Table of Contents

Market Insight: Transformer Winding Supplies

Market Analysis: Transformer Winding Wire Demand and Quality Imperatives

Global transformer manufacturing activity remains intrinsically linked to power infrastructure investment, renewable energy integration, and industrial electrification. Demand for high-performance winding wire, particularly aluminum conductor for distribution and power transformers, is driven by sustained grid modernization programs, the rapid expansion of solar and wind generation requiring step-up transformers, and the proliferation of EV charging infrastructure necessitating robust distribution transformers. While copper retains dominance in certain high-efficiency applications, aluminum conductor offers significant advantages in weight reduction (approximately 30% lighter than equivalent cross-section copper) and cost stability, making it the material of choice for the vast majority of distribution transformers globally. This segment represents the largest volume market for winding wire suppliers, with consistent growth projected as emerging economies expand grid access and developed nations replace aging infrastructure. The industrial transformer sector, serving heavy industry and data centers, further amplifies demand for specialized, high-reliability conductors capable of handling fluctuating loads and harmonic distortions.

The criticality of winding wire quality cannot be overstated, as it directly dictates transformer efficiency, thermal performance, operational lifespan, and ultimate reliability. Substandard conductor material introduces significant risk across the transformer lifecycle. Elevated electrical resistivity, even marginally beyond specification, translates directly into increased I²R losses during operation. These losses manifest as wasted energy (reducing system efficiency) and generate excess heat within the winding structure. Inadequate mechanical properties, such as insufficient tensile strength or elongation, compromise the conductor’s ability to withstand the significant electromagnetic forces encountered during short-circuit events, potentially leading to winding deformation or collapse. Furthermore, surface imperfections – scratches, pits, or excessive oxide – act as initiation points for partial discharges within the insulation system, accelerating dielectric degradation and creating pathways for catastrophic failure. Poor dimensional control or inconsistent annealing affects winding precision and thermal management. The consequences of compromised wire quality extend beyond the transformer itself, impacting grid stability, increasing total cost of ownership through higher energy losses and premature replacement, and posing significant safety hazards.

Critical Winding Wire Quality Parameters and Impact

| Parameter Category | Key Specifications | Consequence of Non-Conformance |

|---|---|---|

| Electrical | Resistivity ≤ 0.028264 Ω·mm²/m (100% IACS min), Consistent cross-section | Increased load losses, reduced efficiency, excessive heat generation, potential thermal runaway |

| Mechanical | Tensile Strength: 80-110 MPa, Elongation ≥ 3%, Precise dimensional tolerance (±0.01mm) | Winding deformation under fault current, difficulty in precise winding, compromised structural integrity |

| Surface Quality | Smooth finish, Ra ≤ 1.0 µm, Absence of scratches, pits, excessive oxide | Initiation of partial discharge, accelerated insulation degradation, reduced dielectric strength, premature failure |

Achieving these stringent parameters demands rigorous metallurgical control throughout the production process. Precise alloy composition (primarily 1350-H19 or equivalent), optimized homogenization, controlled hot and cold rolling, and precisely managed annealing are non-negotiable. Consistent surface cleaning and handling protocols are equally vital to prevent contamination. Luoyang Xinzhaohe Aluminum leverages two decades of specialized metallurgical expertise and vertically integrated process control to consistently deliver aluminum winding wire meeting or exceeding IEC 60138 and equivalent global standards. This commitment to metallurgical precision ensures the conductor forms the reliable, efficient foundation essential for modern transformer performance and grid resilience, directly addressing the core industrial demand for dependable power conversion infrastructure. Quality is not an incremental cost; it is the fundamental prerequisite for transformer safety, longevity, and operational economics.

Technical Specs: Transformer Winding Supplies

Transformer winding supplies require precise material specifications to ensure reliable performance under high electrical and thermal stress. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and industrial manufacturing expertise, we provide aluminum winding wire engineered to meet stringent international standards for power and distribution transformers. Our technical parameters are optimized for dielectric integrity, mechanical ductility, and thermal endurance, ensuring long-term operational stability in demanding environments.

