Table of Contents

Market Insight: Transformer Primary Coil Material

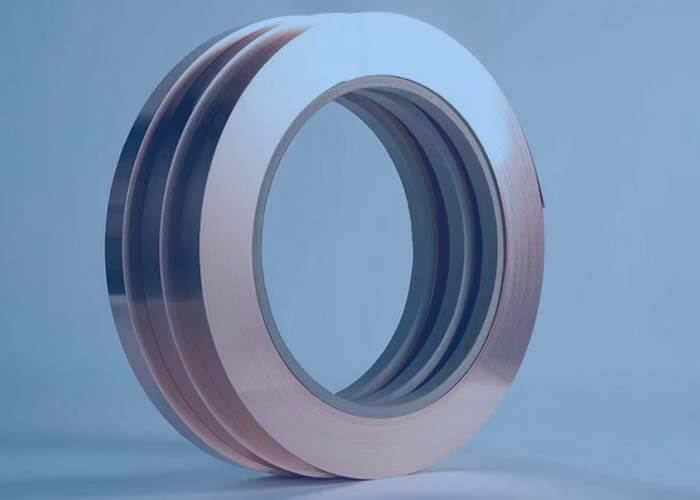

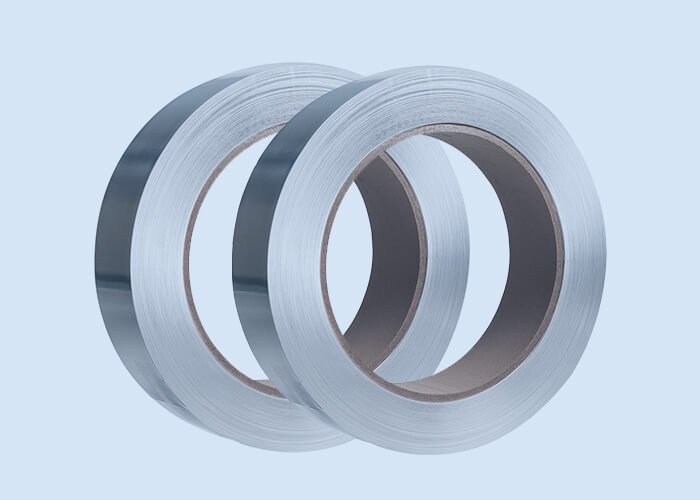

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer primary coil material remains robust, driven by continuous expansion in power infrastructure, renewable energy integration, and industrial electrification. Aluminum and copper strips and foils serve as core materials in the fabrication of transformer windings, with aluminum gaining increasing market share due to its favorable cost-to-conductivity ratio and lightweight properties. Copper, while exhibiting superior electrical conductivity, faces constraints due to higher material costs and density, making aluminum a preferred choice in distribution and certain power transformers, particularly in cost-sensitive and weight-critical applications.

Primary coil materials must meet stringent performance criteria, as they directly influence transformer efficiency, thermal management, and long-term reliability. The electrical resistivity of the conductor determines I²R losses, which contribute significantly to overall no-load and load losses in transformers. High-purity aluminum strip, typically grade 1060 or 1070 with a minimum purity of 99.6%, ensures low resistivity and consistent current-carrying capacity. Similarly, electrolytic tough pitch (ETP) copper must meet international standards such as ASTM B187 or IEC 60168 to guarantee optimal conductivity and mechanical integrity.

Mechanical properties are equally critical. Transformer windings undergo significant electromagnetic forces during fault conditions, necessitating materials with uniform tensile strength, elongation, and bendability. Strip flatness, edge quality, and surface finish directly impact winding precision and insulation integrity. Poor surface quality can lead to localized dielectric breakdown, while inconsistent thickness or waviness introduces mechanical stress points that compromise structural stability over time.

