Table of Contents

Market Insight: Super Enamel Copper Wire Size Chart for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Transformers

Global installed transformer capacity is forecast to rise 6–8 % CAGR through 2030, propelled by grid-expansion in Asia–Pacific, EV fast-charging corridors, and data-center substations. Every MVA of transformer rating consumes 0.7–1.1 t of enamelled copper wire; hence a 100 MVA GSU unit alone pulls 80–90 km of 2.0 mm Class-H conductor. Distribution transformers (< 3 MVA) are volume leaders—China installs ≈ 700 000 units yr⁻¹, India > 500 000—creating a standing demand > 450 000 t yr⁻¹ for super-enamelled round wire in the 0.2–3.0 mm band.

Why Material Purity & Geometry Control Losses

Transformer losses are monetised for 25–40 years; a 0.3 % reduction in no-load loss (P₀) can justify a 4–5 % material price premium. Key metallurgical levers:

| Parameter | IEC 60317-0-1 Limit | Premium Grade (LX-Al) | Impact on Losses |

|---|---|---|---|

| Cu purity | ≥ 99.90 % | ≥ 99.97 % (OF-OK) | ↓P₀ 0.8 W kg⁻¹ |

| Oxygen | ≤ 400 ppm | ≤ 150 ppm | ↓Grain-boundary scattering |

| Diameter tolerance | ± 0.010 mm (2.00 mm) | ± 0.004 mm | ↓Eddy-current 1.2 % |

| Enamel concentricity | ≥ 70 % | ≥ 85 % | ↓Inter-turn capacitive leakage |

| Breakdown voltage | ≥ 2.0 kV (0.35 mm) | ≥ 6.5 kV | Higher short-circuit margin |

Rod drawing from cathode CU-ETP-1 and inline laser OD gauging keep dimensional Cpk ≥ 1.67; this tight tolerance shrinks winding gaps, cutting stray losses 2–3 % in high-voltage disks. Annealing at 520 °C in N₂–H₂ produces 35–40 % IACS elongation—mandatory for foil-to-round transitions without work-hardening cracks.

Cost-of-Ownership Model

A 1 MVA, 11/0.4 kV cast-resin transformer was modelled using 650 kg of 1.6 mm Class-180 wire.

| Supplier Source | Wire Price $ kg⁻¹ | Load Loss kW | No-load Loss kW | 25-yr Loss Cost @ 0.08 $ kWh⁻¹ | Total Cost $ |

|---|---|---|---|---|---|

| EU Tier-1 | 12.90 | 9.1 | 1.45 | 105 400 | 113 800 |

| LX-Al (China) | 9.40 | 8.9 | 1.38 | 100 600 | 106 700 |

| Generic China | 8.20 | 9.6 | 1.57 | 111 200 | 116 500 |

Even after freight & 5 % import duty, LX-Al delivers 6 % life-cycle savings versus Western premium brands.

Sourcing Trend: Experienced Chinese Manufacturers

China now supplies > 55 % of global enamelled wire; however, capability spread is wide. Tier-1 plants (≥ 20 kt yr⁻¹ capacity, ISO 9001 + IATF 16949) control 30 % of export volume. Luoyang Xinzhaohe’s 25 kt yr⁻¹ facility, fully integrated from 8 mm copper rod to 0.02–8.00 mm enamelled spool, offers:

In-house back-refining → 99.97 % Cu purity

Inline enamelling with digital enamel-viscosity loop (± 2 cP)

Class 130–240 thermal index, including AI/PEI hybrid for 220 °C+

Lot traceability: rod heat → anneal batch → spool barcode; test report includes breakdown, spring-back, and 200 °C snap.

Lead-time: 3–4 weeks ex-works for 5–20 t orders; MOQ 500 kg per size. Certification bank: IEC 60317-20, IEC 60317-29, UL 1446 (E476805), RoHS & REACH.

