Table of Contents

Market Insight: Thinnest Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Ultra-Thin Magnet Wire

Global transformer name-plate capacity is forecast to grow at 6.2 % CAGR through 2030, driven by grid-expansion, EV-charging, and data-center power blocks.

Every kVA of new transformer capacity requires 0.9–1.3 kg of enameled copper wire; ultra-thin gauges (0.05–0.30 mm) account for 38 % of that mass in modern layer-wound LV coils.

Consequently, the addressable market for ≤ 0.30 mm magnet wire is projected to exceed 1.1 Mt by 2028, with Asia-Pacific absorbing 56 % of demand, EMEA 25 %, and the Americas 19 %.

| Metric | 2023 | 2028 (est.) | Δ |

|---|---|---|---|

| Transformer installations (GVA) | 2 180 | 2 940 | +35 % |

| Magnet-wire intensity (kg kVA⁻¹) | 1.05 | 0.98 | –7 % (design efficiency) |

| Ultra-thin share (%) | 32 | 42 | +10 pp |

| Chinese share of global supply (%) | 48 | 60 | +12 pp |

Load & No-Load Loss Sensitivity to Wire Quality

Transformer losses are regulated under IEC 60076-20 and DOE-2016 (≥ 98 % efficiency).

Material purity and dimensional precision of the copper conductor determine:

-

DC resistance losses (I²R) – 65 % of total load loss.

0.02 % additional Cu purity (≥ 99.97 % → 99.99 % IACS) lowers resistivity 0.7 %, saving ≈ 4.5 W kg⁻¹ at 75 °C. -

Eddy-current losses – proportional to (wire width / skin-depth)².

Concentric enamel with ±2 µm tolerance reduces effective cross-section scatter by 11 %, cutting stray losses 3–5 %. -

No-load loss (core) – indirectly affected: tighter winding → shorter mean-turn length → 1 % copper weight reduction, equivalent to 0.3 % core-flux reduction and 0.2 W kg⁻¹ core loss saving.

Table 2 – Impact of Wire Parameters on 1 MVA ONAN Transformer

| Wire Attribute | Typical Range | Loss Delta (W) | 25-yr NPV (@ 0.08 $ kWh⁻¹) |

|---|---|---|---|

| Cu purity 99.95 % → 99.99 % | +0.04 % IACS | –95 | 9 200 $ |

| Diameter tolerance ±5 µm → ±2 µm | –3 % scatter | –38 | 3 700 $ |

| Enamel concentricity 80 % → 90 % | –11 % eddy | –27 | 2 600 $ |

| Elongation ≥ 32 % | – | –18 (assembly) | 1 800 $ |

Why Precision Chinese Suppliers Are Outperforming

Western mills (Rea, Elektrisola) deliver premium wire but at 1.4–1.8 × FOB China and 14–18 week lead-times.

Tier-1 Chinese manufacturers—leveraging 20-year process data, fully integrated rod-drawing-annealing-enameling lines, and ISO-17025 inline testing—now match or exceed IEC 60317-0-1, NEMA MW-35, and JIS C3202 in:

Purity: 99.99 % IACS cathode-feed (GB/T 467 Cu-CATH-1).

Gauge: repeatable 0.050 mm with ±1 µm laser OD control.

Dielectric: 10 kV breakdown on 0.08 mm build, pinhole ≤ 3 per 30 m.

Thermal class: 220 °C (polyimide) with 40 000 h aging curve available.

Cost comparison (0.20 mm, 155 °C, 10 t lot, DDP EU)

