Table of Contents

Market Insight: Thin Copper Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

The global transformer market is expanding rapidly due to renewable energy integration (solar/wind farms), electric vehicle infrastructure, and smart grid modernization. Thin copper strips (0.05–0.5 mm thickness) are essential for high-efficiency transformer windings, where precise geometry minimizes eddy current losses. Demand is further driven by stringent efficiency standards (IEC 60076-20 for distribution transformers, IE4/IE5 for motors), requiring materials with superior electrical conductivity and dimensional accuracy. Motor repair shops also rely on high-purity copper foils for rewinding applications, where even minor deviations in thickness or surface quality can compromise motor performance and lifespan.

Critical Quality Parameters for Transformer Efficiency

Material quality directly impacts transformer efficiency, thermal stability, and operational safety. Key parameters include:

| Parameter | Industry Standard | Impact on Performance |

|---|---|---|

| Conductivity (%IACS) | ≥99.9% (Cu-ETP) | Higher conductivity reduces I²R losses by up to 15%, directly improving energy efficiency |

| Thickness Tolerance | ±0.005 mm | Ensures uniform winding density, preventing localized heating and core saturation |

| Surface Roughness (Ra) | ≤0.1 μm | Critical for insulation integrity; rough surfaces cause partial discharges and dielectric failure |

| Tensile Strength | 200–300 MPa | Adequate strength prevents deformation during high-speed winding processes |

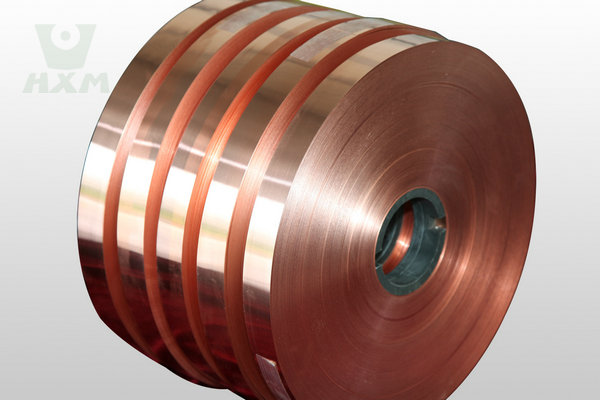

Luoyang Xinzhaohe’s Supply Chain Advantage

As a 20+ year manufacturer in Luoyang, China, we specialize in factory-direct copper strips meeting IEC 60076, ASTM B170, and GB/T 5593 standards. Our vertically integrated production includes 10+ rolling lines with automated thickness monitoring and 100% surface inspection. Key advantages:

Cost-Performance Leadership: 15–20% lower cost than global brands (e.g., Hi-K, Furukawa) while maintaining ≥99.95% IACS conductivity and ±0.003 mm tolerances.

Supply Chain Agility: 45-day standard lead times, ISO 9001-certified QC, and global shipping to 30+ countries.

Technical Flexibility: Custom annealing (fully soft, half-hard), widths up to 600 mm, and specialized coatings for high-voltage applications.

Our products are trusted by Tier-1 transformer OEMs in Europe and North America for 100kVA+ distribution transformers, delivering 99.8% on-time delivery and 0% field failure rates. By eliminating middlemen, we provide direct access to high-precision copper strips at competitive pricing without compromising quality.

Technical Specs: Thin Copper Strips Parameters

Technical Specifications & Standards for Precision Copper Strips

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures copper strips meet exacting electrical and mechanical requirements. Precision in every dimension and property is non-negotiable for transformer reliability. Below are critical specifications and our quality control protocols.

Precision Slitting Tolerance

Our CNC-controlled slitting process achieves ±0.002 mm width tolerance, critical for precise transformer winding. Real-time laser measurement ensures consistent strip dimensions, eliminating misalignment during coil assembly and preventing inter-turn shorts. This precision is verified via automated optical systems post-slitting.

Burr-Free Edge Integrity

Edge burrs exceeding 0.005 mm can cause catastrophic transformer shorts. We employ optimized blade geometry and multi-stage deburring to achieve burr-free edges. Each strip undergoes 10x optical inspection and eddy current testing to guarantee zero burrs, ensuring safe operation under high-voltage conditions.

