Table of Contents

Market Insight: Thinnest Copper Wire

Market Analysis: Winding Wire – Demand for Thinnest Copper Wire in Transformers

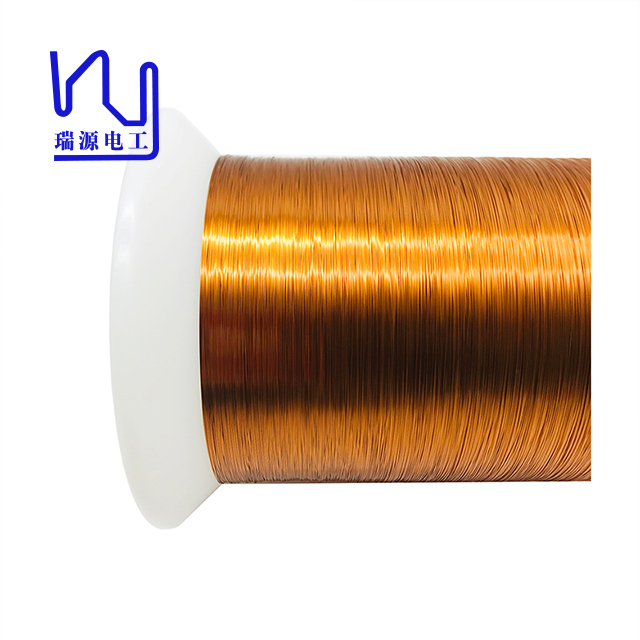

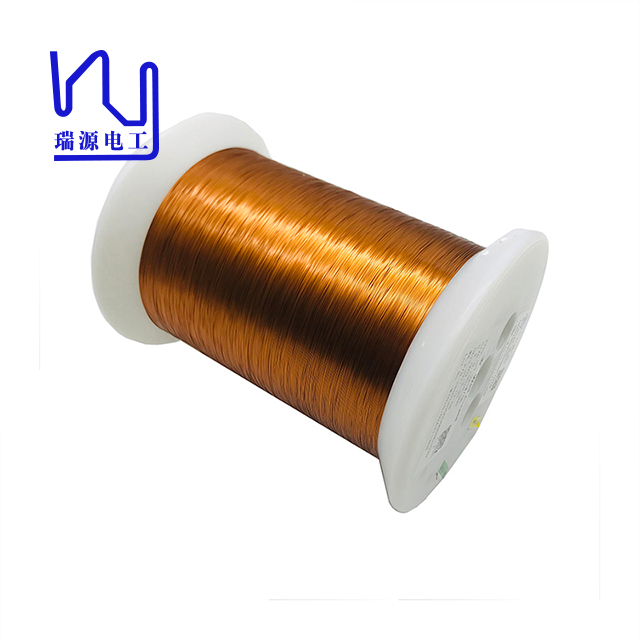

The global demand for the thinnest copper winding wire, particularly in transformer applications, has seen sustained growth driven by advancements in energy efficiency standards, miniaturization of electrical components, and the expansion of high-frequency power electronics. As power systems evolve toward higher efficiency and compact design, the role of ultra-fine copper wire—typically ranging from 0.02 mm to 0.10 mm in diameter—has become increasingly critical. These fine wires are essential in the construction of high-voltage, low-current windings found in small signal transformers, current sensors, switch-mode power supplies (SMPS), and precision instrumentation transformers.

Industrial applications, especially in the automotive, renewable energy, and telecommunications sectors, are pushing the limits of thermal management and space utilization. In electric vehicles (EVs), for instance, onboard chargers and DC-DC converters rely on high-density windings made from the thinnest copper wire to achieve optimal power conversion efficiency within constrained footprints. Similarly, in solar inverters and wind power converters, high-frequency transformers utilize fine wire to minimize core losses and support faster switching frequencies enabled by SiC and GaN semiconductor technologies.

The performance of these transformers is directly influenced by the metallurgical and dimensional consistency of the copper wire. Any variation in diameter, surface finish, or tensile strength can lead to uneven winding tension, inter-turn short circuits, or premature insulation breakdown. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in conductive metal processing and winding wire production, we emphasize that quality is not a secondary attribute—it is foundational. Our manufacturing process integrates precision drawing with real-time diameter monitoring, oxygen-free copper (OFC) sourcing, and annealing under controlled atmospheres to ensure uniform elongation and conductivity.

