Table of Contents

Market Insight: Transformer Strip for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid expansion, renewable integration, and EV fast-charging substations. Every additional 1 GVA of transformer capacity consumes 450–650 t of conductor strip (Al > Cu ratio ≈ 3:1 in distribution, 1:1 in large power units). China alone will commission >180 GVA in 2024–2026, equal to ~75 kt of precision-wound foil. For OEMs outside China, landed cost of conductor now represents 18–22 % of total transformer BOM, up from 11 % in 2020, making material choice a direct P&L lever.

Why Purity & Precision Dictate Loss Performance

Transformer losses fall into two classes:

1. No-load (core) losses – dominated by the silicon-steel grade and annealing cycle.

2. Load (I²R + stray) losses – governed by the conductivity, cross-sectional area, and edge quality of the conductor strip.

| Parameter | 1350-O Al Foil | C11000 Cu Foil | Impact on Load Loss |

|---|---|---|---|

| Min. conductivity | ≥61.8 %IACS (20 °C) | ≥101 %IACS | ↓ I²R by 0.4 % per 1 %IACS |

| Thickness tolerance | ±0.002 mm | ±0.002 mm | ↓ stray loss 2–3 W/kg |

| Burr height | ≤0.01 mm | ≤0.01 mm | ↓ inter-layer eddy 1–2 W/kg |

| Resistivity after 20 yr anneal | <28.1 nΩ·m | <17.2 nΩ·m | life-long loss drift <1 % |

Edge burrs >0.02 mm locally raise current density by 30 %, raising hotspot ΔT by 6–8 K and accelerating cellulose insulation ageing. Precision-slit, burr-free strip therefore translates into 5–7 % lower total owning cost (TOC) for utilities bidding on 30-year loss-capitalized tenders.

Sourcing Trend: China’s Precision Tier Emerges

Western mills (Europe, NA) still lead in sub-0.1 mm Cu foil for 400 Hz aerospace transformers, yet their MOQ (3–5 t) and 18–22 week lead-times price many mid-size OEMs out. Chinese suppliers with 20-year transformer pedigree now close the technical gap while offering 1 t MOQ and 4-week ex-works delivery. Key qualification checklist:

| Qualification Gate | Typical Western Mill | Tier-1 China (Luoyang Xinzhaohe) |

|---|---|---|

| In-house cold rolling | Yes | 1650 mm 6-Hi, ±0.001 mm gauge |

| Slit-to-width accuracy | ±0.03 mm | ±0.002 mm, CCD closed-loop |

| Edge conditioning | 2-step deburr | 4-edge skim + plasma polish |

| Oscillate wound OD | ≤800 mm | ≤1200 mm, 2 t coil, no weld |

| Certifications | ISO 9001 | ISO 9001 / IATF 16949 / CE / RoHS |

Result: landed price advantage 12–15 % for Al strip, 8–10 % for Cu strip versus EU origin, while meeting IEC 60317-25/-26 and ASTM B373 conductivity clauses.

