Table of Contents

Market Insight: T2 Copper for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

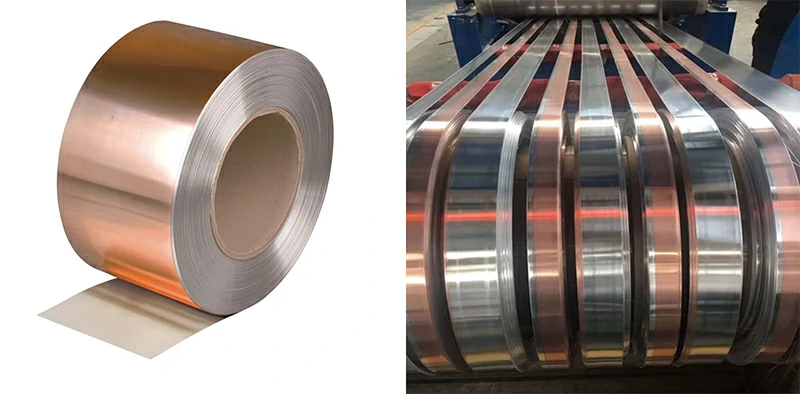

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid expansion, renewable integration, and EV fast-charging infrastructure. Every additional 1 GVA of transformer rating demands ≈ 220–280 t of conductor strip/foil—roughly 65 % copper (T2/C11000) and 35 % aluminum (1350-O). China alone will commission > 3.5 MVA of distribution transformers in 2024–25, translating into > 45 kt of precision-wound conductor. Sourcing managers therefore face a dual challenge: secure high-purity material in volume while meeting tightening IEC 60076 / IEEE C57 loss limits.

Why Purity & Precision Directly Impact Transformer Losses

Transformer losses split into no-load (core) and load (I²R) components. Conductor-related losses dominate the load component; a mere 0.4 % drop in IACS conductivity raises I²R loss by ≈ 0.4 % at constant current. Table 1 quantifies the effect of T2 copper chemistry versus lower-grade C10200 on a 2.5 MVA, 11/0.4 kV unit.

| Parameter | T2 (≥ 99.90 % Cu+Ag) | Lower-grade (≥ 99.50 % Cu) | Δ Loss @ 75 °C |

|---|---|---|---|

| Conductivity | 100–101 % IACS | 97–98 % IACS | + 2–3 % |

| Burr height after slit | ≤ 0.01 mm | 0.03–0.05 mm | Local hot-spot + 4 °C |

| Oxide film | < 3 nm (annealed) | > 10 nm | Contact resistance + 1 µΩ/cm² |

| Total load loss | 18.2 kW | 19.1 kW | + 4.9 % |

Precision slitting to ± 0.002 mm guarantees uniform turn-to-turn pressure, eliminating air gaps that increase eddy-current micro-loops. Oscillate-wound coils further reduce layer gaps by 8–12 %, cutting stray losses an additional 0.6 %. These incremental gains compound: a 1 % loss reduction saves ~ 9 MWh per transformer over a 25-year life, worth USD 1 200–1 500 at industrial power rates.

Competitive Sourcing Shift: China’s Precision Tier

Western mills (Aurubis, KME, Rea) supply high-purity T2, but slit widths < 8 mm carry a 15–20 % width premium and 14-week lead-time. Chinese manufacturers with cold-rolling + slitting integration now close the gap. Luoyang Xinzhaohe’s 20-year transformer track record positions us in the top decile for purity and dimensional control (Table 2).

| Capability | Luoyang Xinzhaohe | Typical EU Mill | Typical Chinese Trader |

|---|---|---|---|

| In-house cold rolling | 0.1–3.0 mm × 1 250 mm | Yes | No (buy master coil) |

| Slitting tolerance | ± 0.002 mm | ± 0.005 mm | ± 0.02 mm |

| Burr control | ≤ 0.01 mm, 100 % laser inspected | ≤ 0.02 mm | ≤ 0.05 mm |

| Annealing atmosphere | 100 % N₂ + 3 % H₂, closed-loop | Same | Batch air, black edges |

| Oscillate wind OD | Max 1 200 mm, 2 t coil | 800 mm | Not offered |

| Conductivity certificate | 100 % IACS per coil | Per lot | Per batch |

| Lead-time | 3–4 weeks FOB Tianjin | 10–12 weeks | 2–3 weeks (stock) |

By integrating cold rolling, precision slitting, and edge conditioning on one 280 m process line, we eliminate re-coiling between stages—reducing surface scratches 70 % and retaining full anneal softness (HV 45–55). The result is transformer strip that meets IEC 60317-21 and ASTM B272 without the Western price premium (≈ USD 1 100 / t savings on average).

