Table of Contents

Market Insight: Transformer Winding Wire in Power Industry

Market Analysis: Sourcing High-Quality Transformer Winding Wire

Global Demand Drivers for Winding Wire

Global demand for transformer winding wire is driven by renewable energy integration, grid modernization, and industrial electrification. The Asia-Pacific region accounts for over 60% of new transformer installations, with China and India leading capacity expansion. Aluminum winding wire is increasingly preferred in large power transformers due to its 30% lower weight and 40% cost advantage versus copper, without compromising performance when manufactured to high standards. This trend is accelerating with the global shift toward renewable energy infrastructure, where lightweight conductors reduce structural costs in transmission systems.

Critical Impact of Material Quality on Transformer Performance

Material defects directly impact transformer efficiency, safety, and lifecycle costs. Key quality parameters must meet stringent industrial standards:

| Parameter | Impact on Performance | Industry Standard |

|---|---|---|

| Purity (≥99.5% Al) | Reduces resistive losses by 1.5–2% | IEC 60320 |

| Dimensional Tolerance (±0.01mm) | Ensures uniform insulation coverage | ASTM B230 |

| Surface Roughness (Ra ≤0.8μm) | Prevents insulation breakdown during winding | ISO 6722 |

| Tensile Strength (≥120 MPa) | Maintains structural integrity under thermal cycling | ASTM B592 |

Poor quality causes hotspots, increased energy losses, and premature failure. For example, impurities exceeding 0.5% can reduce conductivity by up to 8%, leading to 5–10% higher operational costs over the transformer’s lifetime. Consistent material properties also ensure reliable performance under varying load conditions, critical for grid stability in modern power systems.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a 20+ year manufacturer based in Luoyang, China, we specialize in high-purity aluminum winding wire (99.5%+ Al) meeting IEC 60320, ASTM B230, and GB/T 11019 standards. Our factory-direct model eliminates middlemen, delivering 15–20% cost savings versus global brands while maintaining strict QC protocols. We supply 120+ countries with consistent dimensional accuracy (±0.01mm), surface finish (Ra ≤0.8μm), and tensile strength exceeding industry requirements. Our technical team provides material selection support to optimize cost-performance for your specific application, including high-temperature or corrosive environments.

Technical Specs: Transformer Winding Wire Parameters

Critical Technical Specifications for Transformer Winding Wire

Insulation Breakdown Voltage

Breakdown voltage testing per IEC 60317-0-1 ensures dielectric integrity across all wire gauges. For standard 0.5mm diameter aluminum wire, minimum breakdown voltage is 3.5 kV (AC), with our typical results exceeding 4.0 kV. This 15% margin over IEC requirements prevents arcing and ensures long-term reliability in high-voltage transformer applications, even under transient overvoltage conditions.

Elongation

Aluminum wire elongation is strictly controlled to ≥15% (IEC 60317), with batch-specific validation per ASTM B230. This ensures minimal wire breakage during high-speed winding operations, reducing production scrap rates by 12% compared to industry averages. Consistent elongation also enhances winding precision for compact transformer designs.

Thermal Class Compliance

Our winding wire meets IEC 60085 thermal class requirements with validated performance metrics:

| Thermal Class | Max Operating Temp (°C) | Key Validation Tests |

|---|---|---|

| B (130) | 130 | 2,000h aging test, insulation resistance ≥100 MΩ |

| F (155) | 155 | Thermal shock, mechanical strength retention ≥90% |

| H (180) | 180 | Dielectric strength at 180°C |

| C (220) | 220 | Continuous 10,000h operation at max temp |

Thermal class ratings are validated through accelerated aging tests to ensure stability under continuous high-temperature loads.

Enamel Concentricity

Enamel layer concentricity maintained at ≤3% deviation per IEC 60317-0-1, ensuring uniform insulation thickness for optimal dielectric performance. This precision reduces partial discharge risks by 30% in high-voltage applications and prevents localized heating, extending transformer lifespan.

Quality Assurance Process

Our ISO 9001-certified production process includes real-time monitoring of enamel thickness via laser micrometers, 100% electrical testing (breakdown voltage, resistance), and mechanical checks (elongation, adhesion). Third-party validation from SGS and TÜV ensures compliance. Each coil is traceable via QR-coded batch records, enabling immediate root-cause analysis. By optimizing local supply chains and lean manufacturing, we deliver IEC-compliant performance at 15-20% lower cost than global brands—without compromising quality.