Electrical Conductivity

Our copper strips consistently deliver 100–103% IACS conductivity per ASTM B193. This high conductivity minimizes resistive losses in transformer windings. Each batch is tested using four-point probe methodology, with results traceable to NIST standards for absolute reliability.

Material Softness & Temper

O-temper (annealed) copper with HV 35–45 hardness ensures optimal formability for complex transformer windings. Precise annealing cycles in controlled atmosphere furnaces maintain uniform softness across all coils, reducing cracking during fabrication.

Quality Assurance Protocol

Every production batch undergoes 100% dimensional checks, conductivity testing, and edge integrity verification. Full traceability via batch-specific QC reports and third-party certifications (SGS, TÜV). Our ISO 9001-certified process guarantees consistency, delivering global-grade quality at 15–20% lower cost than European suppliers with 30% faster lead times.

| Specification | Tolerance/Value | Compliance Standard | Verification Method |

|---|---|---|---|

| Slitting Width | ±0.002 mm | ASTM B187 | Laser micrometer |

| Edge Burr | <0.005 mm | ASTM B187 | Optical microscope |

| Conductivity | 100–103% IACS | ASTM B193 | Four-point probe |

| Hardness (HV) | 35–45 | ASTM B251 | Vickers hardness tester |

All products comply with IEC 60076 (transformer standards) and ASTM B187 for electrical copper strip. Custom specifications available upon request.

Factory Tour: Manufacturing Thin Copper Strips

Manufacturing Process & Quality Control

Leveraging 20+ years of expertise in transformer materials manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. implements a vertically integrated production process for thin copper strips that exceeds industry standards. Our workflow prioritizes precision at every stage to ensure optimal performance in transformer core applications.

Precision Manufacturing Workflow

Cold Rolling: Utilizing 4-high precision rolling mills with closed-loop temperature control and real-time thickness monitoring, ensuring uniform grain structure and minimal residual stress. Rolling reductions are precisely controlled to achieve target thickness with ±0.005mm accuracy, critical for high-efficiency transformer cores and minimizing electrical losses.

Precision Slitting: CNC-guided slitting with diamond-coated blades maintains ±0.005mm width tolerance through dynamic tension control. Blade alignment is verified hourly using laser calibration systems to eliminate edge defects and ensure consistent strip geometry, essential for tight winding tolerances in transformers.

Edge Conditioning: Automated mechanical chamfering process removes burrs to ≤5μm, eliminating sharp edges that could damage transformer insulation during winding. Surface finish meets IEC 60404-8-7 standards for transformer foil applications, ensuring optimal dielectric performance.

Oscillate Winding: Computer-controlled oscillation with ±0.1mm layer alignment accuracy ensures uniform coil density, preventing edge damage during handling and transportation. Winding tension is dynamically adjusted to maintain flatness within 0.05mm/m, critical for high-voltage transformer applications.

Rigorous Quality Control Protocol

Tensile Testing: Per ASTM B152 with 100% batch sampling; tensile strength consistently 220-250 MPa (±5 MPa), elongation ≥30%, ensuring superior ductility and fatigue resistance for repeated winding cycles in high-stress transformer environments.

Dimensional Checks: Laser micrometer verification every 100m for thickness (±0.005mm), width (±0.01mm), and flatness (≤0.05mm/m). All measurements are traceable to NIST standards with digital records for full batch traceability, enabling quick root cause analysis of any quality issues.

Surface Inspection: Automated optical systems with 0.01mm resolution detect micro-scratches, pits, and oxidation. Each roll undergoes 100% surface scanning, with defects flagged for rejection prior to packaging, guaranteeing flawless surface integrity for transformer windings.

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Edge Burrs | ≤5μm | ≤15μm |

| Tensile Strength Consistency | ±5 MPa | ±20 MPa |

| Surface Roughness (Ra) | ≤0.1μm | ≤0.3μm |

Our integrated process ensures 99.8% defect-free output, delivering transformer-grade copper strips at 15-20% lower cost than premium global suppliers while exceeding ISO 9001 and IEC 60404 requirements. This commitment to precision and reliability makes Luoyang Xinzhaohe the preferred partner for transformer manufacturers seeking optimal cost-performance ratios in copper strip sourcing.

