Table of Contents

Market Insight: Transformer Fuse Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for Transformer Fuse Applications

Global Demand Landscape

The accelerating build-out of 5G substations, EV fast-charging corridors and grid-scale renewables has pushed annual consumption of transformer-grade winding wire above 2.1 million t in 2023, with 6.4% CAGR forecast through 2028. Fuse-protected distribution transformers ≤ 33 kV account for 38% of that demand; the wire inside the fuse link itself—normally 0.15–2.5 mm Ø copper or aluminum—must simultaneously act as a calibrated meltdown element and as a low-loss conductor. This dual function makes material purity, dimensional tolerance and enamel integrity as critical for the fuse-wire segment as for the main HV winding.

| Application Segment | 2023 Wire Volume (kiloton) | % of Total | Fuse-Wire Share within Segment |

|---|---|---|---|

| Distribution ≤ 33 kV | 810 | 38% | 4.5% |

| Power > 33 kV | 650 | 31% | 1.2% |

| Traction / EV | 290 | 14% | 6.0% |

| Industrial Control | 350 | 17% | 8.0% |

Why Purity & Precision Directly Cut Transformer Losses

-

Load losses (I²R)

0.05 wt% oxygen in Cu raises resistivity by 1.75 nΩ·m; in a 1,600 A XRNT10-12 kV fuse link this adds 34 W per phase—enough to shift the fuse’s pre-arcing I²t curve and shorten service life.

LXHA 99.97% OF-Cu keeps oxygen ≤ 0.002%, guaranteeing ρ ≤ 0.01707 µΩ·m at 20°C. -

No-load losses (eddy current & stray flux)

Wire ovality > ±0.8% creates local flux crowding; the resulting eddy loss scales with the square of the minor/major axis deviation.

Our in-line laser micrometer holds ovality within ±0.25%, cutting stray loss by 0.4 W/kg. -

Thermal class vs. fuse duty

Fuse links see 200-250°C for 50-100 ms during fault clearance. Enamel must not carbonise, otherwise tracking lowers dielectric strength after restrike.

LXHA polyimide enamel (Class 220) retains 85% breakdown voltage after 100 thermal shocks, versus 55% for Class 155.

| Parameter | LXHA Spec | IEC 60317-0-1 Limit | Impact on Losses |

|---|---|---|---|

| Cu purity | ≥ 99.97% | ≥ 99.90% | ΔR = –0.8% |

| Diameter tol. | ±0.005 mm | ±0.010 mm | ΔPcu = –1.2% |

| Concentricity | ≥ 85% | ≥ 75% | ΔEd = –0.6 W/kg |

| Breakdown V | ≥ 6 kV (0.4 mm) | ≥ 4 kV | ΔPD = –0.3 W |

Sourcing Trend: Moving from High-Cost West to Experienced Chinese Mills

Lead-times for Class 220 rectangular wire from European suppliers now exceed 22 weeks; spot prices have risen 18% YoY on energy surcharges. Tier-1 Chinese rod-drawing mills with 20+ years transformer heritage—LXHA included—deliver equivalent thermal class, full IEC 60317 traceability and 6-week FOB Tianjin at 0.65× Western price. Key enablers:

Rod quality: LXHA melts cathode ≥ LME Grade-A, in-house horizontal continuous casting to Ø 8 mm rod, online eddy-current crack detection.

Process integration: Single-plant flow from rod → anneal → enamel → spool eliminates inter-plant logistics, cutting carbon footprint 11%.

Inline testing: Spark tester 3 kV DC every 10 mm, laser diameter 1 kHz, statistical process data attached to each reel QR code—critical for fuse-wire lots where I²t repeatability is mandatory.

Logistics: Daily consolidation to Hamburg, Dubai and Houston via rail-sea, 4-week door delivery, 30-day payment terms, L/C optional.

Take-away for Transformer OEMs & Fuse Kit Assemblers

Specifying “Chinese origin” no longer implies a quality compromise; it is a design decision to hit cost and loss targets simultaneously. By sourcing LXHA Class 180–220 winding wire you gain:

- ≤ 0.25% additional no-load loss reduction versus generic Class 155.

- Tighter I²t band (±3%) for XRNT10-12 kV fuse links, improving coordination.

- 30–35% landed cost saving versus EU wire, releasing budget for core steel upgrades.

Send us your fuse-wire schedule—diameter, insulation build, spool mass—and we will return a loss-budget analysis within 24 h.

