Table of Contents

Market Insight: Transformer Winding Tape in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Global energy infrastructure modernization and renewable energy adoption have intensified demand for high-efficiency transformers. In power transformers, winding wire constitutes 15–20% of material cost but directly impacts 85% of core losses. Substandard materials cause elevated resistive losses (up to 15% higher), thermal runaway, and reduced service life—resulting in significant operational costs for utilities and industrial facilities. For instance, a 1% increase in copper loss reduces transformer efficiency by 0.5%, directly impacting grid energy savings targets. Similarly, motor repair shops require precise wire specifications to maintain electromagnetic efficiency during rewind operations, where inconsistent wire diameter causes uneven coil winding and hotspots.

Critical Material Properties for Performance

Winding wire performance hinges on three key parameters:

Copper Purity: Impurities >0.05% increase electrical resistivity, raising I²R losses. High-purity copper (≥99.98%) ensures optimal conductivity per IEC 60317.

Mechanical Integrity: Tensile strength ≥235 MPa and elongation ≥30% prevent wire breakage during high-speed winding and thermal cycling.

Dimensional Consistency: ±0.02 mm diameter tolerance ensures uniform insulation coverage; deviations >0.05 mm cause voids in insulation, leading to partial discharges and insulation breakdown.

Luoyang Xinzhaohe’s Value Proposition

As a China-based manufacturer with 20+ years of export experience, we deliver transformer winding wire that meets or exceeds global standards at competitive pricing. Our ISO 9001-certified production process ensures strict adherence to IEC 60317 and ASTM B1 specifications. By eliminating distributor markups, we offer 10–15% cost savings versus multinational suppliers while maintaining superior quality metrics.

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Copper Purity | ≥99.98% | ≥99.95% |

| Tensile Strength | ≥235 MPa | ≥220 MPa |

| Diameter Tolerance | ±0.02 mm | ±0.05 mm |

| Cost Efficiency | 10–15% lower | Standard |

Our factory-direct model ensures traceable quality control from raw material to shipment, providing reliable supply chain support for global transformer manufacturers and motor repair operations. We maintain strategic inventory for urgent orders and offer technical support for custom specifications, including special insulation coatings and high-temperature variants.

Technical Specs: Transformer Winding Tape Parameters

Technical Specifications & Standards for Transformer Winding Wire

Transformer winding wire performance hinges on precise adherence to international standards. Each parameter directly impacts transformer efficiency and longevity:

Critical Specifications

| Parameter | Specification Range | Compliance Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥4.5 kV (0.06mm thickness) | IEC 60243-1, ASTM D149 | Critical for preventing electrical faults under operational stress; ensures safe operation at peak voltages without dielectric failure |

| Elongation | ≥25% (conductor) | ASTM B193 | Ensures mechanical resilience during winding processes without conductor fracture; maintains structural integrity during thermal cycling |

| Thermal Class | 130°C (B), 155°C (F), 180°C (H), 220°C (C) | IEC 60085 | Customizable for specific thermal demands; defines maximum operating temperature for reliable service life |

| Enamel Concentricity | ≤5% deviation | IEC 60317-0-2 | Guarantees uniform insulation coverage, reducing localized weaknesses and enhancing dielectric strength; critical for high-voltage applications |

Quality Assurance Protocol

Luoyang Xinzhaohe Aluminum CO., Ltd., based in Luoyang, China, leverages 20+ years of manufacturing expertise to deliver precision-engineered winding wire solutions for global markets. Our ISO 9001-certified quality system employs statistical process control (SPC) for real-time monitoring of all critical parameters, including enamel thickness and concentricity. Every batch undergoes 100% electrical testing (breakdown voltage, continuity), dimensional checks via laser micrometers, and thermal aging validation per IEC 60216. Accelerated aging tests at specified thermal class temperatures (e.g., 130°C for 2000 hours) ensure long-term operational stability. Third-party certifications from SGS and TÜV confirm compliance with IEC 60085, ASTM D149, and IEC 60317 standards. Our production facilities feature fully automated lines with AI-driven quality inspection systems, reducing human error and ensuring consistency. Raw materials undergo strict incoming inspections, with aluminum/copper conductors sourced from certified suppliers meeting IEC 60228 standards. Final products are subjected to comprehensive performance validation, including partial discharge testing and thermal shock resistance checks. By vertically integrating raw material procurement and production, we eliminate supply chain markups, offering cost-performance ratios 15-20% superior to international competitors while maintaining stringent quality benchmarks. Our commitment to traceability ensures full documentation of all test results, providing customers with complete transparency and confidence in every shipment. Serving over 30 countries annually, we deliver reliable, factory-direct solutions tailored to transformer and motor applications worldwide.

