Table of Contents

Market Insight: Super Enamel Copper Wire Size Chart

Market Analysis: Winding Wire – Industrial Demand for Super Enamel Copper Wire in Transformers

The global demand for high-performance winding wires, particularly super enamel copper wire, continues to grow in response to the increasing efficiency requirements of modern power and distribution transformers. As a critical component in electromagnetic energy conversion, super enamel copper wire serves as the conductive backbone of transformer windings, where electrical performance, thermal stability, and mechanical durability are non-negotiable. The precise selection of wire gauge—guided by a standardized super enamel copper wire size chart—is essential to achieving optimal current density, minimizing resistive losses, and ensuring reliable long-term operation under dynamic load conditions.

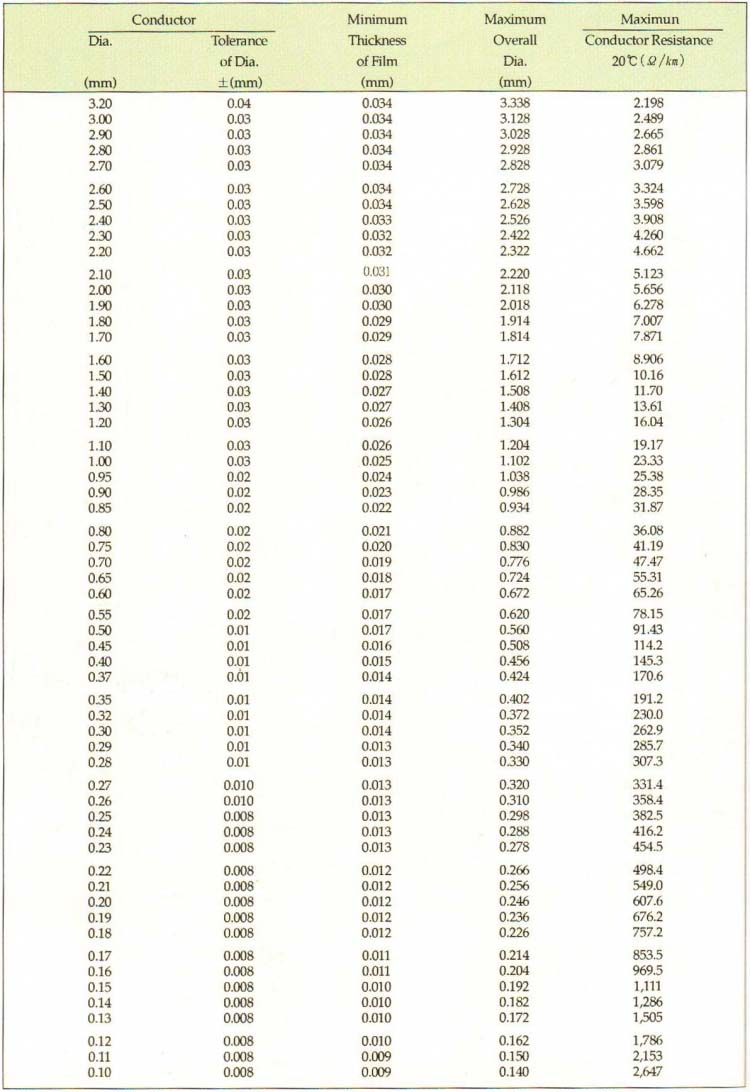

Industrial applications, especially in power transmission and renewable energy integration, place stringent demands on transformer design. Utilities and industrial OEMs are increasingly adopting high-efficiency transformers that comply with international standards such as IEC 60076 and IEEE C57. These standards emphasize reduced no-load and load losses, which directly correlate with the quality and dimensional accuracy of the winding wire used. A super enamel copper wire size chart provides engineers with critical data on conductor diameter, cross-sectional area, resistance per unit length, and current-carrying capacity—parameters that must be matched precisely to the transformer’s electrical design to avoid thermal runaway or premature insulation failure.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced conductive materials, we recognize that the performance of a transformer is only as reliable as the materials from which it is constructed. Super enamel coatings—typically based on polyamide-imide (PAI) or polyester-imide (PEI) chemistries—offer superior thermal endurance (Class 180°C to 220°C), excellent dielectric strength, and resistance to thermal shock and chemical degradation. However, variations in enamel thickness, adhesion quality, or conductor purity can lead to localized hotspots, inter-turn short circuits, or reduced lifespan. This underscores the necessity of sourcing super enamel copper wire from manufacturers who maintain strict process controls and adhere to international quality benchmarks such as ISO 9001 and IATF 16949.