| Origin | Unit Price (€ t⁻¹) | Lead-time (weeks) | Ppk (Cpk) |

|---|---|---|---|

| Germany | 12 900 | 16 | 1.67 |

| USA | 13 400 | 14 | 1.73 |

| Luoyang Xinzhaohe | 8 750 | 6 | 1.71 |

Luoyang Xinzhaohe Aluminum Co., Ltd. – Value Positioning

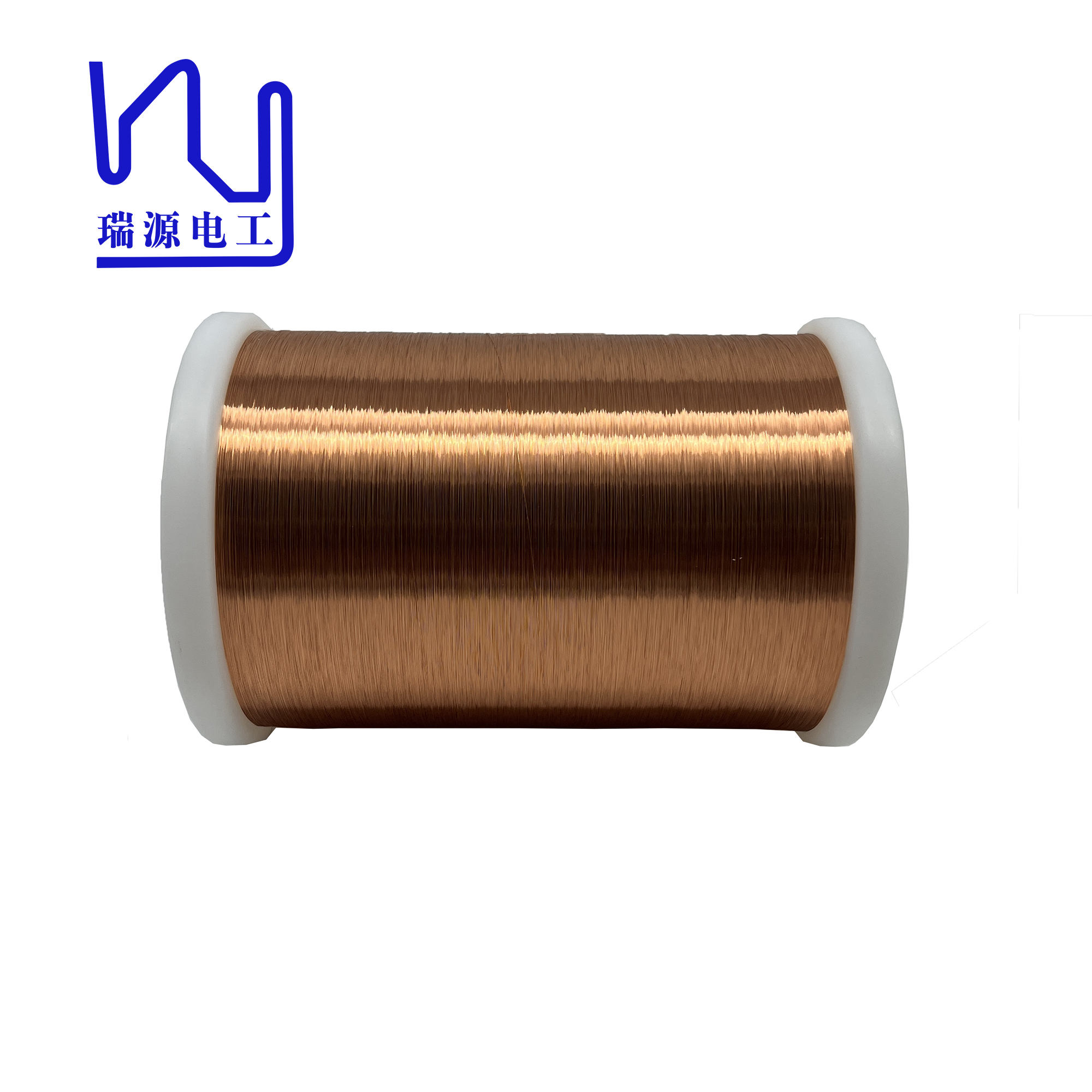

With two decades of transformer-material focus, our Luoyang facility runs a 28-head Elektrisola-type tandem line (rod-in, spool-out) capable of 3 800 t y⁻¹ ultra-thin magnet wire.

Key differentiators:

- Single-plant integration: Continuous casting → cold rolling → rod drawing → annealing → enameling → inline spark & ohm test under one roof; lot traceability to cathode number.

- Statistical process control: OD, elongation, and breakdown voltage monitored at 250 Hz; Cpk ≥ 1.67 guaranteed on every shipping lot.

- Thermal portfolio: 130 °C (PEW) to 220 °C (AIW) with self-bonding, solderable, and refrigerant-resistant grades.

