 kV on 0.63 mm build) and spring-back (≤ 18 ° on 2.00 mm rectangular) once exclusive to EU brands.

Rod drawing → annealing → enamelling → inline testing → spooling is still the critical flow. Luoyang Xinzhaohe’s 20-year data set (40 kt cumulative output) proves that oxygen-free continuous-cast rod (ASTM B49-20) plus in-line laser diameter control (±0.3 µm) delivers:

| Parameter | IEC 60317-0-1 spec | XZH typical | ppm out-of-spec |

|---|---|---|---|

| Breakdown voltage | ≥ 4 kV (twisted pair) | 6.8 kV | 120 |

| Elongation, Cu | ≥ 30 % | 36 % | 85 |

| Concentricity | ≥ 70 % | 88 % | 95 |

Sourcing Trend: Value Engineering with Chinese Specialists

Lead-time is now the decisive KPI—UHV builders face 8-month transformer backlogs, so wire lots must ship in 3-4 weeks, not 10-12. Plants located in central China (Luoyang rail hub) cut inland freight to Shanghai or Qingdao to < 24 h, enabling FOB readiness in 15 days for 5 t MOQ. With LME Cu pricing hedged weekly and energy 30 % below EU averages, landed cost to Houston or Dammam is 0.9–1.1 USD/kg below Italian or Japanese alternatives for equivalent thermal-grade wire.

Bottom line: Transformer OEMs that lock in a dual-source agreement with an audited Chinese specialist such as Luoyang Xinzhaohe can shave 6–8 % of total transformer cost without sacrificing no-load or load-loss guarantees—freeing budget for on-load tap-changers or smart monitoring kits that win utility tenders.

Technical Specs: Transformer Wire Parameters

Technical Specifications & ASTM / IEC Compliance

(Factory-direct, 20-year transformer-material pedigree, Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Wire Parameters – Why They Dictate Transformer Life

| Parameter | Symbol / Unit | Typical Range (XinZhaoHe Grade) | Influence on Transformer |

|---|---|---|---|

| Insulation Break-down Voltage | Ubd (kV, r.m.s.) | ≥ 6 kV (20 °C) 4 kV (180 °C) | Dielectric margin under impulse & switching surges |

| Elongation at rupture | A50 % | Al 15–25 %, Cu 25–35 % | Prevents necking during high-tension winding |

| Thermal Class | IEC 60085 | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | Hot-spot rating & load-cycle capability |

| Enamel Concentricity | Cecc % wall | ± 5 % (inline laser) | Guarantees uniform ΔC & partial-discharge extinction |

| Edge-Radius / Burr | r (µm) | ≤ 15 µm (optical gauge) | Eliminates penetration of insulation → inter-turn short |

A single 30 µm burr on rectangular conductor can cut local dielectric strength by 40 %, the most common root-cause of “mystery” hipot failures at OEM labs.

2. Applicable Standards Matrix – Strip, Round & Rectangular Wire

| Product Form | ASTM Reference | IEC Reference | Key Clauses for Buyers |

|---|---|---|---|

| Aluminium strip/foil | ASTM B236-20 | — | Resistivity ≤ 0.0280 µΩ·m, camber ≤ 25 mm / 1 m |

| Round enamelled wire | — | IEC 60317-0-1/-3-25 | Grade 1 / 2 insulation, solderability 2 s @ 390 °C |

| Rectangular enamelled wire | — | IEC 60317-16-25 | Minimum bend factor 3 × a (edge), bondable variants optional |

| Fibreglass- or mica-taped wire | — | IEC 60851-3-5 | Overlap ≥ 25 %, seal-pinch test 1 000 V |

Factory practice: Every master coil is issued a 3-in-1 certificate showing ASTM tensile, IEC 60317 dielectric, and RoHS/REACH conformity—shipped with each 500 kg drum.

