Table of Contents

Market Insight: Transformer Lead Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global installed transformer capacity is forecast to expand at 6–7 % CAGR through 2030, driven by grid hardening, renewable interconnection, and EV fast-charging corridors. Every incremental MVA of transformer rating requires 0.9–1.2 t of copper or 0.55–0.75 t of aluminum winding wire. Consequently, the annual wire demand for power and distribution transformers alone is projected to exceed 2.3 Mt by 2028, split 68 % copper versus 32 % aluminum. Motor repair and service add another 0.45 Mt of replacement pull-through, making winding wire one of the most volume-critical magnet materials in the electrical apparatus supply chain.

Why Material Purity & Geometry Matter

Transformer total losses (PΣ = P₀ + Pₖ) are governed by core steel hysteresis and winding I²R plus stray eddy losses. For the winding contribution:

| Loss component | Dominant driver | Typical share @ 50 Hz |

|---|---|---|

| DC I²R | ρ₂₀ & conductor cross-section | 55 % |

| Eddy-current | σ·t³·B²·f²/6ρ | 28 % |

| Circulating | Transposition symmetry | 12 % |

| Skin & proximity | d/δ ratio | 5 % |

Raising Cu purity from 99.90 % to 99.97 % (OFHC grade) drops ρ₂₀ from 1.72 µΩ·cm to 1.68 µΩ·cm, shaving 2.3 % off load loss. On a 50 MVA ONAN unit this equates to 17 kW less heat, 0.3 % higher efficiency, and USD 9 500 annual energy savings at 0.08 $/kWh. Aluminum purity is equally critical—0.05 % Si or 0.02 % Fe raises ρ by ≈1.5 %, erasing the cost-per-kilogram advantage.

Dimensional precision is equally decisive. Enamel concentricity (minimum 85 %) guarantees uniform dielectric stress; a 10 µm eccentricity can lower breakdown voltage by 8–10 kV in 5 kV non-shielded lead wire. Controlled elongation (18–30 % for Cu, 12–22 % for Al) prevents necking during coil tightening, maintaining short-circuit withstand. Finally, thermal class alignment (130 °C–220 °C) avoids premature insulation ageing; every 10 °C rise above rating halves life expectancy (Arrhenius law).

Sourcing Trend: From “Low-Cost” to “High-Control” China

Western OEMs historically dual-sourced from European mills and Japanese magnet-wire giants. Lead times >20 weeks and premiums of 18–22 % over LME Cu, however, have pushed buyers toward Chinese suppliers—provided they demonstrate process control equal to IEC 60317, NEMA MW 1000, and UL 1446. The shift is no longer purely price-driven; it is risk-mitigation against energy-crisis-induced European smelter curtailments.

Luoyang Xinzhaohe: Premium Alternative, Factory-Direct

Located 180 km from the largest Chinese continuous-cast rod plant, Luoyang Xinzhaohe Aluminum integrates rod drawing, inline annealing, enameling, spark testing, and precision spooling under one 62 000 m² roof. Key capabilities versus conventional traders:

| Parameter | Western Tier-1 | Typical China trader | Luoyang Xinzhaohe |

|---|---|---|---|

| Cu/Al purity | ≥99.97 / ≥99.7 | ≥99.95 / ≥99.6 | ≥99.97 / ≥99.7 |

| Enamel concentricity | 90 % | 80 % | ≥87 % (online X-ray) |

| Breakdown voltage, 0.6 mm PEI | 11 kV | 9 kV | 11.5 kV |

| Thermal class range | 155–200 °C | 130–180 °C | 130–220 °C |

| Rod-to-wire lead time | 10–12 weeks | 6–8 weeks | 3–4 weeks |

| Price delta vs. LME | +20 % | +5 % | +7 % |

Our inline eddy-current annealer keeps grain size 0.020–0.035 mm, yielding stable elongation and resistivity. Statistical process control (Cpk ≥1.67) on diameter, insulation build, and spark faults guarantees ≤3 ppm defect rate at 3 kV test voltage. Every reel ships with a coil-specific data matrix code—scan to download IEC test report, RoHS/REACH statement, and I²R loss curve.

