Table of Contents

Market Insight: Thin Copper Strips

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for thin copper strips in transformer manufacturing continues robust growth, driven by escalating requirements for efficient power conversion and distribution infrastructure. Key sectors fueling this demand include renewable energy integration, particularly solar and wind inverters requiring high-frequency transformers, electric vehicle charging networks demanding compact and reliable units, data center power supplies necessitating ultra-high efficiency, and ongoing grid modernization programs worldwide. Copper remains the dominant conductor material for critical transformer windings due to its superior electrical conductivity compared to aluminum, especially in applications where space constraints, thermal management, and minimal energy loss are paramount. The shift towards higher operating frequencies in modern power electronics further intensifies the need for precision-engineered thin copper strips, as skin and proximity effects become more pronounced, demanding exceptional dimensional consistency and surface quality to mitigate eddy current losses.

The performance and longevity of transformers are critically dependent on the metallurgical and dimensional integrity of the copper strip used. Transformer-grade copper must adhere to stringent international standards, such as ASTM B152 or IEC 60138, specifying minimum conductivity levels typically exceeding 98% IACS (International Annealed Copper Standard) for electrolytic-tough-pitch (ETP) copper. Deviations in conductivity directly translate to increased resistive (I²R) losses, reducing overall system efficiency and generating excess heat. Surface quality is equally vital; microscopic imperfections, scratches, or excessive roughness act as nucleation points for insulation breakdown under high electrical stress and thermal cycling, leading to premature transformer failure. Dimensional tolerances, particularly thickness uniformity and edge straightness within microns, are non-negotiable for automated winding processes and to ensure consistent magnetic performance and thermal dissipation across the coil. Inadequate mechanical properties, such as improper tensile strength or elongation after annealing, can cause strip breakage during high-speed winding or insufficient formability, disrupting production and increasing scrap rates. Contamination from rolling oils or handling must be rigorously controlled to prevent insulation degradation.

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in precision metal rolling for electromagnetic applications to deliver transformer-grade copper strip meeting these exacting demands. Our deep understanding of the interplay between metallurgical structure, processing parameters, and final electrical performance ensures consistent production of strip with guaranteed conductivity, ultra-smooth surfaces (Ra typically < 0.5μm), and micron-level dimensional tolerances. Rigorous in-process and final quality control, including continuous conductivity monitoring, high-resolution surface inspection, and precise dimensional metrology, underpins our commitment to supplying material that minimizes transformer losses, maximizes reliability, and supports the operational efficiency of the end-user’s power systems. The cost of transformer failure or reduced efficiency far outweighs the investment in certified, high-purity copper strip from a proven metallurgical partner.

Technical Specs: Thin Copper Strips

Technical Specifications for Thin Copper Strips

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision thin copper strips designed for critical applications in power transformers, electrical contacts, and high-efficiency conductors. With over two decades of metallurgical expertise, our production processes ensure dimensional accuracy, superior electrical performance, and edge quality essential for advanced electrical systems. The following technical specifications define the performance parameters of our thin copper strip offerings, aligned with international standards and customized to meet stringent customer requirements.

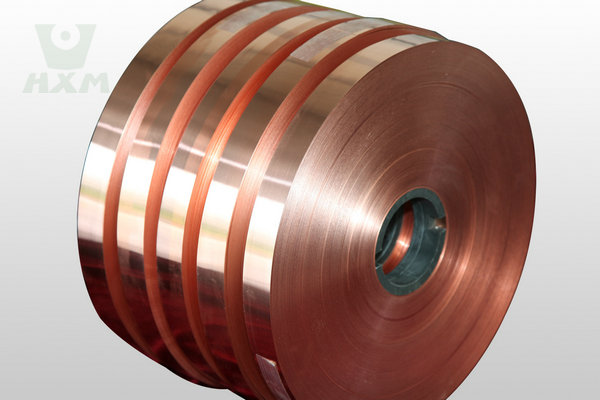

Our thin copper strips are produced from high-purity electrolytic tough pitch (ETP) copper (Cu-ETP1, C11000), ensuring optimal conductivity and mechanical stability. All strips undergo precision cold rolling followed by controlled annealing to achieve the desired temper—ranging from half-hard to fully soft—depending on the application’s formability and strength needs. The strips are available in thicknesses from 0.05 mm to 0.5 mm and widths from 5 mm to 300 mm, with custom dimensions supported upon request.

A key differentiator in our manufacturing process is precision slitting, performed using advanced rotary shear slitters with automatic tension control. This ensures a slit tolerance of ±0.002 mm, critical for minimizing material waste and ensuring compatibility in automated winding and assembly systems. Edge consistency is rigorously monitored to eliminate burrs, which can compromise insulation integrity and lead to electrical arcing in transformer windings. All strips are 100% edge-inspected using optical profilometry, guaranteeing burr-free edges with a maximum edge protrusion of ≤5 µm.

