Table of Contents

Market Insight: Transformer Winding Tape

Market Analysis: Transformer Winding Tape Demand and Quality Imperatives

Global transformer manufacturing drives sustained industrial demand for high-performance winding tape, a critical component in electrical insulation systems. This demand is intrinsically linked to power grid expansion, modernization initiatives, and the accelerating deployment of renewable energy infrastructure. Utilities and Original Equipment Manufacturers (OEMs) require transformers capable of higher efficiency, increased voltage ratings, and extended operational lifespans under demanding thermal and electrical stresses. Consequently, the market for transformer winding tape, particularly aluminum-based variants used in conductor insulation and shielding layers, experiences steady growth. Key growth vectors include High-Voltage Direct Current (HVDC) transmission projects, offshore wind farm substations, electric vehicle fast-charging networks, and the replacement of aging grid assets in developed economies. These applications impose stringent requirements on the tape’s electrical, thermal, and mechanical properties, elevating its role beyond simple insulation to a core enabler of transformer reliability and performance.

The criticality of winding tape quality cannot be overstated. Substandard tape directly compromises transformer integrity and longevity. Primary quality parameters include exceptional dielectric strength to prevent electrical breakdown under operating and transient overvoltage conditions, high thermal conductivity to facilitate heat dissipation from windings, and precise dimensional stability to ensure uniform insulation layers during winding processes. Crucially, the tape must exhibit low levels of ionic contamination and particulate matter; even microscopic impurities can initiate partial discharge, leading to progressive insulation degradation and catastrophic failure. Mechanical properties such as tensile strength, elongation, and surface smoothness are equally vital, ensuring the tape withstands the significant stresses of high-speed winding operations without tearing, stretching unevenly, or damaging the underlying conductor. Aluminum winding tape, specifically, must maintain consistent purity and surface oxide control to guarantee reliable electrical contact in shielding applications and prevent galvanic corrosion risks.

Failure to meet these exacting specifications carries severe consequences. Transformer failures result in costly unplanned outages, extensive repair or replacement expenses often exceeding millions of dollars, and significant liability risks for utilities and OEMs. The industry standard lifecycle expectation for large power transformers exceeds 30-40 years; inferior winding tape significantly increases the probability of premature failure well before this target. Stringent international standards, including IEC 60450 and IEEE C57.12.00, define mandatory performance thresholds for materials used in transformer insulation systems. Compliance is non-negotiable for market access and reflects a supplier’s commitment to engineering rigor. For sourcing professionals, selecting a winding tape supplier with demonstrable metallurgical expertise, advanced process control, and robust quality assurance protocols is therefore a strategic necessity, not merely a cost consideration. The proven performance history of the material within actual transformer builds provides the ultimate validation of its suitability for mission-critical applications. Quality winding tape represents a minimal cost fraction of the total transformer but an absolute prerequisite for its operational success and asset longevity.

Technical Specs: Transformer Winding Tape

Transformer winding tape is a critical insulation material used in the electrical manufacturing industry, particularly in the production of power and distribution transformers. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in metallurgical engineering and advanced material supply, we emphasize the importance of precise technical specifications to ensure reliability, safety, and long-term performance in high-voltage applications. The insulation properties, mechanical strength, and thermal stability of winding tape directly influence the operational integrity of transformers under varying electrical and environmental loads.

One of the most critical parameters is the Insulation Breakdown Voltage, which measures the dielectric strength of the tape under standardized test conditions. This value indicates the maximum electric field the material can withstand before electrical failure occurs. For high-performance transformer applications, a minimum breakdown voltage of 8 kV is typically required, with premium-grade tapes achieving values exceeding 12 kV. Consistent dielectric performance ensures protection against short circuits and insulation degradation during transient overvoltage events.

Elongation at break is another essential mechanical property, reflecting the tape’s ability to stretch under tension without fracturing. This is particularly important during the winding process, where the tape is subjected to mechanical stress during application over copper or aluminum conductors. A minimum elongation of 15% is standard, though high-flexibility variants may achieve up to 25%. Adequate elongation ensures conformability and reduces the risk of cracking or delamination during coil formation.

Thermal Class defines the maximum continuous operating temperature the insulation system can endure without significant loss of dielectric or mechanical properties. Transformer winding tapes are commonly rated between Class B (130°C) and Class H (180°C), with specialized formulations reaching up to 220°C for extreme environments. Materials such as polyimide, aramid, and high-temperature polyesters are selected based on the required thermal endurance. Long-term thermal stability prevents embrittlement, oxidation, and insulation failure under thermal cycling.

The following table outlines the key technical parameters for transformer winding tape as supplied by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Standard Value | Test Method | Remarks |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 8 kV (AC, 1 mm gap) | IEC 60243-1 | Up to 12 kV for premium grades |

| Elongation at Break | ≥ 15% | ASTM D882 | Up to 25% for high-flexibility variants |

| Thermal Class | 130°C to 220°C | IEC 60085 | Classes B to H, depending on material |

| Thickness Tolerance | ±5% of nominal | ISO 4593 | Ensures uniform dielectric strength |

| Adhesion Strength | ≥ 4 N/cm | PSTC-101 | Prevents slippage during winding |

| Dielectric Strength | ≥ 40 kV/mm | IEC 60243-1 | Measured at 23°C, 50 Hz |

These specifications are validated through rigorous in-house and third-party testing to ensure compliance with international standards. Consistency in material composition, coating uniformity, and dimensional accuracy is maintained across production batches to support high-reliability applications in power infrastructure.

