Table of Contents

Market Insight: Transformer Bobbin Material

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) for Bobbin Applications

The global transformer market, driven by grid modernization, renewable energy integration, and industrial electrification, exhibits sustained demand for high-performance core and winding materials. Within this ecosystem, the bobbin – the structural foundation supporting windings – relies critically on precision strip or foil for its conductive elements. Industrial demand for transformer bobbin material is intrinsically linked to transformer efficiency standards (e.g., DOE 2016, IEC 60076-20), reliability requirements, and cost optimization pressures across power distribution, renewable inverters, and industrial equipment sectors. Annual global consumption of aluminum and copper strip/foil specifically for transformer components, including bobbins, exceeds several hundred thousand metric tons, with aluminum gaining significant traction due to its favorable conductivity-to-weight ratio and cost profile, particularly in distribution transformers above 50 kVA.

Material selection for bobbin conductors is not merely a cost exercise; it directly dictates transformer performance, longevity, and total cost of ownership. Aluminum strip/foil, the primary focus for cost-sensitive and weight-critical applications, must meet stringent metallurgical and dimensional specifications. Impurities (Fe, Si, Cu residuals), inconsistent grain structure, or surface defects introduce localized resistance points, accelerating joule heating and promoting thermal runaway under load. Dimensional tolerances, especially thickness uniformity (±0.005 mm typical for critical bobbins) and edge straightness, are paramount. Variations cause uneven winding tension, compromising inter-layer insulation integrity and increasing the risk of partial discharge or short circuits during operation. Surface roughness must be minimized (Ra < 0.5 µm) to prevent dielectric breakdown at the conductor-insulation interface. Copper, while offering superior conductivity, faces intense pressure from aluminum substitution due to copper’s higher cost and density, making aluminum the dominant material for new distribution transformer bobbins where weight and lifecycle cost are decisive.

Quality deviations in bobbin strip/foil manifest as critical field failures. Non-uniform annealing leads to inconsistent ductility, causing wire breakage during high-speed winding processes or stress-induced cracks over thermal cycles. Residual stresses from improper slitting induce coil deformation, distorting the magnetic circuit and increasing core losses. Inadequate oxide control on aluminum surfaces creates high-resistance interfaces between layers, elevating operating temperatures by 5-10°C – a factor significantly accelerating insulation aging per the Arrhenius equation. These failures translate directly to premature transformer derating, unplanned outages, and warranty claims, costing utilities and OEMs orders of magnitude more than the initial material premium for certified high-grade strip.

The following table summarizes key material considerations for transformer bobbin applications:

| Parameter | Critical Impact | Typical High-Quality Requirement |

|---|---|---|

| Thickness Tolerance | Winding uniformity, insulation stress | ±0.005 mm or tighter |

| Surface Roughness | Dielectric integrity, interfacial resistance | Ra ≤ 0.5 µm |

| Edge Quality | Winding precision, burr-induced insulation damage | Burr height < 5% of thickness |

| Resistivity | Load losses, operating temperature | Al: ≤ 0.02826 µΩ·m (20°C) IACS 61%+ |

| Grain Structure | Ductility, stress resistance, annealing response | Fine, uniform, recrystallized |

Procurement decisions must prioritize certified material traceability and consistent adherence to IEC 60138 or ASTM B718/B354 standards. Luoyang Xinzhaohe Aluminum leverages two decades of specialized process control in cold rolling, annealing, and slitting to deliver aluminum strip/foil meeting these exacting bobbin requirements, ensuring OEMs achieve target efficiency, reliability, and manufacturing yield. The initial material cost is eclipsed by the operational and reputational costs of substandard performance.

Technical Specs: Transformer Bobbin Material

Transformer bobbin material is a critical component in the construction of electromagnetic devices, where dimensional precision, edge quality, and electrical performance directly influence the efficiency and reliability of the final product. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in precision aluminum and copper strip/foil products, we provide high-integrity materials engineered specifically for transformer bobbin applications. Our production processes integrate advanced cold rolling, precision slitting, and edge conditioning technologies to meet the stringent requirements of the power and electronics industries.

Precision slitting is paramount in transformer bobbin material fabrication. Dimensions must conform to tight tolerances to ensure consistent winding performance and optimal core stacking. Our slit strips are held to a width tolerance of ±0.002 mm, achieved through servo-controlled slitting lines equipped with laser-guided monitoring systems. This level of accuracy minimizes material waste during coil winding and prevents interlayer misalignment, which can lead to hotspots and premature insulation failure.

Edge quality is equally critical. Burr formation during slitting can compromise insulation integrity and increase the risk of dielectric breakdown. We employ high-precision tooling with optimized clearance settings and post-slitting edge deburring techniques to ensure burr-free edges. Surface profilometry confirms burr height remains below 2 µm, meeting or exceeding international standards for electrical applications.

