Table of Contents

Market Insight: T2 Copper

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – T2 Copper Demand and Quality Imperatives

The global transformer manufacturing sector represents a critical and sustained market for high-purity copper, specifically T2 grade electrolytic tough pitch (ETP) copper strip and foil. Driven by expanding electrical infrastructure, renewable energy integration, and industrial electrification, demand for distribution and power transformers continues robust growth. While aluminum strip/foil serves cost-sensitive applications, T2 copper remains indispensable for high-efficiency, high-reliability transformer windings where superior electrical conductivity and mechanical performance are non-negotiable. Industrial demand for T2 copper strip/foil is intrinsically linked to transformer efficiency standards (e.g., DOE 2016, EU EcoDesign), which mandate minimized I²R losses. Copper’s inherent conductivity (minimum 100% IACS per IEC 60068-2-11 for transformer grade) directly enables compliance, making it the material of choice for premium and critical-duty transformers despite aluminum’s lower raw material cost. Market analysis indicates consistent annual growth of 3-5% in copper transformer strip consumption, concentrated in Asia-Pacific and emerging economies undergoing grid modernization.

Quality of T2 copper strip/foil is not merely a specification checkbox; it is a fundamental determinant of transformer longevity, safety, and operational economics. Impurities and microstructural inconsistencies directly compromise core performance parameters. Oxygen content must be tightly controlled within the standard 200-400 ppm range; deviations risk hydrogen embrittlement during vacuum drying or accelerated oxidation at operating temperatures, leading to catastrophic winding failure. Sulfur and other metallic impurities (Fe, Pb, Sn) significantly reduce conductivity below the critical 100% IACS threshold, increasing resistive losses and localized heating. This thermal stress degrades cellulose insulation over time, shortening transformer lifespan. Furthermore, inconsistent grain structure or surface imperfections—such as scratches, pits, or residual rolling oils—create initiation points for partial discharges under high electrical stress, progressively eroding insulation integrity. Field evidence consistently correlates substandard copper strip with premature transformer failures, unplanned outages, and elevated lifecycle costs that far exceed initial material savings.

The technical requirements for T2 copper transformer strip necessitate rigorous metallurgical control throughout production. Key quality parameters and their industrial impact are summarized below.

| Parameter | Standard Requirement (T2 ETP) | Consequence of Deviation |

|---|---|---|

| Electrical Conductivity | ≥ 100% IACS (20°C) | Increased I²R losses, reduced efficiency, thermal runaway risk |

| Oxygen Content | 200-400 ppm | Hydrogen embrittlement or excessive oxidation at high temps |

| Sulfur Content | ≤ 10 ppm | Conductivity loss, hot spot formation |

| Grain Size | Uniform, ASTM E112 Gr. 4-6 | Poor winding integrity, increased risk of fracture |

| Surface Roughness | Ra ≤ 0.4 µm | Partial discharge initiation, insulation degradation |

For transformer manufacturers, sourcing T2 copper strip/foil from suppliers with demonstrable process control, certified metallurgical testing (including spectrographic analysis and conductivity verification), and adherence to IEC 60138 or GB/T 5584.1 standards is paramount. Luoyang Xinzhaohe Aluminum leverages two decades of precision rolling expertise and stringent quality management systems to deliver T2 copper strip meeting these exacting industrial demands, ensuring optimal transformer performance and reliability. The marginal cost premium for certified high-quality T2 copper is decisively offset by reduced failure rates, extended service life, and compliance with evolving global efficiency regulations.