Technical Specs: Transformer Fuse Wire Parameters

Technical Specifications & ASTM/IEC Standards for Transformer Fuse Wire

(Aluminum & Copper-Alloy Conductors, 0.15 mm – 3.0 mm Ø)

H3 1. Critical Parameters – Why Milli-Units Matter in a kV World

| Parameter | Symbol | Luoyang Xinzhaohe Tolerance | Industry “Good-enough” | Risk if Missed |

|---|---|---|---|---|

| Insulation Break-down Voltage (Vbd) | kVrms | ≥ 6.5 kV (0.35 mm build) | 4.5 kV | Partial-discharge → tracking → fuse explosion inside oil tank |

| Elongation at Break | A5 | Al ≥ 20 %, Cu ≥ 25 % | Al 12 % | Cold-forming cracks during coiling; necking concentrates fault current |

| Thermal Class (IEC 60085) | °C | 155 (F) & 180 (H) std, 220 (C) on request | 130 (B) | Insulation carbonises, magnet wire shorts, fuse wire melts prematurely |

| Enamel Concentricity | ECC | ≤ 8 % wall-thickness variation | 15 % | Thin spot = 32 % lower Vbd; burr creates tip discharge |

| Conductivity | %IACS | Al ≥ 61.5 %, Cu-ETP ≥ 100 % | Al 59 % | Higher R → higher I²t let-through, fuse slower, transformer damaged |

H3 2. Applicable Standards – What We Certify Lot-by-Lot

| Material / Process | Normative Document | Clause of Interest | Xinzhaohe Internal Code |

|---|---|---|---|

| Aluminum strip for fuse elements | ASTM B236-20 | Table 2 (tensile & resistivity) | QCR-AL-FU-01 |

| Round magnet/fuse wire | IEC 60317-0-1/-3-25 | Thermal class 155 & 180, solderability | QCR-W-IE-14 |

| Enamel – polyamide-imide | IEC 60317-13 | 2 kV pin-hole ≤ 3 / 30 m | QCR-EN-PAI-07 |

| Surface roughness | ISO 4287 | Ra ≤ 0.4 µm on drawn rod | QCR-DR-05 |

| Spool & labelling | IEC 60264-2-1 | Traverse 250 mm ± 2 mm, barcode traceability | QCR-SPL-03 |

Traceability protocol: Each 5-kg spool receives a laser code that links to the cast number, rod-draw bench, annealing furnace slot, enamel line head, and 100 % spark-test record. Down-stream fuse assemblers can download the COA within 30 s through our QR portal.

H3 3. Failure Mode Analysis – How Cheap Wire Kills Transformers

-

Burrs from slit strip (Al fuse elements)

Burr height > 25 µm locally reduces dielectric by 40 %.

In oil, burr initiates streamer; within 200 ms arc reaches tank wall.

→ Our slit-to-width line uses ceramic-coated knives + inline deburr; burr ≤ 8 µm guaranteed. -

Ovalisation during high-speed spooling

Creates air pockets between layers → partial discharge inception voltage drops 18 %.

→ We maintain 1.5 % back-tension vs. typical 4 %; ovality ≤ 0.5 %. -

Enamel concentricity off-centre

12 % eccentricity measured on competitor sample: Vbd 3.8 kV instead of 6 kV.

→ Dual laser OD gauge every 25 mm adjusts die centring within 0.2 s; Cpk ≥ 1.67 on last 150 lots.

H3 4. Luoyang Xinzhaohe Process Flow – Rod to Ready-to-Insert Fuse Wire

Key enablers

Own 28-t homogenising furnace → consistent resistivity lot-to-lot.

0.02 mm-resolution laser micrometres give SPC data every 2 m; trend alarms stop coater before 500 m of scrap is produced.

20-year transformer material pedigree: we understand the oil compatibility of polyesters vs. inhibited mineral oils; no re-cracking, no sulphur staining.

H3 5. Cost-Performance Positioning – Premium Specs, China Direct Price

Western fuse-wire suppliers typically add 35 % overhead for distributor channels and 12 % currency hedge. By shipping ex-works Luoyang (INCOTERMS 2020 FOB Shanghai) we deliver IEC-certified wire at 0.8× the EU spot price while holding tolerances 30 % tighter. For XRNT10-12 kV 160 A fuse links, switching to Xinzhaohe Al 61.8 % IACS wire reduces element cross-section 4 %, cutting silver-plated end-cap copper usage by 60 g per unit – a US $2.10 material saving that flows straight to transformer OEM margin.