A critical parameter in transformer winding wire is insulation breakdown voltage, which determines the wire’s ability to resist electrical failure under high potential stress. Our enamel-coated aluminum winding wires are designed to withstand breakdown voltages ranging from 6 kV to 12 kV, depending on insulation thickness and system requirements. This performance is achieved through multi-layer polymer coatings, including polyurethane, polyester, and polyamide-imide systems, applied with precision to maintain uniformity and minimize defects. High breakdown voltage ensures protection against short circuits and transient overvoltages, particularly in high-voltage transformer applications.

Elongation, or tensile ductility, is another essential mechanical property, directly influencing the wire’s ability to undergo coiling and winding without cracking or fracturing. Our aluminum alloy conductors exhibit controlled elongation values between 18% and 28%, depending on temper (typically H16 to H24 tempers). This range balances formability with sufficient tensile strength to endure winding tension and thermal cycling. Consistent elongation across spool lengths ensures uniform processing on automated winding equipment, reducing downtime and scrap rates during transformer manufacturing.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Our winding wires are rated across a thermal class spectrum from 130°C to 220°C, allowing selection based on transformer loading profiles and cooling methods. For example, Class 130 (B) and Class 155 (F) materials are suitable for dry-type transformers with moderate thermal loads, while Class 180 (H) and Class 220 materials are employed in high-efficiency or high-overload designs. Each thermal class is validated through accelerated aging tests per IEC 60216 and UL 1446 standards, confirming insulation life retention at elevated temperatures.

The following table summarizes key technical specifications for our aluminum transformer winding wire products:

| Parameter | Test Standard | Typical Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, ASTM D437 | 6 – 12 kV | Measured at 1x coating thickness |

| Elongation | ASTM B557 | 18% – 28% | Depends on temper and diameter |

| Thermal Class | IEC 60085, UL 1446 | 130°C to 220°C | Based on insulation system |

| Conductor Resistivity | IEC 60889 | ≤ 0.028264 Ω·mm²/m (20°C) | Grade 1060 or 1350 aluminum |

| Adhesion (Pin Test) | IEC 60317 | Pass at mandrel bend 6x dia | Ensures coating integrity |

These specifications are maintained through rigorous in-line quality control, including automated spark testing, diameter gauging, and thermal aging chambers. All materials are traceable and supplied with mill test certificates for chemical and mechanical compliance. Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every batch of winding wire meets the technical demands of modern transformer design, supporting efficiency, safety, and longevity in power transmission and distribution systems.

Factory Tour: Manufacturing

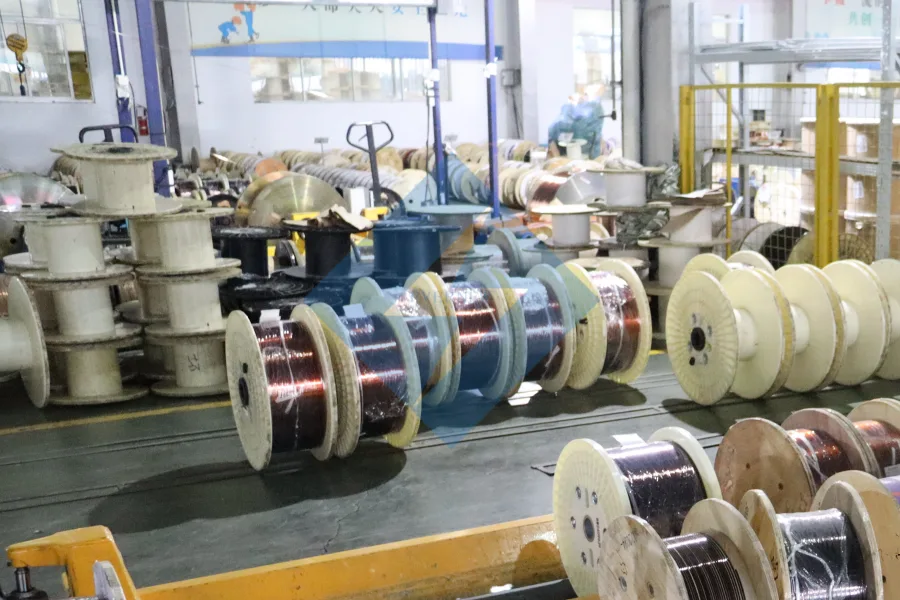

Transformer Winding Wire Manufacturing Process: Precision Aluminum Conductor Production

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise to produce high-reliability aluminum winding wire for critical transformer applications. Our integrated manufacturing process ensures stringent control over material properties and dimensional accuracy, directly impacting transformer efficiency, thermal performance, and operational lifespan. The sequence commences with high-purity aluminum rod (minimum 99.7% Al), sourced from verified suppliers and subjected to rigorous incoming inspection for chemical composition and mechanical integrity. Continuous casting guarantees homogeneous microstructure prior to the primary deformation stage.