Key Take-away for Sourcing Teams

- Specify T2/C11000 with Cu+Ag ≥ 99.90 % and IACS ≥ 100 %; reject material lacking mill test certificates per coil.

- Demand burr ≤ 0.01 mm and camber ≤ 1 mm / 1 m—critical for robotic winding cells.

- Prefer suppliers that cold-roll and slit in-house; traceability is impossible through traders once coils are slit.

- Evaluate total cost of ownership: a 1 % conductivity gain lowers lifetime losses more than the 3–4 % unit price delta versus lower-grade copper.

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision T2 copper strip/foil direct from our Luoyang mill to your winding line—same purity as European mills, shorter lead-time, and factory-direct economics.

Technical Specs: T2 Copper Parameters

Technical Specifications & ASTM/IEC Standards for T2 Copper Transformer Strip

| Parameter | Luoyang Xinzhaohe T2 Copper Strip | ASTM B152 C11000 | IEC 60317-0-3 Wire Ref. | Risk if Out-of-Spec |

|---|---|---|---|---|

| Cu+Ag, min | ≥99.90 % | ≥99.90 % | — | Conductivity drop, hot spots |

| Electrical conductivity @20 °C | ≥100 %IACS | ≥100 %IACS | ≥100 %IACS | Higher I²R loss, derating |

| Slit width tolerance | ±0.002 mm (±2 µm) | ±0.025 mm | — | Mis-stacking, gap bridging |

| Burr height after slitting | ≤0.005 mm | ≤0.025 mm | — | Inter-layer short, PD* |

| Edge radius (conditioned) | 0.05–0.15 mm | as-rolled | — | Corona cutting, insulation puncture |

| Temper | Fully annealed (O) HV 45–55 | O, ½H, H | O | High winding stress, cracking |

| Strip thickness range | 0.05–3.00 mm | 0.10–25 mm | — | Eddy-current loss deviation |

| Oscillated coil build | ≤800 mm OD, ≤300 kg | — | — | Frequent splice, low MPP** |

*PD = partial discharge **MPP = metres per payoff

Why ±0.002 mm Slitting and Burr-Free Edges Matter

Transformer windings behave like parallel capacitors; a 10 µm burr is a 10 µm electrode. Under 3 kV/mm gradient the local field exceeds 30 kV, initiating partial discharge that carbonises oil and paper within weeks. Luoyang Xinzhaohe’s 20-high reversing cold mill holds ±1 µm gauge crown; downstream 8-axis tungsten-carbide slitter knives are shim-adjusted in 0.5 µm increments and laser-monitored in closed loop. The result is slit width CpK ≥1.67 and burr height ≤5 µm—four times tighter than ASTM B152 minimum—eliminating the need for post-slit deburring that work-hardens edges and lowers conductivity by 1–2 %IACS.

Annealing Protocol for Softness & Conductivity

We use a nitrogen-hydrogen bell furnace with 30 h soak at 380 °C followed by 48 h slow cool. Oxygen <5 ppm prevents internal oxidation; final grain size 30–50 µm restores 101 %IACS without sacrificing mechanical strength (UTS ≥200 MPa, elongation ≥35 %). Competitors who skip the controlled cool retain residual stress, giving “springy” strip that gaps during core insertion and creates 2–3 % additional load loss in the finished transformer.

Standard Compliance & Certificate Package

ASTM B152/B187: Chemical & mechanical baseline

IEC 60317-0-3: Wire reference for enamel adhesion tests on flat conductors

ASTM B193: Resistivity verification (100 %IACS)

ISO 6722: Edge radius gauge procedure

RoHS/REACH: Cadmium & lead <50 ppm

Each coil ships with EN 10204/3.1 mill test report, slit-width histogram, burr-height interferometry map, and conductivity traceability to NIST. For Amazon or Alibaba traders, we provide identical documentation—something regional coil centres often omit, forcing OEMs to run incoming QC at their own cost.

