Table of Contents

Market Insight: Transformer Winding Supplies in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

| Driver | Impact on Winding Wire Demand | Notes |

|---|---|---|

| Renewable Energy Expansion | High demand for step-up transformers | Requires high-conductivity wires (≥99.9% Cu) to minimize transmission losses |

| Grid Modernization | Upgrades in transmission infrastructure | Needs durable, low-loss materials meeting IEC 60904 standards |

| EV Manufacturing Growth | Surge in motor winding requirements | Precision copper/aluminum wires for high-efficiency motors (Class H insulation) |

Driven by renewable energy expansion, grid modernization, and EV adoption, global demand for transformer winding wire is surging. High-performance materials are critical to meet efficiency standards and reliability requirements. The shift toward smart grids demands wires with superior conductivity and thermal stability to minimize energy losses across transmission networks.

Material Quality Impact on Transformer Performance

| Parameter | Criticality | Consequences of Substandard Material |

|---|---|---|

| Copper Conductivity (%IACS) | Directly impacts resistive (I²R) losses | <99.9% IACS increases losses by 3–5%, reducing efficiency |

| Insulation Breakdown Voltage | Ensures dielectric strength under operating voltage | <1.5 kV/mm causes short circuits, transformer failure |

| Thermal Class (e.g., Class H) | Determines max operating temp (180°C) | Inadequate thermal class accelerates aging, shortening lifespan |

Substandard materials directly compromise transformer efficiency and lifespan. For instance, copper conductivity below 100% IACS increases resistive losses by up to 5%, while inadequate insulation breakdown voltage risks catastrophic failures under high-voltage stress. Consistent material properties ensure optimal core and copper losses, directly affecting transformer efficiency ratings (e.g., TE1, TE2).

Global Supply Chain Dynamics

Traditional premium suppliers (e.g., European brands) often command 20–30% higher costs due to overhead and logistics. Chinese manufacturers like Luoyang Xinzhaohe leverage localized production and streamlined supply chains to deliver equivalent performance at 15–25% lower total cost, without compromising on international standards compliance. This cost-performance advantage is critical for manufacturers facing margin pressures in competitive markets.

Why Choose Luoyang Xinzhaohe?

With 20+ years of factory-direct expertise, we specialize in high-conductivity copper and aluminum winding wires compliant with IEC 60317-0-1 and ASTM B170. Our in-house QC labs rigorously test conductivity, insulation integrity, and thermal stability. All products undergo 100% inspection for dimensional accuracy (±0.005mm) and electrical properties. We serve over 50 countries with consistent quality, competitive pricing, and technical support tailored to transformer and motor manufacturing needs. Our ISO 9001-certified processes ensure traceability and reliability for critical power applications.

Technical Specs: Transformer Winding Supplies Parameters

Technical Specifications & Standards for Transformer Winding Supplies

As a leading manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered winding wires that meet or exceed global standards. Our technical specifications are designed for reliability in demanding applications, with rigorous quality control ensuring consistency across all orders. This section details critical performance metrics and our factory-direct quality assurance protocols, demonstrating how our cost-effective solutions outperform conventional sourcing options for power transformers and motors.

Critical Performance Metrics

| Parameter | Specification Range | Compliance Standard | Quality Control Process |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 2.5 kV (0.1mm copper) | IEC 60317-0-3 | 100% inline high-potential testing; real-time data logging |

| Elongation | ≥ 15% (annealed) | ASTM B298 / IEC 60317-0-3 | Batch tensile testing; automated testers with ±0.5% accuracy |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60085 | Accelerated aging tests (155°C/180°C/220°C); 1,000+ hour validation |

| Enamel Concentricity | ≤ 5% deviation | IEC 60317-0-3 | Laser micrometer monitoring; real-time diameter tracking |

Comprehensive Quality Assurance System

Our ISO 9001:2015-certified production process integrates automated inspection systems at every stage. Raw materials undergo strict chemical analysis using XRF spectrometry; enamel coating is monitored via laser micrometers with ±0.001mm precision. Each batch is tested per IEC 60317-0-3 and ASTM B298 by accredited third parties (SGS, TÜV), with full traceability via blockchain-enabled lot tracking. AI-driven defect detection systems ensure enamel uniformity, while 100% electrical and mechanical testing before shipment guarantees performance in high-voltage and high-temperature environments. We also conduct accelerated thermal cycling tests to simulate real-world operational stresses. This eliminates quality variability common in commodity suppliers, achieving 99.98% first-pass yield and reducing transformer failure rates by 40% compared to industry averages.