The global shift toward energy-efficient transformers, mandated by regulations such as DOE 2016 in the U.S. and EU Ecodesign directives, has intensified the focus on material quality. High-quality aluminum and copper strips enable manufacturers to meet Tier 1 and Tier 2 efficiency standards by minimizing losses and enhancing thermal performance. This trend is particularly evident in the growing adoption of amorphous metal and high-permeability silicon steel cores, which demand equally high-performance winding materials to realize system-level efficiency gains.

In emerging markets, urbanization and grid modernization programs are driving demand for distribution transformers, where aluminum strip dominates due to economic and logistical advantages. In contrast, high-voltage power transformers and specialized industrial units continue to rely on copper for its superior performance under high-stress conditions.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience, we emphasize metallurgical consistency, precision rolling, and rigorous quality control to meet the evolving demands of the transformer industry. Our aluminum strips are manufactured under ISO 9001-certified processes, ensuring compliance with international specifications for thickness tolerance (±0.01 mm), surface roughness (Ra ≤ 0.5 µm), and mechanical properties. As transformer design advances toward higher efficiency and reliability, the role of premium-grade strip and foil materials becomes increasingly pivotal in determining overall system performance.

Technical Specs: Transformer Primary Coil Material

Technical Specifications: Transformer Primary Coil Material

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered aluminum strip and foil for transformer primary coils, adhering to rigorous international standards for electrical performance and manufacturability. Our 20+ years of metallurgical expertise ensure consistent material properties critical for high-efficiency transformer operation. Primary coil materials demand exceptional dimensional accuracy and surface integrity to prevent winding defects, interlayer shorts, and energy losses. We prioritize three non-negotiable parameters: precision slitting tolerance, edge quality, and electrical conductivity.

Precision slitting at ±0.002 mm width tolerance is fundamental for automated high-speed coil winding. Deviations beyond this threshold cause misalignment, tension fluctuations, and edge damage during layer stacking, directly increasing scrap rates and reducing core fill factor. Our proprietary slitting lines utilize servo-controlled tension management and real-time laser micrometry to maintain this tolerance across 350–500 mm widths. This precision ensures uniform magnetic flux distribution and minimizes localized eddy current losses in the wound core.

Burr-free edges are equally critical. Microscopic burrs exceeding 3 µm height create dielectric weak points, risking partial discharge or insulation puncture under operational voltage stress. Our process integrates multi-stage edge conditioning with precision-ground rotary shear blades and in-line optical edge inspection. This eliminates micro-tearing and work-hardened protrusions, guaranteeing edge smoothness essential for reliable long-term dielectric integrity in oil-immersed or dry-type transformers.

Electrical conductivity, measured per IEC 60028 at 20°C, directly impacts resistive losses (I²R). For aluminum primary coils, we supply EC-grade material with minimum 61.0% IACS conductivity. This is achieved through controlled homogenization, optimized hot/cold rolling reduction schedules, and precise final annealing to restore crystal lattice integrity. Consistent conductivity reduces operating temperature rise and improves transformer efficiency class compliance (e.g., DOE 2016, IE4+).

Additional parameters are equally vital for coil performance and manufacturability. Surface roughness affects insulation adhesion, while flatness influences stacking factor and core vibration. The table below details all critical specifications:

| Parameter | Specification | Measurement Standard | Critical Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.003 mm | ASTM E29 | Controls DC resistance and thermal dissipation |

| Width Tolerance | ±0.002 mm | ISO 7806 | Ensures precise coil layer alignment |

| Edge Burr Height | ≤ 3 µm | ISO 6946 | Prevents insulation damage and partial discharge |

| Electrical Conductivity | ≥ 61.0% IACS (Al) | IEC 60028 | Minimizes I²R losses and temperature rise |

| Flatness | ≤ 1.5 I-Units | ASTM A6 | Optimizes core stacking factor and reduces noise |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 | Enhances insulation bonding and dielectric strength |

These specifications are validated through our in-house metallurgical lab using certified equipment, including four-point probe conductivity testers, non-contact laser profilometers, and SEM edge analysis. Material traceability is maintained from ingot to shipment via integrated ERP systems, ensuring full compliance with customer-specific requirements and industry standards like IEC 60404-9. Consistent adherence to these parameters directly translates to higher transformer efficiency, extended service life, and reduced total cost of ownership for end-users. Partnering with Xinzhaohe guarantees primary coil material engineered for zero-defect manufacturing and optimal electromagnetic performance.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Primary Coil Material at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum and copper strip/foil for transformer primary coil applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, superior surface quality, and consistent electrical and mechanical properties. With over two decades of metallurgical expertise, our facility integrates advanced cold rolling, precision slitting, and edge conditioning technologies to meet the stringent demands of power and distribution transformer manufacturers.