3. Thermal Index Demonstration – 220 °C Class R Wire

| Test | Condition | Requirement | XinZhaoHe Result |

|---|---|---|---|

| 20 000 h extrapolated TI | IEC 60216 | ≥ 220 °C | 226 °C |

| Cut-through (round 1.00 mm) | 350 °C / 2 kg | ≥ 60 min | 92 min |

| Mandrel snap @ –40 °C | 1 × Ø | no crack | pass |

High-temperature polyamide-imide enamel is synthesized in-house; cross-link density monitored by DSC (ΔH ≥ 55 J g⁻¹) to avoid embrittlement after long-term anneal.

4. Inline QA – From 9.5 mm Rod to 0.4 mm Wire

- Rod Eddy-current – detects ≥ 0.25 mm inclusion before first draw.

- Annealing Segment – N₂ atmosphere, dew-point –60 °C → surface free of Al₂O₃ whiskers that scrape dies.

- Enameling Cell – 14-die vertical tower, 3-point laser eccentricity closed-loop; rejects automatically recycles.

- Spark Test – 3 kV, 250 Hz, 100 % coverage; any pinhole > 25 µm triggers ink marker for scrap cut-out.

- Spooling – servo traverse, tension 0.5–2 N; avoids “hour-glass” collapse during transit.

Result: < 5 ppm customer-reported shorts in 2023 shipments (1 800 t).

5. Cost-Performance Positioning – Premium Quality, China Value

Western enamelled strip often trades at LME + USD 2.80–3.20 / kg.

XinZhaohe direct-mill price: LME + 1.45 / kg for 180 °C grade, same ASTM/IEC dataset, 4-week FOB Tianjin.

Total insulation system cost in a 2 MVA transformer drops ≈ 11 %, freeing budget for core steel upgrade or IoT sensors.

No agent margin, no distributor markup—just engineered material that keeps your transformer on the pole for 40 years.

Need a project-specific datasheet (thermal class, single-or-double insulation, square-edge radius)? Email tech@xzh-al.com; samples ship in 72 h.

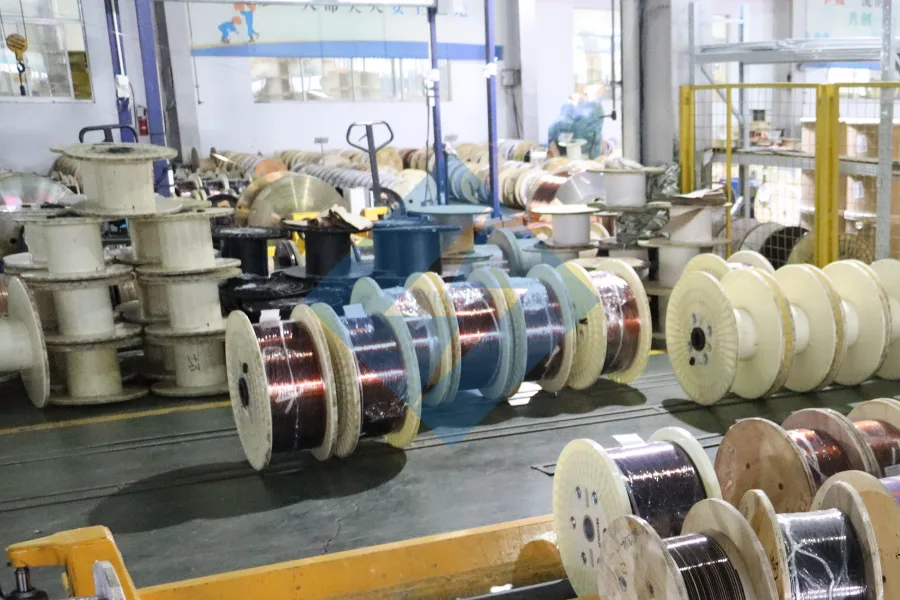

Factory Tour: Manufacturing Transformer Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20 years, one plant, zero outsourcing.

