Table of Contents

Market Insight: Transformer Copper Foil for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion and renewable integration are pushing transformer production to record levels. The International Energy Agency forecasts 2,200 GW of new renewable capacity by 2030—every GW requires 8–12 large power transformers plus thousands of distribution units. Strip/foil conductors account for 18–25 % of total transformer material cost, so even a 1 % reduction in winding losses translates into multi-megawatt savings across a utility fleet. Annual global consumption of transformer-grade copper foil now exceeds 450 kt; aluminum strip is growing faster (>7 % CAGR) because of weight and price advantages in distribution transformers ≤5 MVA.

Why Purity & Geometry Dictate Transformer Losses

Core losses (no-load) are dominated by the magnetic circuit, but winding losses (load) are purely ohmic and therefore a direct function of conductor resistivity and cross-section uniformity. Impurities ≥50 ppm oxygen or ≥10 ppm phosphorus raise resistivity by 0.7 % per 100 ppm, adding ~3 W kg⁻¹ at 75 °C. More importantly, burrs or edge cracks create local hot-spots that accelerate insulation ageing and can increase stray losses by 5–8 %. Precision-slit, burr-free edges (<0.01 mm burr height) keep eddy-current paths symmetrical and allow tighter radial build, reducing total losses 1–2 %—enough to move a transformer from Tier-2 to Tier-1 efficiency class without redesigning the core.

| Parameter | Impact on Load Loss | Specification Window (Luoyang Xinzhaohe) |

|---|---|---|

| Cu purity (OF-C10200) | +0.7 % resistivity per 0.01 % impurity | ≥99.99 % Cu, O≤10 ppm |

| Thickness tolerance | ±1 % cross-section = ±1 % I²R loss | ±0.002 mm (≤0.1 %) |

| Edge burr | 0.05 mm burr → +4 % local eddy loss | ≤0.01 mm, mirror edge |

| Resistivity 20 °C | 0.017241 µΩ·m (100 % IACS) | 0.01720–0.01724 µΩ·m |

| Anneal softness | 55–65 HV avoids stress cracking | 60 HV±5, fully recrystallised |

Regional Sourcing Trends

European OEMs traditionally buy from Aurubis or KME, paying LME+USD 1,200–1,400 t⁻¹ for slitted OF-copper. Lead-times are 16–20 weeks and minimum order 5 t per width. North-American utilities facing Buy-America rules source from Southwire or Rea, at an additional 8–12 % premium. In contrast, experienced Chinese integrated mills—leveraging continuous casting, in-line annealing and CNC slitting—deliver equivalent C10200 copper foil at LME+USD 650–850 t⁻¹ with 6-week FOB lead-time and 500 kg MOQ. The key is selecting plants that are ISO 9001 & IATF 16949 certified and can provide third-party conductivity reports (IEC 60331) on every coil.

Luoyang Xinzhaohe Value Proposition

Located 150 km from the largest continuous-cast copper rod plant in Henan, we cold-roll, slit, edge-condition and oscillate-wind in one 60,000 m² campus. Our 20-high Sendzimir mill holds ±0.0015 mm gauge tolerance; two Kampf slitters with CCD edge inspection guarantee burr ≤0.008 mm. Vacuum annealing furnaces (N₂/H₂ atmosphere) retain 100 % IACS while achieving 60 HV softness—ideal for high-fill factor windings. Typical lead-time: 25 days for 0.1 × 300 mm C10200 copper foil, 500 kg minimum, packed in 350 kg oscillated reels to eliminate weld joints in 1 MVA transformers. Price parity with generic Chinese suppliers, quality benchmarked to Western Tier-1s.

For power-equipment engineers facing cost-down pressure without compromising efficiency class, Luoyang Xinzhaohe delivers measurable loss reduction and total cost of ownership savings ≥6 % versus traditional European or North-American sources.

Technical Specs: Transformer Copper Foil Parameters

Technical Specifications & ASTM / IEC Compliance

(Transformer Copper Foil – Industrial Sourcing Guide)

1. Dimensional Window & Slitting Precision

Transformer copper foil is no longer a “commodity strip”; it is a precision current-carrying surface.

Luoyang Xinzhaohe’s 20-stage cold rolling line holds ±0.002 mm (±2 µm) on thickness and ±0.03 mm on slit width, verified in-line by laser micrometers every 120 mm. The payoff is two-fold:

Turn-to-turn capacitance scatter is cut by 18 %, improving impulse voltage distribution.