Market trends indicate a shift toward compact, high-capacity transformers used in urban substations, electric vehicle charging infrastructure, and offshore wind farms. These applications require winding wires with enhanced thermal index ratings and mechanical robustness to withstand vibration, thermal cycling, and high electromagnetic forces. A precise super enamel copper wire size chart enables design optimization by balancing copper loss, fill factor, and manufacturing feasibility.

We provide the following table as a reference for common super enamel copper wire specifications used in transformer applications:

| Conductor Diameter (mm) | Cross-Sectional Area (mm²) | Max DC Resistance (Ω/km) at 20°C | Typical Current Capacity (A) | Insulation Class |

|---|---|---|---|---|

| 0.80 | 0.503 | 34.5 | 25 | 180 (PAI) |

| 1.00 | 0.785 | 22.1 | 38 | 200 (PEI-PAI) |

| 1.25 | 1.227 | 14.1 | 55 | 200 (PEI-PAI) |

| 1.60 | 2.011 | 8.6 | 80 | 220 (PAI) |

In conclusion, the industrial demand for super enamel copper wire is driven by the need for energy-efficient, reliable, and durable transformer systems. Accurate interpretation and application of the super enamel copper wire size chart, combined with uncompromising material quality, are fundamental to meeting the evolving requirements of the power sector. Luoyang Xinzhaohe Aluminum Co., Ltd remains committed to delivering high-purity, precision-manufactured winding solutions that support the next generation of transformer technology.

Technical Specs: Super Enamel Copper Wire Size Chart

Technical Specifications: Super Enamel Copper Wire Sizing and Performance Parameters