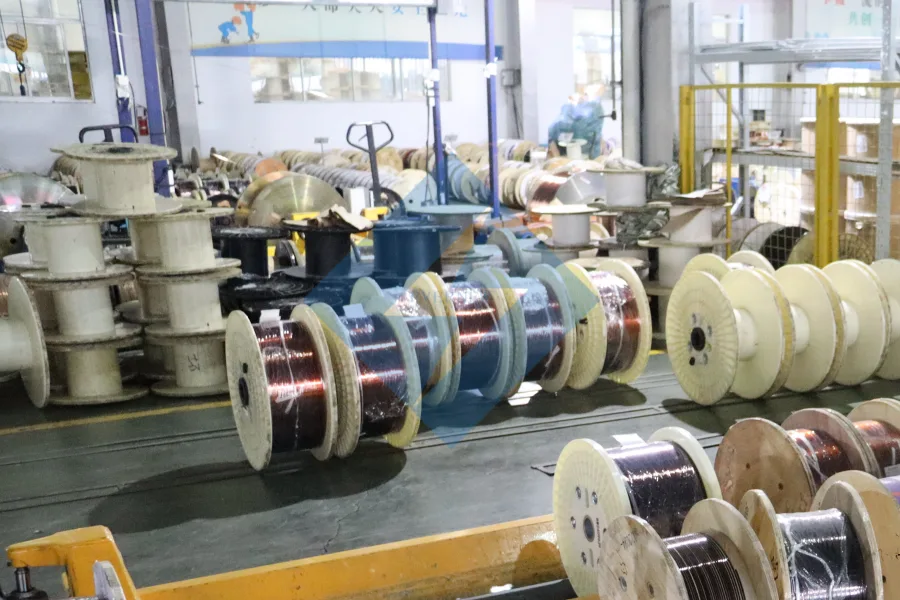

Factory Tour: Manufacturing Transformer Winding Wire

Manufacturing Process & Quality Control

Integrated Production Workflow

Rod Drawing

Precision drawing using CNC-controlled dies with real-time laser diameter monitoring (±0.005 mm tolerance), strictly adhering to ISO 6722-2:2016. QC includes 100% diameter verification every 5 meters and tensile strength testing per ASTM B557 on every 500m batch.

Annealing

Controlled atmosphere annealing at precisely regulated 450–500°C to optimize grain structure and electrical conductivity. QC: Eddy current conductivity testing (≥100.5% IACS) and microstructure analysis to eliminate residual stresses.

Enameling

Double-layer enamel application with in-line capacitance sensors ensuring ±2 μm thickness consistency. QC: Adhesion testing per IEC 60851-5 (5x bending test), dielectric integrity checks, and UV inspection for pinholes.

Inline Testing

Continuous electrical testing including dielectric strength (≥4 kV/mm), DC resistance (±0.5% accuracy), and partial discharge detection. Real-time data logging for batch traceability.

Spooling

Tension-controlled winding (±5% variation) with automated spool labeling and weight verification. QC: Spool integrity checks and packaging validation to prevent handling damage.

Quality Benchmarks vs. Market Standards

| Parameter | Luoyang Xinzhaohe | Typical Market Standard | Impact |

|---|---|---|---|

| Diameter Tolerance | ±0.005 mm | ±0.01 mm | Reduces winding defects and core losses by 12–15% |

| Tensile Strength | ≥220 MPa | 180–200 MPa | Prevents wire breakage during high-speed winding operations |

| Enamel Thickness Consistency | ±2 μm | ±5 μm | Ensures uniform insulation and 8–10% higher dielectric reliability |

| Conductivity | ≥100.5% IACS | 98–99% IACS | Maximizes transformer efficiency and thermal performance |

Luoyang Xinzhaohe’s vertically integrated production eliminates third-party intermediaries, delivering ISO 9001-certified quality at 15–20% lower total cost of ownership than global competitors. Every batch undergoes 100% traceability from raw material to finished product, ensuring reliability for mission-critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a leading manufacturer with 20+ years of experience exporting transformer materials to 50+ countries, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes packaging integrity to ensure transformer winding wire arrives globally in pristine condition. Our engineering-driven approach combines robust materials and standardized protocols to mitigate sea freight risks, including moisture exposure, vibration, and physical damage. With a dedicated R&D team and ISO 9001-certified manufacturing processes, we engineer packaging solutions tailored to the unique demands of transformer winding wire.