Technical Specs: T2 Copper

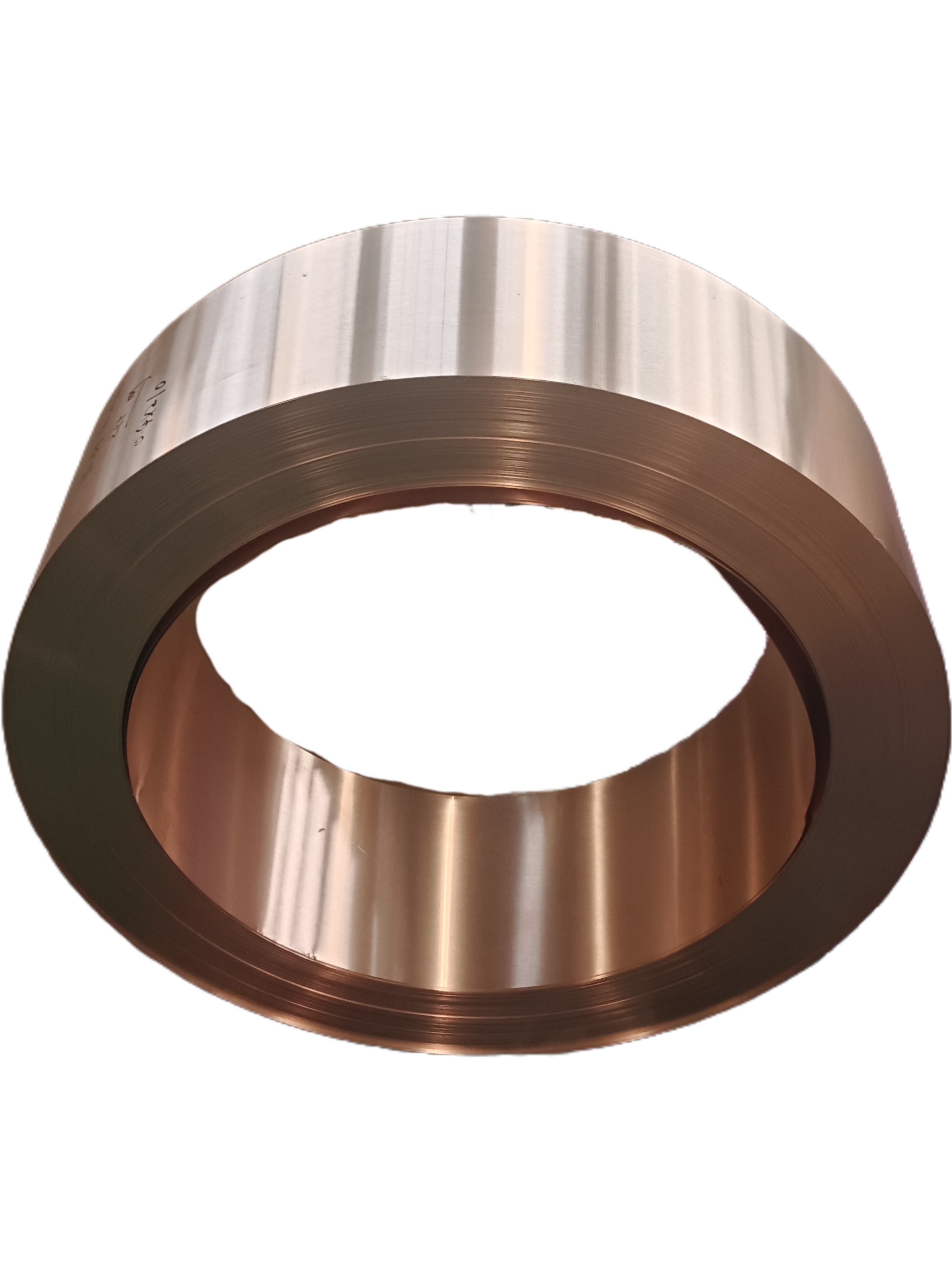

Technical Specifications for T2 Copper Strip in Transformer Applications

T2 copper, recognized under GB/T 5231-2012 standards, is a high-purity, oxygen-free electrolytic copper widely used in precision transformer strip and foil manufacturing due to its superior electrical conductivity, mechanical formability, and thermal stability. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and slitting expertise, we produce T2 copper strip to exacting industrial tolerances, ensuring compatibility with high-efficiency transformer designs and automated winding processes.