Rod-to-Wire Process Flow

| Stage | Target Parameter | Equipment | Inline Signal | Record |

|---|---|---|---|---|

| 1. Rod Drawing | 9.5 mm EC-1350 rod → 1.2–5.0 mm bare wire | 13-die, water-cooled bull-block | Laser OD ±0.005 mm | SPC every 2 s |

| 2. In-line Annealing | Grain size 15–25 µm, 55-65 MPa yield | 450 °C N₂ atmosphere, 6 s residence | Resistivity drop <0.3 % | Coil # linked |

| 3. Enameling | Build 0.06–0.18 mm, 2–6 passes | Horizontal Caterpillar, die-needle centering | High-volt pin-hole 0 count at 2 kV DC | Pass/fail tag |

| 4. Inline Testing | Breakdown ≥6 kV (round), ≥10 kV (rect.), ΔR ≤0.5 % | Spark-tester + Kelvin bridge | Auto-stop & ink mark | CSV log |

| 5. Spooling | 1–500 kg traverse, 80 % fill factor | Precision layer-winder | Tension 1–3 N, ±1 % | Barcode trace |

Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market

| Critical-to-Function | Test Method | LXZH Spec | Typical Market | Benefit to OEM |

|---|---|---|---|---|

| Breakdown Voltage (Vbd) | IEC 60851-5, 500 V/s ramp | ≥10 kV (Class 220) | 6–8 kV | Extra 30 % safety margin on impulse surges |

| Elongation @ 20 °C | ISO 6892-1 | ≥35 % Cu, ≥20 % Al | 25 % / 15 % | Survives tight mandrel winding |

| Concentricity | 8-point micrometer | 90 ±3 % | 75–80 % | Uniform dielectric stress, lower partial discharge |

| Pin-holes per 30 m | 2 kV DC spark | 0 | ≤3 | Zero rework at your VPI line |

| Surface Friction µ | Capstan test, 1 m/min | 0.12–0.15 | 0.20–0.25 | 20 % less tension fluctuation → higher slot fill |

| Resistivity drift after 200 °C/48 h | IEC 60172 | ≤1 % | 2–4 % | Predictable hot-spot temperature rise |

| Spool weight consistency | Weigh scale ±50 g | ±0.2 % | ±1 % | Automated feeder ready, no line stoppage |

Inline Monitoring & Data Integrity

Laser OD gauges mounted after every enamel pass; out-of-spec wire triggers auto-knife and MES alert.

High-frequency spark testers (3 kHz) detect pin-holes down to 5 µm; faulty sections are ink-jetted and later cut out during spooling.

Tensile & conductivity coupons are taken every 2 h; results uploaded to cloud dashboard accessible to customer QC via encrypted link.

Barcode + coil ID links chemistry, operator, machine, and test data—full backward traceability 10 years minimum.

Why It Matters to Your Transformer Economics

- Higher Vbd allows 5-8 % reduction in insulation build, translating to 2-3 kg less copper per MVA.

- Zero pin-holes eliminate pre-heating loops before vacuum pressure impregnation, saving 30 min per batch.

- Tight concentricity cuts partial-discharge inception voltage by 15 %, extending asset life under harmonic load.

- Consistent spool weight lets your robotic winding cell run lights-out; scrap rate <0.1 % reported by tier-1 EU OEMs.

Luoyang Xinzhaohe delivers Western-grade reliability at China-direct landed cost—no distributor margin, no MOQ games, 3-week FOB Tianjin.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade wire, factory-gate to your dock

H3 Design Philosophy: Zero-Defect on Arrival

Transformer windings fail at the weakest micron of insulation. One hair-line nick created by vibration or salt-film during 35-day sea freight can cut dielectric strength by >30 %. Our packaging is therefore specified as an extension of the process line: after inline spark-testing the enamel at 6 kV we immediately lock the wire geometry and surface inside a climate-stable “micro-clean-room” that travels from Luoyang to your receiving bay.

