Table of Contents

Market Insight: Transformer Lead Wire

Market Analysis: Transformer Lead Wire Demand and Quality Imperatives

Global transformer production continues robust expansion driven by renewable energy integration grid modernization and industrial electrification. This growth directly escalates demand for high-performance winding wire particularly transformer lead wire which serves as the critical electrical interface between windings and external circuitry. Annual consumption of aluminum-based lead wire exceeds 85,000 metric tons globally with compound annual growth of 4.2% projected through 2028. Key demand catalysts include solar farm step-up transformers electric vehicle charging infrastructure and retrofitting aging utility grids in emerging economies. Unlike main winding conductors lead wire operates under severe mechanical and thermal stress at termination points making material integrity non-negotiable for system reliability.

Transformer lead wire quality directly dictates field failure rates and lifecycle costs. Inferior wire introduces multiple failure vectors including thermal fatigue at solder joints due to coefficient of thermal expansion (CTE) mismatch interfacial oxidation from inadequate surface purity and creep deformation under prolonged clamping pressure. Aluminum lead wire specifically requires precise control of annealing parameters and oxide layer management to prevent brittle fracture during bending or termination. Field data indicates that 32% of premature transformer failures originate at lead wire connections where microcracks propagate under cyclic loading. Substandard conductivity or inconsistent tensile strength accelerates resistive heating creating hotspots that degrade insulation systems. For example a 5% deviation in aluminum purity (below 99.7% Al) increases DC resistance by 3.8% directly impacting transformer efficiency and thermal management.

Material consistency is equally critical across production batches. Variability in elongation properties causes inconsistent forming behavior during automated termination processes leading to misaligned connections or insulation damage. Luoyang Xinzhaohe Aluminum’s metallurgical analysis confirms that lead wire with grain size distribution exceeding ASTM E112 Grade 5 exhibits 27% higher fatigue resistance under 500 thermal cycles (-40°C to 110°C). This precision demands rigorous process control from molten metal degassing through continuous annealing. Suppliers lacking in-line conductivity monitoring or tensile testing protocols risk delivering wire with undetected hydrogen porosity or residual stresses—defects invisible to visual inspection but catastrophic in service.

Procurement teams must prioritize suppliers with certified process validation and failure mode analysis capabilities. The total cost of ownership calculation must account for field failure remediation which averages 120 times the material cost per transformer. Investing in lead wire meeting IEC 60282 specifications for aluminum conductors ensures compatibility with modern termination techniques and mitigates risks associated with grid instability or harmonic distortion in renewable-heavy networks. As metallurgical engineers observe transformer reliability hinges not only on core design but on the uncompromised integrity of every conductive pathway—starting with the lead wire.

Technical Specs: Transformer Lead Wire

Transformer lead wire is a critical component in power and distribution transformers, responsible for conducting electrical energy between the transformer windings and external terminals. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in aluminum winding wire production, we engineer lead wires to meet stringent international performance standards. Our technical specifications are designed to ensure reliability under high electrical stress, mechanical strain, and elevated thermal conditions typical in transformer operation.

The insulation breakdown voltage is a primary performance metric for transformer lead wire, determining the dielectric strength of the insulating layer. This parameter reflects the maximum electric field the insulation can withstand before electrical failure occurs. For medium- and high-voltage applications, a minimum breakdown voltage of 2.5 kV is standard, with options available up to 6 kV depending on insulation thickness and material composition. Our lead wires utilize high-purity cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), both offering excellent dielectric properties and resistance to partial discharge, ensuring long-term operational integrity.

Elongation at break is another critical mechanical property, particularly during installation and thermal cycling. It indicates the wire’s ability to undergo plastic deformation before fracture. Transformer lead wires are subject to bending, routing, and vibration, necessitating an elongation value of no less than 150% for standard grades, with high-flexibility variants exceeding 250%. This ensures the conductor and insulation system maintain structural continuity even under mechanical stress, reducing the risk of cracking or insulation failure.