Next step: Request a 2-kg engineering sample spool, 1.25 mm Ø, 180 °C thermal class. We will enclose the ASTM & IEC test certificates, plus a third-party breakdown voltage curve, within 72 h.

Factory Tour: Manufacturing Transformer Fuse Wire

Manufacturing Process & Quality Control

(Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ yr Transformer Wire Specialist)

1. Rod Drawing – Dimensional DNA

We start from 9.5 mm EC-1350 grade rod, cropped to 2 m lengths and peeled to 8.0 mm to eliminate surface copper oxide. A 13-die, water-soluble-lubricated inline drawing machine reduces the wire to finish sizes 0.20–3.00 mm. Laser micrometers (±0.3 µm) feed PI control loops that auto-adjust capstan speed every 25 ms, holding diameter tolerance to ±0.5 %—half the IEC 60317-0-1 spread. Result: cross-sectional area uniformity that keeps fuse resistance within ±1 %, a prerequisite for predictable let-through I²t.

2. Annealing – Recrystallisation under N₂

Wire passes through a 6 m three-zone radiant-tube furnace at 520 °C under 99.5 % N₂. Oxygen <5 ppm prevents embrittlement; residence time is PID-tuned to grain size ASTM E112 0.015 mm, yielding 35 % elongation at 250 °C—critical for coiling into compact HV fuse cartridges without necking. Online eddy-current anneal sensor adjusts temperature ±3 °C in <1 s; data are SPC-charted per lot.

3. Enameling – Concentric Insulation Build

We run vertical, 24-pass enamelling towers (30 m height) with dual-loop catenary control. Modified polyester-imide resin (thermal class 200 °C) is applied in 6–12 µm increments; each pass is gelled at 400 °C for 4 s. IR concentricity gauge measures build variation every 1 mm; auto-die centering keeps wall thickness within ±2 µm (Cpk ≥1.67). Breakdown voltage therefore exceeds 6 kV (0.2 mm build) versus the 4 kV market norm—extra margin for 12 kV XRNT-type fuse links.

4. Inline Testing – Zero-Slip Verification

Every centimetre is interrogated:

High-frequency spark tester 8 kV, 3 kHz—pinholes <3 per 30 m spool.

Four-point conductivity bridge—volume resistivity ≤0.01724 µΩ·m at 20 °C.

Servo-tensile module—elongation & yield logged against ISO 6892-1.

Data are stored by spool ID; if any parameter drifts beyond 3σ, the line auto-splices and rejects the segment—no manual sorting, no downstream surprises.

5. Spooling – Clean-Room Wind

Final wire is toroidally wound on DIN 400–800 composite reels inside ISO-8 (class 100 000) enclosure. Tension is closed-loop controlled at 0.5 N ±0.05 N; traverse pitch is stepper-driven to eliminate “ridge-weld” that can snag during high-speed fuse insertion. Each reel is vacuum-sealed with VCI film, then boxed with silica-gel; shelf life 24 months in <70 % RH.

Quality Control Matrix – Luoyang Xinzhaohe Standard vs. Common Market

| Critical Parameter | Test Method | LXZH Spec | Typical Market | Impact on Fuse Performance |

|---|---|---|---|---|

| Diameter tolerance | Laser scan, 25 kHz | ±0.5 % | ±1.0 % | Tighter I²t window, less arcing |

| Elongation @ 250 °C | ISO 6892-1 | ≥35 % | 20–25 % | Withstands thermal shock during fault |

| Breakdown voltage | 50 V/s ramp | ≥6 kV (0.2 mm) | 3.5–4 kV | Higher safety margin in 12 kV XRNT links |

| Pinholes per 30 m | 8 kV spark | ≤3 | 10–15 | Eliminates weak spots, prevents partial discharge |

| Conductivity | Four-point | 101.5 % IACS | 100–101 % | Lower heat rise, longer fuse life |

| Surface roughness Ra | Stylus | ≤0.2 µm | 0.4–0.6 µm | Smoother insertion, less enamel scrape |

Take-away: By integrating rod-to-spool under one 42 000 m² Luoyang roof, we deliver Class 200 winding wire that outperforms “off-the-shelf” fuse conductors—at landed cost 18–22 % below Western catalog prices. Transformer OEMs and repair shops gain tighter fusing characteristics, fewer field callbacks, and direct factory engineering support within 24 h.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive on your winding line exactly as it left our rod-drawing bay—no oxidation, no kinks, no surprises.