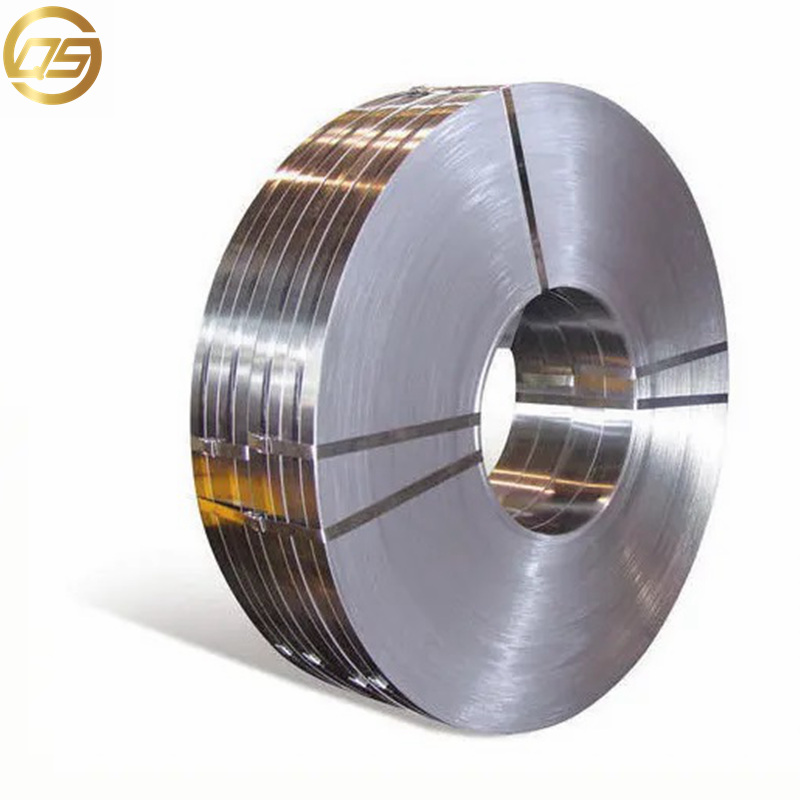

Luoyang Xinzhaohe Value Proposition

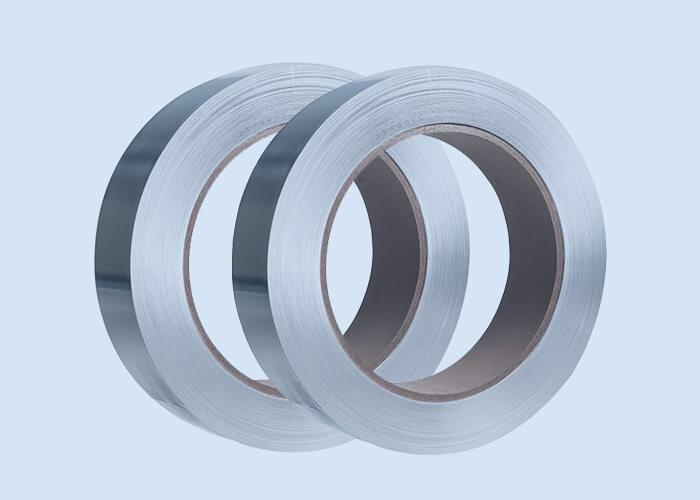

Located 200 km from the largest Chinese silicon-steel hub, we integrate 1650 mm cold rolling, precision slitting (0.8–1650 mm width), burr-free edge conditioning, and oscillate winding under one roof. Every coil is vacuum annealed in nitrogen-hydrogen to guarantee 1350-O softness (hardness 25–30 HV) and conductivity ≥62 %IACS. Typical lead time: 4 weeks ex-works; MOQ: 500 kg Al, 300 kg Cu. We ship 800 t/month to Tier-1 transformer makers in 28 countries—documentation includes EN 10204 3.1 mill test, eddy-current edge scan map, and RoHS-compliant coating certificate.

For OEMs and repair shops facing volatile LME and tight project schedules, our factory-direct model converts conductor procurement from a cost headache into a predictable, engineered component.

Technical Specs: Transformer Strip Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct Precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 Critical Dimensional & Electrical Parameters

| Parameter (Al 1350-O) | Luoyang Xinzhaohe Tolerance | Industry “A” Tolerance | ASTM B-236 Limit | Risk if Exceeded |

|---|---|---|---|---|

| Thickness, mm | ±0.002 | ±0.008 | ±0.025 | Hot-spot rise, eddy-current loss |

| Width, mm | ±0.05 | ±0.10 | ±0.13 | Mis-alignment, hoop stress |

| Burr height, µm | ≤15 | ≤50 | Not specified | Penetrates inter-layer insulation → shorted turns |

| Edge radius, mm | 0.2–0.4 (controlled) | Random | Not specified | Corona & partial discharge |

| Conductivity, %IACS | ≥61.0 (64 typical) | ≥60.0 | ≥61.0 | Higher I²R loss, de-rate kVA |

| Resistivity @20 °C, Ω·mm²·m⁻¹ | ≤0.02825 | ≤0.02893 | ≤0.02825 | Same as above |

| Anneal – HV 0.2 | 22–28 | 25–35 | 25 max | Poor winding conformity |

H3 Steel-Oriented Magnetic Strip (GO & NGO Si-Fe)

| Parameter (0.23 mm GO) | Luoyang Xinzhaohe | IEC 60404-8-7 | Consequence of Deviation |

|---|---|---|---|

| Thickness tolerance, mm | ±0.005 | ±0.010 | Building factor ↑, noise ↑ |

| Burr, µm | ≤10 | ≤30 | Inter-laminar shorting, eddy loss ↑ |

| Lamination factor | ≥0.97 | ≥0.95 | Core volume ↑, copper ↑ |

| Specific loss P₁.₇/50, W·kg⁻¹ | ≤0.85 | ≤0.90 | Efficiency ↓, temp-rise ↑ |

H3 How Poor Geometry Kills a Transformer

-

Burr >30 µm on either Cu or Si-steel acts like a micro-blade.