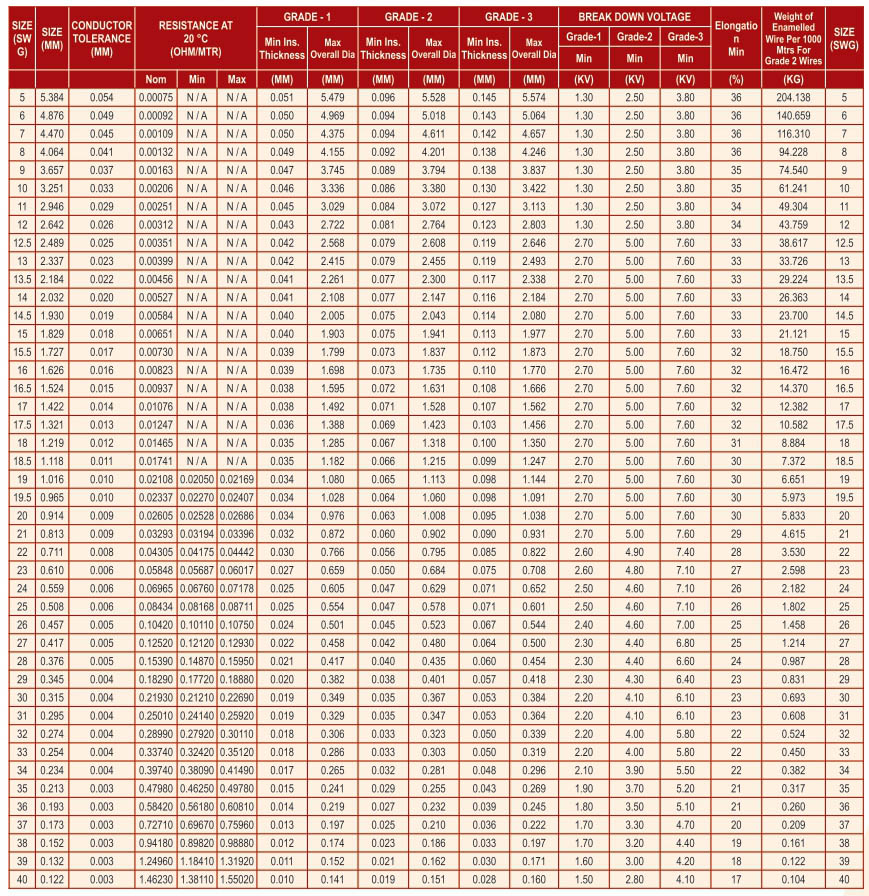

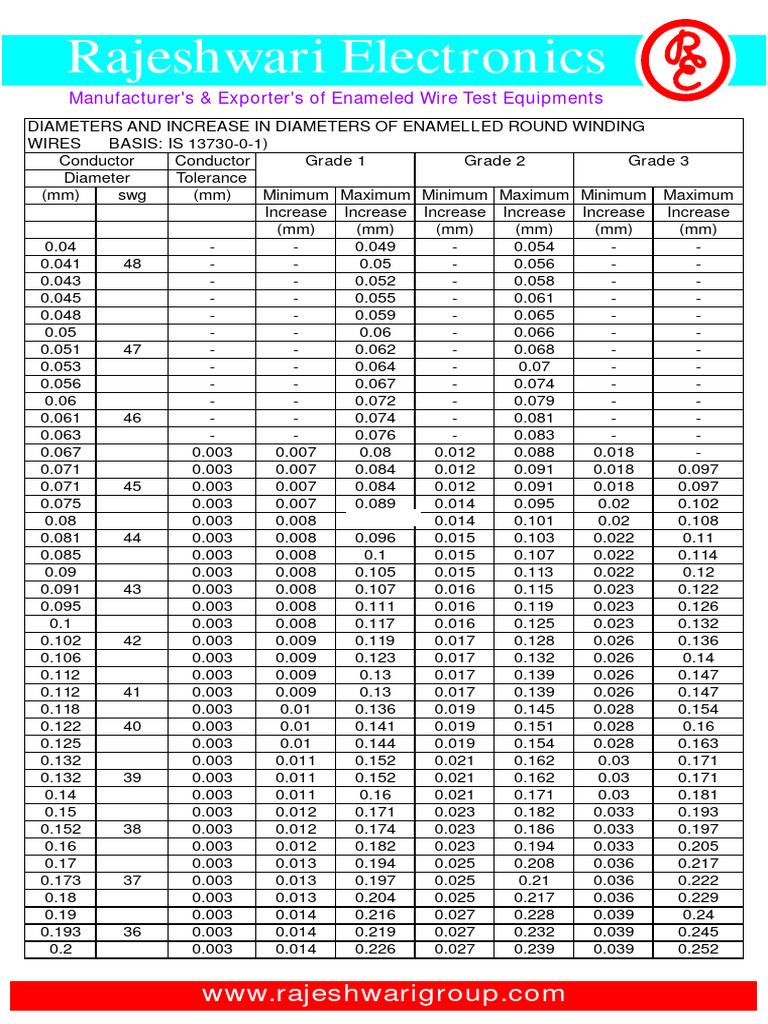

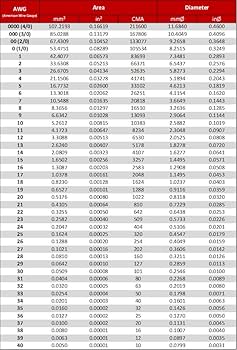

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver precision-engineered super enamel copper winding wire. This technical guide details critical specifications for informed B2B sourcing, focusing on parameters directly impacting motor, transformer, and inductor reliability. Our wire adheres strictly to IEC 60317 and NEMA MW standards, with rigorous in-process validation ensuring consistency across all AWG sizes. Key considerations include insulation integrity under electrical stress, mechanical resilience during high-speed winding, and thermal stability in demanding operational environments.

Insulation breakdown voltage is non-negotiable for dielectric safety. Our super enamel formulation achieves minimum breakdown voltages exceeding 3.0 kV RMS for all gauges, validated per IEC 60851-5 spark test protocols. This exceeds standard enamel wire requirements, mitigating partial discharge risks in high-voltage applications. Elongation percentage directly correlates with winding yield and fatigue resistance; our process controls ensure 10–25% elongation (per ASTM D3800), optimized for each gauge to prevent breakage during complex coil formation. Thermal class defines maximum continuous operating temperature without degradation. We offer grades spanning Class B (130°C) to Class C (220°C), utilizing advanced polymer chemistries: polyesterimide for Classes 155–180°C and polyamide-imide for Classes 200–220°C. Higher thermal classes maintain mechanical strength and adhesion after extended thermal aging, critical for EV traction motors and industrial automation systems.