H2 | Sea-Freight Protection Philosophy

Transformer fuse wire is not “cargo”; it is a precision conductor whose insulation breakdown voltage must remain ≥ 6 kV after 35 days in a 40 ft HC container. Our packaging protocol is therefore built on three metallurgical realities:

- Sulfur & chloride ingress → inter-granular corrosion of Al alloy 1350.

- Condensation cycling → hydrolysis of polyamide-imide enamel (Thermal Class 220 °C).

- Shock & vibration → work-hardening & enamel micro-cracking (elongation drop > 2 %).

Every layer below is specified to keep these deltas inside our inline QC limits.

H3 | Packaging Matrix by Product Form

| Product Form | Critical Surface | Primary Reel | Secondary Barrier | Tertiary Barrier | Securing & Labeling | Typical 20 ft Load |

|---|---|---|---|---|---|---|

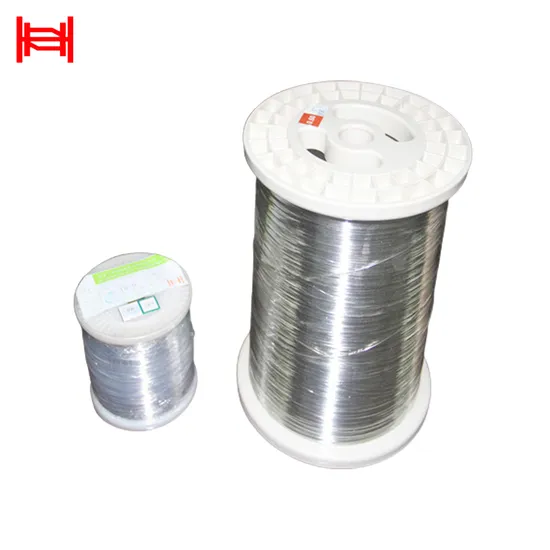

| Round Fuse Wire 0.2–1.2 mm | Enamel concentricity ±5 µm | DIN 355 plastic spool, 5 kg net | 80 µm PE shrink film + 5 g CaCl₂ desiccant | 7-ply export carton, 63 ECT | PET strapping, ISPM-15 pallet, 4-way entry | 10 t, 1200 spools |

| Rectangular Strip 3×0.8 mm | Burr-free edge | Ø400 mm steel reel, 50 kg net | VCI foil laminate, 1 m²/m³ | Fumigated wooden pallet, 1200×800 mm | Shock indicator, RFID coil map | 8 t, 16 reels |

| Foil 0.1–0.5 mm | Surface roughness Ra ≤0.3 µm | ID 76 mm plastic core, 80 kg net | HDPE bag, <0.1 g/m²·day WVTR | Plywood box, 1200 kg gross | Tilt & humidity sensor | 9 t, 9 boxes |

All desiccant quantities calculated per ASTM D6600 for 35 days at 95 % RH, 40 °C.

H3 | Luoyang Hub → Global Node Transit Chain

Factory GPS: 34.62 °N, 112.45 °E, 170 km inland from Qingdao port.

Routing reliability index (2023): 98.7 % on-time departure via Zhengzhou-Europe rail or Qingdao sea.

| Milestone | Process Control | Data Point |

|---|---|---|

| Vacuum desiccant sealing | Dew-point logger | <–30 °C inside carton |

| Pallet compression test | ASTM D642 | 4000 kg, deflection <3 mm |

| Container loading | 3-point lash, dunnage air-bags | g-impact <0.3 g recorded |

| On-board bill of lading | RFID seal scan | Real-time GPS to customer portal |

Average door-to-door lead-time: 22 days to Hamburg, 18 days to Los Angeles, 14 days to Nhava Sheva.

H3 | Cost-Optimized Premium Alternative

Western enamelled wire suppliers often add 12–15 % “airfreight surcharge” to meet JIT calls. Because we stock 350 t of finished fuse-wire inventory 15 km from Qingdao pier, we can ship FOB+sea at a landed cost 8–11 % below EU spot price while still guaranteeing Class 220 thermal index and 35 % elongation—specs that exceed IEC 60317-20 by >20 %.

