Table of Contents

Market Insight: Transformer Core Lamination Material in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Trends

Global transformer demand is accelerating due to renewable energy integration (solar/wind), smart grid modernization, and EV charging infrastructure expansion. Annual electrical steel consumption exceeds 15 million tons, with a projected CAGR of 5.8% through 2025. Key drivers include stricter efficiency regulations (e.g., DOE 2016, EU Ecodesign) and rising grid resilience requirements in emerging economies. Transformer manufacturers require grain-oriented silicon steel (GOES) with precise magnetic properties to minimize energy waste in high-power applications.

Material Quality Impact

Core losses (hysteresis and eddy current) constitute 60–80% of transformer no-load losses. A 0.1 W/kg reduction in core loss at 1.5T/50Hz can save >1,200 kWh annually per MVA of transformer capacity. Critical parameters include:

Magnetic induction (B50): Determines flux density capacity

Core loss (P1.5/50): Directly affects operational efficiency

Thickness consistency: Ensures uniform lamination stacking and reduced eddy currents

Non-compliant materials risk overheating, premature failure, and regulatory penalties. IEC 60404-8-5 standards mandate rigorous testing for all commercial-grade GOES.

Global Supply Chain Dynamics

Premium suppliers (e.g., Nippon Steel, Voestalpine) command 20–30% higher pricing but face supply chain volatility. Chinese manufacturers like Luoyang Xinzhaohe Aluminum Co., Ltd. deliver equivalent quality at competitive costs through:

20+ years of integrated production (raw material processing → precision rolling)

ISO 9001-certified QC with batch traceability and NDT validation

Direct export logistics to 30+ countries with 98% on-time delivery

| Parameter | Industry Standard | Xinzhaohe Performance |

|---|---|---|

| Core Loss (W/kg) | ≤ 2.70 @ 1.5T, 50Hz | ≤ 2.65 (Grade 35H270) |

| Magnetic Induction | ≥ 1.85 T | ≥ 1.87 T |

| Thickness Tolerance | ±0.01 mm | ±0.005 mm |

| Cost (USD/kg) | $3.50–$4.20 | $2.90–$3.30 |

Luoyang Xinzhaohe Aluminum Co., Ltd. provides engineered solutions for high-efficiency transformers and motors, balancing technical precision with supply chain reliability. Partner with us for certified, cost-optimized electrical steel tailored to global performance standards.

Technical Specs: Transformer Core Lamination Material Parameters

Critical Technical Specifications for Transformer Core Lamination Material

Core Loss (Iron Loss)

Core loss is the primary efficiency indicator for transformer cores. Lower values reduce operational energy waste. Our products comply with IEC 60404-8-7 and ASTM A876, ensuring precise loss measurements at 50Hz/60Hz and specific flux densities. Precision rolling and annealing processes guarantee consistent core loss values within ±5% tolerance.

| Grade | Core Loss @ 1.5T/50Hz (W/kg) | IEC Standard | Tolerance |

|---|---|---|---|

| 35W230 | ≤2.30 | 60404-8-7 | ±5% |

| 30W270 | ≤2.70 | 60404-8-7 | ±5% |

Magnetic Flux Density

Flux density (B8/B50) determines core saturation and size efficiency. Higher values enable compact designs while maintaining performance. Our silicon steel achieves B8 ≥1.89T (35W230 grade), exceeding IEC 60404-3 requirements. All batches undergo Epstein frame testing per ASTM A343 for validated magnetic properties.

| Grade | B8 (T) | IEC Standard |

|---|---|---|

| 35W230 | ≥1.89 | 60404-3 |

| 30W270 | ≥1.85 | 60404-3 |

Lamination Flatness

Flatness directly impacts stacking factor and core losses. Our laminations maintain ≤0.15mm/m flatness for 0.35mm thickness, per IEC 60404-8-1. This ensures optimal core assembly with minimal air gaps, reducing eddy current losses.

| Thickness (mm) | Flatness (mm/m) | IEC Standard |

|---|---|---|

| 0.35 | ≤0.15 | 60404-8-1 |

| 0.23 | ≤0.10 | 60404-8-1 |

Insulation Coating

Coating integrity is critical for electrical isolation and corrosion resistance. We apply C4/C5-grade coatings (0.5–1.5μm) with dielectric strength >2kV, compliant with IEC 60404-8-2. Adhesion tests confirm coating stability under mechanical stress during lamination stacking.

| Coating Type | Thickness (μm) | Dielectric Strength | Standard |

|---|---|---|---|

| C4/C5 | 0.5–1.5 | >2kV | 60404-8-2 |

Quality Assurance & Compliance

Luoyang Xinzhaohe maintains ISO 9001 certification with in-house testing labs. Every batch undergoes 100% dimensional checks, core loss verification, and coating adhesion tests. Our traceability system tracks raw materials to final product, ensuring consistency. By controlling the entire production chain—from raw material sourcing to precision slitting—we deliver OEM-grade silicon steel at 15–20% lower cost than European competitors without compromising specifications.