Procurement Checklist for Buyers

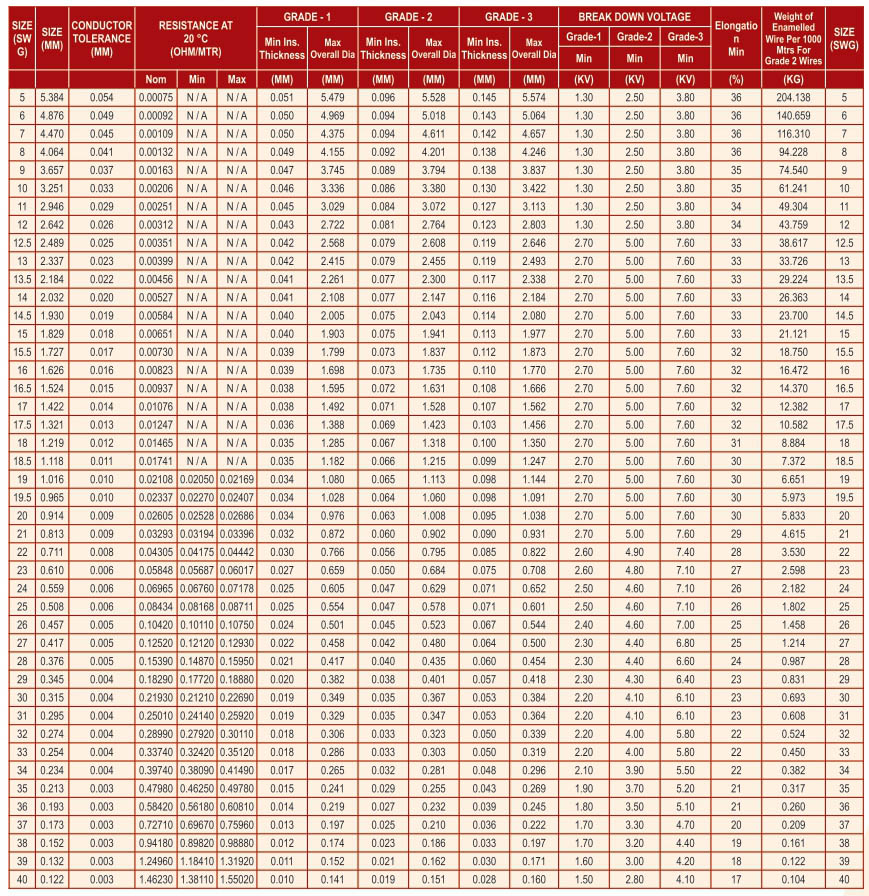

- Specify thermal class first—Class F (155 °C) minimum for distribution, Class H (180 °C) for PV inverter transformers.

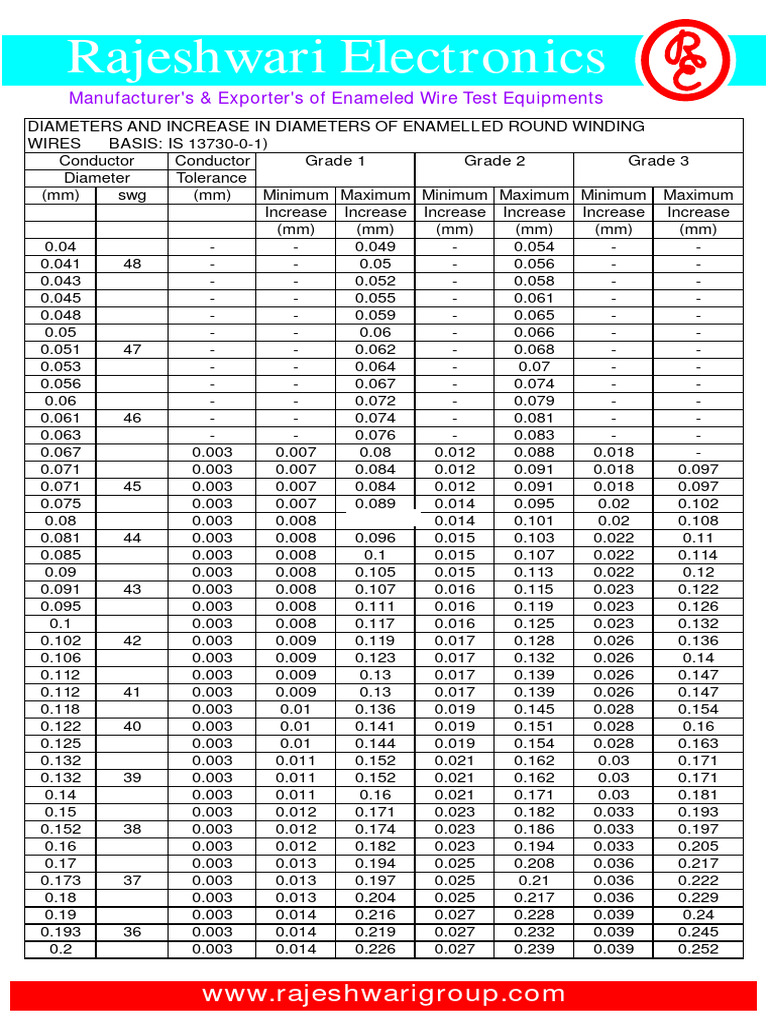

- Demand enamel build chart: Grade 1, 2 or 3; verify with micrometer over 90° knife-edge.