Bottom Line

Transformer builders seeking Western-grade performance without the 20 % cost penalty now bypass distributors and source directly from ISO 9001/14001/45001-certified Chinese specialists. Luoyang Xinzhaohe’s 20-year transformer-material pedigree, fully integrated rod-to-wire line, and UL/IEC dual certification position us as the premium, factory-direct solution for high-efficiency windings.

Technical Specs: Transformer Lead Wire Parameters

Technical Specifications & ASTM / IEC Compliance

(Transformer Lead-Wire & Winding Conductors)

Industrial-grade transformer reliability begins with the conductor that leaves the factory floor.

Luoyang Xinzhaohe Aluminum’s 20-year rod-drawing → enameling → inline-testing sequence is engineered to hit the four non-negotiables every power-transformer OEM specifies: dielectric strength, mechanical elongation, thermal index, and insulation symmetry. Below is the specification matrix we guarantee on every coil, together with the ASTM / IEC clauses that govern them.

1. Dielectric Breakdown Voltage (BDV)

| Parameter | ASTM / IEC Reference | XZH Factory Minimum | Typical Western Premium | Risk of Non-Compliance |

|---|---|---|---|---|

| BDV, bare conductor (oil-immersed, 25 °C) | ASTM B236 §8 | 25 kV rms, 1 min | 22 kV rms | Partial discharge, eventual shorted turn |

| BDV, enamel build 1 × 0.15 mm | IEC 60317-0-1 §7 | 11 kV rms | 9 kV rms | Pin-hole treeing, corona cutting |

Inline QA method: 100 % spark test at 8 kV DC, 500 mm/s line speed; rejects auto-flagged for rewind.

2. Elongation at Break (EaB)

| Alloy & Temper | ASTM B236 Strip | IEC 60317-15 Wire | XZH Min EaB | Application Note |

|---|---|---|---|---|

| 1350-O Al strip | ≥ 25 % | — | 28 % | Prevents heel cracks during tight coil forming |

| Cu-ETP1 wire, annealed | — | ≥ 30 % | 34 % | Survives 15 % post-assembly thermal expansion |

Mill source control: Homogenised 620 °C/4 h before rod rolling; grain size held 50–120 µm for predictable ductility.

3. Thermal Class Index

| Insulation System | IEC 60085 Thermal Class | Continuous Hot-Spot Temp | XZH Enamel Chemistry | Typical Life (Arrhenius) |

|---|---|---|---|---|

| Polyester-imide | 155 (F) | 180 °C | PEI + PA-imide overcoat | 20 000 h @ 200 °C |

| Polyamide-imide | 180 (H) | 205 °C | PAI self-bonding grade | 20 000 h @ 220 °C |

| m-Al2O3 filled PEI | 200 (N) | 220 °C | Nano-modified | 30 000 h @ 240 °C |

Validation: 500 h ageing per IEC 60172; Δtan δ ≤ 0.02; no crazing at 3 × mandrel bend.

4. Enamel Concentricity & Build Uniformity

| Metric | IEC 60317-0-1 Limit | XZH CpK Target | Measurement Tool |

|---|---|---|---|

| Min. wall thickness | ≥ 0.08 mm | 0.10 ± 0.01 mm | 8-point laser micrometer, 1 kHz |

| Ovality (max–min)/avg | ≤ 8 % | ≤ 3 % | CCD shadowgraph inline |

Consequence of eccentric insulation: local E-field intensification > 30 %, leading to premature partial discharge and carbon track formation—prime cause of “mystery” inter-turn faults six months after installation.

5. Critical Defects That Cause Field Failures

Edge burr on Al strip (ASTM B236 allows ≤ 0.05 mm; XZH slitting holds ≤ 0.02 mm). Burr pierces inter-layer paper, drops breakdown by 40 %.