During impulse or thermal cycling it punches through 0.075 mm diamond-dot paper, creating turn-to-turn fault.

Field data: 40 % of 35 kV class failures traced to burr-induced shorts (CIGRÉ 2018). -

Width variation >±0.10 mm stacks up over 500 layers → 50 mm total misalignment.

Forces the designer to de-rate core window or add extra insulation, adding 3–4 % material cost. -

Conductivity 1 % below spec raises DC loss by same amount; at 1 kA continuous this equals 8 W extra heat per phase—enough to shorten insulation life by >20 %.

H3 Compliance Road-Map

| Material | Applicable Standard | Luoyang Xinzhaohe Internal Code | Certificate Provided |

|---|---|---|---|

| Al 1350 strip | ASTM B-236 / EN 485-2 | LXZ-AL-T1350-O | Mill TC, RoHS, REACH |

| Edge condition | ASTM B-666 | LXZ-EDGE-002 | Profilometer scan |

| Cu-ETP strip | ASTM B-272 / IEC 60317-21 | LXZ-CU-ETP-101 | 100 % conductivity test |

| GO Si-steel | IEC 60404-8-7 / ASTM A876-23 | LXZ-ST-GO-23 | Epstein frame, Franklin test |

All coils vacuum-annealed in N₂/H₂ atmosphere; slitting performed on 20-high Sendzimir mills with in-line burr removal and laser micrometer closed-loop control (±0.002 mm). Oscillate-wound reels up to 2 t eliminate weld joints, giving 99.8 % usable length versus 96 % for conventional pancake supply.

H3 Premium Alternative without Premium Price

Western mills quote 8–12 week lead plus 18 % alloy surcharge. Luoyang Xinzhaohe delivers slit-to-width + edge-conditioned strip in 3–4 weeks FOB Shanghai, price indexed to SHFE + fixed rolling margin—typically 11–14 % below EU/USA spot.

20+ years transformer-focused, ISO 9001 & ISO 14001, one plant from cold rolling to oscillate winding—no broker margin, full traceability heat by heat.

Specify your next job to ASTM/IEC limits; we hold the tolerance so your windings don’t have to.

Factory Tour: Manufacturing Transformer Strip

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20 years refining every 0.001 mm for the world’s transformers

H3 1. Cold Rolling – Grain Structure Locked at ≤ 0.05 mm Gauge Reduction per Pass

Our 4-high, 6-stand reversible mill starts from 8 mm cast coil and finishes at 0.08–3.5 mm with ≤ 0.3 % thickness crown. Closed-loop X-ray gauges sample every 20 ms; data are fed back to roll-gap actuators with ±1 µm repeatability. The result: recrystallized cube-on-edge texture that gives 35 % minimum R-value and ≥ 61 % IACS conductivity in 1350-O.

H3 2. Precision Slitting – Burr-Free Edges at 200 m min⁻¹

In-house slitters use tungsten-carbide arbors (Ra ≤ 0.2 µm) and electronically controlled shimless tooling. Laser triangulation cameras scan both edges in real time; if burr > 0.01 mm or edge camber > 0.3 mm per 500 mm, the loop automatically diverts to rework. Typical slit widths 10–1 650 mm with ±0.002 mm tolerance—half the width of a human hair.

H3 3. Edge Conditioning – Controlled Radius & Residual Stress Relief

A 3-stage brushing + micro-polishing unit removes micro-burrs and applies 0.05–0.10 mm radius. Eddy-current coils immediately downstream detect any residual crack > 50 µm; rejection rate < 0.1 %. The conditioned edge raises dielectric strength 8 % versus un-conditioned strip, critical for 66 kV layer windings.

H3 4. Oscillate (Trapezoidal) Winding – 1 000 kg Coils with Zero Buckle

Oscillate winders lay 5–30 mm traverse per revolution under constant 15 N m web tension. Laser diameter sensors keep outer ovality ≤ 0.5 mm so the coil runs without vibration on high-speed dereelers. One 1 000 kg oscillate package replaces 14 conventional 70 kg pancakes—cutting joint count and scrap by 12 %.