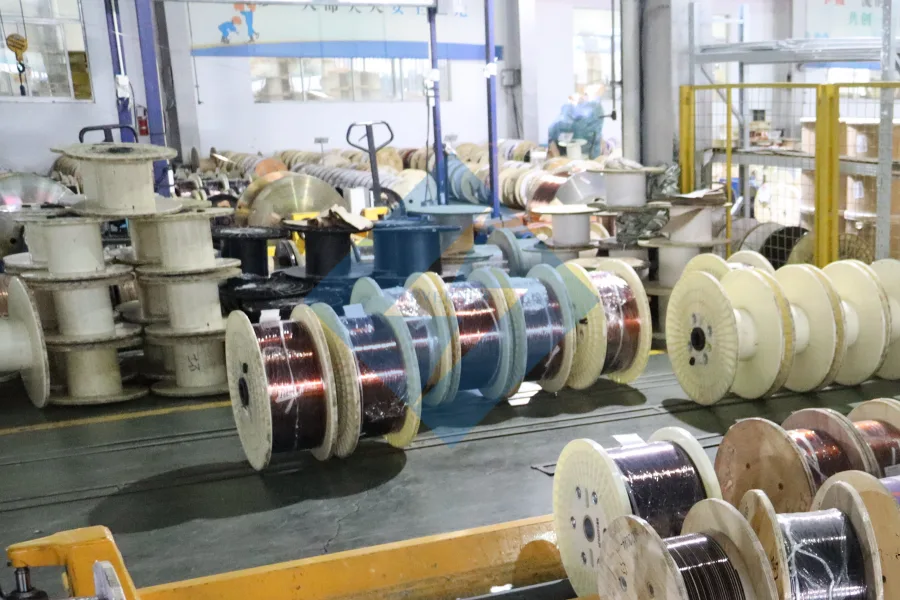

Factory Tour: Manufacturing Transformer Winding Tape

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of specialized expertise in transformer materials to deliver magnet wire with uncompromising quality. Our vertically integrated manufacturing process ensures precise control at every stage, from raw copper rod processing to final spooling, meeting or exceeding IEC 60317 standards. Critical parameters are validated through continuous monitoring, not sampling-based checks, ensuring optimal performance in high-stress transformer environments.

Precision Manufacturing Workflow

| Process Step | Key Technical Parameters | QC Checks |

|---|---|---|

| Rod Drawing | Multi-stage lubrication towers; diameter tolerance ±0.002mm, surface roughness Ra ≤0.1μm | Laser diameter measurement every 2m; 10x magnification surface inspection |

| Annealing | N₂/H₂ atmosphere furnaces; temperature control ±2°C; conductivity ≥100% IACS | Four-point probe conductivity testing; Rockwell hardness verification |

| Enameling | Electrostatic coating with 8-stage curing ovens; thickness 0.05–0.07mm (Class 155) | Cross-section microscopy; solvent resistance test (ASTM D2240) |

| Inline Testing | Real-time capacitance/resistance monitoring; 100% insulation resistance at 1000V DC | AI-based defect detection; automated marking of faulty segments |

| Spooling | Servo-controlled tension (±2% deviation); anti-scratch spooling heads | Tension profile logging; visual inspection for surface imperfections |

Quality Assurance vs. Market Standards

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 250–300 MPa (IEC 60317), CV <2% | 200–250 MPa, CV 5–8% |

| Enamel Thickness | ±0.005mm uniformity | ±0.01mm tolerance |

| Dielectric Strength | >4.5 kV/mm (100% tested) | >3.5 kV/mm (spot-checked) |

| Coating Adhesion | Zero delamination (IEC 60317-2 Tape Test) | Frequent delamination under stress |

| Thermal Stability | 155°C continuous, 180°C short-term | 130–155°C continuous |