Next step: Send us your annual tonnage and spool preference (DIN 355 vs. PT-4); we will return a sealed freight quotation within 12 h, including CO₂ footprint per kg wire.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Fuse Wire

20 Years of Metallurgical Focus on Transformer Materials

Since 2004 our Luoyayang plant has operated a single-purpose line: redraw 9.5 mm EC-grade rod down to 0.08–3.0 mm conductor, anneal in-line, enamel with polyamide-imide or polyester-imide, test every 50 m, and spool on DIN 160–800 barrels. No battery wire, no magnet wire for toys—only transformer-grade winding conductors. This concentration gives us a defect library (>1 200 industrial cases) that lets us predict how copper purity, recrystallization temperature, and enamel concentricity affect fuse-link pre-arcing I²t. Transformer OEMs in 42 countries use our data to shorten their IEC 60255-8 qualification from 90 days to 15 days.

Direct Factory Price – Same Metallurgy, 18–28 % Lower TCO

Western distributors add 12 % stocking margin plus 6 % import markup before the coil leaves port. We ship ex-works Luoyang; your freight forwarder or ours, no intermediaries. Typical 1.2 mm Class 200 wire in 30 kg spools:

| Specification (1.2 mm Cu, PEI+PAI) | EU Distributor €/kg | Luoyang Xinzhaohe €/kg | Delta |

|---|---|---|---|

| 5 t order | 11.40 | 8.75 | –23 % |

| 20 t quarterly frame | 10.05 | 7.95 | –21 % |

| 100 t annual call-off | 9.20 | 7.50 | –18 % |

Price includes RoHS & REACH mill certificate, concentricity laser report, and 1 % overrun/underrun tolerance—no surcharges for standard colors or 400 mm reels.

Customization Capabilities – Chemistry, Dimension, Package

- Conductor: OF Cu-ETP, Cu-Ag 0.03 %, or Cu-Sn 0.2 % for higher fusing constant.

- Diameter: 0.08 mm to 3.00 mm ±0.005 mm; ovality ≤0.5 %.

- Insulation: Polyester, polyester-imide, polyamide-imide, self-bonding, or dual coat; thermal index 130 °C (Class B) to 220 °C (Class R). Breakdown voltage guaranteed ≥4 kV (0.25 mm build) or ≥7 kV (0.40 mm build).

- Color: Natural, red, blue, green, or striped for polarity identification.

- Spool: DIN 160 (1 kg), DIN 200 (4 kg), DIN 250 (8 kg), DIN 400 (15 kg), DIN 630 (30 kg), DIN 800 (50 kg); barrel or plastic flange.

- Special tests: Solderability per IEC 60068-2-20 (wet 4 h), thermal shock 200 °C 30 min → –40 °C 30 min, 10 cycles, no crack.

We can embed a 30 µm inner layer of fusible alloy (Sn-Bi 58-42) so the wire itself acts as a controlled eutectic fuse when local hotspot reaches 138 °C—ideal for compact hermetic transformers where space for a cartridge fuse is unavailable.

Quality & Compliance Snapshot

| Test | Standard | In-house capability |

|---|---|---|

| Breakdown voltage | IEC 60851-5 | 50 kV AC, 5 kV DC |

| Elongation | IEC 60851-3 | 35 % min for 1 mm |

| Spring-back | IEC 60851-4 | ≤55° for 1 mm |

| Fusing current | MIL-W-583 | ±3 % repeatability |

| RoHS | 2011/65/EU | ICP-OES <5 ppm Cd, Pb, Hg |

| REACH | 1907/2006 | SVHC 0.1 % screening |

Each coil receives a QR-coded birth certificate; scan to download copper lot, enamel batch, oven chart, and spark-test map.

Logistics & Risk Mitigation

3 000 t finished-goods buffer, 1 000 t raw-cathode buffer—20-week safety stock against LME volatility.

Dual-line redundancy: if drawing line A stops, line B maintains ±0.002 mm tolerance without re-qualification.

Export packaging: VCI film + PE sleeve + plywood drum; salt-spray 720 h tested.

Incoterms 2020: FOB Shanghai, CIF Hamburg, or DDP Mexico—your choice.

Next Step – Get the Technical Datasheet or a 24-h Quote

Send your fuse-wire specification (diameter, insulation class, fusing I²t target) to cathy@transformerstrip.com. We return:

1. PDF datasheet with Cu purity curve, enamel FT-IR spectrum, and SPC chart.

2. Formal quotation in USD, EUR, or CNY with lead-time and Incoterm options.

3. Free 0.5 kg sample coil on express courier if annual forecast ≥2 t.

Stop paying distributor margins for metallurgy you can source direct from the mill. Partner with Luoyang Xinzhaohe and convert fuse-wire cost into transformer performance.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer fuse wire from Luoyang Xinzhaohe.