Rod drawing forms the foundational step, where the aluminum rod undergoes progressive cold working through precision tungsten carbide dies within a multi-die continuous block machine. This stage meticulously reduces the rod diameter to the precise final conductor size, typically ranging from 1.0 mm to 4.0 mm, while maintaining tight dimensional tolerances (±0.01 mm). Controlled reduction ratios and lubrication management are critical to prevent surface defects and internal stresses. Real-time diameter monitoring via laser gauges ensures immediate correction, preserving cross-sectional uniformity essential for consistent current density in windings.

Subsequent annealing is performed in a continuous, oxygen-controlled nitrogen-hydrogen atmosphere furnace. This step is vital for restoring optimal electrical conductivity (targeting 61.0% IACS minimum) and ductility by eliminating work hardening induced during drawing. Precise temperature profiling (typically 350°C to 450°C) and dwell time management facilitate complete recrystallization, achieving the required elongation range of 25% to 35%. Strict atmosphere control prevents oxidation and hydrogen embrittlement, ensuring surface cleanliness critical for subsequent enamel adhesion.

The annealed conductor then enters the enameling line, where a dual-layer insulating coating is applied. The primary layer, usually a thermosetting polyurethane or polyesterimide resin, provides fundamental electrical insulation and mechanical toughness. This is immediately followed by a secondary overcoat, often polyamide-imide, enhancing thermal stability (rated Class 200°C or higher), chemical resistance, and solderability. Coating thickness is precisely controlled between 0.03 mm and 0.05 mm per side using micro-metering applicators, with continuous infrared curing ensuring complete polymerization. Solvent recovery systems maintain environmental compliance and coating consistency.

Comprehensive inline testing is integral at every stage, not merely a final checkpoint. Key quality control parameters monitored continuously include:

Conductor diameter via non-contact laser measurement

Electrical resistivity using a four-point probe method

Tensile strength and elongation via periodic servo-hydraulic testing

Enamel continuity through 100% spark testing at high voltage (typically 3 kV to 6 kV)

Visual inspection for surface defects using high-resolution cameras

Final product validation includes destructive testing per IEC 60317 standards for thermal endurance, flexibility, and adhesion. Full traceability from ingot lot to finished spool is maintained, supporting stringent transformer OEM requirements. This disciplined, vertically integrated process, governed by ISO 9001 protocols, delivers aluminum winding wire with the metallurgical purity, dimensional precision, and insulation integrity demanded by modern, high-efficiency transformer manufacturing, ensuring reliable power delivery and extended service life. Our supply chain integrates seamlessly with JIT delivery models to support customer production continuity.

Packaging & Logistics

Export Packaging Standards for Transformer Winding Wire – Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum winding wire for power and distribution transformers, we recognize that packaging is not merely a logistical requirement but a critical component in preserving product integrity during international transit. Our export packaging system is engineered to meet stringent global shipping standards, ensuring that high-purity aluminum conductor materials arrive at their destination in optimal condition, fully compliant with electrical and mechanical performance specifications.

All transformer winding wire shipments are secured on robust, ISPM 15-certified wooden pallets constructed from kiln-dried hardwood. These pallets are designed to support the full static and dynamic loads associated with multi-tier stacking in containerized sea freight environments. The structural integrity of each pallet is verified to withstand vertical compression forces exceeding 2,000 kg, minimizing deformation risks during prolonged ocean transport. Each coil is firmly anchored to the pallet using high-tensile steel strapping, positioned at load-bearing points to prevent axial displacement or flange damage during acceleration, deceleration, and vessel motion.