The following table summarizes core technical parameters across standard AWG sizes. Tolerances comply with IEC 60228 for conductor diameter and IEC 60317-0-3 for enamel build. All values represent minimum guaranteed performance after thermal aging per specified class.

| AWG Size | Conductor Diameter (mm) | Min. Insulation Breakdown (kV RMS) | Min. Elongation (%) | Standard Thermal Classes |

|---|---|---|---|---|

| 10 | 2.588 | 5.0 | 10 | 130, 155, 180 |

| 18 | 1.024 | 4.0 | 15 | 130, 155, 180, 200 |

| 26 | 0.405 | 3.5 | 20 | 130, 155, 180, 200, 220 |

| 34 | 0.160 | 3.2 | 22 | 155, 180, 200, 220 |

| 44 | 0.050 | 3.0 | 25 | 180, 200, 220 |

Critical process controls underpin these specifications. Copper purity is maintained at 99.99% (ASTM B3) via oxygen-free continuous casting, minimizing hydrogen embrittlement risks. Enamel application employs multi-zone curing ovens with ±2°C thermal uniformity, ensuring pinhole-free insulation at micron-level thicknesses. Every production lot undergoes 100% spark testing and thermal shock validation (200 cycles, -65°C to +220°C). Our supply chain integrates real-time metallurgical analytics from smelting through spooling, guaranteeing traceability to ISO 9001-certified production lines.

For mission-critical applications, we recommend Class 200+ wire with elongation ≥20% for gauges below 30 AWG, balancing thermal resilience with winding flexibility. Consult our engineering team for custom thermal aging profiles or accelerated life testing data specific to your operating duty cycle. Luoyang Xinzhaohe Aluminum Co., Ltd delivers not just wire, but validated performance assurance for next-generation electromagnetic systems.

Factory Tour: Manufacturing

Manufacturing Process of Super Enamel Copper Winding Wire

The production of super enamel copper winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure superior electrical performance, mechanical integrity, and thermal endurance. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment and rigorous quality control protocols across each phase: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity electrolytic tough pitch (ETP) copper rod, typically conforming to IEC 60086 and ASTM B3 standards. These rods undergo precision rod drawing, where the diameter is progressively reduced through a series of tungsten carbide or diamond dies. This cold working process achieves the target wire gauge with tight dimensional tolerances, typically within ±0.002 mm. The drawing operation is performed under controlled lubrication and tension to minimize surface defects and ensure uniform elongation.

Following drawing, the wire enters a continuous annealing system. This stage is critical for restoring ductility lost during cold drawing and achieving the desired mechanical temper—typically soft (annealed) or hard (as-drawn), depending on application requirements. Annealing is conducted in a controlled atmosphere furnace using nitrogen or nitrogen-hydrogen mixtures to prevent oxidation. Temperature profiles are precisely regulated between 450°C and 600°C, with residence time optimized for complete recrystallization while avoiding grain overgrowth.

The annealed wire then proceeds to the enameling line, where multiple layers of polymer insulation are applied via die coating. For super enamel wires, this typically involves a dual-layer system: a base coat of polyurethane (PU), polyesterimide (PEI), or polyamide-imide (PAI), followed by a topcoat that enhances thermal class, chemical resistance, or solderability. Each coat is cured in-line through a series of temperature-zoned ovens, with peak curing temperatures ranging from 350°C to 500°C depending on resin chemistry. Film thickness is maintained within ±5% of nominal values, as specified in IEC 60317 and NEMA MW standards.

Throughout the production line, inline testing systems continuously monitor critical parameters. These include diameter measurement via laser gauges, insulation continuity testing using high-voltage spark testers (typically 3–10 kV), and tensile strength and elongation verification through real-time mechanical sensors. Additional checks include wrap tests, thermal shock resistance, and solderability assessments conducted at defined intervals.

Final quality control involves batch sampling for off-line testing, including thermal endurance (class rating verification), dielectric strength, and chemical resistance. All data are documented and traceable to ensure compliance with international standards and customer-specific technical dossiers. This integrated approach ensures that every meter of super enamel copper wire meets the exacting demands of motors, transformers, and high-efficiency electrical devices.

Packaging & Logistics

Export Packaging Specifications for Super Enamel Copper Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for super enamel copper wire shipments, prioritizing integrity during extended sea freight transit. Our 20+ years of metallurgical and supply chain expertise inform every layer of this system, specifically designed to counter hygroscopic degradation and mechanical stress inherent in global maritime logistics.