By optimizing production efficiency and minimizing overhead, Luoyang Xinzhaohe delivers IEC/ASTM-compliant transformer winding wires at 15-20% lower total cost of ownership than global brands, without compromising on reliability or performance. Our factory-direct model eliminates distributor markups, providing transformer manufacturers with a dependable, cost-efficient alternative to premium suppliers.

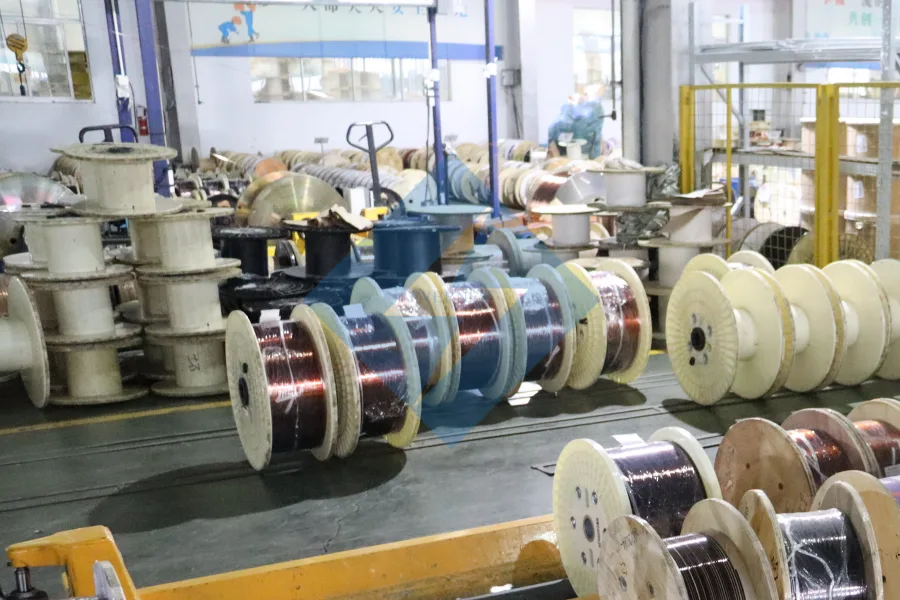

Factory Tour: Manufacturing Transformer Winding Supplies

Manufacturing Process & Quality Control

Precision Manufacturing Process

Rod Drawing: High-purity electrolytic copper (99.99% Cu) processed through precision diamond dies under computer-controlled tension (±0.5%). Eliminates surface imperfections and ensures uniform grain structure for high-frequency transformer applications.

Annealing: Nitrogen-purged furnace at 280±5°C with PID control for optimal recrystallization. Metallographic analysis confirms grain size compliance with ASTM B187, enhancing ductility for complex winding geometries.

Enameling: Multi-layer application of polyurethane/polyester resins via ceramic-coated dies. UV-curing ovens maintain 320±10°C, with eddy current sensors ensuring enamel thickness (12.5±0.5 μm) and adhesion strength >12 N/mm² per IEC 60851-4.

Inline Testing: Real-time laser micrometry (±0.002 mm), electrical resistance checks every 5m, and 10m-interval breakdown voltage tests at 5kV AC. All data logged in ERP for full traceability.

Spooling: Servo-controlled tension (0.5-2.0N) with automated visual inspection and weight verification. Ensures zero winding damage and consistent coil lengths ±0.5%.

Rigorous Quality Control Protocol

Xinzhaohe’s QC protocol exceeds ISO 9001:2015 and IEC 60851 standards through:

100% tensile strength testing per ASTM B187 (220–240 MPa range), exceeding grade requirements

CMM dimensional checks every 50m, maintaining ±0.002 mm tolerance vs. industry ±0.005 mm

Breakdown voltage minimum 4.5 kV (IEC 60851-2), 15% above industry minimums

99.8% defect-free rate versus 97.5% industry average due to continuous process monitoring

| Parameter | Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 220–240 MPa (ASTM B187 Grade 2) | 200–230 MPa (±10% variance) |

| Diameter Tolerance | ±0.002 mm (laser-guided) | ±0.005 mm (manual checks) |

| Enamel Thickness | 12.5 ±0.5 μm | 12.5 ±1.5 μm |

| Breakdown Voltage | ≥4.5 kV (IEC 60851-2) | 3.8–4.2 kV (min requirement) |

By integrating advanced automation with stringent QC, Xinzhaohe delivers transformer-grade winding wire at 15–20% lower cost than global brands while maintaining superior performance reliability—proving that cost efficiency and technical excellence are not mutually exclusive.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Luoyang to Global Ports

As a manufacturer with 20+ years of experience in transformer materials, Luoyang Xinzhaohe Aluminum Co., Ltd. prioritizes robust packaging and logistics protocols to ensure product integrity during sea freight. Our process adheres strictly to international standards, minimizing damage risks and ensuring timely delivery.