The chemical composition of T2 copper conforms to strict purity requirements, with a minimum copper content of 99.90%, and controlled trace elements such as oxygen (≤0.06%), lead (≤0.005%), and sulfur (≤0.005%). This high purity is critical for minimizing electrical losses and ensuring long-term reliability in power transmission components. Our in-house spectrographic analysis and quality control protocols ensure batch-to-batch consistency and full traceability.

Mechanical and dimensional precision is paramount in transformer strip applications. Our T2 copper strip is cold-rolled to achieve uniform thickness across the full coil width, with tight thickness tolerances maintained within ±0.002 mm through precision slitting technology. This level of dimensional control ensures consistent winding tension, reduces interlayer stress, and prevents dielectric breakdown in transformer coils. The slitting process is performed using high-speed, servo-controlled rotary shear lines equipped with laser-guided edge detection systems to maintain straightness and minimize camber (<0.5 mm/m).

Edge quality is a critical performance factor. All T2 copper strips produced by Luoyang Xinzhaohe are burr-free, achieved through optimized blade geometry, controlled clearance settings, and post-slitting edge inspection using optical profilometry. Burr heights are consistently held below 2 µm, eliminating the risk of insulation puncture and partial discharge in high-voltage windings.

Electrical performance is validated through direct conductivity measurements. T2 copper strips exhibit a minimum conductivity of 100% IACS (International Annealed Copper Standard) at 20°C, measured via the four-point probe method in accordance with ASTM B193. This ensures optimal current carrying capacity and minimal resistive heating in service.

Surface finish is controlled to Ra ≤0.4 µm, providing excellent adhesion for insulating coatings and reducing eddy current losses. Coils are supplied in hardened (H04) or annealed (M20) tempers, depending on customer forming requirements, with tensile strength ranging from 200–380 MPa and elongation of 5–40% accordingly.

All material is packaged in moisture-resistant, anti-corrosion wrapping with interlayer protection to prevent surface oxidation during transit.

| Parameter | Specification |

|---|---|

| Material | T2 Copper (GB/T 5231-2012) |

| Purity | ≥99.90% Cu |

| Thickness Tolerance | ±0.002 mm |

| Width Tolerance | ±0.05 mm |

| Edge Burr Height | ≤2 µm |

| Conductivity | ≥100% IACS |

| Surface Roughness (Ra) | ≤0.4 µm |

| Tensile Strength | 200–380 MPa (depending on temper) |

| Elongation | 5–40% |

| Camber | <0.5 mm/m |

| Available Tempers | H04 (Hard), M20 (Annealed) |

| Coil ID | 200 mm, 300 mm, 505 mm (customizable) |

| Max Coil OD | 1200 mm |

Factory Tour: Manufacturing

T2 Copper Transformer Strip Manufacturing Process Overview

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical refinement to deliver precision T2 copper transformer strip and foil meeting stringent global electrical standards. T2 copper (C11000), characterized by minimum 99.90% Cu content and oxygen levels of 0.02-0.04%, provides the essential 100% IACS minimum conductivity and thermal stability required for high-efficiency transformer windings. Our integrated production sequence ensures dimensional precision, surface integrity, and electrical performance critical for reliable transformer operation.

Cold rolling forms the foundational stage for T2 copper strip production. High-purity electrolytic tough pitch (ETP) copper ingots undergo initial hot rolling before transitioning to multi-stand reversing cold mills. Precise roll gap control, tension management, and interstand lubrication are maintained to achieve target thicknesses ranging from 0.05mm to 3.0mm with tolerances as tight as ±0.005mm. Critical process parameters including reduction per pass (typically 30-50%), rolling speed (150-400 m/min), and interstand tension are continuously monitored via PLC systems. In-process quality control employs laser micrometers for real-time thickness profiling across the strip width and surface inspection systems to detect scratches, pits, or roll marks. Material undergoes intermediate annealing in controlled atmosphere furnaces (N₂/H₂ mix) between rolling passes to restore ductility and prevent work hardening fractures, with strict adherence to time-temperature profiles to avoid grain coarsening or surface oxidation.

