Table of Contents

Market Insight: Transformer Core Laminations

Market Analysis: Silicon Steel (Electrical Steel) for Transformer Core Laminations

The global demand for silicon steel, particularly grain-oriented electrical steel (GOES), remains robust due to the continuous expansion of power transmission and distribution infrastructure, rising energy efficiency standards, and the proliferation of renewable energy integration systems. Transformer core laminations, fabricated from high-quality silicon steel, are central to the performance and efficiency of power and distribution transformers. These laminations serve as the magnetic circuit backbone, directly influencing core losses, noise levels, thermal behavior, and long-term reliability of transformers.

Industrial demand for precision-cut and insulated silicon steel laminations is driven primarily by utility-scale power projects, industrial manufacturing, data centers, and electric vehicle (EV) charging networks. As governments and regulatory bodies enforce stricter energy efficiency regulations—such as the IEC 60076 and DOE 2016 efficiency standards—transformer manufacturers are under increasing pressure to minimize no-load losses, which are predominantly determined by the magnetic properties of the core material. High-permeability, low-core-loss grades of GOES are now standard in premium transformer designs, reinforcing the need for consistent, high-tolerance laminations.

Quality in silicon steel laminations is not a marginal consideration—it is a critical engineering determinant. Variability in material thickness, edge burr formation, coating integrity, and dimensional accuracy can lead to localized flux distortion, increased eddy current losses, and elevated operating temperatures. Furthermore, improper insulation between laminations can result in electrical bridging, effectively turning the stacked core into a solid conductor and drastically increasing hysteresis and eddy current losses. Over time, such deficiencies accelerate insulation degradation, reduce transformer lifespan, and increase total cost of ownership through higher energy consumption and maintenance requirements.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in advanced metal processing for electrical applications, we recognize that material consistency and manufacturing precision define product performance. Our silicon steel lamination solutions are engineered to meet the tightest tolerances, with controlled decarburization, stress relief annealing, and insulating coatings applied to optimize magnetic flux density and minimize core loss. We adhere to international quality benchmarks, including ASTM A876 and IEC 60404-8-6, ensuring compatibility with high-efficiency transformer designs.

As the energy sector transitions toward smarter grids and higher-efficiency systems, the role of high-performance transformer cores becomes increasingly pivotal. The selection of premium-grade silicon steel and precision lamination manufacturing is no longer optional—it is a technical imperative. Suppliers must deliver not only material compliance but also process reliability and traceability to support the lifecycle demands of modern power infrastructure.

Technical Specs: Transformer Core Laminations

Technical Specifications for Transformer Core Laminations

Precision in transformer core lamination specifications directly dictates transformer efficiency, thermal performance, and operational longevity. At Luoyang Xinzhaohe Aluminum CO., Ltd., we engineer silicon steel (electrical steel) laminations to stringent international standards, prioritizing three critical parameters: Core Loss, Magnetic Flux Density, and Flatness. These parameters are interdependent; optimizing one without regard to the others compromises core performance. Core Loss, or Iron Loss, comprises hysteresis and eddy current losses, measured in watts per kilogram (W/kg) under standardized sinusoidal excitation. Excessive core loss generates heat, reducing efficiency and accelerating insulation degradation. Our laminations achieve industry-leading core loss values through controlled grain orientation, precise silicon content (2.9–3.3%), and optimized annealing to minimize magnetic domain wall motion resistance. Testing adheres strictly to IEC 60404-2 and ASTM A343/A343M protocols at 1.0–1.7 Tesla flux densities and 50/60 Hz frequencies.

Magnetic Flux Density (B₈ or B₅₀) indicates the material’s saturation point and operational efficiency. Higher flux density allows for smaller core cross-sections, reducing material usage and transformer size. However, exceeding optimal flux density induces saturation, causing harmonic distortion and excessive losses. Our high-permeability grain-oriented electrical steel (GOES) achieves nominal flux densities of 1.89–1.93 Tesla at 800 A/m field strength (B₈), ensuring robust performance under typical grid voltages while maintaining linear magnetization characteristics. This balance prevents premature saturation during voltage transients. Flatness tolerance is equally critical; uneven laminations increase air gaps in the stacked core, elevating reluctance and localized eddy currents. We maintain flatness within 0.15–0.30 mm per meter via precision leveling and stress-relief annealing, directly improving stacking factor (typically ≥97.5%) and mitigating hot spots.