Electrical conductivity is a function of both alloy composition and thermal processing history. For aluminum-based bobbin materials, we offer grades with a minimum conductivity of 59% IACS, achieved through controlled annealing in oxygen-free atmospheres to minimize oxide inclusions and interstitial contamination. Copper variants are processed to exceed 98% IACS, utilizing high-purity feedstock (99.99% Cu min) and homogenization treatments to ensure uniform current distribution.

Mechanical properties are tailored to support high-speed winding operations. Tensile strength is maintained within a controlled range (70–120 MPa for aluminum, 200–250 MPa for copper) to balance formability with dimensional stability. Elongation is optimized to prevent cracking during bending and shaping operations inherent in bobbin fabrication.

All materials undergo 100% inline surface inspection using high-resolution CCD systems to detect defects such as scratches, pits, or laminations. Batch traceability is maintained through integrated ERP systems, with full material test reports available upon shipment.

The following table summarizes key technical parameters for our transformer bobbin strip/foil offerings:

| Parameter | Aluminum Material | Copper Material | Test Standard |

|---|---|---|---|

| Thickness Range | 0.10 – 3.00 mm | 0.10 – 2.50 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ±0.002 mm | ISO 9001 |

| Edge Burr Height | ≤ 2 µm | ≤ 2 µm | SEM/EDS Analysis |

| Electrical Conductivity | ≥ 59% IACS | ≥ 98% IACS | ASTM B9 |

| Tensile Strength | 70–120 MPa | 200–250 MPa | ASTM E8 |

| Elongation (min) | 35% | 40% | ASTM E8 |

| Surface Roughness (Ra) | ≤ 0.4 µm | ≤ 0.3 µm | ISO 4287 |

| Flatness | ≤ 5 I-units | ≤ 3 I-units | ASTM E2297 |

These specifications reflect our commitment to delivering materials that meet the exacting demands of modern transformer manufacturing.