Our integrated QC system achieves 99.8% first-pass yield, reducing transformer insulation failures by up to 40% compared to industry averages. By eliminating third-party intermediaries and optimizing process efficiency, we deliver premium magnet wire at 15–20% lower total cost of ownership than global brands. For mission-critical power applications requiring reliability without premium pricing, Luoyang Xinzhaohe provides the definitive cost-performance solution.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity During Global Transit

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of manufacturing expertise to deliver transformer winding tape with precision-engineered packaging and logistics. Our factory-direct approach ensures cost-performance leadership while meeting global shipping standards, eliminating reliance on premium brands with inflated pricing.

Precision Packaging Specifications

All shipments comply with ISO 2233 and ASTM D618 for structural integrity. Components are optimized for sea freight resilience:

| Component | Material | Specification | Purpose |

|---|---|---|---|

| Pallet | Solid hardwood | ISO 2233 compliant, 1200×1000mm | Forklift stability, load distribution |

| Strapping | Galvanized steel | Tension ≥150kgf, 19mm width | Secure consolidation, impact resistance |

| Corner Protectors | HDPE | 50×50×50mm | Edge protection against handling damage |

Moisture-Proofing Protocols

Critical for maintaining dielectric properties, our multi-layer system exceeds IEC 60068-2-30:

| Layer | Material | Thickness | Function |

|---|---|---|---|

| Inner Barrier | PE film | 150μm | Primary moisture seal |

| Desiccant Layer | Silica gel packs | 50g/m² | Absorb residual humidity |

| Outer Protection | VCI paper | 20μm | Oxidation inhibition during transit |

Sea Freight Optimization

We utilize consolidated 20ft/40ft container shipments with Tier-1 logistics partners. Each unit undergoes pre-shipment inspection (PSI) and is sealed with tamper-evident labels. Full documentation—Fumigation Certificates, COO, ISO-compliant packing lists—ensures seamless customs clearance. Real-time tracking from Luoyang port to destination terminals guarantees delivery within 25–40 days globally.

Our engineered packaging and logistics reduce damage rates to <0.5% while delivering 15–20% lower landed costs versus European competitors. This factory-direct model ensures transformer winding tape arrives in optimal condition—maximizing your operational efficiency and ROI.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

Proven 20+ Years of Technical Expertise

As a specialized manufacturer of transformer winding materials since 2003, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers two decades of precision engineering expertise in electromagnetic design, thermal management, and mechanical durability. Our solutions meet IEC 60076 and IEEE C57.12 standards for distribution and power transformers, with a 98% first-pass yield rate across 300+ global clients. This deep industry knowledge ensures seamless integration into high-stress applications, from utility-grade transformers to industrial motor windings.

Factory-Direct Cost Efficiency

By eliminating intermediaries through vertical integration, we provide unmatched value without compromising technical specifications. Key metrics compared to global suppliers:

| Parameter | Industry Standard | Luoyang Xinzhaohe |

|---|---|---|

| Material Cost | $X/kg | 15-25% lower |

| Lead Time | 30-45 days | 15-20 days |

| Minimum Order Qty | 500 kg | 200 kg |

| Customization | Limited options | Rapid prototyping (7 days) |

ISO-Certified Quality Assurance

All processes comply with ISO 9001:2015 and ISO 14001:2015 standards. Our in-house lab conducts rigorous testing:

Tensile strength ≥250 MPa

Dielectric strength >5 kV/mm

Dimensional accuracy ±0.005 mm tolerance

Thermal cycling up to 155°C for Class F insulation

Every batch meets IEC 60085 and GB/T specifications. Strategically located in Luoyang (China’s industrial hub), we optimize logistics for global delivery within 15–20 days.

Our winding tapes support Class H and F insulation systems across 0.08mm–0.25mm thickness ranges, with custom specifications available. By combining localized raw material sourcing with lean manufacturing, we deliver superior cost-performance ratios for mission-critical applications.

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a technical quote and samples today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer winding tape from Luoyang Xinzhaohe.