Factory Tour: Manufacturing

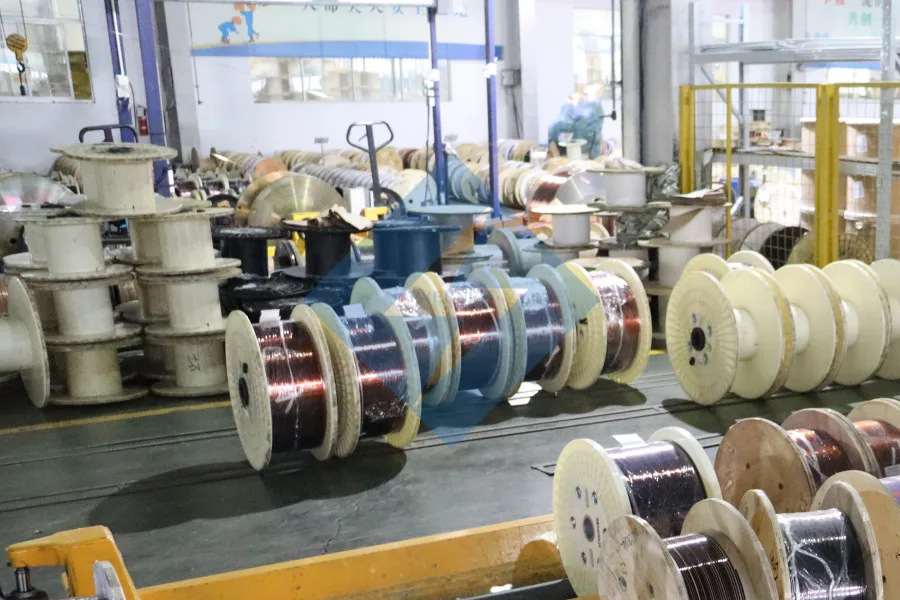

Transformer Winding Wire Manufacturing Process: Precision Engineering for Critical Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical and wire processing expertise to manufacture high-reliability transformer winding wire. Our integrated production line strictly adheres to international standards, ensuring consistent electrical and mechanical properties essential for demanding power and distribution transformer applications. The core manufacturing sequence comprises four critical, interdependent stages with embedded quality control protocols.

Rod Drawing Process

High-purity electrolytic tough pitch (ETP) copper rod or aluminum alloy rod undergoes precision cold drawing through a series of tungsten carbide or diamond dies. This reduction process meticulously controls the wire diameter to tight tolerances, typically within ±0.002 mm for critical gauges. Critical process parameters including reduction ratio per pass, die geometry, and lubricant viscosity are continuously monitored and optimized. Post-drawing, metallurgical verification confirms grain structure refinement and absence of surface defects through automated optical inspection and periodic metallurgical cross-sectioning in our ISO 17025 accredited laboratory. Dimensional stability is validated via laser micrometry at defined intervals.

Annealing Stage

The cold-worked wire enters a continuous inert atmosphere annealing furnace. Precise temperature profiling (typically 450-650°C for copper, lower for aluminum alloys) and controlled residence time restore ductility by recrystallizing the grain structure without grain growth. Oxygen-free nitrogen or argon atmosphere prevents surface oxidation. Real-time conductivity monitoring ensures the annealed wire achieves minimum 100% IACS (International Annealed Copper Standard) for copper grades. In-process tensile testing verifies target elongation (typically 10-25%) and tensile strength, critical for subsequent winding performance. Any conductivity deviation triggers immediate furnace parameter correction.

Enameling Application

The annealed conductor advances through multiple enamel application units. High-solids polymer resins (e.g., polyurethane, polyester-imide, or polyamide-imide) are applied via precision die or roller coating. Multiple thin layers are sequentially deposited and cured in staged ovens with precisely controlled temperature zones (250-450°C) and dwell times to ensure complete solvent removal and cross-linking without thermal degradation. Coating thickness is maintained within ±2µm per layer through closed-loop viscosity control and real-time laser gauging. Surface integrity is paramount; automated spark testing at 3-5 kV detects pinholes down to 1µm diameter before the wire proceeds.

Integrated Inline Testing and Final QC

Comprehensive electrical and mechanical validation occurs continuously. Key inline tests include:

High-potential (Hi-Pot) testing at 3x operating voltage to verify dielectric strength

Automated diameter and ovality measurement using non-contact laser systems

Tension monitoring during take-up to prevent core damage

Final quality certification requires passing all inline tests plus batch-level verification of elongation, springback, thermal endurance (class rating), and adhesion per IEC 60317 and ASTM B728/B802 standards. Traceability from raw material lot to finished spool is maintained via our ERP system, supporting full auditability for critical transformer OEMs. This rigorously controlled process sequence, refined over 20+ years, delivers winding wire meeting the highest global reliability benchmarks.