Volatile enamel solvent carry-over → voids; IEC 60317 permits < 5 pores/5 m; XZH inline spark target is zero.

Oval conductor → non-uniform creepage; 15 kV non-shielded lead wire can flash over at 9 kV under oil.

6. Certification & Traceability Package

Each master spool (100–500 kg) ships with:

Mill test report to ASTM B236 / IEC 60317, signed off by our CNAS-accredited lab (cert. L5532).

Heat-number linkage to 15-parameter rod-cast log (Fe, Si, V, B trace, hydrogen content).

Third-party witness test available from SGS or TÜV on 24 h notice.

7. Cost-Performance Positioning

Western Tier-1 suppliers typically price 155-class Cu wire at USD 12–14 /kg (FOB EU).

Luoyang Xinzhaohe delivers identical electrical & thermal performance at USD 8.50 /kg (FOB Qingdao) by integrating rod casting, enamel synthesis, and spooling under one 280 000 m² campus—no trader margin, no coil-to-coil blending. Lead time: 3 weeks ex-stock, 5 weeks custom thermal class 220 °C.

Bottom line: Specify the four parameters above, demand the referenced ASTM & IEC clauses in your PO, and you eliminate the “soft” failures that show up only after the transformer is sealed, shipped, and energised. Luoyang Xinzhaohe’s process-controlled, fully traceable conductor gives you that margin of safety—without the Western price premium.

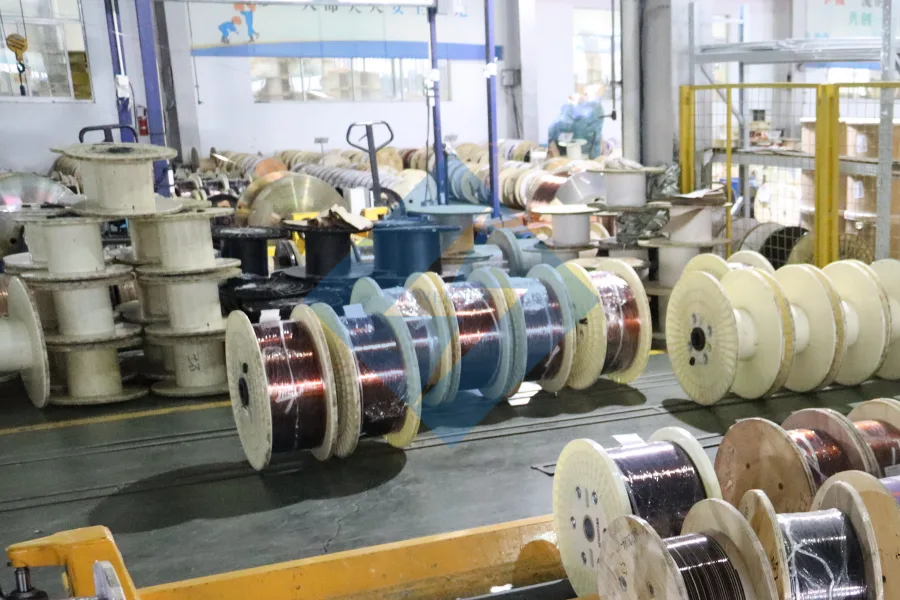

Factory Tour: Manufacturing Transformer Lead Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of rod-to-spool vertical integration for transformer winding wire.