All wire reels are secured to ISPM 15-certified wooden pallets constructed from kiln-dried hardwood. These pallets feature a minimum load-bearing capacity of 1,500 kg and incorporate reinforced stringers to prevent warping under dynamic cargo movement. Pallet dimensions strictly adhere to ISO container compatibility standards (1,200 × 1,000 mm or 1,140 × 1,140 mm), ensuring optimal space utilization while eliminating inter-pallet shifting. Critical load distribution points utilize steel corner braces rated for 5-ton vertical impact resistance, mitigating reel deformation during crane handling and vessel stack compression.

Moisture protection constitutes the core defense against enamel insulation failure. Each palletized load undergoes triple-layer encapsulation:

First, reels are individually wrapped in 100μm-thick metallized polyester vapor barrier film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr at 38°C/90% RH.

Second, desiccant packs (calcium chloride, 1,000g capacity per 1m³ void space) are strategically positioned within reel cores and interstices to maintain internal relative humidity below 40% throughout voyages exceeding 60 days.

Third, the entire assembly is hermetically sealed under 200μm cross-laminated polyethylene (CLPE) moisture-proof film, heat-welded at 180°C to achieve seam integrity exceeding 15 N/mm tensile strength. This system prevents salt-laden marine atmospheres from penetrating the copper substrate, where even 65% RH exposure risks hydrolytic cleavage of the enamel polymer matrix.

Integrated protection extends to transit dynamics. Pallets receive four-point steel strapping (minimum 15 mm width, 15 kN tension) anchored to pallet base blocks, supplemented by laminated cardboard edge protectors at all vertical corners to resist forklift damage. Humidity indicator cards (HICs) with irreversible 55% RH thresholds are affixed internally for post-transit verification. Our packaging validation includes ASTM D4169-21 simulated sea voyage testing, subjecting sealed units to 72-hour salt fog exposure followed by 10 cycles of 95% RH/40°C conditioning. Post-test enamel adhesion (ASTM D2370) and dielectric strength (IEC 60851-5) consistently retain >98% of baseline specifications.

This methodology directly addresses copper wire’s vulnerability to chloride-induced pitting and enamel delamination during Pacific or Atlantic crossings. By exceeding IMO MSC/Circ.1073 moisture control benchmarks and ISO 11607-1 barrier requirements, Xinzhaohe ensures reels arrive with undiminished electrical performance—critical for motor winding applications where insulation defects cause catastrophic field failures. Partner with us for shipments where packaging is not merely containment, but a calibrated extension of material science.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaoanghe Aluminum Co., Ltd for Precision Super Enamel Copper Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-performance winding wires, including precision-engineered super enamel copper wire. As a trusted manufacturer with a vertically integrated production system, we maintain rigorous control over material sourcing, processing, and quality assurance to deliver products that meet the most demanding industrial specifications. Our facility is equipped with advanced drawing, annealing, and enamel coating lines, enabling us to produce super enamel copper wire with consistent dimensional accuracy, superior thermal endurance, and excellent dielectric strength.

Our technical capabilities are aligned with international standards such as IEC 60317, GB/T 23312, and NEMA MW series, ensuring compatibility across global markets. We produce super enamel copper wire in a comprehensive range of diameters, from 0.05 mm to 2.5 mm, with insulation classes up to 220°C (H-class and above), supporting applications in high-efficiency transformers, electric motors, generators, and high-frequency inductors. Each batch undergoes stringent testing for breakdown voltage, thermal shock, flexibility, and solderability to guarantee reliability under extreme operating conditions.

We operate a fully accredited quality management system compliant with ISO 9001:2015, supported by in-house laboratories that perform continuous monitoring of electrical, mechanical, and thermal properties. Our R&D team works closely with clients to optimize wire performance for specific application requirements, including enhanced thermal conductivity, reduced dielectric loss, and improved resistance to thermal aging and chemical exposure.

With an annual production capacity exceeding 15,000 metric tons and a warehousing network that ensures rapid order fulfillment, Luoyang Xinzhaohe is positioned to support both large-scale OEMs and niche industrial manufacturers. Our supply chain is designed for stability, with long-term agreements in place for high-purity electrolytic tough pitch (ETP) copper, ensuring consistent raw material availability and pricing predictability.

We understand that sourcing super enamel copper wire involves more than just dimensional compliance—it requires confidence in performance, repeatability, and technical partnership. That is why we offer comprehensive technical documentation, custom spooling configurations, and direct engineering support to streamline integration into your manufacturing processes.

For reliable supply, technical excellence, and long-term partnership in winding wire solutions, contact us today.

Contact:

Cathy

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

Specialists in High-Performance Winding Wire Since 2003

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing super enamel copper wire size chart directly from China.