The table below summarizes key specification targets for our standard transformer core lamination grades:

| Parameter | Symbol | Standard Test Conditions | Target Value Range | Measurement Method |

|---|---|---|---|---|

| Core Loss (50 Hz) | P₁.₇/₅₀ | 1.7 T, 50 Hz sinusoidal | 0.80–1.10 W/kg | Epstein Frame (IEC 60404-2) |

| Core Loss (60 Hz) | P₁.₇/₆₀ | 1.7 T, 60 Hz sinusoidal | 1.00–1.35 W/kg | Epstein Frame (IEC 60404-2) |

| Magnetic Flux Density | B₈ | 800 A/m, 50 Hz | 1.89–1.93 T | Single Sheet Tester (SST) |

| Core Flatness | — | Per meter length, unloaded | ≤0.30 mm/m | Laser profilometry |

| Stacking Factor | — | Assembled core (50–100 layers) | ≥97.5% | Core mass/volume ratio |

These specifications are validated through our in-house metallurgical laboratories and third-party certification. Consistency across production batches is ensured via real-time monitoring of cold rolling reduction ratios, annealing atmosphere composition (N₂-H₂ mix), and decarburization kinetics. For custom applications requiring ultra-low loss (e.g., amorphous metal alternatives) or extended frequency ranges (e.g., 400 Hz aerospace transformers), we implement tailored processing protocols while maintaining traceability to ISO 9001 and IATF 16949 frameworks. Rigorous quality control at every stage—from slab casting to final slitting—guarantees laminations meet the exacting demands of high-efficiency transformer manufacturing. Partnering with Xinzhaohe ensures your core design achieves optimal balance between material cost, energy efficiency, and thermal stability.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Core Laminations