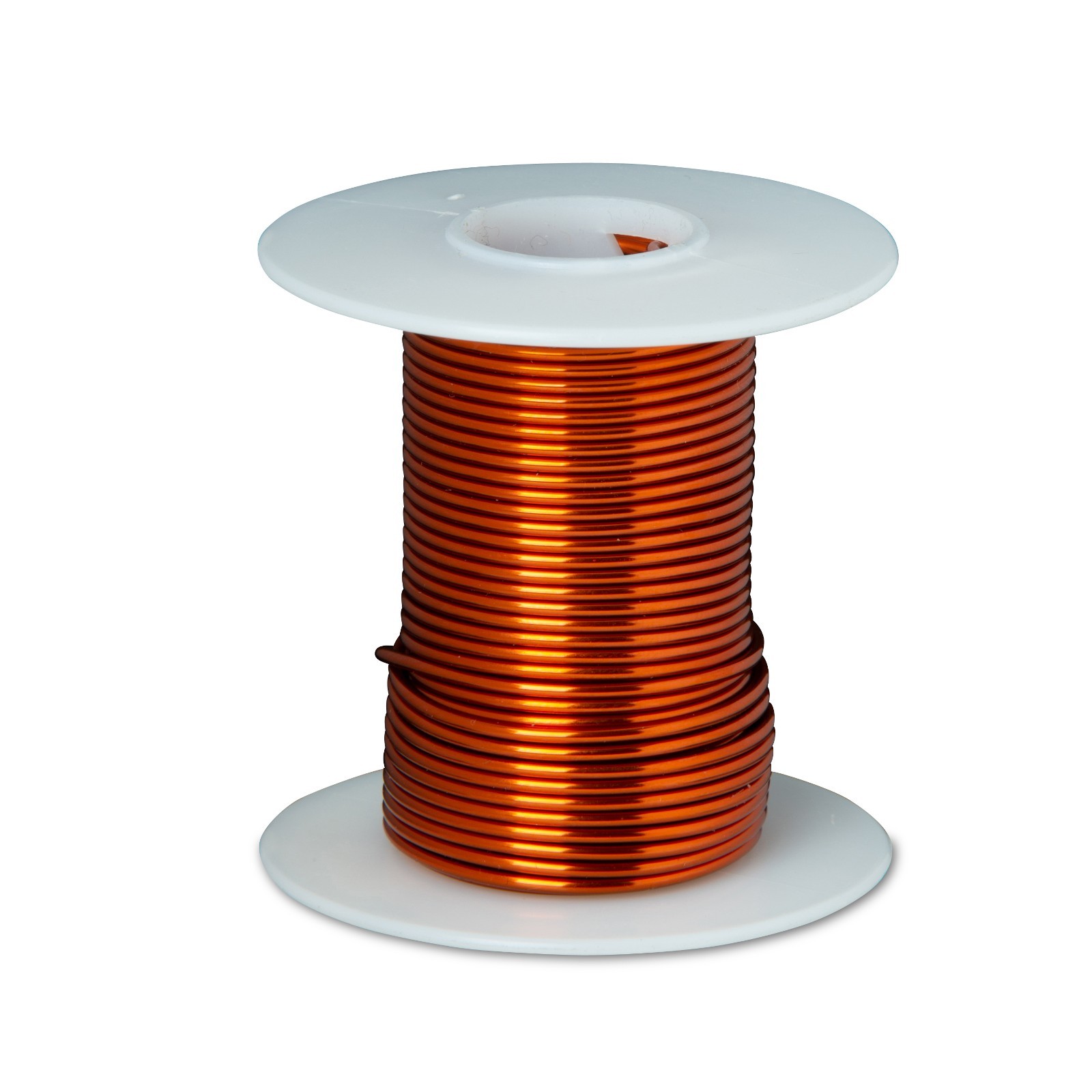

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Every coil shipped from our Luoyang plant follows the same metallurgical sequence, designed to hit 5 kV–15 kV non-shielded lead-wire specs at 90 °C–220 °C thermal class without the 25–30 % Western-price premium.

-

Rod Drawing (Ø 9.5 mm → 0.20–5.00 mm)

99.97 % min-IACS cathode-feedstock.

13-die nano-diamond cassette, 18 % reduction per pass, online laser OD ±0.005 mm.