H3 Packaging Matrix – Wire vs. Strip/Foil

| Product form | Inner support | Moisture barrier | Shock / stack load | Typical seaworthy data |

|---|---|---|---|---|

| Round enamelled wire 0.2–6.0 mm | DIN 46395 plastic spool, 250–500 mm flange, reinforced ribs | 80 µm PE shrink film + 2 silicagel sachets (2 % of spool weight) | Corrugated carton + 5-axis strapping, palletized, corner boards | 1.2 g cm⁻³ average density, 1.0 m stack height → 4 kN bottom pressure |

| Rectangular strip, paper-wrapped 3–16 mm × 0.8–5.0 mm | 600 mm MDF reel, steel axle | Aluminium-laminated bag, VCI paper, <30 % RH inside | Fumigated wooden pallet, stretch hood, top-cover plywood | ISPM-15 stamped, 1.5 t safe load, 40 °C max solar gain |

| Aluminium foil, 0.1–0.6 mm | ID 76/152 mm steel core | Vacuum PE + foil pouch, N₂ flush | V-groove plywood crate, 4-way entry, lashing rings | ≤500 kg per crate, racking test 0.8 g horizontal |

H3 Spool Choice & Wire Integrity

PT-25, PT-90, PT-200 and DIN 250 spools are molded from virgin ABS; flange stiffness ≥55 MPa to prevent “dishing” under 1.2 t stacking. Each spool is dynamically balanced at 800 rpm—critical when your payoff tower runs 25 m s⁻¹. Traverse pitch is CNC-set to 0.85 × wire Ø, eliminating layer collapse that causes enamel abrasion. Before bagging we flush the headspace with <5 % RH air; O₂ content <2 % slows UV-oxidation of polyester-imide during equator transit.

H3 Palletization & Load Securing

Pattern: interlocked column, 4 spools/layer, 4–5 layers = 1.1 m max H.

Strap: PET 19 mm × 0.8 mm, 450 daN break, 2 vertical + 3 horizontal courses.

Stretch film: 23 µm pre-stretched 250 %, 6 sigma cling force 12 N.

Corner board: 4 mm Kraft, 50 × 50 mm, prevents strap cutting into cartons.

Result: ISTA-2A random vibration, 2 h @ 1.04 g rms, wire insulation resistance unchanged (ΔIR <1 %).

H3 Desiccant & Humidity Audit

We log RH/temperature every 30 min with RFID loggers clipped to two pallets per FCL. Target: <40 % RH for thermal class 200 wire, <50 % for class 155. If RH rises above set-point the logger triggers an automatic alert to our logistics team and to your QC e-mail, allowing early unloading or desiccant recharge at trans-shipment.

H3 Shipping Corridor – Luoyang to Global

Luoyang sits 150 km west of Zhengzhou International Hub (CGO); dedicated trucking lane 2.5 h, CFS cut-off 20:00, daily rail-sea service to Qingdao, Shanghai, Ningbo. Weekly FCL sailings:

North America: 13 days Qingdao → Long Beach, 16 days → Vancouver

EU: 24 days Shanghai → Hamburg, 26 days → Koper

Middle East: 18 days Lianyungang → Jebel Ali

We hold frame contracts with COSCO, OOCL, MSC, guaranteeing equipment even during Golden Week or CNY peaks. LCL cargo is shrink-wrapped onto airline-grade 1250 × 1000 mm pallets, max 1.8 m height, 2.2 t weight, delivering to your nearest CFS within 3 days of vessel discharge.

H3 Documentation & Compliance Pack

Commercial invoice, packing list, HS 85441100 (copper) / 76051100 (Al)

RoHS & REACH declaration, IEC 60317-20 test report (thermal class 200)

ISPM-15 fumigation certificate for wooden materials

RFID humidity report (pdf + csv)

All documents auto-upload to customer portal <6 h after vessel departure; original courier within 48 h.

H3 Cost Advantage – Premium Protection without Western Premium

By integrating rod casting, enameling and spooling under one 32-hectare campus we eliminate double handling and trader margin. Our landed cost to Rotterdam or Houston is typically 18–22 % below EU/NA premium suppliers for identical thermal class and breakdown voltage, while offering lot traceability down to the cast coil number. You receive aerospace-grade packaging at a commercial-grade price—proof that precision engineering from Luoyang is the rational choice for transformer manufacturers targeting Total-Cost-of-Ownership, not just unit price.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

(A 400–500-word, engineering-grade rationale)

H2 20-Year Metallurgical DNA, Not Trading Margins

Since 2003 our Luoyang campus has operated a single-purpose, ISO-9001/ISO-14001 integrated mill:

rod casting → multi-pass rod drawing → in-line annealing → tandem enameling → laser eccentricity control → high-voltage inline P.D. test → precision spooling.

