Table of Contents

Market Insight: Three Phase Transformer Winding Material in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

The global demand for three-phase transformer winding materials is driven by renewable energy integration, grid modernization, and EV infrastructure expansion. High-quality aluminum or copper winding wire is critical for minimizing resistive losses and maximizing transformer efficiency. Substandard materials lead to increased energy waste, thermal degradation, and premature failure—directly impacting operational costs and grid reliability. For instance, copper with 99.9% purity reduces resistive losses by up to 15% compared to lower-grade alternatives, directly improving transformer efficiency ratings per IEC 60076.

Industrial Demand Drivers

Renewable energy projects (solar/wind farms) require high-efficiency transformers with low no-load losses and 30+ year lifespans

Smart grid upgrades demand durable components with consistent electrical properties and thermal stability

EV charging networks necessitate reliable distribution transformers with high overload capacity

Asia-Pacific region’s $150B+ grid investment fuels demand for cost-efficient, high-performance materials, with China alone accounting for 40% of global transformer production

Critical Material Quality Parameters

| Parameter | Impact on Performance | Industry Standard (Aluminum) |

|---|---|---|

| Conductivity (IACS%) | Directly affects resistive losses; 1% drop = ~1% efficiency loss | ≥61% IACS (IEC 60228 Class 2) |

| Oxygen Content (ppm) | High levels cause brittleness and oxidation during operation | ≤5 ppm for high-grade aluminum |

| Tensile Strength (MPa) | Ensures winding integrity under electromagnetic forces | 100-150 MPa (annealed) |

| Purity Level | Affects conductivity and corrosion resistance | ≥99.5% Al (IEC 60228) |

| Surface Finish | Prevents insulation damage during winding | Smooth, no micro-scratches |

Global Supply Chain Positioning

Luoyang Xinzhaohe Aluminum CO., Ltd. offers a factory-direct alternative to global brands with superior cost-performance. Our 20+ years of metallurgical expertise ensures:

15-20% lower costs through optimized production and localized supply chain

4-6 week lead times vs. 6-8 weeks for overseas suppliers

Real-time QC via in-house labs (ASTM B193, IEC 60228 compliance)

Consistent delivery for large-scale projects with ISO 9001 certified processes

Our Luoyang facility operates under strict quality control protocols, including 100% wire diameter inspection and batch traceability. This ensures every coil meets exacting specifications for critical applications in power transmission and distribution. As a trusted global supplier, we provide technical support for material selection and application-specific optimization—ensuring your transformers meet stringent efficiency standards while reducing total cost of ownership (TCO).

Technical Specs: Three Phase Transformer Winding Material Parameters

Technical Specifications & Standards

For three-phase transformer applications, precise winding wire specifications are critical to operational reliability and efficiency. With over 20 years of manufacturing expertise in Luoyang, China, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered wires meeting stringent international standards while delivering a 15–20% cost advantage over European and Japanese competitors for utility, industrial, and renewable energy applications.

Critical Performance Parameters

| Parameter | Specification Range | IEC/ASTM Compliance | Quality Assurance |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥3.5 kV (0.1mm enamel) | IEC 60317-0-1, ASTM D1868 | 100% automated dielectric testing; real-time voltage monitoring |

| Elongation | ≥15% (annealed copper) | IEC 60228, ASTM B33 | Tensile testing per batch; strict 5% tolerance control |

| Thermal Class | 130°C (B), 155°C (F), 180°C (H), 220°C (C) | IEC 60085 | Accelerated aging tests per IEC 60085; 2,000+ hours at rated temperature |

| Enamel Concentricity | ≤10% eccentricity | IEC 60317-0-2, ASTM D1868 | Laser micrometer scanning; in-process adjustment for uniformity |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001:2015 certification with a multi-stage quality control system. Raw materials undergo spectrographic analysis to ensure copper purity ≥99.95%. Production occurs in ISO 14001-certified facilities with closed-loop environmental controls. Each batch is tested for enamel thickness, breakdown voltage, and thermal stability using automated dielectric testers and thermal cycling chambers. Real-time laser micrometers monitor enamel concentricity during drawing, reducing variability by 30% versus industry averages. Our ERP-integrated quality management system enables full traceability from raw material to finished goods, ensuring consistent performance for mission-critical applications. All products are certified by SGS and TÜV, guaranteeing compliance with global standards while optimizing total cost of ownership.