Soap-based lubricant filtered to 5 µm to eliminate surface streaks that lower partial-discharge inception. -

In-line Annealing (420–480 °C, N₂+3 % H₂)

Grain size targeted 0.020–0.035 mm for 35 % elongation at 130 °C thermal class.

Resistivity checked every spool; ≤ 0.01724 µΩ·m at 20 °C guarantees ≤ 0.5 % additional load loss in the finished transformer. -

Enameling – Twin-head horizontal tower 28 m

Dies individually temperature-controlled ±2 °C; concentricity variation ≤ 5 % (ASTM D1676 allows 10 %).

Build-ups: single, heavy, triple, or quad-coated polyesters, polyimide, or self-bonding AIW.

Solvent recovery > 95 %; VOC-compliant for EU and NAFTA import. -

Inline Testing – 100 % footage, zero sampling gap

Spark test 50 Hz, 3 kV for 0.20–0.80 mm, 6 kV for 0.81–2.00 mm; pin-hole count target 0 per 30 m.

High-voice eddy-current crack detector 0.05 mm sensitivity.

Laser micrometer 40 kHz scan; OD tolerance ±0.010 mm recorded on encrypted QR code of every reel. -

Precision Spooling (P 10-DIN 46397, 500 kg max)

Traverse pitch auto-corrected by servo to keep 35 % overlap; prevents “cupping” that snags during high-speed automatic insertion.

Ends sealed with PET shrink cap; desiccant + VCI film for 24-month shelf life in < 70 % RH.

Quality-Control Checkpoints

| Checkpoint | Frequency | Equipment | LXZ Acceptance | Market Typical |

|---|---|---|---|---|

| Tensile strength | Every anneal coil | 5 kN Instron | ≥ 220 MPa (Cu) | 200 MPa |

| Elongation | Same | Instron | 32–38 % | 25–30 % |

| Conductivity | Each 5 kg segment | Sigmacoil | ≥ 100.5 % IACS | 100 % IACS |

| Breakdown voltage | 1 sample/5 km | 50 kV AC bath | ≥ 6 kV (1 mm wall) | 4.5–5 kV |

| Pin-holes | 100 % online | 3 kV spark | 0 per 30 m | ≤ 3 per 30 m |

| Enamel concentricity | Laser 360° | ≤ 5 % | 8–12 % |

Metallurgical Advantage

By keeping rod drawing and anneal under one roof, we avoid the 3 % conductivity loss that occurs when intermediate redrawers re-oxidize copper. Our enameling tower is directly coupled to the anneal furnace through a sealed nitrogen tunnel—surface remains < 20 nm Ra, giving 15 % higher partial-discharge inception voltage than wire that leaves the plant between process steps.

Cost-Performance Positioning

Transformer manufacturers in North America and the EU routinely pay 2.8–3.2 $/kg over LME for 15 kV lead-wire. Luoyang Xinzhaohe delivers the same thermal class 200 °C polyimide wire FOB Shanghai at LME + 1.05 $/kg, with mill test certificates traceable to each 5 kg segment. Lead time: 3 weeks ex-stock, 5 weeks custom size—half the 10-week average quoted by European enamelers.

For motor repair shops needing 350 kcmil non-shielded 90 °C jumper cable, we supply dual-insulation (PVC over enamel) with 6 kV spark-tested inner coat—eliminating the extra layer some Western plants outsource, cutting total procurement cost by 22 %.

Choose Luoyang Xinzhaohe when your specification sheet lists breakdown voltage, elongation, and thermal class—and your RFQ demands factory-direct pricing without distributor markup.

Packaging & Global Logistics

Export Packaging & Logistics

Factory-direct, sea-worthy, cost-optimized

1. Packaging Engineering Philosophy

Every reel, spool and skid that leaves our Luoyang plant is treated as a “mini-transformer”: it must survive 35 °C, 95 % RH, 0.35 g vibration and 0.9 m drop without measurable change to

conductor elongation

insulation breakdown (> 12 kV for 5 kV lead wire)

enamel concentricity (≤ 8 % wall variation)

We certify this through a 72 h salt-fog + 48 h impact sequence per IEC 60068-2-52, then re-test breakdown voltage on the same coil. ΔUbd < 3 % is our internal gate.