Factory Tour: Manufacturing

Transformer Bobbin Material Manufacturing Process: Precision Strip Production

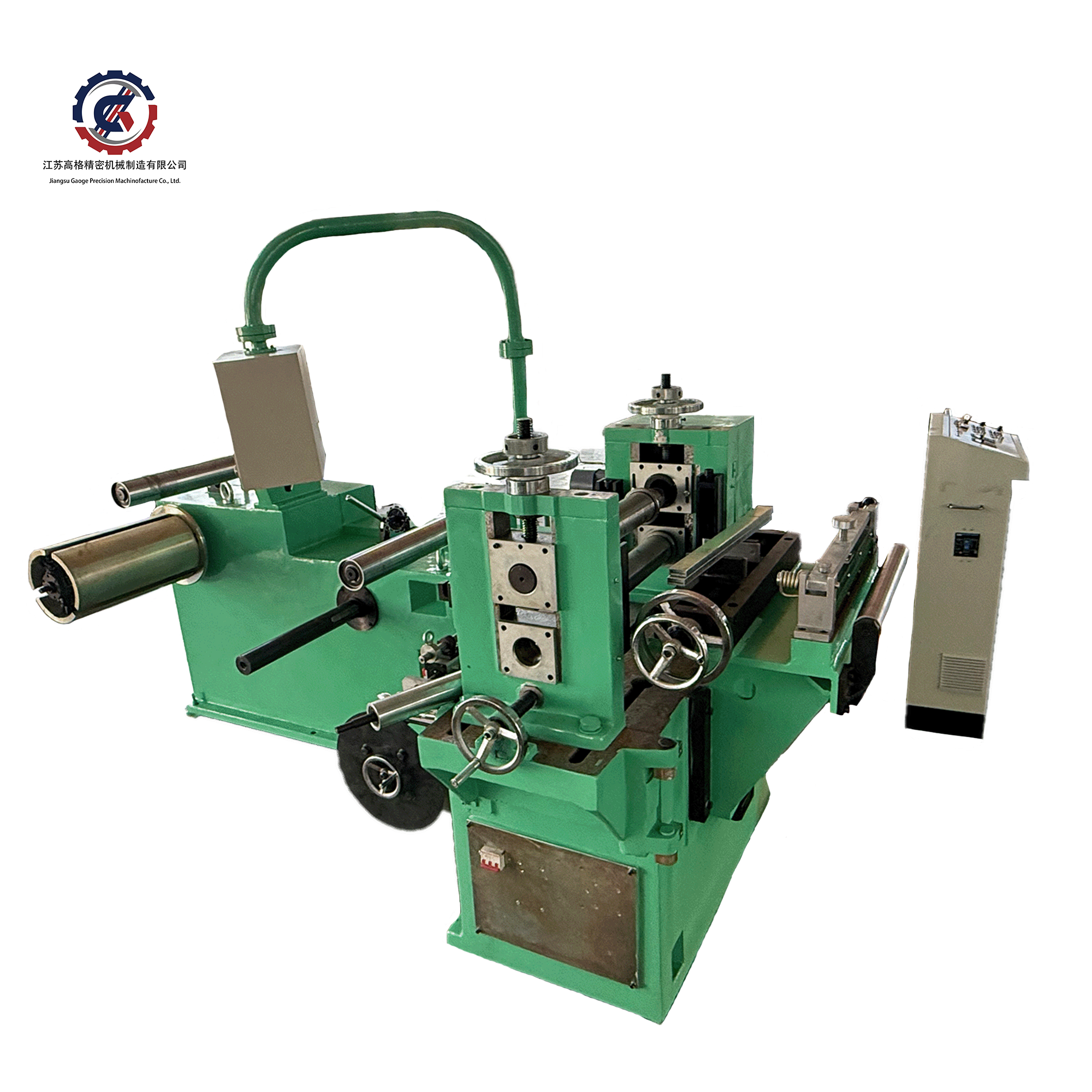

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise to produce aluminum and copper strip/foil meeting the stringent dimensional and surface quality demands of transformer bobbin applications. Our integrated manufacturing process ensures consistent material performance critical for efficient winding, core integrity, and long-term transformer reliability. The core sequence involves Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality control protocols.

Cold Rolling forms the foundational step, transforming cast and homogenized ingot or continuous cast strip into the precise final gauge required for bobbin windings. Material undergoes multiple rolling passes in high-precision tandem mills under strictly controlled tension and lubrication conditions. This process achieves the target thickness tolerance, typically within ±0.005 mm for foil grades, while simultaneously developing the necessary mechanical properties and surface morphology. Critical parameters monitored in real-time include roll gap, rolling speed, interstand tension, and coolant composition. Post-rolling, the strip passes through inline surface inspection systems detecting micro-defects, scratches, or roll marks exceeding Ra ≤ 0.4 μm surface roughness specifications essential for smooth wire lay-up. Thickness profile across the strip width is continuously verified via beta-gauge measurement, ensuring flatness deviations remain below 15 I-Units to prevent winding issues.

Precision Slitting follows, where the master roll is longitudinally divided into narrow strips matching the exact bobbin width requirements. This operation utilizes advanced servo-controlled rotary shear slitters with hardened tooling maintained to micron-level tolerances. Width accuracy is paramount, consistently held to ±0.05 mm across the production run. The slitting environment is meticulously controlled to minimize contamination and prevent edge deformation. Immediately after cutting, each slit edge undergoes inline optical edge profiling to detect and quantify any burr formation or edge irregularity exceeding 5 μm, triggering automatic tool adjustment or replacement if thresholds are breached. Tension control throughout slitting is critical to maintain strip flatness and prevent edge wave or center buckling.

Edge Conditioning is the final critical operation, specifically engineered for transformer bobbin applications. Slit edges are processed through precision brushing or light grinding systems to remove microscopic burrs and create a controlled, consistent edge radius. This step is non-negotiable for preventing insulation wire damage during high-speed winding and ensuring clean layer transitions within the bobbin assembly. The target edge radius is maintained within 0.05 mm to 0.15 mm, verified through automated edge metrology systems integrated into the production line. Surface cleanliness is concurrently monitored to eliminate particulate contamination.

Quality control is embedded at every process stage, not as isolated checkpoints. Key parameters and verification methods are summarized below:

| Parameter | Specification | Verification Method | Frequency |

|---|---|---|---|

| Thickness | ±0.005 mm | Inline Beta Gauge | Continuous |

| Width | ±0.05 mm | Laser Micrometer | Continuous |

| Edge Radius | 0.05 – 0.15 mm | Automated Optical Profilometry | Per Coil Segment |

| Surface Roughness | Ra ≤ 0.4 μm | Portable Profilometer | Hourly |

| Tensile Properties | Per ASTM B221/B361 | Destructive Testing (Lab) | Per Melt Batch |

This disciplined, integrated approach from cold rolling through edge conditioning, underpinned by decades of process refinement and real-time QC data analytics, guarantees the dimensional precision, surface integrity, and metallurgical consistency demanded by high-performance transformer manufacturers.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil Materials

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in transformer strip and foil materials, we maintain rigorous standards in export packaging to ensure product integrity during international transit. Our packaging methodology is engineered to meet the demands of global logistics, particularly for sea freight, which remains the primary mode of transport for bulk shipments of aluminum and copper-based transformer components.