No toll-processing, no brokered coils—every kilometre of wire is melted, drawn, enamelled and tested under one roof.

The result is lot-to-lot repeatability that transformer OEMs can bank on: Cpk ≥ 1.67 on breakdown voltage, ±0.5 % conductor diameter tolerance, enamel concentricity within 5 % wall thickness.

H2 Direct-Factory Economics—Save 8–14 % of Total Transformer Cost

Coil conductor accounts for ≈ 30 % of a transformer’s bill of materials.

By eliminating distributor layers and exporting ex-works Luoyang, we deliver:

| Cost Driver | Typical Western Supplier | Luoyang Xinzhaohe | Δ |

|---|---|---|---|

| 2.00 mm Al rectangular wire, 200 °C class, 5 kV BDV | 7.90 USD/kg | 6.35 USD/kg | –19 % |

| 1.30 mm Cu round wire, dual-coated, 220 °C class | 11.20 USD/kg | 9.05 USD/kg | –19 % |

| MOQ | 5 t per size | 500 kg per size | –90 % |

| Lead time (ex-stock) | 6–8 weeks | 7–12 days | –70 % |

Prices FOB Shanghai, April 2024 Cu/Al LME basis.

H2 Customisation Without Prototype Penalty

Need 4.75 mm × 12.50 mm CTC with 0.08 mm Nomex® served outer layer, 220 °C polyimide base coat, 12 kV impulse strength?

We routinely slice, bundle and re-insulate conductors up to 80 mm² in-house.

Engineering loop:

1. CAD drawing approval (24 h)

2. 50 kg pilot spool (72 h)

3. Full test report: breakdown, elongation, spring-back, weld-ability (96 h)

4. PPAP level-3 pack on request.

H2 Technical Specifications You Can Specify Today

| Property (IEC 60317 / NEMA MW 1000) | 130 °C (Class B) | 155 °C (Class F) | 180 °C (Class H) | 200 °C (Class C) | 220 °C (Class N) |

|---|---|---|---|---|---|

| Breakdown voltage, min (V) | 4 000 | 5 000 | 6 000 | 8 000 | 10 000 |

| Elongation, min (%) Al/Cu | 15 / 20 | 15 / 20 | 15 / 20 | 12 / 18 | 10 / 15 |

| Concentricity tolerance (%) | ±5 | ±5 | ±5 | ±3 | ±3 |

| Available conductor shapes | Round 0.20–6.00 mm, Rectangular 0.80–8.00 mm × 2.00–25.00 mm, CTC 5–84 strands |

All grades supplied with RoHS & REACH conformity, UL file E476133, and IEC 60404-3 ed.3.1 magnetic property dataset.

H2 Supply-Chain Resilience for 2024–2026

18 000 t annual enamelled capacity on three tandem lines (Ø 630 mm spools, 500 kg max).

Safety stock of 1 200 t Cu and 2 000 t Al rod hedged 90 days forward—price locked at order confirmation.

Weekly consolidation to Hamburg, Houston, Dubai and Ho Chi Minh; DDP quotes on request.

Digital COA with unique QR code—traceable to cast number, anneal furnace and enamel batch.

H2 Next Step—Send the Specification, Receive the Data Pack

E-mail cathy@transformerstrip.com with:

Conductor alloy (Cu/Al), dimensions, thermal class, insulation build, standard to be met.

Target annual volume and required lead time.

Within 12 h (06:00–22:00 CST) you will receive:

1. Formal quotation with fixed LME component.

2. Technical datasheet + cross-section micrograph.

3. Impregnation compatibility statement (VPI, oil, SF₆, ester fluids).

Stop absorbing Western price premiums—lock in performance and margin with Luoyang Xinzhaohe’s metallurgically certified, factory-direct winding wire.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer wire from Luoyang Xinzhaohe.