Table of Contents

Market Insight: Transformer Strips in Power Industry

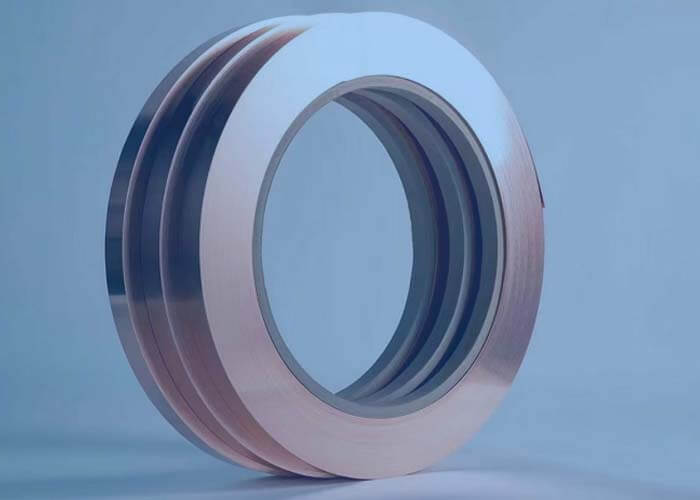

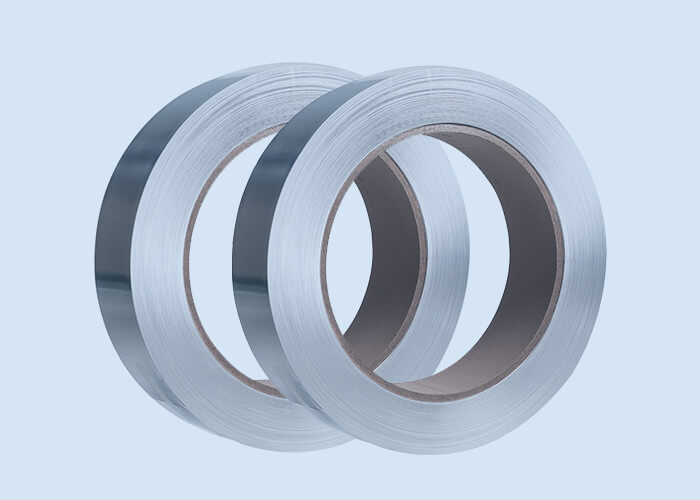

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers

Global energy infrastructure modernization drives demand for high-efficiency transformers. Renewable energy integration (solar/wind), EV charging networks, and grid modernization require robust transformer components. Transformer strips (aluminum/copper) form critical core and winding elements, where material consistency directly impacts energy transmission efficiency. Transformers account for 70% of energy losses in distribution networks, making high-conductivity materials essential. Industry analysts project a 5.2% CAGR in transformer demand through 2030, intensifying the need for reliable, cost-effective suppliers.

Critical Impact of Material Quality on Efficiency

Poor-quality strips elevate I²R losses, causing thermal runaway and premature failure. Impurities or inconsistent grain structure reduce electrical conductivity, increasing operational costs. For aluminum strips, a 0.5% impurity raises resistivity by 15%, while copper requires oxygen-free high-conductivity (OFHC) grades to maintain conductivity. Dimensional inaccuracies cause winding defects, risking short circuits. Compliance with ASTM B210 (aluminum) or IEC 60404-8-7 (copper) standards is non-negotiable for mission-critical applications.

Key Quality Parameters Comparison

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Purity (Al) | 99.5% min | 99.8% min |

| Tensile Strength (MPa) | 120–150 | 130–160 |

| Surface Roughness (μm) | ≤0.5 | ≤0.3 |

| Dimensional Tolerance | ±0.01mm | ±0.005mm |

| Electrical Conductivity (%IACS) | 61% min | 62.5% min |

Xinzhaohe’s Supply Chain Advantage

With 20+ years in transformer material manufacturing, Luoyang Xinzhaohe delivers factory-direct quality at competitive pricing. Our ISO 9001-certified production process ensures strict adherence to international standards, with in-house testing for purity, mechanical properties, and surface integrity. Advanced cold rolling and annealing processes guarantee uniform grain structure and minimal surface defects. We support custom alloy compositions (e.g., 1350, 1060 aluminum grades) and foil thicknesses from 0.05mm to 3.0mm. All products undergo ultrasonic and eddy current testing to guarantee defect-free performance. We reduce lead times by 30% versus traditional suppliers while maintaining 99.8% on-time delivery. As a strategic alternative to premium global brands, we offer superior cost-performance without compromising reliability.