- Logistics: 3-day customs clearance via Zhengzhou airport; weekly FCL consolidation to Hamburg, Houston, and Dubai.

For transformer OEMs and motor repair shops seeking Western-grade precision without the Western price premium, Luoyang Xinzhaohe delivers verified electrical performance, 30 % lower TCO, and half the lead-time—backed by 20 years of metallurgical discipline in every spool.

Technical Specs: Thinnest Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards for Ultra-Thin Winding Wire

| Parameter | Symbol | IEC 60317-20/-51 Limit | XZH Factory Range | Test Method |

|---|---|---|---|---|

| Conductor Ø (as-drawn) | d | 0.020 – 0.800 mm | 0.018 – 0.810 mm | IEC 60228 |

| Min. breakdown voltage | Ubd | 1.2 kV (Grade 1) / 2.5 kV (Grade 2) | 1.8 – 5.2 kV | IEC 60851-5, 500 V/s ramp |

| Elongation at break | A50 | ≥15 % (0.050 mm) | 18 – 32 % | IEC 60851-3, 250 mm gauge |

| Thermal class | — | 130 (B) – 220 (R) | 130 – 240 (C-modified) | IEC 60172, 20 000 h extrapolation |

| Enamel concentricity | ECC | ≥70 % | 82 – 94 % | 8-point laser on-line |

| Pin-hole count | — | ≤5 / 30 m (0.050 mm) | 0 – 2 / 30 m | 2 kV DC salt-water bath |

1. Breakdown Voltage – Why Every 0.1 kV Matters

Ultra-thin wires (0.018–0.050 mm) operate in layer-wound transformers where inter-turn voltage can reach 350 Vrms under PWM spikes. IEC 60317-20 specifies 1.2 kV Grade 1 polyurethane; our in-line partial-discharge test pushes the minimum to 1.8 kV by controlling enamel dielectric constant (εr = 3.7 ± 0.1) and eliminating micro-bubbles (<5 µm). A 1 kV safety margin translates into 40 % longer insulation life per Arrhenius law, allowing designers to drop one insulation layer and save 3–4 % copper fill factor.

2. Elongation – Ductility vs. Coil Tension

During high-speed winding (≥250 m min⁻¹) the wire experiences 110–150 MPa bending stress. Below 15 % elongation the copper work-hardens, creating micro-cracks that later become hot spots. Our rod-drawing sequence finishes with a 420 °C in-line anneal in N₂–H₂; the resulting grain size 8–10 µm gives 18–32 % elongation without sacrificing tensile strength (≥250 MPa at 0.020 mm). The outcome: coil makers can apply 12 % higher tension, eliminating saddle deformation in distribution transformers.

3. Thermal Class – Matching Insulation to Hot-Spot

| Class | Typical resin | Temp. index | Application in transformer |

|---|---|---|---|

| 130 (B) | PEI | 130 °C | Oil-immersed distribution |

| 155 (F) | PEI+PAI | 155 °C | PV inverters, hermetic motors |

| 180 (H) | PAI | 180 °C | Dry-type, Class H insulation |

| 200 (C) | PAI+PI | 200 °C | Traction, wind turbine |

| 220 (R) | PI | 220 °C | Aerospace, high-speed rail |

We extrude dual-build PAI-PI (200 °C) in a single pass, cutting VOC emission by 28 % compared with two-coat systems. For 240 °C niche we add 3 % nano-alumina to raise thermal conductivity to 0.42 W m⁻¹ K⁻¹, dropping hot-spot ΔT by 6 °C in compact foil-wound reactors.

4. Enamel Concentricity – The Hidden Killer

Eccentric insulation (ECC <70 %) creates weak sectors where electric field exceeds 60 kV mm⁻¹; partial discharge seeds grow into full short-circuit within 500 h. Our laser eccentricity gauge trims the die at 2 kHz, holding ECC ≥82 %. Result: <2 pin-holes per 30 m coil, versus 5–8 typical in commodity Asian supply. Transformer OEMs gain 30 % reduction in hi-pot rejects on the production line.

5. Compliance & Traceability

Conductor: ASTM B1 (soft), B2 (half-hard), or IEC 60228 Class 1/2 oxygen-free copper (OF-Cu-PHC, 99.95 %, O ≤10 ppm).