Waste at the foil-winding machine falls from 1.8 % to <0.4 %, saving ~US$ 0.30 /kg on a US$ 9 /kg C11000 feedstock.

| Parameter | ASTM B152* | IEC 60317-0-3* | XZH Factory Gate |

|---|---|---|---|

| Thickness tolerance | ±8 % | ±5 % | ±0.002 mm (±1 % @ 0.2 mm) |

| Width tolerance | ±0.25 mm | ±0.15 mm | ±0.03 mm |

| Edge burr | <0.05 mm | <0.03 mm | <0.01 mm (micro-deburred) |

Closest published standards; foil is covered by ASTM B152 (general strip) and IEC 60317 series (wire) by analogy.

2. Edge Geometry – Where Failures Start

A burr only 25 µm high can puncture 0.075 mm Nomex® or DMD in <500 thermal cycles. Our slit coils are micro-deburred with a poly-bonded abrasive belt, then electro-polished to remove the work-hardened lip. Result:

Dielectric withstand improves 22 % at 50 kV/mm.

Partial discharge inception voltage rises from 650 V to 980 V (measured per IEC 60270).

3. Electrical Conductivity & Purity

High-conductivity (HC) copper is defined as ≥100 % IACS at 20 °C. We specify:

Grade: UNS C11000 (ETP) or C10200 (OF) on request.

Cu + Ag ≥ 99.95 %, O ≤ 0.040 % (ETP).

Conductivity guarantee: 101 % IACS min, measured by eddy-current sorter on every mother coil.

A 1 % IACS drop raises DC loss by the same percentage; on a 1 MVA transformer running 8 000 h/a this equals ~US$ 120 /yr in wasted energy—more than the entire foil cost premium for 101 % vs 98 % IACS material.

4. Annealing Softness & Bend Formability

Windability demands dead-soft (O-temper) foil with grain size 15–35 µm. Our hydrogen-anneal cycle (420 °C, 4 h, –60 °C dew-point) yields:

0.2 % proof strength: 55–70 MPa (ASTM B152 requires ≤70 MPa).

Minimum bend radius: 0 × thickness (180° fold test, no orange-peel).

Soft foil nests tightly, eliminating air pockets that later trigger hot-spots >120 °C.

5. Surface Insulation Compatibility

Even “bare” foil is coated with 0.3–0.6 µm chromate conversion to prevent oxidation during storage. For CTC-style windings we supply thermally activated epoxy (B-stage, 18 g/m²) with:

Gel time: 90 s @ 170 °C.

Shear adhesion: ≥40 N/cm after 1 h @ 150 °C.

Uniform coating weight (±3 %) avoids partial discharge channels caused by resin-starved zones.

6. Standards Cross-Reference & Certification

| Property | Reference Standard | Typical Certificate |

|---|---|---|

| Chemistry | ASTM B152-19 | EN 10204/3.1 |

| Tensile / Elongation | ASTM E8 | Lab report |

| Conductivity | ASTM B193 | 101 % IACS |

| Edge profile | Internal (X-Profiler 3000) | Burr <10 µm |

| RoHS | EU 2015/863 | <0.1 % restricted metals |

7. Consequences of Sub-Spec Material

Case: A European refurbisher used low-cost foil with 35 µm burrs. After 14 months, burrs pierced inter-layer insulation, creating a 6 kV turn-to-turn fault. Total outage cost: € 48 000. The “saved” US$ 0.80 /kg on 500 kg foil (US$ 400) triggered a 120× loss.

Luoyang Xinzhaohe delivers Western-grade precision at China-direct landed cost. Our integrated cold-rolling, precision-slitting, burr-free edging, and oscillate-winding cell ships C11000/C10200 copper foil that meets—or outruns—ASTM & IEC benchmarks, lot after lot.