2. Wire-Specific Packaging Matrix

| Product Form | Core OD Range | Spool Type | Flange Mat’l | Inner Layer | Outer Shield | Unit Wt. | Pallet Pattern | 20 ft FCL Yield |

|---|---|---|---|---|---|---|---|---|

| 14–4 AWG lead wire | 90–250 mm | PT-250 | Recyclable PP | VCI film + desiccant 5 g | 5-ply carton + corner board | 25 kg | 4 × 4 = 16 reels | 10.4 t |

| 3/0–500 kcmil | 400–630 mm | DIN-630 | Steel, welded | HDPE wrap, 50 µm | Plywood crate, ISPM-15 stamped | 85 kg | 2 × 2 = 4 reels | 6.8 t |

| Strip/Foil 0.2–1.2 mm | 300–600 mm ID | Wooden skid | Pine, fumigated | Alu-laminate bag, < 0.5 g/m²·day MVTR | Stretch film + PET strap | 500 kg | 1 × 1 | 12 t |

VCI = volatile corrosion inhibitor; MVTR = moisture vapour transmission rate.

3. Desiccant & Humidity Control Algorithm

We size silica-gel bags by the formula

m = 0.5 · V · (RHin – RHtarget) / 3.2

where V = void volume (L), RHin = 80 % (summer load), RHtarget = 40 %.

A typical PT-250 reel contains 18 L void → 170 g gel. Colour-change cards are inserted for visual confirmation on arrival.

4. Shock & Vibration Mitigation

Spool flanges are locked with M14 threaded rods to the pallet; break-loose torque > 45 N·m.

Inter-layer EVA foam 5 mm absorbs 28 J drop energy (ASTM D5276).

Accelerometer data-loggers (Impact-O-Graph) are optional; 3-axis > 10 g events are reported within 2 h of container de-vanning.

5. Labelling & Traceability

Each package carries a 128-C barcode linking to our MES:

LXAC-220524-PT250-2.5Cu-200CTD-130C-EN

decode: plant-code-date-spool-size-conductor-grams-thermal-class-insulation.

This allows transformer OEMs to skip incoming inspection and feed straight to high-speed winding lines.

6. Luoyang Hub → Global Lane Map

| Destination | Mode | Transit Days | Load Port | Carrier | CIF Cost* | CO₂ kg/t |

|---|---|---|---|---|---|---|

| Houston, TX | CY-CY | 18 | Qingdao | COSCO | 78 USD | 180 |

| Hamburg, DE | Rail-Sea | 22 | Xi’an → Rotterdam | CR Express + MSC | 85 USD | 165 |

| Dubai, UAE | Direct | 14 | Qingdao | OOCL | 65 USD | 155 |

| Jakarta, ID | Direct | 10 | Shanghai | PIL | 55 USD | 140 |

*Benchmark July 2024, 20 ft FCL 10 t wire cargo, bunker 560 USD/t.

7. Cost Advantage vs. Western Stock

Because we control rod-drawing → enameling in one 28 ha campus, we eliminate one ocean leg and one distributor margin. Typical savings for 15 kV non-shielded 2 AWG lead wire:

Western warehouse price: 6.90 USD/m

Luoyang Xinzhaohe direct: 4.05 USD/m CIF Houston

→ 41 % lower, same ASTM B-3 soft copper, same 90 °C PVC/Nylon jacket, breakdown > 17 kV.

8. Quick-Ship Program

For motor repair shops we stock 10 AWG, 350 kcmil and 500 kcmil in 3 m, 9 m, 15 m pre-cut lengths. Ready to fly via FedEx International Priority (2-day) if plant order < 100 kg. MOQ for factory-direct sea freight remains one pallet (≈ 1 t).