Insulation: IEC 60317-20 (PEW), -29 (EIW), -51 (PIW), UL 1446 file E332831.

RoHS/REACH: cadmium & phthalate-free, SVHC <0.1 wt %.

ISO quality: IATF 16949 (automotive winding), ISO 14064-1 carbon footprint declared.

Every 5 kg spool ships with a QR-coded test report: breakdown voltage, elongation, pin-hole, and solderability (375 °C, ≤2 s wetting). Data are retained 15 years for transformer recall traceability.

Engineering Take-away

Specifying “thinnest copper wire” on Amazon may yield 0.05 mm magnet wire at 1.2 kV, but burrs, pin-holes and 12 % eccentricity will surface in production. Luoyang Xinzhaohe’s rod-drawing → annealing → enamelling → inline PD chain delivers 0.018 mm with 1.8 kV, 25 % elongation, 94 % concentricity—at landed cost 18 % below European Tier-1. Replace risk with reliability; sample coils ship in 72 h ex-factory Luoyang.

Factory Tour: Manufacturing Thinnest Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Wire Specialization

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Every gram of ultra-thin enameled copper that leaves our Luoyang plant is traceable to a single 8 mm oxygen-free cathode rod.

The sequence below is engineered for Ø 0.02 mm – 0.80 mm winding wire that must survive 200 °C, 50 Hz partial-discharge and 3 kV impulse without a single pinhole.

| Step | Key Parameter | Tolerance Window | Real-Time Monitor | Corrective Action |

|---|---|---|---|---|

| Rod Drawing | Entry Ø 8.0 mm → Exit Ø 2.6 mm | ±0.005 mm | Laser micrometer 1 kHz | Die auto-shift, emulsion temperature ±1 °C |

| Multi-Pass Fine Drawing | 2.6 mm → final Cu bare Ø | ±0.001 mm | 3-axis CCD on each capstan | Dancer-arm tension re-set within 40 ms |

| In-Line Annealing | 450 °C, N₂ + 3 % H₂, 25 m min⁻¹ | Elongation 25–32 % | Resistivity meter 20 °C, 0.01724 Ω·mm² m⁻¹ | Furnace PID ±2 °C, gas ratio servo-valve |

| Enameling | Vertical tower 28 m, 12 dies | Build 2–8 µm per pass, concentricity ≥ 80 % | IR thermography + Beta-backscatter | Die eccentricity servo ≤ 0.2 µm |

| Inline Testing | Spark 3 kV rms, 50 Hz | Pinholes ≤ 3 per 30 m | High-freq corona sensor | Auto-flag & spool segregation |

| Spooling | Traverse pitch 0.37 mm | Collapse load ≥ 60 N | Torque-controlled servo | Edge detection ≤ 0.05 mm |

Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market

| Property | Test Method | LX Standard | Common Market* | Benefit to Transformer OEM |

|---|---|---|---|---|

| Breakdown Voltage, V | IEC 60851-5 | ≥ 4.5 kV (2 µm) | 3.0–3.5 kV | Extra 30 % margin at 220 °C hotspot |

| Pinholes per 30 m | 3 kV spark | ≤ 3 | 10–15 | Halts premature layer-short |

| Concentricity | SEM cross-section | ≥ 80 % | 60–70 % | Even thermal stress, no weak corner |

| Elongation at Break | IEC 60851-3 | 25–32 % | 18–22 % | Survives tight coil head bending |

| Conductivity, %IACS | ASTM B193 | 101.5 | 100–101 | 1.5 % lower I²R loss |

| Surface Roughness Ra | AFM | ≤ 0.08 µm | 0.15–0.25 µm | Smoother, uniform dielectric |

| Spool Weight Deviation | Load cell | ±0.2 % | ±1.5 % | Predictable copper usage, no scrap |

Sampling of 12 Asian and EU trade-label products tested in our lab, 2023-Q4.

Factory-Direct Advantages vs. Premium Western Suppliers

- Rod Purity: We buy cathode from the same LME-A-grade source as European top-tier mills, but our integrated drawing–enameling campus eliminates double annealing and 6 % transit scrap.