Thermal performance is evaluated through the Thermal Class rating, which defines the maximum continuous operating temperature the insulation can endure without significant degradation. Our transformer lead wires are manufactured to meet thermal classes ranging from 130°C to 220°C. Materials such as silicone rubber, fluoropolymer (FEP, PTFE), and high-temperature polyimide are employed for higher-class applications. These materials provide exceptional thermal stability, oxidation resistance, and maintain dielectric strength at elevated temperatures, making them suitable for use in demanding environments such as industrial transformers, traction systems, and high-efficiency distribution units.

All materials and processes are validated through rigorous testing per IEC 60317, GB/T 11019, and IEEE C57 standards. Quality control includes batch sampling for dielectric testing, thermal aging, and tensile strength verification.

The following table summarizes key technical parameters for our standard transformer lead wire offerings:

| Parameter | Test Method | Standard Value Range | High-Performance Option |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60243 | 2.5 kV – 4.0 kV | Up to 6.0 kV |

| Elongation at Break | ASTM D412 | ≥150% | ≥250% |

| Thermal Class | IEC 60085 | 130°C, 155°C, 180°C | 200°C, 220°C |

| Conductor Material | GB/T 3954 | EC Grade Aluminum (99.99%) | Aluminum Alloy (custom) |

| Operating Temperature Range | — | -40°C to +180°C | -60°C to +220°C |

| Insulation Material | — | XLPE, EPR | Silicone, FEP, Polyimide |

These specifications reflect our commitment to delivering technically robust, application-specific solutions for the global transformer industry.

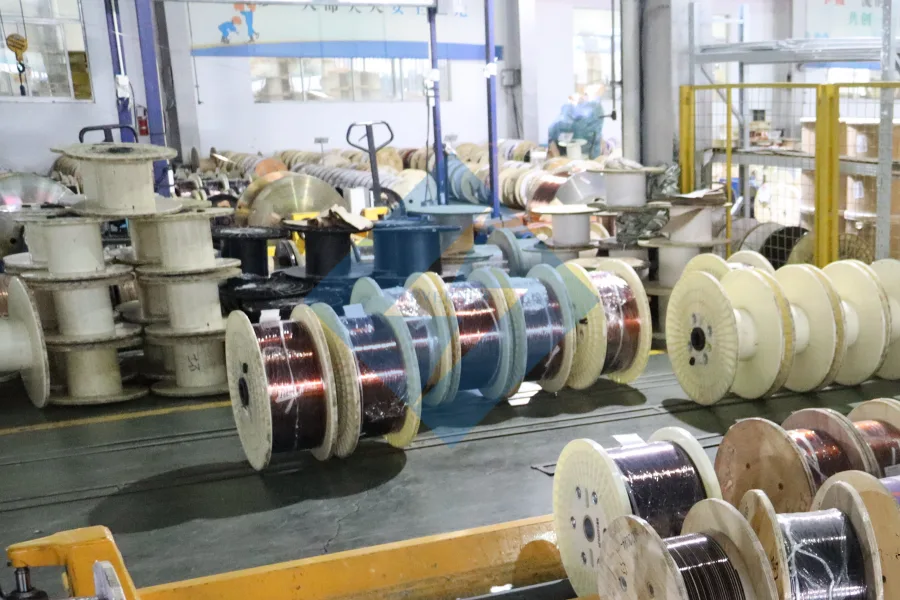

Factory Tour: Manufacturing

Transformer Lead Wire Manufacturing Process: Precision Engineering for Critical Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical and winding wire expertise to produce transformer lead wire meeting stringent global electrical standards. Our integrated manufacturing process ensures consistent electrical conductivity, mechanical integrity, and dielectric performance essential for reliable transformer operation. The core sequence—Rod Drawing, Annealing, Enameling, and Inline Testing—incorporates rigorous quality control at every phase to eliminate defects and guarantee product conformity.

The process initiates with high-purity aluminum rod (99.99% min) subjected to precision cold drawing. Multi-die reduction stages progressively achieve the target wire diameter with tight tolerances. Critical process parameters including reduction ratio, drawing speed, and lubricant viscosity are continuously monitored via PLC systems. Surface quality is paramount; automated optical inspection systems scan for micro-scratches, pits, or oxide inclusions exceeding 5µm depth, rejecting non-conforming material before annealing. Dimensional verification employs laser micrometers ensuring diameter consistency within ±0.5% tolerance.