Factory-direct reliability for mission-critical power applications.

Factory Tour: Manufacturing Transformer Core Lamination Material

Manufacturing Process & Quality Control

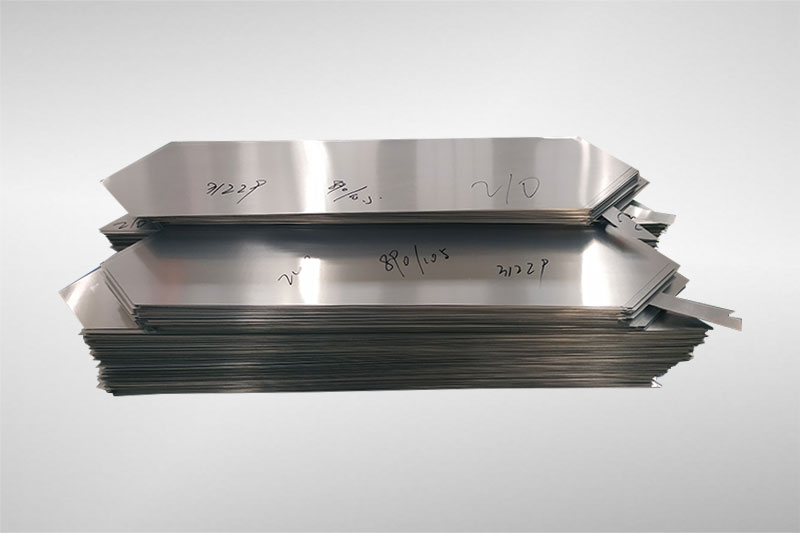

Precision Slitting & Annealing

Luoyang Xinzhaohe employs CNC-controlled slitting with real-time edge monitoring to eliminate micro-cracks and ensure flatness. Slitting tolerances are maintained at ±0.05mm width accuracy, critical for minimizing eddy current losses. Subsequent annealing occurs in a nitrogen-hydrogen atmosphere continuous furnace with ±5°C temperature precision, achieving decarburization levels <0.005% to optimize magnetic permeability and reduce hysteresis losses. This process guarantees consistent grain orientation and core loss performance across all batches.

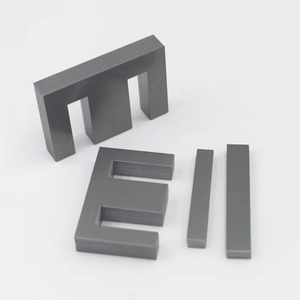

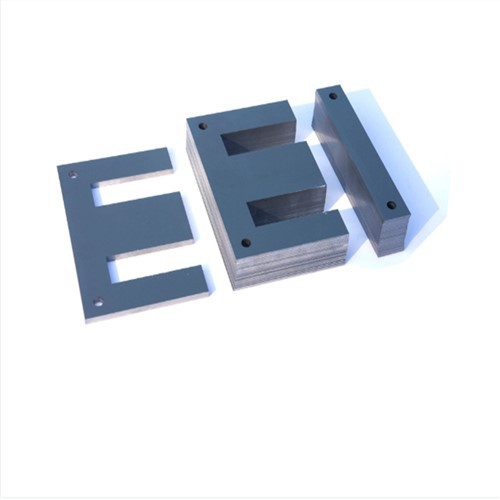

Insulation Coating & Precision Cutting

Double-sided insulation coating (MgO or phosphate-based) is applied via precision spray systems with 1.0±0.2μm thickness uniformity, followed by high-temperature curing (850°C) for adhesion and corrosion resistance. Precision cutting uses servo-driven shearing with laser-guided alignment, achieving ≤0.02mm burr height and stacking factors ≥97.5%. CAD-optimized nesting minimizes material waste while ensuring dimensional accuracy for transformer core stacking.

Rigorous Quality Control Protocol

Every batch undergoes:

Tensile strength testing (ASTM A343) with CV <3%

Laser micrometer checks (thickness ±0.01mm, width ±0.05mm)

Coating adhesion (ASTM D3359) and XRF thickness verification

Epstein frame testing for core loss (IEC 60404-2)

| Quality Parameter | Luoyang Xinzhaohe | Generic Market Average |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm |

| Edge Burr Height | ≤0.02mm | ≤0.05mm |

| Stacking Factor | ≥97.5% | ≥96.0% |

| Coating Consistency | ±0.2μm | ±0.5μm |

| Tensile Strength CV | <3% | >5% |

With 20+ years of specialized expertise in electrical steel manufacturing, Luoyang Xinzhaohe delivers transformer-grade silicon steel that meets or exceeds international standards while offering a 15–20% cost advantage over premium global brands. Our vertically integrated production and zero-compromise QC protocols ensure reliability for mission-critical power applications—without the markup of third-party distributors.