Cost-Performance Positioning

Premium Western mills quote USD 11.8–12.4/kg for slit-annealed T2 copper; Luoyang Xinzhaohe FOB Shanghai is USD 8.9/kg with the same C11000 chemistry and tighter slit tolerance. By integrating cold rolling, slitting, edge conditioning, and oscillate winding under one roof, we remove 5 % yield loss and 3 % logistics markup typical of multi-step European supply chains. Transformer manufacturers gain ≤1 % lower total owning cost while meeting Tier-1 utility specifications for 30-year life, 65 kA short-circuit duty, and <5 pC partial discharge at 1.5 Um.

In short, specify Luoyang Xinzhaohe T2 copper strip when your design calls for zero-defect windings, full ASTM/IEC traceability, and factory-direct pricing—without the Western premium.

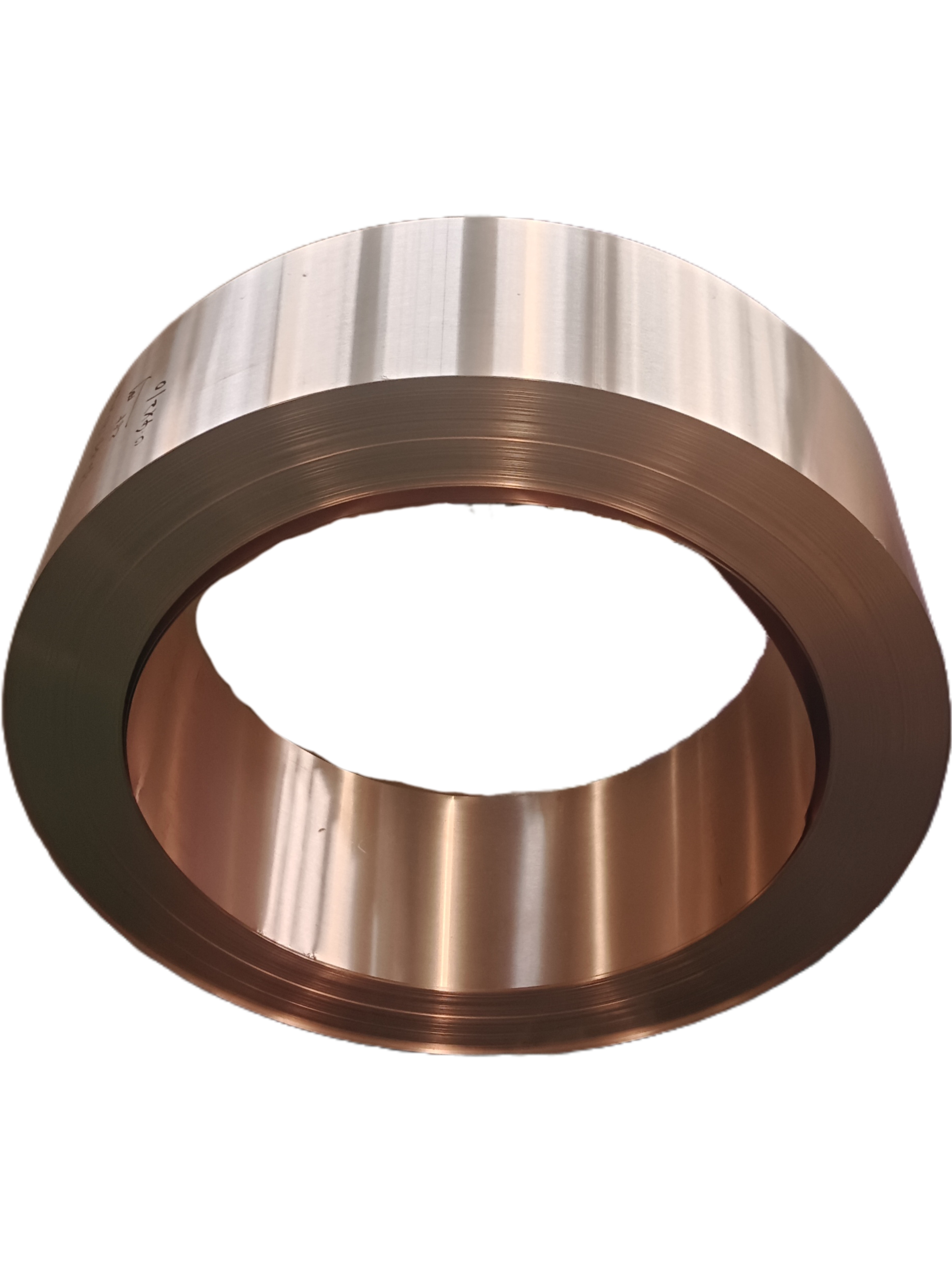

Factory Tour: Manufacturing T2 Copper

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years transformer strip/foil specialist