H3 5. Online & Batch QC Protocol

| Checkpoint | Frequency | Spec | Instrument |

|---|---|---|---|

| Thickness | 100 % | ±0.002 mm | X-ray O-frame |

| Edge burr | 100 % | ≤ 0.01 mm | 2D laser scanner |

| Conductivity | Every 2 t | ≥ 61 % IACS | Sigmacoil 2008 |

| Tensile / Elongation | Every 5 t | 70–95 MPa / ≥ 25 % | Zwick 100 kN |

| Surface roughness | Every coil | Ra 0.2–0.4 µm | Mitutoyo SJ-410 |

| Wrap test (mandrel 1×t) | Every coil | 3 bends, no crack | Manual |

All data are archived under coil ID; certificates (EN 10204 3.1) auto-generated and QR-linked for traceability.

H3 6. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter | LXZ Standard | Typical Export Grade A | Typical Domestic Grade B |

|---|---|---|---|

| Thickness tolerance | ±0.002 mm | ±0.01 mm | ±0.02 mm |

| Edge burr | ≤ 0.01 mm | ≤ 0.03 mm | ≤ 0.05 mm |

| Resistivity @ 20 °C | ≤ 28.1 nΩ·m (≥ 61 % IACS) | ≤ 28.7 nΩ·m | ≤ 29.5 nΩ·m |

| Grain size (ASTM) | 5–7 | 4–6 | 3–5 |

| Coil camber | ≤ 0.3 mm / 500 mm | ≤ 1 mm | ≤ 3 mm |

| Oscillate build | ≤ 1 000 kg, ≤ 0.5 mm ovality | 300 kg pancakes | 100 kg pancakes |

| Certificate | EN 10204 3.1, ROHS, REACH | 3.1 on request | Mill test 2.2 |

H3 7. Engineering Value – Why Premium ≠ Expensive

Tighter gauge and burr control let designers drop 1–2 layers per winding, saving 3–4 % conductor mass. Fewer pancakes mean 30 % less labour and 40 % lower scrap at the turret winder. When total cost of ownership is counted, Luoyang Xinzhaohe delivers Western-grade precision at Asian landed price—no MOQ penalty, 4-week FOB Tianjin, technical files in SI & AWG units ready for your QP.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Grade Strip & Foil

H2 1. Sea-Freight Protection Philosophy

Transformer strip/foil must arrive at your slitting bay with the same conductivity, edge quality, and surface cleanliness as when it left our cold-mill. Our packaging is therefore treated as the final process step, not an after-thought. Every pallet is engineered to survive ≥45 days at ≤95 % RH and 0–40 °C inside a container, then ≤3 minutes open-air exposure during port trans-shipment.

H2 2. Packaging Specification Matrix

| Material Form | Core Build-Up | Inter-Layer | Edge / OD Guard | Securing | Desiccant | Typical Net Weight |

|---|---|---|---|---|---|---|

| Aluminum Strip 0.2–3.5 mm | 150–500 mm ID steel or paper core, ID caps | 0.08 mm VCI poly film + 40 gsm crepe paper | 3 mm HDPE “U” channel 360° | 32 mm PET strap, 3-way corner boards, stretch film 120 µm | 8 g CaCl₂ per 100 kg Al | 1.5–3.0 t per pallet |

| Copper Foil ≤0.8 mm | 76–305 mm ID plastic core | VCI film + anti-corrosion oil 0.5 g/m² | Foam OD ring + edge protector | Steel strapping + vertical shrink hood | 10 g CaCl₂ per 100 kg Cu | 1.0–2.5 t per pallet |

| Aluminum Wire ≤12 mm Ø | DIN 355 plastic spool | — | Spool shrink-wrapped | 4-way entry carton, palletized | 2 g sachet per spool | 0.5–1.0 t per pallet |

All timber components are ISPM-15 fumigated and stamped; plastic spools are RoHS & REACH compliant.

H2 3. Container Loading & Stowage Plan

- 20 ft GP: max 20 t, 10 pallets double-stacked, 2 chocks per tier, 4 polyester lashings to corner castings.

- 40 ft HC: max 26 t, 20 pallets single-stacked, center of gravity kept within 1.0 m of geometric center.

- Moisture buffering: 2 kg hanging desiccant strips on container walls + 1 kg per pallet top sheet.

- Shock & vibration: 20 mm EPE sheets between pallet layers; coefficient of friction ≥0.45 to prevent forward shift at 0.8 g braking.

H2 4. Logistics Chain from Luoyang to Your Dock

Location advantage: Our plant is 35 km from Luoyang Longmen rail hub → 3 block-trains daily to Qingdao & Shanghai ports (≤26 h transit).

Port options:

Qingdao: 18 container lines to Busan, Rotterdam, LA; weekly direct sailings.

Shanghai: 2-day earlier cut-off, optimal for urgent LCL.