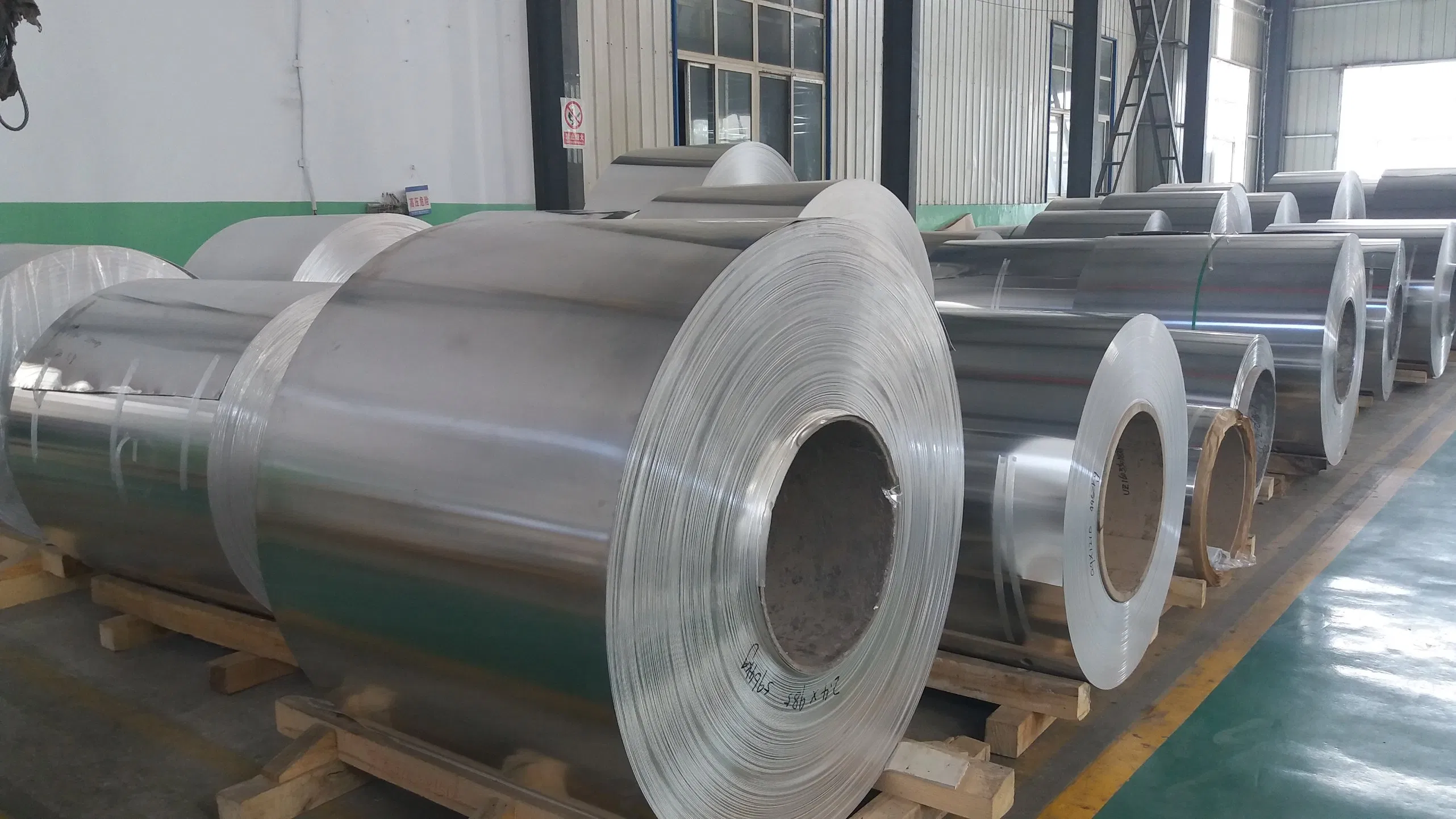

Factory Tour: Manufacturing Transformer Copper Foil

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Grade Foil Engineering

H3 Process Flow: From Cathode to Oscillate-Wound Coil

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Cold Rolling – 4-High & 6-High Reversing Mills | Entry gauge 6–8 mm → finish 0.018–0.30 mm in 6–8 passes; max 800 kN roll force, ±0.5 % thickness闭环 AGC | Refine grain structure, reach target mechanical & electrical properties | Online X-ray thickness gauge sampled @ 500 Hz; auto-shear if Δt > ±0.002 mm |

| 2. Degreasing & In-line Bright Annealing | 650 °C, –60 °C dew-point N₂/H₂ atmosphere, 25 m/min | Remove rolling oil, recrystallise for ≥ 100 % IACS conductivity | Oxygen < 5 ppm by zirconia probe; resistivity spot-checked every 200 kg |