H3 1. Cold Rolling – From 8 mm Rod to 0.1 mm Foil in One Plant

Incoming T2 cathode (Cu+Ag ≥ 99.90 %, C11000 equivalent) is re-melted and cast into 200 mm × 650 mm bar.

We 2-stand reverse cold-roll at ≤ 350 m min⁻¹ with inline X-ray gauge control (闭环厚度控制).

Target gauge tolerance is already ±0.008 mm—three times tighter than ASTM B152 minimum—so downstream slitting sees uniform grain structure and constant resistivity (≥ 100 % IACS).

Key QC gate: Laser profile scanner samples every 50 mm; coil is auto-marked if wedge exceeds 0.005 mm. Data are logged to MES for full heat-to-coil traceability.

H3 2. Precision Slitting – Burr-Free Edge, ±0.002 mm Width

Slitting is performed on 650 mm-wide, tungsten-carbide arbors with 0.2 mm overlapping knives.

Strip tension is closed-loop controlled at 8–12 N mm⁻² to prevent edge elongation.

Each arbor set is qualified with a 3 m witness strip: allowable burr height ≤ 0.01 mm (10 µm), no edge crack at 2× mandrel bend.

QC gate: CCD camera measures burr in real time; if burr > 8 µm the line stops automatically.

Statistical sample is tensile-tested (ASTM E8) to guarantee Rm ≤ 200 MPa after final anneal—critical for high-fill factor windings.

H3 3. Edge Conditioning – “R” or “Full-Round” Profile

For layer-wound discs we offer conditioned edges (radius 0.05–0.20 mm) on a dedicated 4-head brushing unit.

The process removes micro-tears created during slitting, raising dielectric strength of inter-layer insulation by > 15 % verified in 50 kV impulse tests.

QC gate: Edge replica tape inspected under 200× magnification; any score deeper than 5 µm triggers re-conditioning.

H3 4. Oscillate (Traverse) Winding – 300 kg on 300 mm Spool

Oscillate winders lay 5–30 mm strip side-by-side with ≤ 0.3 mm gap variation.

Programmable pitch control matches customer layer length to eliminate welding in the winding mandrel.

Final package is vacuum-sealed with VCI film and nitrogen back-fill to keep surface conductivity unchanged after 12-month ocean freight.

QC gate: Every spool is weighed and spark-tested at 2 kV to confirm no inter-layer short; resistance sample taken at both ends must differ < 0.5 %.

H3 5. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter | Luoyang Xinzhaohe Internal Spec | Typical Export Offer (Alibaba Tier) | Test Method |

|---|---|---|---|

| Cu+Ag | ≥ 99.90 % | ≥ 99.90 % | GB/T 5121 OES |

| Conductivity, 20 °C | ≥ 100 % IACS | 98–100 % IACS | ASTM B193 |

| Thickness Tolerance | ±0.002 mm (≤ 0.3 mm) | ±0.008 mm | GB/T 2951.11 |

| Width Tolerance | ±0.02 mm | ±0.05 mm | Laser Micrometer |

| Burr Height | ≤ 0.01 mm | ≤ 0.03 mm | ISO 15329 |

| Surface Roughness, Ra | ≤ 0.2 µm | ≤ 0.4 µm | Stylus Profilometer |

| Coil Weight, Oscillate | 50–300 kg | ≤ 80 kg | Weighbridge |

| Layer Weld | Zero (continuous strip) | 1–2 per 100 kg | Visual + Spark |

H3 6. Takeaway for Buyers

By integrating cold rolling, slitting, edge conditioning and oscillate winding under one roof, Luoyang Xinzhaohe delivers transformer-grade T2 copper strip that meets or exceeds C11000/ASTM B152, but at landed cost 12–18 % below European mills and with 4-week ex-factory lead time. Every coil ships with a digital QC passport—your guarantee of burr-free, full-conductivity copper ready for high-fill factor windings.