Precision slitting follows cold rolling to achieve the final strip width required for specific transformer coil designs. Strips are fed through high-precision slitting lines equipped with tungsten carbide rotary knives. Key parameters include optimal knife clearance (5-8% of material thickness), precise knife alignment, and controlled strip tension to prevent edge distortion or camber. Width tolerances are maintained within ±0.1mm for standard grades and ±0.05mm for ultra-precision applications. Post-slitting, the strip undergoes inline eddy current testing to detect subsurface inclusions or conductivity variations exceeding 0.5% IACS deviation, ensuring electrical homogeneity essential for uniform current distribution in windings.

Edge conditioning is a non-negotiable step for transformer-grade copper. Slit edges are processed through dedicated brushing or grinding units to eliminate micro-burrs and achieve a controlled edge radius of 0.05-0.15mm. This prevents insulation damage during coil winding and mitigates partial discharge risks in the finished transformer. Edge quality is verified using optical edge profilers and microscopic examination per ASTM E3.

Comprehensive quality control is embedded throughout the process chain. Final product validation includes:

| Test Parameter | Method/Standard | Acceptance Criteria |

|---|---|---|

| Thickness & Width | Micrometer/Laser Scan | Per order spec ±0.005mm |

| Tensile Strength | ASTM E8 | 200-240 MPa |

| Electrical Conductivity | ASTM E1004 | ≥100% IACS (20°C) |

| Surface Roughness (Ra) | profilometer | ≤0.4 µm |

| Edge Radius | Optical Profiler | 0.05-0.15 mm |

This rigorously controlled manufacturing sequence, combining advanced rolling technology, precision slitting, mandatory edge refinement, and multi-stage QC, ensures Luoyang Xinzhaohe delivers T2 copper strip with the dimensional accuracy, surface perfection, and electrical properties demanded by high-reliability transformer manufacturers worldwide.

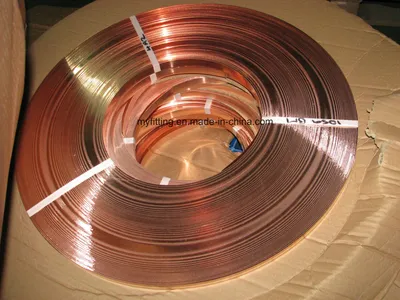

Packaging & Logistics

Export Packaging for T2 Copper Transformer Strip and Foil

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and international distribution of high-purity electrical conductive materials, we maintain rigorous standards in the export packaging of T2 copper transformer strip and foil. The integrity of the product upon arrival is directly influenced by packaging performance during extended maritime transport, particularly under variable climatic and handling conditions. Our export packaging system is engineered to ensure mechanical stability, moisture resistance, and contamination control throughout the global supply chain.

All T2 copper coils and strips are wound with precision and mounted on robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to withstand stacking loads and dynamic stresses encountered during containerized sea freight. The structural integrity of the pallet is reinforced with steel strapping, evenly distributed across load-bearing points to prevent coil displacement or edge damage during transit. Each pallet is fabricated to meet international shipping standards, ensuring compatibility with automated handling equipment at ports and distribution centers.

Immediately after palletization, the copper product is fully wrapped in multi-layer moisture-proof composite film. This vapor barrier film features a metallized polymer core laminated between high-density polyethylene layers, providing a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. The film is hermetically sealed using heat-welded seams, creating a fully enclosed micro-environment that protects against salt-laden air, condensation, and humidity fluctuations typical in marine environments. Desiccant packs are strategically placed within the sealed envelope to absorb any residual moisture and further reduce the risk of surface oxidation.