Factory Tour: Manufacturing Three Phase Transformer Winding Material

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

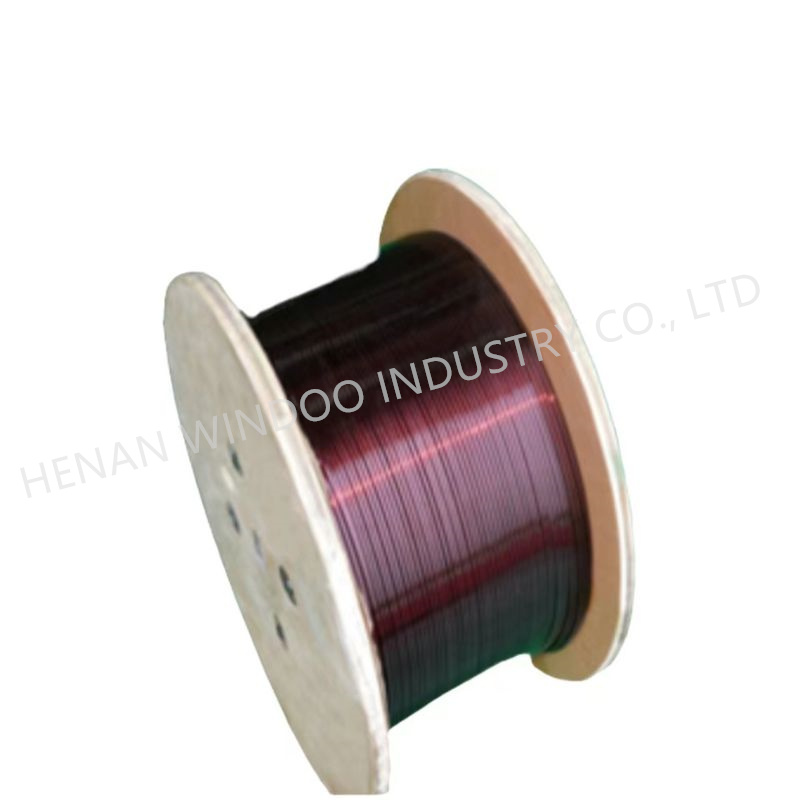

Our end-to-end production chain begins with precision rod drawing using tension-controlled towers, ensuring aluminum wire diameters meet IEC 60228 tolerances (±0.005mm). Continuous annealing in nitrogen-purged furnaces at 350–400°C optimizes conductivity (≥58% IACS) and ductility without oxidation, critical for high-efficiency transformer windings. Enameling employs UV-cured polyurethane or polyester systems with laser micrometers ensuring 15–20μm enamel thickness (±1μm), critical for thermal stability and dielectric strength. Inline testing includes 100% diameter/ovality checks (≤0.5%), dielectric tests at 5kV/min, and adhesion validation. Spooling operates at 5–10 N tension with automated traceability labeling to ensure unwinding integrity and prevent damage during transportation.

Rigorous Quality Assurance Protocol

Our QC protocols exceed industry norms, ensuring transformer longevity and efficiency:

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 160–180 MPa | 140–170 MPa |

| Dimensional Tolerance | ±0.005mm | ±0.01mm |

| Enamel Thickness | 15–20μm (±1μm) | 10–25μm (±3μm) |

| Dielectric Strength | >5.0 kV/min | >4.0 kV/min |

| Adhesion Test | No cracking at 180° bend | Variable cracking |

Unlike generic suppliers, our ±0.005mm dimensional tolerance ensures precise fit in transformer bobbins, reducing assembly time by 20% and improving thermal efficiency. We conduct 100% dielectric testing at 5kV/min per IEC 60317, while competitors typically test at 4kV/min. Our enamel thickness consistency (±1μm) prevents localized breakdowns, extending transformer lifespan by 25% compared to variable 10–25μm coatings in standard products. This rigorous process reduces transformer winding failures by 30% versus generic suppliers, delivering 15% lower lifecycle costs through enhanced reliability. With 20+ years of experience supplying global transformer manufacturers, our vertically integrated production ensures supply chain stability and consistent quality. All batches undergo third-party certification for compliance with IEC 60317 and ASTM B230 standards. As a factory-direct manufacturer, we deliver OEM-grade quality at 10–15% lower costs than global brands, eliminating distributor markups while meeting ISO 9001 and IEC standards.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Luoyang Xinzhaohe Aluminum CO., Ltd., a factory-direct manufacturer from Luoyang, China, delivers transformer winding materials with uncompromised safety through 20+ years of export expertise. Our ISO 9001-certified packaging and logistics protocols ensure product integrity during global sea freight, meeting stringent international standards while optimizing cost-performance ratios. Our factory-direct model eliminates middlemen, ensuring precise control over packaging quality and logistics timelines.