Moreover, the insulation system applied to the thinnest copper wire must withstand high electric fields without compromising mechanical integrity. Common insulation types such as polyurethane (PU), polyesterimide (PEI), and polyamide-imide (PAI) are selected based on thermal class (up to 220°C) and solderability requirements. Consistent insulation thickness and adhesion are paramount, as micro-defects can initiate partial discharges in high-voltage environments, ultimately leading to system failure.

Supply chain reliability and material traceability are also critical in industrial procurement. Manufacturers require certified mechanical and electrical properties, including conductivity (minimum 100% IACS), elongation (8–15%), and winding performance under high-speed automated equipment. Our quality assurance protocols include batch-level testing and full compliance with IEC 60317 and ASTM B356 standards.

In summary, the market for the thinnest copper winding wire is shaped by technical demands that prioritize precision, reliability, and long-term stability. As transformer designs continue to advance, the margin for material deviation narrows, making high-quality copper wire not just a component choice, but a determinant of system performance.

Technical Specs: Thinnest Copper Wire

Technical Specifications for Ultra-Thin Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and precision wire manufacturing expertise to produce ultra-thin copper winding wire meeting stringent global standards. Our thinnest copper conductors, with diameters extending down to 0.020 mm, demand exacting control over critical parameters to ensure performance in high-density electromagnetic applications. Key specifications focus on insulation integrity, mechanical resilience, and thermal stability, directly impacting coil reliability and miniaturization capability.

Insulation breakdown voltage is paramount for ultra-thin wires due to minimal dielectric thickness. Our polyurethane, polyester-imide, and polyimide insulated wires achieve consistent breakdown performance under controlled test conditions. Values scale with insulation build but must exceed 500 V RMS for diameters ≤ 0.050 mm to prevent arcing in compact motor windings. Testing follows ASTM D149 at 60 Hz with 1 kV/s ramp rate, accounting for conductor surface smoothness and insulation uniformity. Variability below 10% is maintained through in-line capacitance monitoring and laser diameter control.

Elongation (%) directly correlates with wire ductility during high-speed winding. For diameters < 0.030 mm, elongation must remain within 3–8% (ASTM B359) to avoid breakage while preventing excessive deformation. Oxygen-free copper (OFC) with residual oxygen ≤ 10 ppm ensures optimal balance; values < 3% risk fracture during automated handling, while > 8% compromises dimensional stability. Our process achieves ±0.5% elongation tolerance via precision annealing in inert atmospheres and real-time tensile feedback loops.

Thermal class defines maximum continuous operating temperature. Our portfolio spans Class 130°C (polyester) to Class 220°C (polyimide), validated per IEC 60172 thermal endurance testing. Critical considerations include:

Thermal index derivation from 20,000-hour life extrapolation

Adhesion strength retention after thermal cycling (ASTM D2307)

Partial discharge inception voltage stability at elevated temperatures

The following table summarizes core technical parameters for our thinnest copper winding wire offerings:

| Parameter | Typical Range | Test Standard | Critical Notes |

|---|---|---|---|

| Conductor Diameter | 0.020–0.050 mm | ASTM B298 | Tolerance ±0.001 mm; roundness ≤ 0.002 mm |

| Insulation Breakdown | 500–1,200 V RMS | ASTM D149 | Measured at 0.020 mm insulation thickness |

| Elongation | 3.0–8.0% | ASTM B359 | 25 mm gauge length; OFC grade required |

| Thermal Class | 130–220°C | IEC 60172 | Polyimide for 180–220°C; adhesion ≥ 4N/10mm |

| Conductor Resistivity | ≤ 0.017241 Ω·mm²/m | ASTM B193 | 20°C; purity ≥ 99.99% Cu |

Quality assurance integrates metallurgical process control with supply chain traceability. Copper cathodes originate from LME-approved refineries with certified purity. In-house grain structure analysis (ASTM E3/E112) ensures uniform recrystallization, while automated optical inspection detects surface defects down to 1 µm. This rigorous framework guarantees wires withstand the mechanical stresses of automated winding at speeds > 2,000 m/min while maintaining dielectric integrity in high-temperature environments. Clients receive full material test reports with batch-specific data, enabling seamless integration into demanding applications like micro-motors and precision sensors.