All packaged units are labeled with UV-resistant, tamper-evident identification tags containing critical shipment data, including heat number, dimensions, net weight, and handling instructions. Labels are affixed to both the exterior film and the wooden base to ensure traceability even after partial unpacking. Additionally, each package includes a waterproof document pouch containing the material test certificate (MTC) in accordance with GB/T 5231-2012 and ISO 13379, confirming compliance with T2 copper specifications (minimum 99.90% Cu + Ag).

Our packaging protocol has been validated through accelerated aging tests simulating 60-day ocean voyages under tropical conditions. This ensures that the copper surface remains free from oxidation, staining, or mechanical deformation upon customer receipt. By integrating structural durability with advanced moisture mitigation, Luoyang Xinzhaohe Aluminum Co., Ltd. guarantees the delivery of T2 copper transformer materials in as-produced condition, meeting the stringent quality demands of transformer and electrical equipment manufacturers worldwide.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision T2 Copper Transformer Strip

With over two decades of specialized metallurgical engineering and supply chain execution, Luoyang Xinzhaohe Aluminum Co., Ltd delivers uncompromising quality in T2 copper transformer strip and foil production. Our vertically integrated facility in Henan Province combines deep materials science expertise with rigorous process control to meet the exacting demands of global transformer and inductor manufacturers. We focus exclusively on high-purity electrical conductors, ensuring every coil adheres to IEC 60468 and ASTM B187 standards while exceeding baseline T2 specifications for critical applications.

Our metallurgical advantage begins with stringent raw material sourcing from certified LME-grade copper cathodes, processed through a proprietary refining sequence that achieves minimum 99.95% Cu+Ag purity. Advanced oxygen content control (200–300 ppm) prevents hydrogen embrittlement, while precision annealing in oxygen-free nitrogen atmospheres optimizes grain structure for superior conductivity (100–102% IACS) and mechanical stability. This results in strip with exceptional surface integrity—free from pits, scratches, or laminations—that ensures consistent winding performance and minimizes dielectric losses in final assemblies. Dimensional precision is non-negotiable; our continuous casting and cold-rolling lines maintain thickness tolerances of ±0.005 mm and flatness deviations below 0.5 mm/m, critical for high-frequency transformer efficiency.

Production capabilities are engineered for scalability and reliability. Our 50,000-ton annual capacity for copper strip (0.05–3.0 mm thickness, 50–800 mm width) is supported by in-house slitting, tension-leveling, and edge-finishing systems, eliminating third-party quality variables. Real-time statistical process control (SPC) monitors conductivity, tensile strength (200–240 MPa), and elongation (≥40%) at every stage, with full traceability via blockchain-enabled batch records. This infrastructure reduces lead times to 15–25 days for standard orders while accommodating custom alloys and widths for specialized designs.

Supply chain resilience is embedded in our operational DNA. Dual sourcing for critical process gases, strategic raw material stockpiling, and partnerships with COSCO and DB Schenker guarantee on-time delivery across 30+ countries. Our ISO 9001:2015 and IATF 16949-certified quality management system includes pre-shipment conductivity verification and packaging designed for humidity-controlled ocean freight, preventing transit-related oxidation.

Partner with us to transform your T2 copper sourcing from a procurement challenge into a strategic advantage. Our engineering team collaborates directly with clients to resolve material performance gaps—from optimizing annealing profiles for ultra-thin foils to mitigating edge burrs in high-speed slitting processes. Request a technical datasheet or schedule a metallurgical consultation to validate how our strip enhances your transformer efficiency and yield.

Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to initiate a capability review. Include your target specifications and volume requirements for a tailored production plan within 48 hours. Luoyang Xinzhaohe: Where metallurgical precision powers global energy infrastructure.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing t2 copper directly from China.