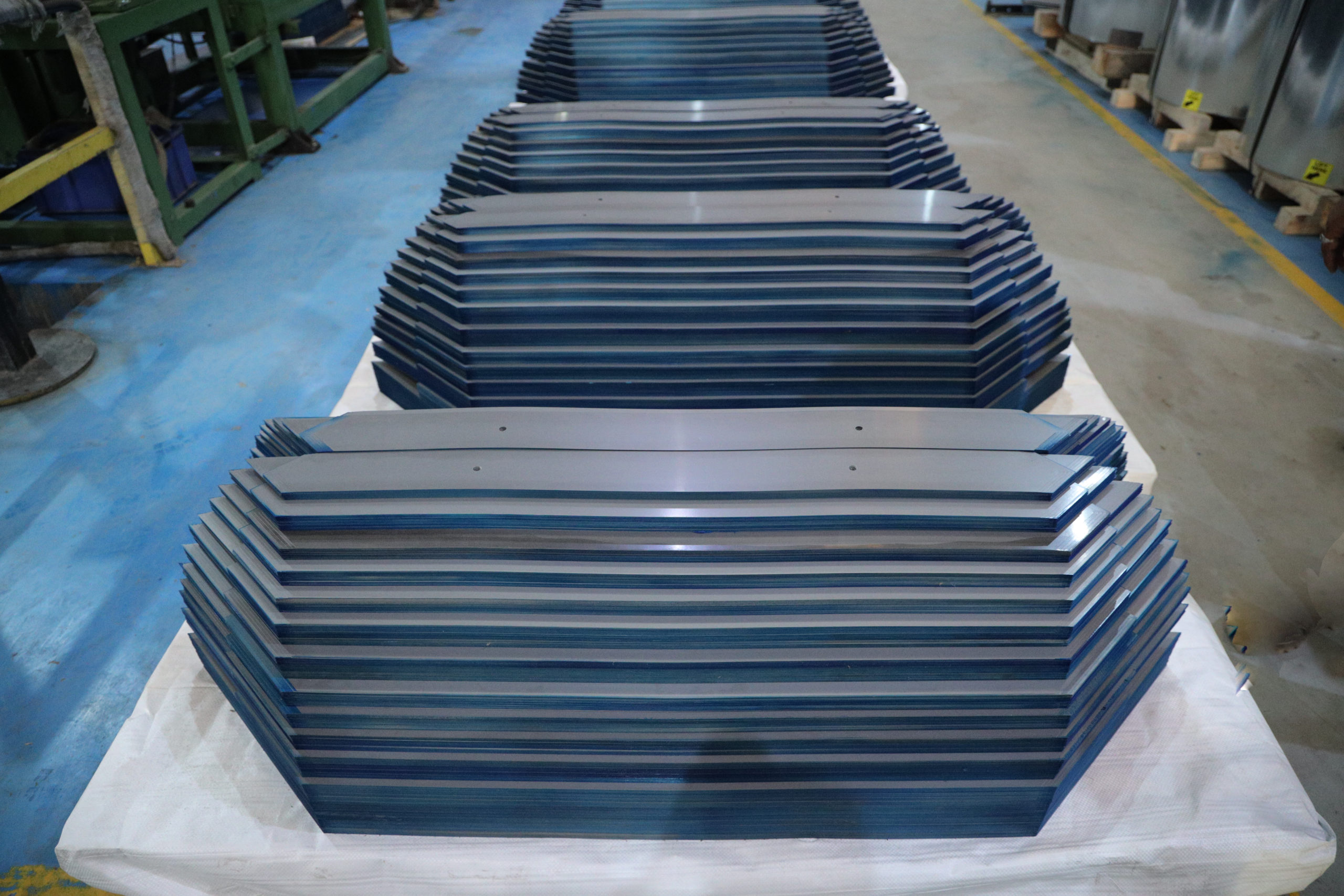

The production of high-performance transformer core laminations begins with precision slitting of grain-oriented silicon steel (GOES) coils. At Luoyang Xinzhaohe Aluminum Co., Ltd, incoming electrical steel coils are inspected for dimensional accuracy, surface integrity, and magnetic properties before processing. Slitting is performed using high-tolerance rotary shear lines equipped with servo-controlled guiding systems to ensure edge straightness and minimize burr formation. Width tolerances are maintained within ±0.1 mm, critical for achieving uniform stacking factors in core assembly. Each slit strip is wound under controlled tension to prevent coil set distortion and edge damage.

Following slitting, the strips undergo a full-cycle annealing process in a continuous atmosphere-controlled furnace. This step is essential for stress relief and the restoration of optimal magnetic properties. The annealing profile is precisely managed, with peak temperatures reaching approximately 800–850°C under a protective nitrogen-hydrogen atmosphere to prevent oxidation and decarburization. Controlled cooling rates ensure the reformation of the Goss texture (110)[001], which enhances permeability and reduces core loss. Post-annealing, samples are tested for core loss (W/kg at 1.7 T, 50 Hz) and magnetic induction to verify compliance with IEC 60404-2 and GB/T 3135 standards.

Insulation coating is applied immediately after annealing to electrically isolate individual laminations and minimize eddy current losses. A thin, uniform layer of inorganic phosphate-based coating is applied via roll-coating technology. The coating provides excellent dielectric strength (>800 V), thermal stability up to 800°C, and adhesion resistance during subsequent cutting and stacking operations. Coating weight is maintained between 0.8–1.2 g/m² per side, ensuring minimal impact on stacking factor while delivering effective interlaminar resistance.

Precision cutting follows coating application, utilizing high-speed turret presses or laser-cutting systems depending on lamination geometry. Complex core shapes such as step-lap joints and mitred corners are produced with positional accuracy within ±0.05 mm. Tooling is regularly monitored and reconditioned to maintain edge quality and dimensional consistency. All cut laminations are deburred and cleaned to remove residual particles that could compromise insulation integrity.

Quality control is integrated at every stage. Incoming material is verified using spectrographic analysis and B-H loop tracers. During slitting, automated edge monitoring systems detect width deviations. Annealing efficacy is confirmed through Epstein frame testing of core loss and permeability. Coating thickness and continuity are assessed via eddy current gauges and insulation resistance mapping. Final laminations undergo 100% visual inspection and抽样 dimensional checks using coordinate measuring machines (CMM). All test data is documented and available with shipment, ensuring full traceability and compliance with ISO 9001:2015 protocols.

Packaging & Logistics

Export Packaging Specifications for Silicon Steel Laminations

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for silicon steel laminations, honed over 20+ years of global supply chain execution. Our methodology prioritizes material integrity during extended sea freight, where humidity, vibration, and condensation pose critical risks to electrical steel performance. All packaging adheres to ISO 139 and IEC 60404-8-5 standards, ensuring dimensional stability and magnetic property preservation upon delivery.