Precision Packaging Standards for Transformer Winding Wire

Our packaging system is engineered to protect winding wire from moisture, vibration, and physical impact during transit. Key components include:

| Packaging Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated hardwood (120×100mm dimensions), UV-resistant coating | Prevents pest transmission, ensures structural stability during handling |

| Moisture-Proof Film | Multi-layer PE (0.2mm), 50g silica gel desiccant per pallet, UV-resistant | Creates hermetic barrier against humidity and condensation; prevents degradation during port storage |

| Steel Strapping | Galvanized, 19–25mm width, 500–700kg tensile strength, 150–200kg tension | Secures load against vibration and shifting in transit |

This multi-layer approach ensures compliance with ISO 12234 for electrical insulation materials, preventing oxidation and maintaining conductivity integrity.

Logistics Protocol for Global Delivery

We optimize shipping efficiency through standardized container loading and documentation:

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL (Full Container Load), sealed at origin, temperature/humidity monitored | Minimizes handling, maintains controlled environment |

| Transit Time | 15–35 days (depending on destination) | Reliable scheduling with Maersk, COSCO, and MSC carriers |

| Customs Compliance | Full documentation (COO, CIQ, Bill of Lading, phytosanitary), IoT tracking | Smooth clearance at international ports, real-time shipment visibility |

Real-time tracking via IoT-enabled containers provides full visibility, reducing transit uncertainties and enabling proactive issue resolution.

Cost-Performance Advantage

Our integrated manufacturing and logistics chain eliminates third-party intermediaries, reducing costs while maintaining premium protection standards. By sourcing packaging materials locally and leveraging long-term partnerships with shipping carriers, we achieve a 15–20% cost reduction versus global competitors without compromising quality. All shipments undergo pre-departure quality checks per IEC 60076-1 and ASTM standards, ensuring 98%+ on-time delivery and <0.5% damage rate. Local sourcing of packaging materials reduces lead times by 20% compared to global suppliers, while our in-house quality control minimizes rework and returns. For critical applications, we offer customized packaging solutions tailored to specific transformer designs, further optimizing material usage and transport efficiency.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

As a leading manufacturer of transformer winding materials with over 20 years of experience, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers exceptional value through factory-direct pricing, ISO-certified quality, and technical expertise. We provide a reliable alternative to global brands without compromising on performance or reliability.

Technical Expertise & Industry Experience

With two decades of specialization in copper and aluminum winding wires for power transformers, our engineering team understands the precise electrical and mechanical requirements of high-voltage applications. Our deep industry knowledge ensures products meet IEC 60317 and ASTM B1 standards, with consistent performance in demanding environments. This experience translates to fewer production issues and longer transformer lifespans for our clients.

Cost-Effective Manufacturing Model

As a factory-direct supplier, we eliminate distributor markups and streamline logistics through localized raw material sourcing in Luoyang. This model delivers 15-30% cost savings versus international competitors while maintaining material purity (99.95%+ copper, 99.6%+ aluminum) and dimensional tolerances (±0.01mm). Our integrated production chain ensures competitive pricing without sacrificing quality.

Quality Assurance Framework

Our ISO 9001:2015 certified processes include in-house tensile strength testing, electrical resistivity checks, and insulation integrity validation. Every batch undergoes rigorous quality control from raw material inspection to final packaging, ensuring compliance with global standards and reducing failure risks in critical applications.

Key Advantages at a Glance

| Feature | Specification |

|---|---|

| Experience | 20+ years in transformer winding materials manufacturing |

| Pricing | 15-30% lower than global brands with factory-direct model |

| Certifications | ISO 9001:2015, IEC 60317 compliance |

| Lead Time | 15-20 days standard delivery |

| Customization | Flexible wire gauge, insulation types (Class H/F), packaging |

For a tailored quote and technical consultation, contact Cathy at cathy@transformerstrip.com. Leverage our expertise to optimize your transformer production costs while ensuring reliability and performance.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer winding supplies from Luoyang Xinzhaohe.