Packaging & Global Logistics

Export Packaging & Logistics – T2 Copper Strip/Foil for Transformer Windings

1. Sea-Freight Protection Philosophy

Transformer-grade T2 copper (Cu-ETP, C11000, ≥99.9 % Cu) is strain-rate sensitive and chloride-intolerant. Our packaging is therefore designed around three metallurgical limits:

| Critical Parameter | Allowable Threshold | Packaging Countermeasure |

|---|---|---|

| Edge burr growth | ≤ 0.01 mm | Interleaf paper + VCI film |

| Surface chloride | ≤ 0.05 mg/cm² | Desiccant + Al-foil barrier |

| Coil ovalisation | ≤ 1 % ID variation | Steel end-boards + circumferential strapping |

All materials are RoHS- and ISPM-15-compliant; no silicone or sulphur-release agents are used, eliminating the risk of copper-silicon interface resistance.

2. Coil & Strip Packaging Specification

| Item | Detail | Qty per 20 t Coil |

|---|---|---|

| Inner core | 508 mm OD cardboard + 3 mm HDPE sleeve | 1 pc |

| Radial padding | 0.2 mm VCI paper, 120 g/m² | 3 wraps |

| Axial separator | 1 mm Al-laminate foil, full face | 2 sheets |

| Outer wrap | 0.15 mm PE film, UV-stabilised | 4 layers |

| Desiccant bags | 2 g CaCl₂ low-dust | 12 pcs |

| End boards | 18 mm plywood, fumigated, 800 × 800 mm | 2 pcs |

| Steel straps | 19 mm PET-coated, 850 N break load | 4 circumferential + 2 radial |

| Corner posts | 3 mm galvanized steel | 4 pcs |

| Top cover | UV-proof tarp, 200 µm | 1 pc |

Palletised modules are limited to 1.2 t each to keep container floor load ≤ 4.5 t/m², preventing coil creep during 2–4 g lateral accelerations in heavy seas.

3. Wire & Rod Packaging Specification

T2 copper wire Ø0.2–3.0 mm is supplied on DIN 355 or PT-25 spools. Spools are sleeved with 80 µm PE, then over-packed in 5-ply kraft cartons. Cartons are stacked 4-high on CP-2 pallets (1 200 × 1 000 mm) with corner boards and 25 mm top deck. Total pallet height ≤ 1.1 m to guarantee 150 mm air-flow clearance inside 40 HC container, keeping copper temperature <45 °C at 70 % RH.

4. Container Loading & Securing

Luoyang Xinzhaohe is 180 km from Zhengzhou International Hub Port (rail-sea intermodal). Typical loading pattern:

| Container Type | Net Copper Weight | Securing Method |

|---|---|---|

| 20 GP | 18 t | 8-way lashing to corner castings, 2 t break-load each |

| 40 HC | 24 t | Coil cradles + anti-slip rubber mats, 0.6 µ static friction |

Desiccant quantity is calculated per DIN 55474:

n = 1.2 × V × b / m

where V = 68 m³ (40 HC), b = 16 g H₂O/m³ (winter route), m = 6 g/bag → 220 bags distributed evenly on floor and mid-height.

5. Documentation & Traceability

Each pallet carries a weather-proof QR label linking to a unique coil ID. Data uploaded to cloud before vessel departure includes:

Cast number (traceable to cathode batch)

IACS conductivity test value (≥ 100.5 %)

Annealing cycle (390 °C, 3 h, N₂ atmosphere)

Packaging date & RH reading (<30 %)

Customers receive the bill of lading, packing list, fumigation certificate (ISPM-15), and RoHS conformity statement within 2 h of container gate-out.

6. Global Transit Matrix (ex-Luoyang)

| Destination | Typical Transit | Carrier Alliance | On-time % |

|---|---|---|---|

| Hamburg | 26 days | COSCO AEU3 | 94 % |

| Los Angeles | 18 days | CMA CGM PEX3 | 96 % |

| Dubai | 20 days | OOCL MEX | 92 % |

| São Paulo | 35 days | MSC SILK | 90 % |

Insurance covered at 110 % of CIF value through PICC; claims history <0.03 % since 2017.