Electrical conductivity is maintained at a minimum of 98% IACS (International Annealed Copper Standard) at 20°C, verified through four-point probe resistivity testing per ASTM B3. Surface finish is controlled to an Ra value of ≤0.4 µm, reducing skin effect losses in high-frequency applications. The strips exhibit uniform grain structure and low residual stress, contributing to excellent flatness and coil stability during high-speed processing.

All products are supplied in coil form on galvanized or plastic spools, vacuum-sealed with desiccant to prevent oxidation during transit and storage. Material certification, including chemical composition, mechanical properties, and conductivity test reports, is provided with each shipment.

Below is a summary of standard technical parameters:

| Parameter | Specification |

|---|---|

| Material Grade | Cu-ETP1 (C11000), ASTM B187 |

| Thickness Range | 0.05 mm – 0.5 mm |

| Width Range | 5 mm – 300 mm |

| Slitting Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, ≤5 µm protrusion |

| Electrical Conductivity | ≥98% IACS (20°C) |

| Temper | Soft (O), 1/2 Hard (H02), Hard (H04) |

| Surface Roughness (Ra) | ≤0.4 µm |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm (customizable) |

| Packaging | Vacuum-sealed with anti-corrosion protection |

These specifications reflect Luoyang Xinzhaohe’s commitment to delivering copper strips that meet the highest standards of electrical and mechanical performance in demanding industrial environments.

Factory Tour: Manufacturing

Manufacturing Process for Precision Copper Transformer Strips

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical expertise in non-ferrous rolling to produce high-performance thin copper strips essential for advanced transformer cores. While specializing in aluminum solutions, our stringent copper strip manufacturing process adheres to the same exacting standards, ensuring dimensional precision and electromagnetic efficiency. The core sequence involves Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality control.

Cold rolling forms the critical foundation for strip quality. Starting with high-conductivity electrolytic tough pitch (ETP) copper ingots, homogenized and hot-rolled to intermediate gauges, the material undergoes multi-stand cold reduction. Our state-of-the-art rolling mills utilize computer-controlled tension and precision-ground work rolls to achieve target thicknesses typically ranging from 0.05mm to 0.50mm. This process demands meticulous control of reduction ratios per pass, interstand tension, and roll coolant systems to prevent surface defects, ensure uniform microstructure, and minimize residual stress. Thickness variation is continuously monitored in real-time using non-contact laser micrometers, maintaining tolerances within ±0.002mm across the strip width. Surface roughness is optimized to Ra ≤ 0.20µm to facilitate subsequent insulation layer adhesion in transformer windings.

Following cold rolling, Precision Slitting subdivides the master coil into the final required widths. This operation employs high-precision rotary shear slitters with hardened, ground tooling sets maintained to exacting geometries. Critical parameters include optimal blade overlap, side clearance, and strip tension control to eliminate burrs, edge pull-down, or camber. Width tolerances are held to ±0.05mm for standard grades and ±0.02mm for high-precision applications. In-process verification uses optical measurement systems to confirm dimensional accuracy immediately post-slitting, ensuring consistency critical for automated transformer winding equipment.

Edge Conditioning is a vital step specific to transformer strip performance. The slit edges undergo controlled mechanical brushing or light grinding to remove micro-burrs and create a consistent, slightly rounded edge profile. This process eliminates sharp protrusions that could puncture interlaminar insulation during core stacking or winding, significantly reducing the risk of electrical shorts and core losses. The target edge radius is precisely controlled within 0.05mm to 0.15mm, verified using optical edge profilers on sampled sections.

Comprehensive Quality Control is embedded throughout the production flow. All batches undergo strict final inspection per ASTM B152 and customer specifications. Key parameters measured include:

| Parameter | Standard Tolerance | Measurement Method |

|——————–|——————–|————————–|

| Thickness | ±0.002mm | Laser Micrometer |

| Width | ±0.02mm to ±0.05mm | Optical Gauge |

| Edge Radius | 0.05mm – 0.15mm | Optical Profiler |

| Surface Roughness | Ra ≤ 0.20µm | Contact Profilometer |

| Tensile Strength | 200-250 MPa | Universal Testing Machine|

| Elongation | ≥ 5% | Universal Testing Machine|

This integrated manufacturing and QC approach guarantees strips with exceptional dimensional stability, surface integrity, and edge quality, directly contributing to transformer efficiency, reduced core losses, and long-term operational reliability demanded by the power transmission sector.

Packaging & Logistics

Export Packaging for Thin Copper Strips: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of transformer-grade aluminum and copper strips, we recognize that proper export packaging is as critical as material quality in ensuring customer satisfaction. For thin copper strips—material forms that are particularly susceptible to mechanical damage, oxidation, and environmental degradation during transit—we employ a robust, multi-layered packaging system designed specifically for the rigors of global sea freight.