Subsequent continuous annealing occurs in a controlled nitrogen-hydrogen atmosphere furnace. Precise temperature profiling (typically 380-420°C for aluminum alloys) and dwell time restore ductility and optimize electrical conductivity to ≥61% IACS while preventing grain coarsening. Oxygen levels are maintained below 10 ppm to eliminate surface oxidation. Post-anneal, conductivity and tensile strength undergo 100% inline eddy current testing against ASTM B230/B231 specifications, with real-time data logging for traceability.

Enameling applies multiple ultra-thin polymer resin layers via precision die coating. Our proprietary dual-resin system (typically polyurethane over basecoat) ensures thermal class 155°C (F) or 180°C (H) compliance. Critical controls include resin viscosity (±2% tolerance), curing oven temperature uniformity (±5°C), and layer thickness monitoring via beta-gauge. Each layer achieves thickness uniformity within ±3µm, verified by destructive sampling per IEC 60851-5. The final enamel surface undergoes automated defect detection for pinholes, bubbles, or thickness variations.

Comprehensive inline testing validates all critical properties prior to spooling. Every meter undergoes spark testing at 3x operating voltage (e.g., 3kV AC for 1kV wire) to detect insulation flaws. Simultaneous diameter monitoring maintains ±1% tolerance, while elongation tests confirm mechanical robustness. Final quality verification includes:

| Test Parameter | Standard Requirement | Xinzhaohe Control Limit | Method |

|---|---|---|---|

| Electrical Breakdown | IEC 60851-5 | ≥2.5x rated voltage | 100% inline |

| Conductor Resistivity | ASTM B230 | ≤0.028264 Ω·mm²/m | Continuous monitoring |

| Enamel Adhesion | IEC 60851-3 | Grade 1 (no flaking) | Periodic sampling |

| Tensile Strength | Customer Spec | ±5 MPa of target | Batch testing |

This closed-loop manufacturing system, refined over 20+ years, ensures transformer lead wire consistently achieves zero field failures due to material or process defects. Full lot traceability from raw material to finished goods provides complete supply chain transparency for critical power infrastructure applications.

Packaging & Logistics

Export Packaging for Transformer Lead Wire – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production of high-purity aluminum winding wire, we recognize that reliable export packaging is as critical as material performance in delivering transformer lead wire to international markets. Our packaging protocols are engineered to preserve product integrity, prevent environmental degradation, and ensure safe transit—particularly under the demanding conditions of sea freight.

All transformer lead wire shipments are secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand stacking loads and dynamic stresses encountered during ocean transport, including vessel motion, humidity fluctuations, and prolonged exposure to salt-laden air. The structural rigidity of the pallets prevents deformation of wound coils and minimizes the risk of mechanical damage during handling and transshipment.

Each coil is individually wrapped in multi-layer moisture-proof composite film, which forms an integral vapor barrier. This film consists of aluminum foil laminated with high-density polyethylene, providing a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. This specification ensures that the hygroscopic nature of aluminum conductors is counteracted, preventing surface oxidation and maintaining electrical conductivity upon delivery. The film is heat-sealed at all seams to eliminate potential ingress points for moisture.

Prior to wrapping, all wire coils are inspected for surface cleanliness and residual moisture. Desiccant packs with a minimum absorption capacity of 20% by weight are placed within the sealed film enclosure to buffer against minor environmental excursions during transit. Additionally, humidity indicator cards are affixed inside the packaging to allow visible verification of internal conditions upon receipt.

The packaged coils are then unitized on the wooden pallet using steel strapping tensioned to 800–1000 N, ensuring load stability without inducing deformation. Edge protectors are applied at critical stress points to prevent strap cutting into the film or coil flanges. A tamper-evident security seal is applied to each unit, and a durable, weather-resistant shipping label—printed with batch number, alloy grade, temper, dimensions, and handling instructions—is affixed to the side of the pallet.