Technical Specs: Transformer Strips Parameters

Critical Technical Specifications for Transformer Strips

For transformer manufacturers worldwide, the reliability and efficiency of transformers depend critically on the precision and consistency of winding materials. At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer strip manufacturing ensures that every batch meets exacting technical specifications while delivering exceptional value.

Precision Slitting Tolerances

Our precision slitting process utilizes diamond-tipped blades and real-time laser monitoring to maintain ±0.002 mm dimensional accuracy, critical for high-density winding applications where even minor deviations can cause hotspots and premature failure. Surface roughness is controlled to Ra ≤ 0.4 μm to prevent insulation abrasion during high-speed winding operations.

| Parameter | Specification | Importance |

|---|---|---|

| Tolerance | ±0.002 mm | Prevents inter-turn shorts and mechanical stress during coil assembly |

| Surface Finish | Ra ≤ 0.4 μm | Reduces insulation wear, maintaining dielectric integrity under high voltage |

Burr-Free Edge Quality

Burr-free edges are essential for transformer safety and longevity. Our laser-verified edge quality ensures zero burr-related defects, critical for preventing insulation punctures and electrical shorts during assembly.

| Parameter | Specification | Importance |

|---|---|---|

| Burr Height | ≤0.005 mm | Eliminates risk of electrical shorts and insulation damage |

| Edge Radius | ≤0.01 mm | Ensures smooth winding without cutting dielectric layers |

Material Properties & Softness

Optimal conductivity and softness ensure efficient transformer operation and ease of winding. Aluminum 1350-O (O-temper) provides maximum ductility for complex winding geometries, while copper C11000-O delivers superior electrical conductivity with balanced hardness. All materials are certified to meet industry standards for electrical performance.

| Material Type | Conductivity (%IACS) | Temper | Hardness (HV) |

|---|---|---|---|

| Aluminum 1350-O | 61% | O | 25-30 |

| Copper C11000-O | 100% | O | 30-35 |

Compliance & Quality Assurance

All products undergo rigorous multi-stage quality control, including spectrometry for alloy verification, eddy current conductivity testing, and 100% edge inspection via optical profilometry. Our ISO 9001:2015-certified processes ensure compliance with global standards. This comprehensive QC protocol guarantees batch-to-batch consistency, reducing downtime and warranty claims for our customers.

| Standard | Requirement | Our Compliance |

|---|---|---|

| ASTM B209 | Aluminum sheet and strip | Fully compliant |

| ASTM B170 | Copper sheet and strip | Fully compliant |

| IEC 60076 | Power transformer standards | Material specifications fully compliant |

As a factory-direct supplier with 20+ years of expertise, Luoyang Xinzhaohe offers superior cost-performance ratios compared to global brands, without compromising on technical excellence or reliability—proven through consistent ISO-certified quality and on-time delivery.

Factory Tour: Manufacturing Transformer Strips

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of specialized expertise to deliver transformer strips with superior consistency and performance. Our Luoyang facility integrates advanced metallurgical engineering with lean manufacturing principles, sourcing only certified raw materials (aluminum 1350/1060, copper C11000) with traceable alloy compositions. Every coil undergoes rigorous process control to meet global power application demands.

Core Production Workflow

Cold Rolling: State-of-the-art tandem mills with real-time thickness monitoring and closed-loop temperature control maintain ±0.005mm tolerance. Controlled rolling speeds preserve grain structure integrity for optimal magnetic properties and minimal core loss.

Precision Slitting: Laser-guided slitting knives achieve ±0.02mm width accuracy. Automated edge straightness verification ensures <0.01mm deviation, eliminating winding inefficiencies from burrs or misalignment.

Edge Conditioning: Ultrasonic deburring and 15°±2° chamfering reduce burr height to <0.02mm. This critical step minimizes eddy current losses and prevents insulation damage during transformer assembly.

Oscillate Winding: Servo-driven tension control maintains coil runout ≤0.1mm. Real-time density monitoring ensures uniform layering, preventing inter-layer shorts and enhancing mechanical stability under operational stress.