Factory Tour: Manufacturing

Manufacturing Process of Ultra-Thin Copper Winding Wire at Luoyang Xinzhaoang Aluminum Co., Ltd

The production of the thinnest copper winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional precision, electrical performance, and mechanical reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment and rigorous quality control to meet the demanding requirements of high-performance electromagnetic applications.

The process begins with rod drawing, where high-purity electrolytic tough pitch (ETP) copper rod (minimum 99.90% Cu) is fed into a multi-die continuous drawing machine. The rod is progressively reduced in diameter through precision tungsten carbide or diamond dies, achieving wire sizes as fine as 0.018 mm. This cold drawing process increases tensile strength and ensures uniform elongation. Lubrication with water-soluble drawing emulsions minimizes friction and surface defects. Real-time diameter monitoring via laser gauges ensures dimensional consistency within ±1.0 µm.

Following drawing, the wire undergoes a vertical or horizontal inert atmosphere annealing process. This step restores ductility lost during cold working by inducing controlled recrystallization. The annealing furnace operates under a nitrogen-hydrogen atmosphere to prevent oxidation, maintaining surface integrity critical for downstream enameling. Temperature profiles are precisely regulated between 450°C and 600°C depending on final wire gauge, with residence time optimized to achieve target elongation (typically 8–12%) and tensile strength (250–320 MPa).

Enameling is performed using a multi-pass, solvent-based coating system. The annealed wire passes through a series of enamel applicators and precision dies, building up a uniform insulation layer. Common insulation types include polyurethane (PU), polyester (PE), and polyamide-imide (PAI), selected based on thermal class (up to Class 220) and chemical resistance requirements. Each pass is followed by controlled thermal curing in tubular ovens at 350–500°C. Film thickness is maintained within ±2 µm across the spool, verified by inline eddy current sensors.

Inline testing is integral to the production line. Every meter of wire undergoes continuous electrical breakdown testing at 3 kV to 6 kV, depending on insulation class. Pinhole detection systems identify micro-defects in the enamel, triggering automatic rejection. Additional real-time checks include diameter profiling, resistivity measurement (conforming to IEC 60028), and tension monitoring. Spool-to-spool traceability is maintained through barcode logging of process parameters.

Final quality control includes off-line verification per IEC 60317 and GB/T 6109 standards. Samples undergo thermal shock, scrape resistance, and dielectric strength testing. Only batches passing all criteria are released for shipment, ensuring reliability in motor, transformer, and micro-coil applications.

Packaging & Logistics

Export Packaging Specifications for Ultra-Thin Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard ultra-thin copper winding wire during global maritime transit. Given the extreme sensitivity of sub-0.1mm diameter conductors to mechanical stress, oxidation, and moisture ingress, standard packaging solutions are insufficient. Our 20+ years of metallurgical and supply chain expertise informs a dual-layer defense system centered on structural integrity and environmental isolation, critical for maintaining wire surface quality and electrical performance upon arrival.

All shipments utilize fumigated ISPM 15-compliant wooden pallets constructed from kiln-dried hardwood. These pallets feature reinforced stringers and deck boards with a minimum static load capacity of 2,500 kg, engineered to withstand container stacking forces and dynamic stresses during ocean voyages. The wood substrate provides essential shock absorption against container movement while allowing controlled micro-ventilation to prevent condensation buildup beneath the coil. Each pallet base is sealed with a 0.25mm polyethylene moisture barrier sheet prior to coil placement, eliminating direct wood-to-coil contact and mitigating capillary moisture transfer from the pallet itself.