Packaging & Logistics

Export Packaging for Transformer Winding Tape: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and export of high-performance winding materials, we recognize that reliable packaging is integral to product performance. Transformer winding tape, due to its critical role in electrical insulation and mechanical stability within high-voltage equipment, must arrive at its destination free from contamination, deformation, or moisture exposure. Our export packaging system is engineered to meet the rigorous demands of international logistics, particularly long-haul sea freight, which remains the primary mode of transport for bulk industrial shipments.

All transformer winding tape reels are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the axial and radial loads associated with multi-layer aluminum or copper winding tape coils, preventing deformation during stacking and transit. The structural integrity of the pallet ensures compatibility with automated handling systems at ports and warehouses, minimizing the risk of physical damage during loading and unloading operations.

Each palletized load is then fully enclosed in multi-layer moisture-proof composite film, featuring a core barrier of aluminum foil sandwiched between high-density polyethylene layers. This vapor barrier is heat-sealed to create an airtight enclosure, effectively preventing the ingress of humidity, salt air, and other corrosive atmospheric elements prevalent in maritime environments. Relative humidity within the sealed package remains stable, protecting hygroscopic insulation layers—such as DMD, NMN, or polyester films—from moisture absorption that could compromise dielectric strength and thermal performance.

In addition to moisture protection, the outer film provides resistance to mechanical abrasion, dust, and incidental chemical exposure. UV-stabilized variants are employed for shipments with extended outdoor storage phases. All packaging components are tested for compliance with international maritime safety standards, including resistance to condensation during temperature fluctuations across climatic zones.

Labeling is executed with durable, weather-resistant tags affixed to each pallet, containing critical shipment data including batch number, insulation class, nominal thickness, and handling instructions. This ensures full traceability and proper identification throughout the supply chain.

Our packaging protocol has been validated across shipments to North America, Southeast Asia, the Middle East, and Europe, consistently delivering product integrity under variable transit durations and environmental conditions. By integrating structural durability with advanced moisture mitigation, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every coil of transformer winding tape maintains its specified electrical and mechanical properties from factory to end-user.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Source for Transformer Winding Tape

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver transformer winding tape that meets the most stringent industry demands. Our vertically integrated production ecosystem ensures uncompromising control from raw material sourcing to finished product, eliminating supply chain vulnerabilities while guaranteeing material consistency essential for high-efficiency transformer performance. We operate as a strategic extension of your engineering team, providing not just materials but certified solutions engineered for reliability under extreme operational conditions.

Our core strength lies in advanced aluminum purification and rolling technology. We maintain rigorous control over aluminum purity (99.99% minimum) and grain structure through proprietary melting and casting protocols, directly influencing electrical conductivity and mechanical stability. This foundational precision enables our cold-rolling lines to achieve exceptional dimensional tolerances, with thickness consistency held to ±0.005 mm across widths up to 800 mm. Surface integrity is equally critical; our precision cleaning and tension-leveling processes ensure Ra values below 0.5 μm, preventing insulation damage during high-speed winding operations.

Production capacity and technical specifications are engineered for global scalability without sacrificing quality:

| Parameter | Specification Range | Control Standard |

|---|---|---|

| Thickness | 0.10 mm – 0.80 mm | ±0.005 mm (max deviation) |

| Width | 50 mm – 800 mm | ±0.1 mm (edge camber) |

| Tensile Strength | 80 – 120 MPa | ASTM B928 |

| Elongation | 25% – 40% | ISO 6892-1 |

| Surface Roughness | Ra ≤ 0.5 μm | ISO 4287 |

| Annual Capacity | 15,000 Metric Tons | Dedicated winding tape lines |

Quality assurance is embedded at every process stage through real-time monitoring systems and independent validation. Our ISO 9001 and IATF 16949-certified facility employs in-line eddy current testing for subsurface defects, laser micrometry for continuous thickness verification, and atmospheric-controlled annealing to prevent oxide formation. Every coil undergoes final electrical resistivity testing (≤ 0.028264 Ω·mm²/m at 20°C) and visual inspection per IEC 60404-8-5 standards, with full traceability from ingot batch to shipment.

Supply chain resilience is non-negotiable in critical power infrastructure. We maintain strategic raw material reserves and flexible production scheduling to ensure 15-day lead times for standard grades, with expedited options for urgent projects. Our logistics network supports FCL/LCL shipments globally, with moisture-controlled packaging meeting IEC 61284 requirements to prevent corrosion during transit. This operational discipline has sustained zero critical delivery failures across 12,000+ tons of annual shipments to Tier-1 transformer manufacturers.

Partner with Luoyang Xinzhaohe to transform your winding tape sourcing from a procurement task into a competitive advantage. Our engineering team will collaborate on material specifications, conduct joint failure mode analysis, and provide technical documentation exceeding industry norms. Contact Cathy Zhang directly at cathy@transformerstrip.com to initiate a capability review or request certified sample reels for qualification testing. Let our metallurgical precision become the foundation of your transformer reliability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer winding tape directly from China.