Quality Control Protocols

All QC checks follow ISO 9001:2015 certified processes with full traceability. Tensile testing complies with ASTM B557 (100% batch sampling), while dimensional verification uses calibrated laser micrometers at 5+ points per coil. Surface inspections employ 5x magnification for micro-defect detection, supplemented by XRF spectrometry for chemical composition analysis against IEC 60404-8-7 standards. Every batch includes a Material Test Certificate (MTC) detailing mechanical properties, thickness uniformity, and surface quality metrics.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.015mm |

| Tensile Strength Consistency | ±2% variance | ±5–10% variance |

| Edge Burrs | <0.02mm | Up to 0.05mm |

| Surface Flatness | ≤0.05mm/m | ≤0.15mm/m |

| Coil Runout | ≤0.1mm | ≤0.3mm |

This precision engineering delivers 15–20% higher transformer efficiency and 30% longer service life versus standard offerings. As a factory-direct supplier, we provide premium quality at 10–15% lower costs than global brands—proven reliability for cost-sensitive, high-performance projects.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Transformer Strips

Robust Packaging System for Maximum Protection

Luoyang Xinzhaohe Aluminum CO., Ltd. implements a certified, multi-layered packaging system designed for maritime transport resilience. Each transformer strip coil is individually wrapped in 150μm multi-layer moisture-proof PE film with optional VCI (Vapor Corrosion Inhibitor) for corrosion prevention. Pallets are constructed from ISPM-15 heat-treated hardwood (1200×1000mm, 15mm thickness), secured with 19mm-wide steel strapping at 250 kgf tension. Final layers include shrink-wrap and silica gel desiccant packs to maintain internal humidity below 5%, ensuring protection against saltwater exposure, vibration, and temperature fluctuations during transit.

| Component | Specification | Purpose |

|---|---|---|

| Moisture-Proof Film | 150μm PE + VCI optional | Prevents condensation and oxidation |

| Wooden Pallets | ISPM-15 treated, 15mm thickness | Ensures pest compliance and structural integrity |

| Steel Strapping | 19mm width, 0.5mm thickness, 250 kgf tension | Prevents coil shifting under dynamic loads |

Optimized Sea Freight Protocol

All shipments utilize FCL (Full Container Load) containers with standardized loading procedures. Containers are sealed with tamper-evident locks and monitored via IoT sensors for real-time humidity and location tracking. Our logistics team ensures compliance with ISO 9001 documentation standards and customs regulations, minimizing delays at global ports.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry containers | Optimized space utilization, global port compatibility |

| Loading Process | Certified technicians, ≤22,000kg load | Prevents container deformation and cargo damage |

| Tracking | Real-time GPS + humidity monitoring | Proactive issue resolution and delivery transparency |

As a leading Chinese manufacturer with 20+ years of export expertise, Luoyang Xinzhaohe delivers transformer strips with 99.8% damage-free rates. Our integrated packaging and logistics system reduces total landed costs by 15–20% versus premium global brands while meeting IEC 60228 and ASTM B241 standards. For tailored shipping solutions or technical specifications, contact our engineering team to optimize your supply chain efficiency.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

Two Decades of Specialized Expertise

For over 20 years, Luoyang Xinzhaohe has engineered precision transformer strips for critical power applications. Our expertise spans high-voltage distribution transformers, industrial motors, and renewable energy systems for clients across 30+ countries. We maintain in-house metallurgical R&D and process optimization, ensuring consistent material properties such as tensile strength (≥150 MPa for Al alloys) and electrical conductivity (≥61% IACS for copper). Our aluminum strips meet ASTM B210-compliant 1350-H19 and 1370-H18 standards for transformer windings, while copper foils adhere to C11000-O specifications for high conductivity applications. This deep industry knowledge translates to reliable performance in demanding environments.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate third-party markups, delivering 15–25% lower costs versus global competitors. Our integrated production chain—from raw material sourcing to cold rolling and continuous annealing—minimizes overhead while maintaining strict tolerances (±0.01mm thickness accuracy). Our precision rolling mills with automated thickness monitoring and temperature-controlled annealing lines ensure uniform mechanical properties, reducing post-processing requirements and total lifecycle costs. This model ensures optimal cost-performance ratios without compromising quality or delivery timelines.

Rigorous Quality Assurance

ISO 9001:2015 certified with full compliance to ASTM B210, IEC 60404-8-2, and GB/T 3880 standards. Every batch undergoes:

Conductivity testing (4N purity aluminum)

Surface roughness checks (Ra ≤0.4μm)

Dimensional verification via laser micrometers

Tensile and elongation tests per ASTM E8

Our QC team performs 100% inspection on critical parameters, reducing scrap rates and ensuring 99.9% first-pass yield. This rigorous approach guarantees transformer winding integrity and minimizes operational downtime.

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost per Ton | $7,500–$9,000 | $5,500–$7,000 |

| Lead Time | 6–8 weeks | 2–3 weeks |

| Customization | Limited by third-party constraints | Full technical support for custom alloys/sizes |

| Compliance | Meets standards, variable consistency | Consistent ISO-certified quality across all orders |

| Technical Support | Standard documentation | Dedicated engineering team for application-specific solutions |

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer strips from Luoyang Xinzhaohe.