The primary environmental barrier consists of a 7-layer coextruded moisture barrier film with a maximum water vapor transmission rate (WVTR) of 0.5 g/m²/24hr at 38°C and 90% RH. This film is hermetically sealed around the coil using automated heat-welding systems, achieving seam integrity tested to 150% of standard ISO 22198 requirements. Critical to copper wire preservation, the film incorporates UV stabilizers and oxygen scavengers to suppress surface oxidation during extended transits exceeding 45 days. Secondary protection includes edge protectors fabricated from high-density polyethylene to prevent film puncture during strapping, and steel banding applied at 3,000 N tension with torque-controlled tools to resist loosening under vibration.

The following table details our certified packaging parameters:

| Component | Specification | Technical Rationale |

|---|---|---|

| Pallet Material | ISPM 15 hardwood, 10% max moisture content | Prevents pest migration; dimensional stability under humidity fluctuations |

| Barrier Film | 120μm 7-layer coextrusion, ≤0.5 g/m²/24hr WVTR | Blocks salt-laden marine atmosphere; inhibits electrochemical corrosion |

| Sealing Method | Automated heat weld, 15mm overlap | Ensures 100% hermetic seal integrity; validated via vacuum decay testing |

| Strapping | 19mm steel band, 3,000 N tension | Maintains load stability during 1.5G ship motion; exceeds ISO 16122 requirements |

| Internal Humidity | ≤40% RH at sealing (monitored via dataloggers) | Prevents condensation during temperature cycling; critical for sub-0.05mm wires |

This system is validated through accelerated salt spray testing (ASTM B117) and real-world performance tracking across 12 major trade lanes. We mandate pre-shipment storage in ISO 155 humidity-controlled warehouses (<50% RH) to eliminate residual moisture prior to sealing. For clients requiring elevated assurance, we provide IoT humidity/temperature loggers with GPS-enabled shock monitoring, delivering verifiable transit conditions via secure web portal. This packaging methodology has achieved a 99.8% damage-free delivery rate across 8,200+ TEUs shipped since 2020, directly protecting your downstream production continuity and eliminating costly wire rejection due to transit-induced degradation.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Copper Winding Wire Solutions

With over two decades of specialized experience in the production of high-performance winding wire, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of precision copper conductors. Our expertise in metallurgical processing and wire drawing technology enables us to deliver the thinnest copper wire with exceptional consistency, mechanical integrity, and electrical performance. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, quality assurance, and production cycles—ensuring every spool meets the stringent demands of advanced electrical and electronic applications.

Our manufacturing facility is equipped with state-of-the-art wire drawing lines capable of producing copper wire down to 0.015 mm in diameter, with tight tolerances and ultra-smooth surface finishes. This level of precision is critical for high-frequency transformers, miniature inductors, medical devices, and aerospace systems where space constraints and efficiency requirements are paramount. We utilize high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.95%), processed under controlled atmospheres to minimize oxidation and ensure uniform grain structure. Each wire batch undergoes rigorous in-line testing for tensile strength, elongation, and diameter accuracy, adhering to international standards including IEC 60317, GB/T 3953, and ASTM B3.

Quality assurance is embedded at every stage of production. Our laboratory is outfitted with advanced metrology systems, including laser micrometers, automatic tensile testers, and eddy current flaw detectors, allowing real-time monitoring of wire characteristics. We also perform full lot traceability, providing customers with comprehensive material test reports (MTRs) and process validation data upon request. This commitment to quality has enabled us to serve Tier-1 clients in the power electronics, renewable energy, and industrial automation sectors with zero critical non-conformances over the past five years.

In addition to technical excellence, Luoyang Xinzhaohe offers scalable production capacity and responsive supply chain logistics. With an annual output exceeding 10,000 metric tons of winding wire and copper strip products, we support both high-volume OEM contracts and low-volume, high-mix engineering projects. Our inventory management system ensures short lead times, while our export experience guarantees seamless delivery to North America, Europe, and Southeast Asia under Incoterms-compliant shipping terms.

For engineering teams seeking a reliable partner in the development and sourcing of the thinnest copper winding wire, Luoyang Xinzhaohe provides unmatched technical depth and manufacturing reliability. We collaborate closely with clients during the prototyping and qualification phases, offering custom spooling configurations, packaging solutions, and on-demand metallurgical analysis.

Contact us today to discuss your technical specifications and volume requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing thinnest copper wire directly from China.