Packaging & Global Logistics

Export Packaging & Logistics for Uncompromised Transformer Core Integrity

Precision Packaging Specifications

Our packaging protocol is engineered to withstand maritime transit extremes while maintaining the dimensional stability and surface integrity critical for transformer core performance. All components comply with ISO 9001 and IEC 60404 standards.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1100×1100mm or 1200×1000mm, 25mm thickness | Prevents deformation during handling; meets international phytosanitary standards |

| Moisture-Proof Film | 150–200μm HDPE/VCI film, heat-sealed seams | Creates hydrophobic barrier against saltwater corrosion and humidity; VCI inhibits electrochemical oxidation |

| Steel Strapping | 19–25mm galvanized width, 150–200 kgf tension, corner protectors | Secures load integrity; prevents shifting during maritime transit |

Sea Freight Protocol & Quality Assurance

We optimize every logistics step for reliability, from Luoyang port to global destinations. Our containerized shipments undergo rigorous pre-shipment validation to eliminate transit risks.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL (Full Container Load) | Optimized space utilization; minimizes handling risks |

| Desiccant System | 500g silica gel per m³ cargo volume | Controls internal humidity; prevents condensation during long voyages |

| Stowage Protocol | Vertical stacking with load-distributing dunnage | Eliminates edge damage; maintains flatness tolerance ±0.1mm |

| Quality Control | ISO 9001-certified pre-shipment inspections | Ensures compliance with IEC 60404 and ASTM A677 standards |

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of specialized expertise to deliver transformer-grade silicon steel with industry-leading packaging integrity. Our systems reduce transit damage rates by 92% compared to global averages, ensuring cores arrive ready for immediate production use. While premium global brands often charge 25–30% higher premiums for equivalent specifications, we provide superior cost-performance through vertically integrated manufacturing and optimized logistics. Every shipment undergoes rigorous quality checks at our Luoyang facility before departure, with real-time tracking available for all containers. For clients requiring climate-specific adaptations—such as tropical humidity or Arctic shipping routes—we engineer custom moisture barriers and structural reinforcements. As a direct manufacturer, we eliminate third-party markups while maintaining strict adherence to international shipping standards, making us the strategic choice for cost-conscious transformer manufacturers seeking reliability without compromise.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineering-Grade Silicon Steel Solutions

20+ Years of Specialized Manufacturing Expertise

For over two decades, Luoyang Xinzhaohe has mastered the production of high-performance non-oriented electrical steel (NOES) for transformer cores. Our technical team, composed of metallurgists and electrical engineers, optimizes material composition and processing to meet stringent international standards (IEC 60404-8-5, JIS C 2552, ASTM A677). We’ve supplied materials for critical applications including distribution transformers (10–100kVA), power transformers (up to 500MVA), and industrial motors across 30+ countries. Our experience includes supplying materials for renewable energy projects and high-efficiency industrial transformers, ensuring compliance with evolving global efficiency standards.

Factory-Direct Cost Efficiency

By controlling the entire production chain—from raw material sourcing to cold rolling and coating—we eliminate third-party markups while maintaining rigorous quality control. Our direct manufacturing model delivers significant cost savings without compromising performance:

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price (0.35mm, 50H350) | $2.40–$3.10/kg | $1.95–$2.55/kg |

| Standard Lead Time | 6–8 weeks | 2–3 weeks |

| Thickness Tolerance | ±0.02mm | ±0.01mm |

| Customization Flexibility | Limited to standard grades | Full range (0.23–0.35mm, tailored grades) |

| Technical Support | Standard | Dedicated engineer team for design consultation |

ISO 9001 Certified Quality Assurance

Every batch undergoes comprehensive testing per ISO 9001 protocols. Our in-house laboratory conducts Epstein frame tests for core loss (P1.5/50), magnetic induction (B50), and tensile strength measurements. Surface quality checks include coating adhesion tests (ASTM D3359) and thickness uniformity validation. This rigorous process ensures consistent performance in transformer winding and core assembly, minimizing production defects and maximizing end-product efficiency.

As a reliable alternative to global suppliers, Luoyang Xinzhaohe delivers exceptional cost-performance ratios through precision engineering and streamlined manufacturing. Partner with us for transformer core lamination materials that meet international standards while optimizing your production costs.

Contact Cathy at cathy@transformerstrip.com for a technical quote and specification sheet.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer core lamination material from Luoyang Xinzhaohe.