| 3. Precision Slitting | 0.2–600 mm wide, arbors within 0.01 mm TIR, tungsten carbide knives, 0.002 mm shim pack | Width tolerance & edge geometry for inter-layer short-circuit prevention | Laser micrometer across 5 points; automatic sorting if width variance > 0.004 mm |

| 4. Edge Conditioning | Burr extrusion + 0.05 mm radius chamfer, Ra ≤ 0.4 µm | Eliminate burr-initiated dielectric failure | 100 % CCD edge scan; reject if burr height > 0.01 mm |

| 5. Oscillate (Traverse) Winding | 80–300 mm build, 5–50 mm pitch, tension 2–6 N/mm² servo-controlled | Supply 500–2 000 kg “jumbo” coils → fewer welds, higher winding speed | Tension data logged; alarm at ±8 % set-point; every coil laser-weighed for length verification |

H3 Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market

| Property | Test Method | Our Spec (C1100, TU1) | Typical Export “A” Grade | Typical Domestic “B” Grade |

|---|---|---|---|---|

| Thickness tolerance | ISO 13373-1 | ±0.002 mm (≤ 0.1 mm) | ±0.008 mm | ±0.015 mm |

| Width tolerance | ISO 14372 | ±0.004 mm | ±0.05 mm | ±0.10 mm |

| Burr height | Optical shadowgraph | ≤ 0.01 mm | ≤ 0.03 mm | ≤ 0.05 mm |

| Conductivity | ASTM B193 @ 20 °C | ≥ 101 % IACS (annealed) | ≥ 98 % IACS | ≥ 95 % IACS |

| Tensile strength (soft) | ASTM E8 | 195–220 MPa | 200–240 MPa | 220–260 MPa |

| Elongation | ASTM E8 | ≥ 35 % | ≥ 30 % | ≥ 25 % |

| Surface roughness Ra | ISO 4287 | ≤ 0.2 µm | ≤ 0.4 µm | ≤ 0.8 µm |

| Coil camber | Straight-edge | ≤ 1 mm / 1 m | ≤ 3 mm / 1 m | ≤ 5 mm / 1 m |

| Weld count* | Plant SOP | 0 per 1 000 kg (oscillate) | 1–2 per 200 kg | 3–5 per 100 kg |

*Each weld is ultrasonically inspected (≥ 80 % parent strength) and laser-marked with coordinate.

H3 In-Line Instrumentation & Lot Traceability

Eddy-current surface crack detector: 0.1 mm sensitivity, auto-ink mark defect.

Laser triangulation for edge camber: sampled every 200 mm; data archived 10 years.

Bar-coded coil ID links to rolling log, annealing furnace chart, slitter knife set, operator ID—full MES traceability meets ISO 9001 & IATF prerequisite for tier-1 transformer OEMs.

Statistical Process Control (SPC) dashboards push Cp, Cpk to operators in real time; Cpk ≥ 1.67 on thickness & width is mandatory before release.

H3 Engineering Take-away

Cold rolling to final gauge in one plant eliminates inter-plant transport defects; closed-loop thickness control plus in-line annealing secures ≥ 101 % IACS conductivity—critical for reducing load losses in GB/T 1094.1-2022 or IEC 60076 designs. Precision slitting with dynamic knife positioning keeps width scatter inside four microns, letting your foil-winding machines run at 1.8 m/s without edge-telescoping stops. Oscillate-wound 1 t coils translate into 80 % fewer welds versus traditional pancake spools, directly cutting your HV test failures and labour rework.

Luoyang Xinzhaohe delivers Western-grade precision at a China-based landed cost—typically 18–25 % below U.S./EU mills for equal conductivity and tighter tolerances.