All thin copper strip shipments are systematically secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are engineered to support coil weights ranging from 500 kg to over 3,000 kg, depending on strip dimensions and order volume, while maintaining structural integrity under dynamic maritime conditions. The use of nailed hardwood ensures resistance to compression, impact, and potential deformation during container stacking and long-haul transport.

Prior to palletization, each copper coil is individually wrapped in a dual-layer moisture-proof composite film. The inner layer consists of vapor-corrosion inhibitor (VCI) film, which actively suppresses oxidation by releasing corrosion-inhibiting molecules into the enclosed environment. This is followed by an outer layer of high-density polyethylene (HDPE) film with a thickness of 120–150 μm, providing a physical barrier against humidity, salt spray, and condensation—common hazards in marine environments. The film is hermetically sealed using heat-welded seams to eliminate gaps or exposure points.

Once sealed, the coils are center-aligned and fixed onto the pallet using galvanized steel strapping, tensioned to ISO 14954 standards. Edge protectors made from laminated cardboard or steel are applied at critical contact points to prevent deformation of coil edges during handling. Additional lateral stability is achieved through the integration of wooden braces or corner boards, fastened directly to the pallet frame.

For containerized shipments, pallets are arranged in interlocking patterns within 20-foot or 40-foot dry freight containers, maximizing space utilization while minimizing lateral movement. Desiccant packs are strategically placed within each container to absorb residual moisture and maintain internal relative humidity below 60%, further mitigating the risk of tarnishing or surface oxidation.

This comprehensive packaging protocol has been validated through accelerated climate testing and real-world logistics performance across key export routes, including trans-Pacific, trans-Atlantic, and Asia-Africa corridors. It ensures that our thin copper strips arrive at destination ports with preserved dimensional accuracy, surface finish, and electrical conductivity—meeting the exacting standards required for transformer and high-efficiency winding applications.

Luoyang Xinzhaohe Aluminum Co., Ltd adheres to international export packaging norms, including ISO 16107 and ISTA 3A, ensuring compliance with global freight carrier requirements and minimizing the risk of cargo claims. Our packaging is not merely a containment solution—it is an engineered extension of product quality assurance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Thin Copper Strip Supply

For mission-critical transformer and electrical applications demanding uncompromising precision in thin copper strip, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers engineered metallurgical solutions backed by over two decades of specialized manufacturing excellence. Our strategic pivot into high-purity copper strip production leverages deep-rooted expertise in non-ferrous metal rolling, annealing, and surface treatment processes originally honed for aluminum transformer foil. This cross-metallurgical proficiency ensures rigorous control over the unique material science challenges inherent in sub-0.2mm copper strip, where dimensional stability, electrical conductivity, and mechanical properties are paramount.

Our vertically integrated production facility in Luoyang, China, features dedicated continuous casting and rolling lines specifically optimized for oxygen-free electronic copper (C10100, C10200, C11000). Critical process capabilities include precision cold rolling under controlled tension to achieve thickness tolerances down to ±2µm, inline skin-pass rolling for enhanced flatness and residual stress management, and continuous annealing in oxygen-controlled atmospheres to consistently achieve 100% IACS conductivity with tensile strength tightly controlled within 15-25 MPa ranges. Advanced inline surface monitoring systems coupled with rigorous offline testing per ASTM B152 and IEC 60138 standards guarantee defect-free surfaces essential for high-voltage insulation integrity. Every production lot undergoes comprehensive certification, including full mechanical property reports, conductivity verification, and dimensional traceability data.

Supply chain resilience is engineered into our operational model. We maintain strategic raw material partnerships with certified LME-grade copper refiners, ensuring consistent input purity exceeding 99.99% Cu+Ag. Our 30,000-ton annual production capacity for thin copper strip (<0.5mm) incorporates buffer stock protocols for critical alloys, mitigating market volatility risks. Dedicated logistics coordination provides just-in-time delivery scheduling with full container load (FCL) or less-than-container load (LCL) flexibility to global destinations, supported by real-time shipment tracking and customs documentation expertise. This integrated approach minimizes lead time variability while maintaining the stringent lot traceability required for automotive and energy sector compliance frameworks including IATF 16949 and ISO 9001:2015.

Partnering with Luoyang Xinzhaohe means accessing not just a supplier, but a metallurgical engineering resource. Our technical team collaborates directly with your design and procurement groups to resolve application-specific challenges, from optimizing strip profile for automated winding processes to resolving microstructural anomalies affecting formability. We provide comprehensive material data sheets, process validation support, and failure analysis services to de-risk your transformer manufacturing. For sourcing thin copper strip where micron-level precision directly impacts end-product reliability and efficiency, our proven process control and supply chain discipline deliver measurable cost-in-use advantages.

Contact Senior Sourcing Manager Cathy Zhang at cathy@transformerstrip.com to discuss your specific thin copper strip requirements and receive a technical capability dossier with production capacity details.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing thin copper strips directly from China.