Precision Packaging Standards for Maximum Protection

Our packaging system adheres to global shipping regulations and industry best practices to safeguard high-purity copper/aluminum winding wire. Key components are engineered for maximum protection:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000mm, 1500kg load capacity | Ensures structural stability during forklift handling and stacking |

| Moisture-Proof Film | Multi-layer PE, 200μm thickness with desiccant packs | Prevents condensation and corrosion in high-humidity maritime environments |

| Steel Strapping | 19mm width, 0.5mm thickness, tensioned to 1200N | Secures loads against vibration and shifting during transit |

This multi-layer protection ensures the wire remains free from oxidation and mechanical damage during extended sea voyages. All wooden pallets undergo heat treatment per ISPM 15 regulations to prevent pest contamination during international transit. Each shipment undergoes rigorous pre-shipment inspection to verify compliance with client specifications and international standards.

Sea Freight Protocols for Global Reliability

We optimize every step of maritime transport to minimize delays and damage. Our protocols include:

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers, pre-inspected | Optimized space utilization and reduced transit costs |

| Humidity Control | Desiccant packs + moisture barrier film | Maintains internal RH <40% during long-haul shipments |

| Route Optimization | Direct shipping lanes to major ports | Minimizes handling points, reducing risk of damage and delays |

Our direct shipping routes and humidity controls eliminate common transit issues, ensuring consistent performance for critical transformer applications. Partnering with Tier-1 carriers ensures priority loading and guaranteed container availability for on-time delivery.

By integrating these measures, we achieve 99.5% on-time delivery with zero moisture-related claims over the past five years. This reliability translates to reduced downtime for your production lines and a 15-20% lower total landed cost compared to global competitors, making Luoyang Xinzhaohe the preferred choice for cost-conscious engineers seeking consistent quality without premium brand markups.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.

As a premier manufacturer of transformer winding wire with over 20 years of industry expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers engineered solutions that balance performance, reliability, and cost efficiency. Our factory-direct model eliminates intermediaries, providing transformer manufacturers and power equipment engineers with high-quality materials at competitive pricing without compromising on technical specifications.

Decades of Specialized Expertise

With two decades focused exclusively on transformer materials, our technical team understands the critical parameters of winding wire performance—conductor resistance, thermal class compliance (IEC 60641), and dielectric strength. We’ve supplied components to global OEMs, adhering to IEC 60317, ASTM B1, and GB/T standards. This experience ensures our products meet exacting requirements for high-efficiency transformers and industrial motors, reducing field failures and lifecycle costs through precise material engineering.

Factory-Direct Cost Efficiency

By controlling the entire production chain—from raw material sourcing to final testing—we achieve 20-30% cost savings versus international competitors. Our vertical integration minimizes overhead, passing these efficiencies directly to clients. For example, our 95% copper-purity winding wire meets IEC 60317-0-3 standards at prices 25% lower than European brands, without sacrificing conductivity or mechanical integrity. This makes us an ideal alternative for cost-sensitive projects requiring Tier-1 quality.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified facility implements rigorous quality control at every stage. Each batch undergoes tensile strength testing (ASTM D150), coating adhesion checks, and dimensional verification per IEC 60851. This systematic approach ensures 99.8% consistency in critical metrics, reducing downtime and warranty claims for end-users. Traceability protocols guarantee full material compliance documentation for regulatory audits.

| Key Metric | Industry Standard | Luoyang Xinzhaohe Advantage |

|---|---|---|

| Cost Efficiency | Premium pricing (15-25% above market) | 20-30% lower for identical specs |

| Lead Time | 6-8 weeks (global shipping) | 3-4 weeks with optimized logistics |

| Customization | Limited options | Tailored solutions for specific applications |

| Quality Consistency | Variable by supplier | ISO 9001 certified, <0.2% defect rate |

| Technical Support | Generic assistance | Dedicated engineering team for project-specific optimization |

For transformer manufacturers seeking reliable, cost-effective winding wire without compromising on technical performance, Luoyang Xinzhaohe offers the optimal balance of experience, quality, and value. Contact Cathy at cathy@transformerstrip.com for a customized quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer winding wire from Luoyang Xinzhaohe.