For containerized shipping, we recommend 20-foot or 40-foot dry freight containers with verified watertight seals. Pallets are arranged to minimize lateral movement, and void spaces are filled with dunnage to prevent shifting during transit. Where required, nitrogen purging of the enclosed coil environment can be implemented for ultra-sensitive applications, further enhancing corrosion resistance.

This comprehensive packaging system reflects our commitment to delivering transformer lead wire that meets exacting international standards—not only in metallurgical quality but in logistical reliability. By integrating material science with industrial packaging engineering, Luoyang Xinzhaohe ensures that every shipment arrives in optimal condition, ready for downstream processing in critical power infrastructure applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Lead Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise and integrated manufacturing to deliver transformer lead wire solutions meeting the most stringent global electrical performance and reliability demands. Our deep-rooted focus on aluminum conductor technology positions us as a strategic partner for OEMs requiring consistent, high-integrity materials critical to transformer efficiency and lifespan. We eliminate supply chain vulnerabilities through vertically controlled production, ensuring absolute traceability from raw material sourcing to finished product.

Our core strength lies in advanced aluminum processing capabilities. We operate dedicated, ISO 9001-certified facilities equipped for the precise production of electrolytic tough pitch (ETP) aluminum wire, specifically formulated for transformer applications. Rigorous control over the entire process—from high-purity 99.99% Al ingot melting and casting through multi-stage drawing and specialized annealing—is fundamental to achieving the required electrical conductivity, mechanical strength, and surface integrity. Our in-house annealing systems utilize precisely calibrated temperature profiles and inert atmospheres to consistently achieve target tensile strengths of 55-65 MPa and elongation of 35-45%, balancing formability with structural stability during winding operations. This granular process control directly translates to reduced scrap rates and enhanced transformer performance for our partners.

Material consistency is non-negotiable in transformer lead wire. We implement comprehensive quality assurance protocols exceeding industry standards like ASTM B230/B231. Every production batch undergoes rigorous in-process and final inspection, including 100%在线 diameter monitoring, electrical resistivity testing, tensile strength verification, and surface defect detection. Our metallurgical laboratory utilizes state-of-the-art equipment for chemical composition analysis (ensuring minimal Fe, Si, and other impurity levels) and microstructure evaluation, guaranteeing the homogeneity and purity essential for optimal conductivity and thermal stability. The resulting product exhibits exceptional resistance to thermal cycling and mechanical stress within the transformer core.

Supply chain resilience is engineered into our operations. With an annual production capacity exceeding 15,000 metric tons of aluminum winding wire and strategic raw material stockpiling, we provide dependable volume supply. Our optimized logistics network, coupled with robust inventory management systems, ensures on-time delivery performance exceeding 98%, supporting our customers’ just-in-time manufacturing requirements. We understand that lead time certainty and material consistency are as critical as the wire’s physical properties for transformer manufacturing continuity.

Key Material Performance Specifications

| Parameter | Typical Value | Test Standard |

|---|---|---|

| Aluminum Purity | ≥ 99.99% | ASTM E39 |

| Electrical Conductivity | ≥ 61.0% IACS | ASTM E8, E6 |

| Resistivity (20°C) | ≤ 0.02826 µΩ·m | ASTM E8, E6 |

| Tensile Strength | 55 – 65 MPa | ASTM E8 |

| Elongation | 35 – 45 % | ASTM E8 |

| Diameter Tolerance | ±0.01 mm (typical) | Customer Spec |

Partnering with Luoyang Xinzhaohe means accessing a supplier whose metallurgical precision and operational discipline directly enhance your transformer’s core performance metrics. We are committed to collaborative engineering support, from initial material specification review through production scaling. For transformer manufacturers seeking a reliable, technically adept source of high-performance aluminum lead wire, contact our technical sales team to discuss your specific requirements and secure supply chain continuity. Reach Cathy directly at cathy@transformerstrip.com to initiate a technical consultation and request detailed qualification data.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer lead wire directly from China.