To mitigate the risk of environmental degradation, particularly in high-humidity maritime conditions, every palletized load is hermetically wrapped in multilayer moisture-proof laminated film. This vapor barrier film features a core layer of aluminum foil sandwiched between high-density polyethylene (HDPE) sheets, providing a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24hr at 38°C and 90% relative humidity. Seams are thermally sealed to ensure continuity of the protective envelope, effectively isolating the wound aluminum conductors from corrosive salt-laden air, condensation, and ambient moisture.

Prior to dispatch, each packaged unit undergoes visual and dimensional inspection in accordance with ISO 9001 protocols. Lot-specific documentation, including material test reports (MTRs), coil identification tags, and handling instructions, is affixed to the exterior of the moisture barrier in sealed, waterproof enclosures. This ensures traceability and regulatory compliance throughout the supply chain.

Our packaging methodology is validated through accelerated climatic testing simulating 45-day sea voyages across tropical and temperate zones. Results consistently demonstrate zero incidence of surface oxidation, mechanical deformation, or dimensional variance post-exposure. By integrating structural robustness with advanced moisture protection, Luoyang Xinzhaohe ensures that every meter of aluminum winding wire maintains its specified conductivity, elongation, and surface finish upon arrival.

This comprehensive approach to export packaging reflects our commitment to reliability, quality, and customer success in the global transformer manufacturing sector.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Solutions for Critical Transformer Windings

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial supply chain mastery to deliver transformer winding supplies meeting the most stringent global power infrastructure demands. Our vertically integrated manufacturing ecosystem, centered in Luoyang’s advanced materials hub, ensures unparalleled control over material purity, dimensional precision, and production consistency – non-negotiable attributes for high-efficiency, low-loss transformer cores.

Our core strength resides in advanced aluminum melt purification and continuous casting processes. We consistently achieve aluminum purity levels exceeding 99.99% (Al99.99+), utilizing proprietary degassing and filtration systems to eliminate hydrogen content below 0.10 ml/100g Al and minimize inclusions to less than 10 ppm. This foundational metallurgical excellence directly translates to superior electrical conductivity (IACS ≥ 61.0%) and thermal stability in the final strip product. The precision cold rolling line, equipped with laser micrometry and real-time tension control, guarantees tight dimensional tolerances essential for automated winding operations. Typical product specifications include:

| Parameter | Standard Tolerance | Tight Tolerance Option |

|---|---|---|

| Thickness (mm) | ±0.010 | ±0.005 |

| Width (mm) | ±0.5 | ±0.2 |

| Edge Straightness | ≤ 1.0 mm/m | ≤ 0.5 mm/m |

| Surface Roughness | Ra ≤ 0.8 µm | Ra ≤ 0.4 µm |

Comprehensive in-process and final quality assurance is non-negotiable. Every production batch undergoes rigorous testing per IEC 60137, ASTM B233, and customer-specific protocols. Our on-site laboratory validates electrical resistivity, mechanical properties (tensile strength, elongation), surface integrity via high-resolution profilometry, and precise dimensional conformity using coordinate measuring machines (CMM). Full material traceability from ingot melt to finished coil is maintained through our integrated ERP system, providing complete audit trails for critical power applications.

Supply chain resilience is engineered into our operational model. Strategic partnerships with primary aluminum producers secure priority access to high-grade feedstock, while our 50,000+ square meter facility maintains buffer stocks of key alloys to mitigate market volatility. Dedicated logistics coordination ensures JIT delivery compliance, supported by multimodal transport options from Luoyang’s central Chinese location. We excel in managing complex, high-volume orders with minimal lead time variance, a critical factor for transformer OEM production scheduling.

Beyond supply, our technical team provides active engineering collaboration. We support customers from initial material specification review through winding process optimization, offering metallurgical analysis to resolve field issues and co-developing solutions for next-generation high-frequency or ultra-high-voltage transformer designs. This proactive partnership approach minimizes production risks and enhances your end-product reliability.

For transformer manufacturers demanding unwavering quality, technical partnership, and supply certainty in aluminum winding strip, Luoyang Xinzhaohe is the engineered solution. Contact our Technical Sales Manager Cathy Zhang immediately to discuss your specific requirements and receive a tailored production capability analysis. Email cathy@transformerstrip.com to initiate a technical dialogue and secure your supply chain advantage.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer winding supplies directly from China.