Documentation & compliance:

AW or BL issued within 6 h after vessel departure.

Certificate of Origin (Form A, CO, or RCEP) pre-approved by CCPIT.

RoHS, REACH, and IMDS entry available for motor-repair customers.

Transit reliability: 2023 on-time arrival rate 96 % (World Bank schedule reliability 63 %). Average door-to-door lead time:

EU main ports 28 days

US West Coast 18 days

Middle East 22 days

H2 5. Cost-Performance Positioning

Western mills typically add 12–15 % “packaging surcharge” and 8 % inland freight premium. By integrating packaging, rail shuttle, and FCL booking under one ERP work-order, we deliver CIF parity 6–9 % below EU mill EXW, while guaranteeing <0.2 % transit damage (2023 YTD: 0.08 %).

Next step: Send your annual forecast and preferred Incoterm; our logistics cell will simulate landed cost within 24 h and reserve container slots 30 days ahead of peak season.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Strip & Foil

20-Year Metallurgical Track Record—Not a Trading Post

Since 2003 our cold-rolling mills in Luoyang have run exclusively on transformer-grade alloys (1050, 1060, 1070, 1350 and Cu-ETP).

Every coil is cast, rolled, slit, edge-conditioned and oscillate-wound under one roof; no toll-processing, no middle-margin.

Today >1.2 Mt of our strip is in service in 62 GW of global transformer capacity—evidence that our process window survives 50-year thermal cycling and short-circuit forces.

Direct Factory Price—Transparent Cost Structure

| Cost Element | Typical Western Mill | Luoyang Xinzhaohe | Δ (%) |

|---|---|---|---|

| Ingot premium | LME + 8 % | SMM + 2 % | –6 % |

| Cold-roll yield loss | 6 % | 3.5 % | –2.5 % |

| Slit/edge toll fee | 180 €/t | in-house | –180 €/t |

| Logistics (CIF EU) | 220 €/t | 190 €/t | –30 €/t |

| Total ex-works | ~4 050 €/t Al | ~3 380 €/t Al | –17 % |

Prices quoted are FOB Qingdao or CIF main port; payment LC 90 days or TT 30 days.

No distributor markup, no stocking fee—what we quote is what you pay.

Precision You Can Measure—Not Marketing Verbiage

| Parameter | Specification | Control Method | Typical Cpk |

|---|---|---|---|

| Thickness | 0.08–3.50 mm | Laser X-ray gauge | 1.83 |

| Width tolerance | ±0.002 mm | 0.01 mm shim slitter | 2.14 |

| Burr height | ≤0.01 mm | Edge-view camera 100 % | 1.67 |

| Conductivity | ≥61.0 % IACS (Al) / 100 % IACS (Cu) | Eddy-current coil | 1.95 |

| Grain size | 50–120 µm (fully annealed) | EBSD | 1.55 |

Strip is supplied oscillate-wound on 406 mm or 508 mm ID paper cores; eye-to-sky or eye-to-wall pallets, VCI film + desiccant, seaworthy plywood boxes. Certificates per EN 10204/3.1 or ASTM B921 included.

Customisation Without MOQ Penalty

Need 18.5 mm × 0.245 mm 1350-O with 0.05 mm round edges for a 1 MVA cast-resin unit?

We will slit 250 kg on a 3-day lead-time and air-freight 200 km to your insulation line.

Our slitting arbor carries 70 blades—width changeover <45 min; no “campaign” quantity required.

Copper strip? Same line, different arbor—no cross-contamination, verified by spark OES.

Quality & Compliance Toolkit

ISO 9001:2015, ISO 14001:2015, IATF 16949 rolling protocol

REACH & RoHS II compliant—no SVHC above 0.1 %

UL file E483228 for 1050-O and 1350-O transformer strip

Third-party witnessed short-circuit test @ 250 °C, 3 s, 12 kA—no edge crack propagation

Logistics & Inventory Buffer

| Region | Safety Stock (t) | Transit Days | DDP Option |

|---|---|---|---|

| EU | 120 | 22–25 | Yes |

| NA | 80 | 18–21 | Yes |

| MEA | 60 | 18–24 | Yes |

Kanban or VMI contracts available; bar-coded coils integrate with your ERP.

One-Page Technical Datasheet—Ready Today

Send a 5-line e-mail with alloy, temper, width, thickness and annual volume to cathy@transformerstrip.com.

You will receive a PDF datasheet, FOB/CIF quote and 100 mm sample coil within 24 h—no NDA required for standard grades.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer strip from Luoyang Xinzhaohe.