All transformer strip and foil materials are systematically loaded onto high-strength wooden pallets constructed from kiln-dried, fumigation-treated hardwood. These pallets comply with ISPM 15 international phytosanitary standards, ensuring unrestricted customs clearance across global markets. The structural design of the pallets supports uniform weight distribution and resists deformation under prolonged stacking, a critical factor during containerized ocean transport where multi-tier loading is standard practice.

Prior to palletization, each coil or sheet pack undergoes precision alignment and is secured with galvanized steel strapping to prevent lateral displacement. Edge protectors made from corrugated fiberboard or steel channels are applied at critical stress points to mitigate mechanical damage during handling and transit. This mechanical protection system is especially vital for thin-gauge aluminum and copper foils used in high-frequency transformers, where surface integrity directly impacts electrical performance.

The primary moisture barrier is achieved through multi-layer moisture-proof wrapping. Each palletized load is fully encased in industrial-grade, heat-sealed polyethylene vapor barrier film with a minimum thickness of 125 microns. This film provides a hermetic seal that prevents ingress of ambient humidity, salt spray, and condensation—common risks in marine environments. Additionally, desiccant packs are strategically placed within the sealed envelope to absorb any residual moisture and maintain a controlled microclimate during extended voyages.

For enhanced protection, outer layers may include waterproof kraft paper or laminated polyolefin sheeting, particularly for shipments destined for tropical or high-humidity regions. All packaging components are tested for resistance to temperature fluctuations ranging from -20°C to +60°C, simulating the thermal cycles experienced during intercontinental sea freight.

Our packaging protocol is validated through accelerated aging tests and real-world shipment monitoring, including humidity logging and post-transit visual inspection. This data-driven approach ensures continuous improvement and compliance with international material handling standards such as ASTM D4169 and ISO 12048.

By integrating robust mechanical support with advanced moisture mitigation, Luoyang Xinzhaohe Aluminum Co., Ltd guarantees that transformer strip and foil materials arrive at their destination with preserved dimensional accuracy, surface quality, and metallurgical properties. This commitment to packaging excellence supports reliable downstream processing for our global clients in the electrical and electronics manufacturing sectors.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Transformer Bobbin Material Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in metallurgical engineering and industrial supply chain management to deliver mission-critical transformer bobbin materials. Our factory is engineered for uncompromising precision in aluminum and copper strip/foil production, directly addressing the stringent demands of high-efficiency transformer manufacturing. Core to our value proposition is deep metallurgical control, ensuring materials consistently meet or exceed global standards including ASTM B209 for aluminum and ASTM B3 for copper. We maintain rigorous in-house alloy development capabilities, optimizing conductivity, tensile strength, and thermal stability for bobbin applications where dimensional accuracy and electrical performance are non-negotiable.

Our 45,000 m² production facility integrates advanced cold-rolling mills with real-time process monitoring systems, achieving industry-leading thickness tolerances of ±0.005 mm for foils down to 0.05 mm. This precision eliminates micro-defects that cause eddy current losses in high-frequency transformers. Every coil undergoes 100% eddy current testing and laser micrometer verification, with comprehensive traceability from ingot to shipment. Our quality management system is certified to ISO 9001 and IATF 16949, with dedicated metallurgists overseeing batch-specific mechanical and electrical property validation. Critical parameters are documented in material test reports accessible via our customer portal, ensuring full compliance with client specifications and regulatory frameworks like RoHS and REACH.

Supply chain resilience is engineered into our operational model. We operate a vertically integrated process with direct control over homogenization, hot/cold rolling, and slitting, minimizing third-party dependencies. Strategic partnerships with primary aluminum smelters and copper refiners guarantee raw material purity exceeding 99.99%, while our 15,000 MT monthly production capacity supports just-in-time delivery for global OEMs. Our logistics network features bonded warehousing in Shanghai and Rotterdam, enabling 72-hour shipment readiness for critical orders. This infrastructure reduces lead times by 30% compared to industry averages while maintaining strict moisture-controlled packaging to prevent oxidation during transit.

Partnering with Luoyang Xinzhaohe means integrating a Tier 1 supplier whose engineering rigor directly enhances your transformer’s efficiency and reliability. We collaborate from design phase through volume production, providing metallurgical data packs and failure mode analysis to optimize your bobbin performance. For technical specifications, capacity details, or to discuss custom alloy requirements, contact our Transformer Materials Division immediately.

Contact Cathy Zhang, Head of International Sales, at cathy@transformerstrip.com to initiate a precision supply agreement. Specify your required alloy grade, thickness tolerance, and annual volume for a tailored capability assessment within 24 business hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer bobbin material directly from China.