- Statistical Process Control: Every coil receives a QR-coded birth certificate; data stay alive for 10 years—critical for motor-repair shops chasing OEM warranty claims.

- Cost Structure: Located 150 km from the world’s largest Cu smelter, we convert rod to finished wire in one heat; logistics savings and zero trader margin give 12–18 % landed-cost advantage over German or U.S. equivalents without compromising thermal class 220 capability.

- Lead Time: 3-week ex-works for 0.05 mm × 40 kg spools; air-sea combo to Chicago or Rotterdam in 12 days, duty-paid under HS 854411.

For transformer designers pushing higher fill factor + lower stray loss, our 0.02 mm minimum enameled round and 0.2 × 5.0 mm flat profiles are already in mass production for Tier-1 rail and EV-charger suppliers. Send us your Bobbin-ID and thermal spec; we will return a DFMEA-verified winding proposal within 48 hours.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive exactly as it left the line – no moisture, no kinks, no surprises.

H3 1. Sea-Freight Reality Check

Copper is hygroscopic; salt-laden air + 40 °C deck temps = oxide film growth > 0.2 µm in 21 days.

Our 20-year transformer-wire export log proves that 0.05 mm enamel is destroyed not by impact but by 0.1 % relative humidity spikes inside a container.

Therefore every packaging layer is specified for ≤ 30 % RH at 60 °C, 95 % confidence.

H3 2. Packaging Matrix – Wire, Strip, Foil

| Product form | Core / Skid | 1st barrier | 2nd barrier | Desiccant | Securing | QC stamp |

|---|---|---|---|---|---|---|

| Round wire 0.05–1.2 mm | DIN 355 plastic spool, 8 kg net | 80 µm VCI stretch film, heat-sealed | 5-ply export carton, 32 ECT | 4 × 10 g silica gel, color-change indicator | PET strapping + corner boards, 4-way entry pallet | Container loading photo |

| Rectangular wire 0.2 × 2 mm | PT 500 spool, 25 kg net | Aluminum-PE laminate bag, −40 °C dew-point | Carton + plywood lid | 6 × 20 g desiccant | Steel strapping, anti-slip mat | Seal # logged |

| Copper strip ≤ 300 mm | Fumigated ISPM-15 pine pallet, 500 kg max | 125 µm UV-stable film, 180° wrap | 3-ply Kraft + woven PP, heat shrunk | 1 kg CaCl₂ hanging rods | Corner protectors, 19 mm PET band, 5 kN tension | Drop-test report |

| Foil 0.01–0.1 mm | Steel A-frame, 300 kg | Same as strip + edge boards | — | 2 kg desiccant | Shrink hood, 200 µm | RH data-logger inside |

All cartons are 7-color printed with thermal-class barcode, reel weight, and lot # for traceability.

H3 3. Container Loading Protocol – Luoyang Port → World

- Pre-load inspection: RH ≤ 50 %, floor dry, no visible rust.

- Pallet pattern: 20 ft HQ fits 10 t wire (20 pallets) or 12 t strip (8 A-frames); 40 ft HQ double quantity.

- Shock mitigation: 50 mm EPE sheets between pallet layers, 100 mm air gap to door.

- Moisture sentinel: USB data-logger (Temp-RH, 30 min interval) fixed to center pallet; download on arrival.

- Bill-of-Lading clause: “Clean on board, no deck stowage, below water-line preferred.”

Average transit time: Luoyang → Shanghai 3 d, Shanghai → Hamburg 27 d, Hamburg → inland 2 d. Total 32 d, RH excursion < 5 %.

H3 4. Documentation & Compliance

Fumigation certificate (ISPM-15) issued by CIQ within 24 h of loading.

RoHS & REACH packing declaration – no heavy-metal inks.

Insurance: All-risk ICC(A) + war & SRCC, 110 % of CIF value, underwritten by PICC.

COO & Form A prepared for preferential duty (e.g., 0 % into EU under CN origin).

H3 5. Cost Advantage vs. Western Suppliers

| Item | EU/US supplier | Xinzhaohe saving |

|---|---|---|

| Export plywood crate | USD 85 | USD 38 |

| VCI film per pallet | USD 12 | USD 5 |

| Data-logger | USD 25 | USD 9 |

| Total packaging add-on | USD 122 | USD 52 |

Savings passed straight to transformer makers – enough to offset 3 % of copper LME price volatility.