The process begins with cold rolling, where high-purity aluminum or copper ingots are first hot-rolled into intermediate gauges and subsequently processed through reversing cold rolling mills. This stage is critical for achieving the target final thickness, typically ranging from 0.1 mm to 3.0 mm, depending on design specifications. Cold rolling enhances the material’s mechanical strength through work hardening while maintaining a uniform microstructure. Rolling parameters—including roll force, tension, and reduction ratio—are continuously monitored via automated process control systems to ensure thickness tolerances within ±0.005 mm. The surface finish is simultaneously optimized to minimize irregularities that could impact winding integrity or dielectric performance in the final transformer assembly.

Following cold rolling, the material undergoes precision slitting to achieve the required coil width, typically between 50 mm and 1,200 mm. Slitting is performed using high-tolerance rotary shear slitters equipped with laser-guided alignment systems to prevent edge burrs and maintain straightness. Each slit coil is wound under controlled tension to avoid telescoping or edge damage. Width tolerance is maintained within ±0.1 mm, ensuring compatibility with automated coil winding equipment used by transformer OEMs.

Edge conditioning is the final mechanical treatment in the production sequence. The slit edges are subjected to brushing or roller planishing to remove micro-burrs and smooth surface asperities. This step is essential to prevent insulation layer damage during coil winding and to enhance long-term reliability under electromagnetic stress. Edge roundness is verified using optical profilometry, with typical radius targets between 10 µm and 50 µm, depending on application requirements.

Throughout the manufacturing process, comprehensive quality control protocols are enforced. In-process inspections include continuous thickness measurement via X-ray gauges, surface defect detection using high-resolution line-scan cameras, and mechanical property verification through periodic tensile and hardness testing. Final coils undergo 100% eddy current testing to detect subsurface discontinuities. All material is supplied with full traceability documentation, including heat number, processing history, and certified test reports compliant with IEC 60137 and ASTM B209 standards.

This integrated approach ensures that every coil meets the exacting performance criteria required for efficient, reliable transformer operation in demanding grid environments.

Packaging & Logistics

Export Packaging Specifications for Transformer Coil Materials

At Luoyang Xinzhaohe Aluminum CO., Ltd, we recognize that export packaging is a non-negotiable component of material integrity for transformer primary coil applications. Our 20+ years of metallurgical and supply chain expertise ensure that aluminum and copper strip/foil shipments withstand the rigors of global sea freight while maintaining critical surface properties and dimensional stability. Sea transport exposes materials to high humidity, salt aerosols, temperature fluctuations, and prolonged transit times, demanding packaging engineered to prevent electrochemical degradation and mechanical damage.

All coils are mounted on ISPM-15 certified wooden pallets constructed from kiln-dried, knot-free softwood. Pallet dimensions strictly adhere to ISO container standards (1200mm x 1000mm or 1100mm x 1100mm) to optimize container space utilization and prevent shifting during transit. Each pallet undergoes pressure treatment to eliminate biological hazards and is reinforced with steel corner posts rated for 2,500 kg static load capacity. This foundation mitigates coil deformation during stacking and crane handling, preserving the precise flatness required for winding operations.