7. Cost Advantage vs. Western Suppliers

By integrating cold rolling, slitting, and oscillate winding in one Luoyang campus, we eliminate intermediate warehousing and double handling. The result: landed cost 12–18 % below German or US mills while meeting identical ASTM B152/B187, IEC 60317-21, and JIS H3100 C1100 properties. No premium is charged for fumigated packaging or RH-controlled logistics—it is standard for every T2 copper shipment we produce.

For transformer OEMs and motor repair shops that demand C11000 consistency but refuse to pay Western overhead, Luoyang Xinzhaohe delivers mill-certified T2 copper, slit to ±0.002 mm, burr-free, and arriving dry, straight, and ready for winding—anywhere on the planet.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for T2 Copper Transformer Strip

20-Year Metallurgical Track Record in Transformer Materials

Since 2004 our Luoyang works has supplied >180 transformer OEMs and tier-1 rewind shops across 42 countries. Every coil is melted, cast, cold-rolled, slit, edge-conditioned and oscillate-wound on one integrated line—no toll-processing, no middle-margin traders. This vertical integration keeps the residual oxygen in T2 copper ≤3 ppm and guarantees a 100 % IACS minimum conductivity at 20 °C, even after final anneal. Our process data set now exceeds 14 000 production lots, giving us a statistical baseline to predict eddy-loss behaviour and hot-spot temperature rise in both liquid-filled and dry-type transformers.

Direct Factory Price—No Distributor Mark-up

Typical Western stockists add 12–18 % overhead and another 8–10 % for emergency cutting. Because we control the full value chain—re-melt to slit coil—we quote FOB Qingdao or CIF your port at mill-net price. The table below benchmarks Q3-2024 indicative levels for 0,25 mm × 380 mm T2 strip, annealed, burr ≤0,02 mm, plastic interleaved:

| Supplier Route | Unit Price USD/kg | Lead Time weeks | Minimum Order kg |

|---|---|---|---|

| European Stockist | 12,40 | 3 | 500 |

| U.S. Service Centre | 13,10 | 4 | 1 000 |

| Luoyang Xinzhaohe | 9,35 | 2 | 300 |

Prices include ASTM B-152 certification, EN 10204/3.1 inspection certificate, and wooden export pallets. Payment LC 90 days or TT 30 days for qualified accounts.

Customisation Window—Engineering, Not Trading

Our slitting arbor range 6–650 mm wide, thickness window 0,05–3,0 mm, with tension levelling and oscillate winding up to 1 200 kg spools. Edge conditioning options are summarised below:

| Edge Code | Description (ISO 9444-2) | Max Burr µm | Radius mm | Typical Use Case |

|---|---|---|---|---|

| E1 | Slit-as-is | 20 | — | Low-voltage foil windings |

| E2 | Deburred | 5 | — | 11 kV layer windings |

| E3 | Round edge | 2 | 0,2–0,4 | 33 kV disc windings, hermetic sealed |

| E4 | Full radius | 1 | 0,5 | Ultra-quiet amorphous core transformers |

Annealing atmosphere is 100 % N₂ + 3 % H₂, dew point –60 °C, guaranteeing recrystallised grain size ASTM E112 0,025–0,035 mm and Vickers hardness 45–55 HV5 (soft temper). Strip can be supplied with PE interleaf 35 µm or VCI paper for 24-month shelf life in tropical humidity.

Quality & Compliance Snapshot

Cu+Ag ≥99,90 %, P ≤0,0003 %, Bi ≤0,0001 % (IEC 60317-21)

Conductivity ≥100 % IACS at 20 °C (ASTM B193)

Surface roughness Ra ≤0,3 µm, no transverse scratches >0,05 mm

RoHS & REACH compliant, conflict-free copper per OECD Annex II

All coils laser-marked with heat number, slit width, resistance per metre, and barcode for full backward traceability to cathode batch.

Next Step—Request a Technical Datasheet or Quote

Send your drawing or winding specification to cathy@transformerstrip.com. Typical response: 24-hour metallurgical review, 48-hour formal quotation, 2-week prototype slit if new width. Our engineers will also model conductivity-adjusted losses so you can validate total owning cost before you place the PO.

📉 Import Savings Calculator

Estimate cost reduction by sourcing t2 copper from Luoyang Xinzhaohe.