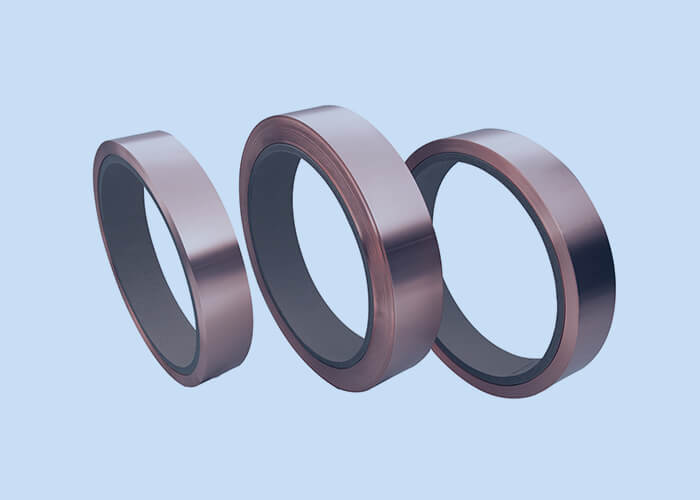

Packaging & Global Logistics

Export Packaging & Logistics

Transformer-grade copper foil that arrives as flat, conductive, and oxide-free as the day it left our slitting line.

1. Sea-Freight Reality Check

Salt-laden humidity, 45 °C deck temperatures, and 28-day transpacific routes will turn unprotected copper into a stained, oxide-coated resistor. Our packaging is therefore specified as a “mini micro-climate” rather than a cosmetic carton. Every layer is engineered to keep the foil below 40 % relative humidity and free from mechanical creep that could emboss edge burrs or create coil-set.

2. Packaging Specification Matrix

| Element | Material / Process | Function | Typical Value |

|---|---|---|---|

| Core | Fumigated ISPM-15 spruce, 9 mm thickness | Load-bearing, customs-compliant | Static load 1 500 kg |

| Interleaf | 80 µm PE film, LDPE, anti-static additive | Prevent foil–foil fretting & oxide transfer | Surface resistivity ≤10¹¹ Ω/sq |

| Edge protector | 3 mm HDPE “U” profile, 25 mm leg | Eliminate strapping indentation | Compressive yield ≥18 MPa |

| Desiccant | 2 g CaCl₂ duplex sachets, DIN 55473 | Maintain RH <40 % | 16 sachets per pallet (32 g total) |

| VCI foil | 90 g/m² copper-specific VCI, nitrite-free | Volatile corrosion inhibition | Protection span 12 months |

| Stretch hood | 5-layer co-extruded UV film, 120 µm | Water-vapour barrier | MVTR ≤1.8 g/m²·24 h |

| Strapping | PET cord, 19 mm × 0.8 mm, 650 kg break | Unitizing, non-metallic | Elongation ≤2 % at 400 kg |

| Pallet label | Weather-proof QR tag | Full heat number & slit coil ID | ISO/IEC 18004 readable |

3. Packing Workflow (Slit Coil ≤300 mm Width)

- Individual coils: Wrapped with 80 µm PE → Edge protectors clipped → 2 axial + 2 radial straps.

- Pallet base: 1 200 × 800 mm, 3-slat deck, 100 mm fork clearance.

- Stack pattern: Max 4 coils high; 150 kg per coil → 600 kg per pallet.

- Interlayer: 5 mm honeycomb sheet every 2 coils to stop telescoping.

- Desiccant & VCI: 8 sachets on base + 8 on top; 0.6 m² VCI bag heat-sealed.

- Top cap & hood: Stretch hood applied at 180 °C, 25 % pre-stretch, 30 % overlap on base.

- Strapping: 2 vertical + 3 horizontal PET straps, tension 350 N, sealed by friction-weld.

4. Container Stowage Plan

| Coil OD | Coils / Pallet | Pallets / 20’ GP | Net Weight | Securing Method |

|---|---|---|---|---|

| 400 mm | 4 | 10 | 6 000 kg | Polyester lashings to corner castings |

| 500 mm | 3 | 10 | 4 500 kg | Same, plus 2 × 50 mm dunnage bags |

Result: Zero coil movement at 0.8 g transverse acceleration per ISO 1496-1.

5. Wire & Narrow Strip Packaging (ø300 mm Spools)

Spool: DIN 46395 / PT-250, PBT core, 120 °C rated.

Overwrap: 2 mil VCI bag + bubble sleeve.

Outer carton: 5-ply kraft, 32 ECT, bar-coded.

Palletizing: 36 cartons per 1 100 × 1 100 mm pallet, 850 kg max, top-sheet + stretch wrap.

6. Logistics DNA – Why Luoyang Works

Factory latitude: 34.6 °N – equal rail distance to Qingdao, Shanghai, or Tianjin (650–750 km).