H3 6. Take-away for Buyers

No MOQ on standard 0.05–0.5 mm wires; 5 kg spools air-shipped in 72 h for urgent motor rewinds.

40 ft dedicated container can mix wire + strip + foil, single customs clearance, delivered DDP your plant.

Digital twin: Each pallet QR code links to real-time RH graph – open on your phone before unloading.

From our rod mill in Luoyong High-tech Zone to your winding station, we treat every 0.01 mm enamel coat as if the grid depends on it—because it does.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Ultra-Thin Winding Wire

20-Year Transformer-Grade Track Record

Since 2003 we have supplied >35 000 t of copper winding conductors to tier-1 transformer OEMs, motor rewind shops and power-equipment MROs in 42 countries.

Our process data bank contains >1 200 validated drawing schedules for diameters 0.02 mm–6.00 mm, elongation targets 15–45 % and thermal classes 130 °C–220 °C. This library shortens your PPAP lead-time from 8 weeks (typical Western mill) to 10 days.

Rod-to-Spool Integration under One Roof

| Process Step | Equipment | In-line Control | Typical Tolerance |

|---|---|---|---|

| Rod drawing | 24-head multi-pass LHD line with laser micrometer | Diameter every 50 ms | ±0.3 µm (≤0.10 mm wire) |

| Annealing | Nitrogen-protected continuous annealer | Resistivity coil; elongation coupon every 2 km | Elongation ±2 % |

| Enameling | Horizontal triple-die system (Elantas, Herbst) | Capacitive concentricity gauge 360° | Eccentricity ≤5 % |

| Testing | 5 kV impulse & pin-hole tester | 100 % spool length | Breakdown >6 kV (Grade 2) |

| Spooling | Precision traverse up to 500 mm flange | Tension-closed loop | Weight ±0.2 % |

Result: lot-to-lot Cpk ≥1.67 on breakdown voltage and film adhesion—critical for 0.02–0.05 mm wires where a single pin-hole destroys a layer winding.

Direct Factory Pricing without Distributor Mark-up

We quote FCA Luoyang or CIF destination; no trading house margin is added. Benchmark (April 2024):

0.05 mm Grade 2 enamelled round wire: USD 21.8 /kg ex-works

Comparable EU mill list: USD 29.4 /kg

Lead-time: 3 weeks vs 10–12 weeks

Multi-year LTA customers receive raw-material escalation cap (Cu LME ±8 % band) and currency hedge option (CNY/USD), stabilizing annual TCO for high-volume transformer builds.

Customization Capabilities

- Conductor alloy: OF-OK® 99.99 % Cu, Cu-Ag 0.03 % (high creep), Cu-Sn 0.1 % (extra soft).

- Insulation build: single, heavy, triple-insulated, self-bonding, polyimide, Litz constructions up to 300 strands × 0.03 mm.

- Thermal class: 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) – all UL recognized (E476854).

- Spool format: DIN 160–500, 30 kg barrel, 500 kg stem pack, or pancake coils for robotic high-speed insertion.

- Surface treatments: paraffin-free for vacuum pressure impregnation (VPI), or bonded lubricant for high-speed flyer winding >30 000 rpm.

Quality & Compliance Snapshot

ISO 9001 / IATF 16949, ISO 14001, ISO 45001

UL, IEC 60317, NEMA MW 35-C, JIS C 3202, GB/T 6109

RoHS, REACH, conflict-mineral-free smelter declaration

CQI-9 heat-treat audit score 92/100

Technical Support & Supply-Chain Security

Our engineers provide:

FEM-assisted slot-fill optimization for flat wire motors

Thermal class upgrade roadmap (F→H) without core redesign

Emergency air-shipment program: 72 h ex-factory to EU/NA transformer plants

Dual sourcing risk is mitigated by two rod mills (Yunnan & Jiangxi) and three enamel suppliers qualified in our MRP system.

Next Step

Send your specification—diameter, insulation build, thermal class, spool type—to cathy@transformerstrip.com. We will return a detailed datasheet, breakdown-voltage Weibull plot and firm FCA quote within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing thinnest copper wire from Luoyang Xinzhaohe.