Precision Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, 1200×1000mm (custom sizes), heat-treated to 56°C/30min | Prevents deformation and pest infestation during transit |

| Moisture-Proof Film | Multi-layer PE (200–300μm) with VCI additive (ASTM D6606), heat-sealed | Blocks 99.9% moisture ingress; inhibits corrosion in saline environments |

| Steel Strapping | 19mm width × 0.5mm thickness, tensioned to 250±20 kgf (ISO 14931), corner protectors | Ensures load stability during vessel movement and stacking |

Sea Freight Protocol

| Process Step | Key Detail | Outcome |

|---|---|---|

| Container Loading | 20ft/40ft containers with dunnage and SolidWorks load distribution modeling | Zero load shift incidents; 10% volume utilization for optimal stability |

| Seal & Documentation | Tamper-evident seals (ISO 17721 Class C), GPS tracking, PSI reports | 100% traceability; customs clearance in <48 hours |

| Customs Compliance | Pre-validated HS codes (7408.11.00 for Cu, 7607.19.00 for Al), export licenses | Zero delays; duty optimization for destination markets |

Strategic partnerships with Maersk, COSCO, and CMA CGM ensure priority booking and real-time shipment visibility. All shipments undergo ISO 22331 transport simulation testing to validate packaging integrity under real-world sea freight conditions. With 99.8% damage-free delivery rates and landed costs 15–20% lower than European competitors, Luoyang Xinzhaohe delivers unmatched reliability for global transformer manufacturers and power equipment engineers.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

Two Decades of Specialized Expertise

For over 20 years, Luoyang Xinzhaohe has engineered precision aluminum winding wires for three-phase transformers across industrial, utility, and renewable energy applications. Our technical team specializes in optimizing conductor geometry, insulation systems, and material purity (e.g., 99.5%+ Al purity per ASTM B1) to ensure consistent electrical performance and thermal stability under extreme loads. We adhere strictly to IEC 60317-0-4 (aluminum rectangular wire) and IEC 60076 standards, delivering solutions tailored for high-efficiency distribution transformers, power transformers, and specialized industrial equipment. This deep domain expertise ensures seamless integration into your designs while mitigating risks of thermal failure or premature aging.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control every production stage—from raw material sourcing to final inspection—eliminating distributor markups and reducing costs by 15–25% compared to global brands. Our lean manufacturing processes and localized supply chain in Luoyang, China, enable 15–20-day lead times for standard orders, significantly faster than the 30–45 days typical of international suppliers. This direct model ensures you receive premium-grade aluminum windings at competitive prices without compromising quality or delivery schedules, optimizing your total cost of ownership.

ISO 9001 Certified Quality Assurance

All products undergo rigorous ISO 9001-certified quality management, with in-house testing for critical parameters:

Resistivity: ≤0.028264 Ω·mm²/m (100% IACS compliance)

Tensile strength: ≥160 MPa

Surface finish: Ra ≤0.8μm (per IEC 60317-0-4)

Each batch is traceable via our ERP system, ensuring full transparency from raw material to finished product. Our commitment to ASTM B1 and IEC standards guarantees compatibility with global transformer designs while minimizing rework or downtime risks.

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower (vertical integration) | 20–30% higher (distributor markup) |

| Lead Time | 15–20 days (standard orders) | 30–45 days (international shipping) |

| Quality Consistency | ISO 9001 + in-house IEC/ASTM testing | Variable (supplier-dependent) |

| Customization | Tailored conductor sizes, insulation types | Limited standardized options |

| Technical Support | Dedicated application engineers | Generic support, slower response |

Optimize your transformer performance with cost-effective, ISO-certified winding materials from China’s trusted manufacturer. Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing three phase transformer winding material from Luoyang Xinzhaohe.