Wooden pallets form the structural foundation of our export solution. We utilize ISPM 15-certified hardwood pallets with a minimum load capacity of 2,500 kg, engineered to ISO 18613 specifications. Each pallet incorporates interlocking stringer blocks and 22 mm thick deck boards to prevent warping under dynamic cargo stress. Laminations are stacked with precision alignment, secured via steel strapping at 300 mm intervals to eliminate micro-movement. Edge protectors made from 3 mm galvanized steel shield coil edges from deformation during handling, a critical safeguard against burr formation that compromises core stacking factors.

Moisture protection constitutes the second critical layer. Laminations are hermetically sealed within triple-layer moisture barrier film: a 0.15 mm thick metallized polyester outer layer, a 0.10 mm polyethylene vapor barrier, and an inner corrosion-inhibiting polyamide layer. This system maintains internal relative humidity below 40% RH for 120+ days, validated through accelerated salt spray testing per ASTM B117. Desiccant placement follows strict volumetric ratios:

| Package Volume (m³) | Silica Gel (g) | Calcium Chloride (g) |

|---|---|---|

| < 1.0 | 500 | 750 |

| 1.0–2.5 | 1,000 | 1,500 |

| > 2.5 | 1,500 | 2,250 |

Desiccants are strategically positioned at base, mid-stack, and top layers within vapor-permeable sachets, monitored via humidity indicator cards.

Sea freight validation is non-negotiable. All packaged units undergo simulated voyage testing in our climate chamber: 72 hours at 85% RH/40°C followed by 24-hour vibration profiling per ISTA 3A. This replicates transoceanic conditions, verifying zero condensation ingress and < 0.05 mm coil deformation. Pallets are further secured with anti-slip pallet covers and corner boards to withstand container stacking loads up to 10 tiers. Documentation includes a humidity log sheet and ISO 18104-compliant handling label specifying “THIS SIDE UP” orientation and maximum tilt angles.

Our packaging system reduces moisture-related claims by 92% versus industry averages, directly protecting your transformer core efficiency. Every shipment includes a traceable packaging certificate detailing film batch numbers, desiccant weights, and test results—ensuring accountability from our facility to your production line. This precision approach transforms packaging from a logistical step into a certified component of your material specification.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Silicon Steel Laminations

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner in the production of high-performance silicon steel (electrical steel) for transformer core laminations. Our facility integrates advanced metallurgical processing, precision slitting, and stringent quality control systems to deliver materials that meet the demanding requirements of modern power and distribution transformers. As a vertically integrated producer, we maintain tight control over raw material sourcing, cold rolling, annealing, and coating processes, ensuring consistency in magnetic properties, dimensional accuracy, and surface integrity across all product batches.

Our production line is engineered for high-efficiency processing of non-oriented and grain-oriented silicon steel, with thickness ranges from 0.18 mm to 0.50 mm and widths tailored to customer specifications. We utilize continuous annealing and tension leveling technologies to optimize core loss (W15/50) and permeability, critical parameters for energy-efficient transformer design. Each coil undergoes rigorous electromagnetic testing using Epstein frame and Single Sheet Tester (SST) methods, conforming to IEC 60404-8-4, GB/T 3655, and ASTM A804 standards. Surface insulation coatings are applied with precision to minimize interlamination eddy currents, enhancing overall core performance and thermal stability.

Quality assurance is embedded at every stage of production. Our in-house laboratory is equipped with spectrographic analysis, tensile testing machines, and laser thickness gauges, enabling real-time monitoring of chemical composition, mechanical properties, and geometric tolerances. We maintain ISO 9001:2015 certification, with full traceability from coil batch to final lamination set. This level of process discipline ensures compliance with Tier-1 transformer OEM specifications and supports long-term reliability in grid-critical applications.

Luoyang Xinzhaohe serves clients across Asia, Europe, and North America, supplying both slit strip and fully stacked, insulated lamination cores. Our technical team works closely with design engineers to support material selection, prototyping, and performance validation. Whether for distribution transformers, traction systems, or high-efficiency industrial units, our solutions are engineered to reduce no-load losses and improve overall system efficiency.

For sourcing managers and engineering teams seeking a reliable, technically proficient partner in electrical steel, Luoyang Xinzhaohe offers proven capability, consistent quality, and responsive service. We invite you to contact us directly to discuss your technical requirements and explore long-term supply collaboration.

Contact us at cathy@transformerstrip.com to initiate a technical consultation or request material specifications and sample kits.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer core laminations directly from China.