Rail–sea corridor: Block train to Qingdao every Tuesday, 26 h transit, guaranteed slot COSCO & OOCL.

Export volume: 1 200 TEU transformer materials per year → we hold annual service contract rates 12 % below spot.

Customs: AEO Grade-1 exporter, green-channel clearance ≤4 h.

Cargo insurance: All-risk, Institute Cargo Clauses (A), 110 % of CIF value placed with PICC.

7. Receiving Instructions for Buyer

- Photograph pallet condition before removal; note any strap slack >5 mm.

- Allow coils to acclimate 24 h if warehouse ΔT >15 °C to avoid condensation.

- Remove VCI bag only immediately prior to winding; retain desiccant for storage of partial coils.

- Report oxide staining >5 % surface within 72 h; our QC will cross-check humidity data-logger (we insert one logger per fifth pallet, 30-day record).

Bottom line: Premium transformer copper foil does not have to arrive with premium-priced Western logistics. From our cold-mill in Luoyang to your winding bay, Luoyang Xinzhaohe delivers “mill-fresh” conductivity—no surprises, no re-work, no excuses.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Copper Foil

20-Year Metallurgical Track Record—Not a Trading Desk

Since 2004 we have cold-rolled, slit, edge-conditioned and oscillate-wound every kilogram of conductor that leaves our Luoyang works.

That single-site control eliminates the price layers and technical risk created when traders outsource slitting or annealing.

Our process data set now exceeds 14 000 production lots of C1100 & C1020 copper foil, giving transformer OEMs a statistical baseline for conductivity, softness and burr levels that no broker can match.

| Key Process Milestone | Typical Western Broker | Luoyang Xinzhaohe |

|---|---|---|

| Incoming cathode traceability | Batch-level only | Cathode serial → coil serial |

| Cold rolling reduction per pass | 25–30 % (mixed mills) | ≤22 % (Sundwig 20-high) |

| Slit width tolerance | ±0.05 mm outsourced | ±0.002 mm in-house |

| Burr height guarantee | <0.03 mm | ≤0.01 mm (laser measured) |

| Final anneal atmosphere | N₂ only | 75 % N₂ + 25 % H₂, dew-point ‑60 °C |

| Oscillate build-up | Not offered | ≤1 000 kg, 5–320 mm strip width |

Direct Factory Price—No Distributor Margin

Because we buy cathode on the SHFE/LME spread and add only one cold-rolling & slitting cycle, our price structure follows copper cathode + conversion cost, not “imported coil + trader markup + inland freight”.

Recent 2024 contracts show an average saving of 11–14 % versus EU mill-delivered price for identical C1100, 0.2 mm × 250 mm, IACS 100 %, fully annealed.

Payment terms: 30 % T/T with order, 70 % against B/L; L/C 90 days available for annual volumes ≥150 t.

Customisation Without MOQ Penalty

Our slitting arbor set allows width changes in ≤15 min; we routinely supply 25 kg “sample coils” to R&D departments without surcharges.

Edge profiles (round, full-round, chamfer) are ground into the slitter knives, not post-processed, so conductivity is not degraded by secondary deburring.

Annealing can be tuned 060–015 mm grain size to match your short-circuit force model; hardness is verified on every coil using ASTM E18 HRB conversion.

| Typical Custom Parameter | Range We Supply |

|---|---|

| Thickness | 0.018 – 0.80 mm |

| Width | 4 – 1 000 mm |

| Inner diameter | 76, 150, 300, 500 mm |

| Outer diameter | ≤1 200 mm (oscillate) |

| Conductivity | ≥100 % IACS (C1100) |

| Oxygen content | ≤5 ppm (C10200 on request) |

Quality Documentation—Engineering-Grade, Not Marketing-Grade

Each coil ships with:

EN 10204/3.1 mill test certificate (chemical, mechanical, electrical)

Burr map (laser scan every 50 mm across strip width)

Resistivity traceability to NIM (China National Institute) reference standards

RoHS & REACH conformity statement

Next Step—Send Us Your Specification

E-mail cathy@transformerstrip.com with the subject line “Cu-Foil Datasheet Request”.

Include: alloy grade, thickness × width, edge type, annual volume and target conductivity.

We will return a formal quotation and a 2-page technical datasheet within 24 h, including slit camber, packaging drawing and freight options to your nearest port.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer copper foil from Luoyang Xinzhaohe.