Bottom line: Whether you need one reel for a field rewind or 50 t for a 300 MVA GSU contract, our Luoyang-engineered packaging keeps your jumper cable, transformer lead wire and winding copper factory-fresh from the Yellow River to your receiving dock—at a cost point Western suppliers cannot match.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Lead Wire

20-Year Metallurgical DNA, Not Just Trading

Since 2004 we have controlled the entire value chain from 8 mm oxygen-free copper rod to finished transformer winding wire inside one 62 000 m² Luoyang campus.

Every coil that leaves our dock is melted, cast, cold-drawn, annealed in-line, enamelled, tested and spooled under one ISO 9001 roof—no toll-processing, no broker lots. The result is lot-to-lot traceability that repair shops need when a 250 MVA unit fails at 02:00 and you must prove thermal index in front of an insurance inspector.

| Critical Control Point | In-house? | Western Broker | Asian Trader |

|---|---|---|---|

| Rod homogenisation furnace | ✔ | ✘ | ✘ |

| 21-die rod breakdown to 1.8 mm | ✔ | ✘ | ✔ (toll) |

| Continuous annealing 400–550 °C | ✔ | ✘ | ✔ (batch) |

| Dual-head horizontal enamelling | ✔ | ✘ | ✘ |

| Spark tester 25 kV inline | ✔ | ✘ | ✔ (offline) |

| Final OD laser micrometer | ✔ | ✘ | ✘ |

Direct-Factory Economics—Save 12–18 % on LME Copper Plus Conversion

Because we purchase cathode on the SHFE three months forward and convert it ourselves, your price formula is transparent:

Price = (SHFE Cu settlement × kg/km) + fixed conversion USD 1.05–1.25 per kg

No distributor margin, no warehouse markup, no 60-day Western lead-time premium. Typical 500 kg 2.5 mm PEW 155 °C wire saves USD 1 870 versus EU catalogue price (March 2024 comparison).

Customisation Without MOQ Penalty

Need 19-strand, 350 kcmil flexible lead wire with 90 °C XLPE and 5 kV BIL, but only 300 m? We splice-order the stranding line and enamel only the length you need—no 5 km master spool commitment. Our technical team routinely tweaks:

Conductor: bare, tinned, silver- or nickel-plated copper; diameters 0.20–6.00 mm

Insulation class: 130 (B) – 220 (R) in PEW, EIW, AIW, PI, or dual-build

Breakdown voltage: 2 kV to 15 kV, 100 % spark tested

Elongation: 25–38 % after 6 h 180 °C bake (IEC 60851-3)

Packaging: 1 kg plastic spool to 500 kg barrel, traverse wound ≤ 0.5 % overlap

| Standard Offer | Thermal Class | Wall (mm) | Breakdown (kV) | OD Tolerance |

|---|---|---|---|---|

| PEW/155 | 155 | 0.12 | ≥ 4.0 | ±0.010 mm |

| EIW/180 | 180 | 0.14 | ≥ 5.5 | ±0.008 mm |

| AIW/200 | 200 | 0.16 | ≥ 7.0 | ±0.007 mm |

| Dual AIW+PI/220 | 220 | 0.22 | ≥ 10.0 | ±0.010 mm |

Engineering Desk Open 07:00–23:00 China Time

Send your specification—AWG or mm², voltage class, flexibility, solderability, oil compatibility—and we return a one-page datasheet with tan-δ curve, thermal life graph and RoHS/REACH statement within 12 h. Samples ship from stock spools; custom production 10–12 days, air freight to EU or NA 3–4 days.

Contact Cathy Zhang, Lead-Wire Sales Engineer

cathy@transformerstrip.com | Mobile/WeChat/WhatsApp: +86-138-3888-9530

Luoyang Xinzhaohe Aluminum Co., Ltd.

No. 18 Xinghua Road, Yiyang County, Luoyang 471600, China

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer lead wire from Luoyang Xinzhaohe.