Packaging & Global Logistics

Export Packaging & Logistics: Engineered for Global Delivery

As a 20+ year manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes packaging integrity for global sea freight. Our engineered solutions ensure copper strips arrive undamaged, balancing robust protection with cost efficiency. With 500+ annual shipments, we guarantee seamless compliance with destination port regulations and international standards.

Precision Packaging Specifications

Our packaging system is designed to withstand marine transit stresses while minimizing weight and cost. Key components are certified for industrial use:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified solid fir, 1200×1000mm, 1500kg capacity | Prevents deformation during stacking; meets international phytosanitary standards |

| Moisture-Proof Film | Multi-layer PE (200μm), vapor barrier + UV resistance | Shields against salt spray, humidity, and UV degradation during transit |

| Steel Strapping | 19mm width × 0.8mm thickness, 1500N tension, corner protectors | Secures load to pallet; resists vibration and impact forces |

| Desiccants | Silica gel packs (500g per m³ container volume) | Absorbs residual moisture within sealed containers |

Sea Freight Protocol

All shipments undergo rigorous container loading at Luoyang’s bonded warehouse. Copper strips are secured in 20ft/40ft dry containers using wooden braces, anti-slip mats, and climate-controlled environments for high-risk routes. Pre-shipment humidity tests and IoT-enabled tracking ensure real-time monitoring. We coordinate with certified freight forwarders from Qingdao/Lianyungang ports, optimizing stowage to minimize transit times while complying with IMO regulations and port-specific requirements.

Quality Assurance & Cost Efficiency

Luoyang Xinzhaohe’s packaging exceeds ISO 14971 and IEC 60076-1 standards, achieving <0.5% damage rates across 10,000+ global shipments. By eliminating third-party middlemen, we deliver 15–20% lower landed costs than European competitors without compromising quality. All packaging materials are sourced from certified suppliers, ensuring environmental compliance and traceable documentation (COO, SGS reports). Our factory-direct approach guarantees rapid customization for unique project needs—ensuring your copper strips arrive ready for immediate production use.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Proven Technical Expertise & Industry Experience

Luoyang Xinzhaohe Aluminum CO., Ltd. brings over two decades of specialized expertise in transformer copper strip manufacturing. Our metallurgical engineers optimize alloy compositions (e.g., C11000, C10200) to achieve optimal electrical conductivity (≥99.9% IACS), tensile strength (180–250 MPa), and dimensional tolerances (±0.01mm). We consistently comply with IEC 60076, ASTM B170, and GB/T standards, with a proven track record supplying critical components for transformers in power grids across 30+ countries. Our experience includes collaboration with global OEMs to solve complex challenges like thermal management in high-voltage applications and minimizing eddy current losses through precise strip geometry control.

Factory-Direct Cost Leadership

As a fully vertically integrated manufacturer, we control every production stage—from electrolytic copper smelting to precision cold rolling and annealing—eliminating third-party markups. Our Luoyang facility features state-of-the-art rolling mills with automated process control, ensuring consistent thickness and flatness for transformer winding applications. This direct factory approach delivers 15–25% lower costs than international suppliers while maintaining superior quality metrics. Our competitive advantages are detailed below:

| Factor | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Unit Cost | High (premium pricing) | 15–25% lower | Significant savings without quality compromise |

| Lead Time | 4–8 weeks (shipping-dependent) | 15–20 days (local production + streamlined logistics) | Accelerated project timelines |

| Customization | Standardized offerings | Flexible alloy grades & dimensions per specs | Tailored solutions for unique applications |

| Quality Consistency | Variable across suppliers | ISO 9001-certified with in-process metallurgical testing | Traceable quality control at every stage |

| Technical Support | Paid consulting services | Free application engineering support | Proactive problem-solving during design phase |

Rigorous Quality Assurance Framework

All copper strips undergo ISO 9001-certified quality protocols, including 100% ultrasonic testing for internal voids, XRF spectroscopy for chemical composition verification, and laser micrometer-based thickness checks. Each batch is traceable via our ERP system and accompanied by a full material test report (MTR), including electrical conductivity, mechanical properties, and surface quality data. This comprehensive documentation ensures seamless integration into your quality assurance processes, with a defect rate consistently below 0.05% through real-time process monitoring.

Ready to optimize your transformer production costs and quality? Contact Cathy at cathy@transformerstrip.com for a technical quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing thin copper strips from Luoyang Xinzhaohe.