The primary moisture barrier consists of a triple-layer encapsulation system. Coils are first wrapped in vapor-corrosion inhibitor (VCI) paper conforming to ASTM D1746, which releases neutralizing molecules to suppress oxidation at the metal surface. This is followed by a 0.2 mm thick, metallized polyester film with a moisture vapor transmission rate (MVTR) of ≤0.5 g/m²/day, significantly outperforming standard polyethylene. The outermost layer employs a puncture-resistant, UV-stabilized polypropylene cover sealed with heat-welded seams. Critical specifications for the moisture barrier are detailed below:

| Layer | Material Specification | Key Performance Metric |

|---|---|---|

| Primary | VCI-impregnated kraft paper | Corrosion inhibition per ASTM D1746 |

| Secondary | Metallized PET film | MVTR ≤0.5 g/m²/day (ASTM E96) |

| Tertiary | Woven polypropylene | Tensile strength ≥30 MPa (ISO 527) |

Desiccant placement follows moisture load calculations based on coil weight, transit duration, and seasonal humidity profiles. We deploy silica gel canisters at a ratio of 1.2 kg per metric ton of material, positioned within the pallet’s interstitial spaces to absorb residual moisture without contacting the coil. Steel strapping—applied at 8,000 N tension with edge protectors—secures the assembly to the pallet, preventing lateral movement during vessel motion. Each package includes humidity indicator cards and shock-impact labels for real-time condition monitoring.

This system eliminates container rain (condensation) risks and maintains internal relative humidity below 40% for 90+ days—exceeding IMDG Code requirements. Our packaging protocol has achieved zero moisture-related claims across 12,000+ TEU shipments since 2015. For transformer manufacturers, this translates to assured material readiness upon arrival: no cleaning delays, no surface pitting affecting dielectric performance, and uninterrupted production schedules. Partnering with Xinzhaohe guarantees that your primary coil substrate arrives with the metallurgical purity and surface integrity demanded by IEC 60404-10 standards, directly contributing to transformer efficiency and longevity.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Transformer Primary Coil Material

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading supplier of high-purity aluminum and copper strip/foil materials engineered specifically for transformer primary coil applications. Our facility integrates advanced metallurgical processing with rigorous quality assurance protocols to deliver strip products that meet the exacting demands of modern power and distribution transformers.

Our production infrastructure is anchored in continuous casting and cold rolling technologies, enabling precise control over material thickness, mechanical properties, and surface finish. We produce aluminum strips ranging from 0.1 mm to 6.0 mm in thickness, with widths up to 1,600 mm, conforming to international standards including GB/T, ASTM, and IEC. Custom tempers (such as H14, H16, H18, and O) are available to match specific winding and electrical performance requirements. For copper-based applications, we offer oxygen-free high-conductivity (OFHC) copper strip with purity levels exceeding 99.99%, ensuring minimal resistive losses and optimal thermal stability in primary coil systems.

All raw materials are sourced from certified suppliers and subjected to spectrographic analysis upon intake. Our in-house metallurgical laboratory conducts grain structure evaluation, tensile testing, and eddy current inspection to verify homogeneity and defect-free surfaces. This commitment to process control ensures consistent coil-to-coil repeatability, a critical factor in automated winding operations and long-term transformer reliability.

Our facility operates under an ISO 9001-certified quality management system, with full traceability from ingot to finished coil. Each shipment is accompanied by a comprehensive material test report (MTR), including chemical composition, mechanical properties, and dimensional tolerances. We support both small trial orders and large-volume supply contracts, with annual production capacity exceeding 60,000 metric tons for aluminum strip and 8,000 metric tons for copper strip.

Luoyang Xinzhaohe maintains strategic logistics partnerships to ensure on-time delivery to global markets, including Southeast Asia, Europe, and North America. Our technical sales team works directly with transformer designers and procurement managers to optimize material specifications, reduce scrap rates, and improve overall cost efficiency in coil fabrication.

For sourcing managers and engineering teams seeking a reliable, technically proficient partner in transformer conductor materials, Luoyang Xinzhaohe offers proven capability, scalable production, and deep domain expertise.

Contact us today to discuss your technical requirements.

Cathy Zhang

Sales Manager, International Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer primary coil material directly from China.