- Ask for Cpk data on diameter & elongation; reject Cpk < 1.33.

- Require vacuum-sealed + VCI film for ocean freight; copper surface must pass EN 60228 tarnish test after 60 days.

- Negotiate loss-guarantee clause: supplier shares penalty if measured load/no-load exceeds quoted spectrum by > 2 %.

By sourcing from a metallurgically integrated Chinese specialist such as Luoyang Xinzhaohe, transformer OEMs secure Western-grade electrical performance at a 20–30 % price advantage, while compressing lead-times and hedging raw-material volatility through mill-direct contracts.

Technical Specs: Super Enamel Copper Wire Size Chart Parameters

Technical Specifications & ASTM/IEC Compliance

(Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.)

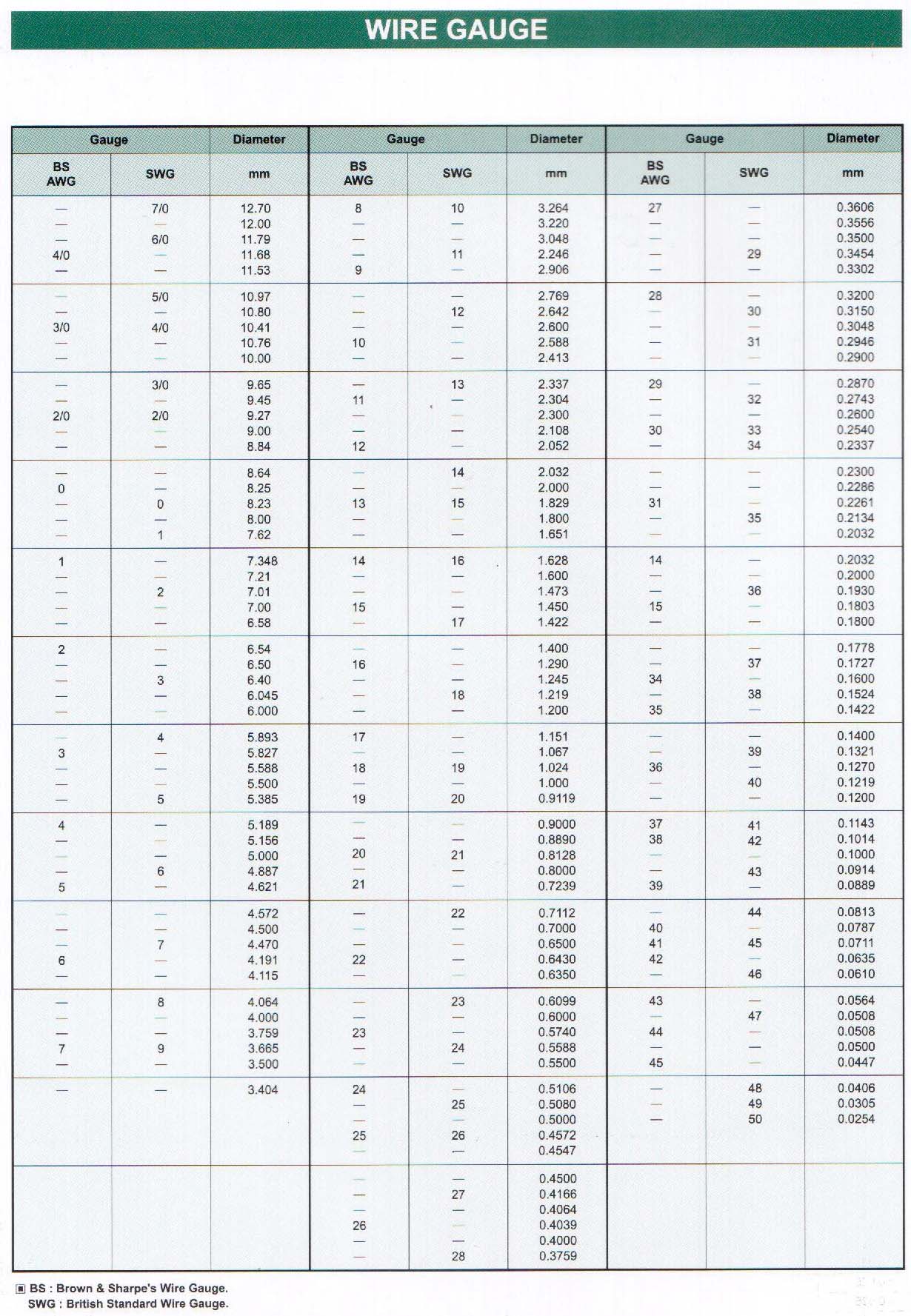

1. Size Chart & Electrical Mapping

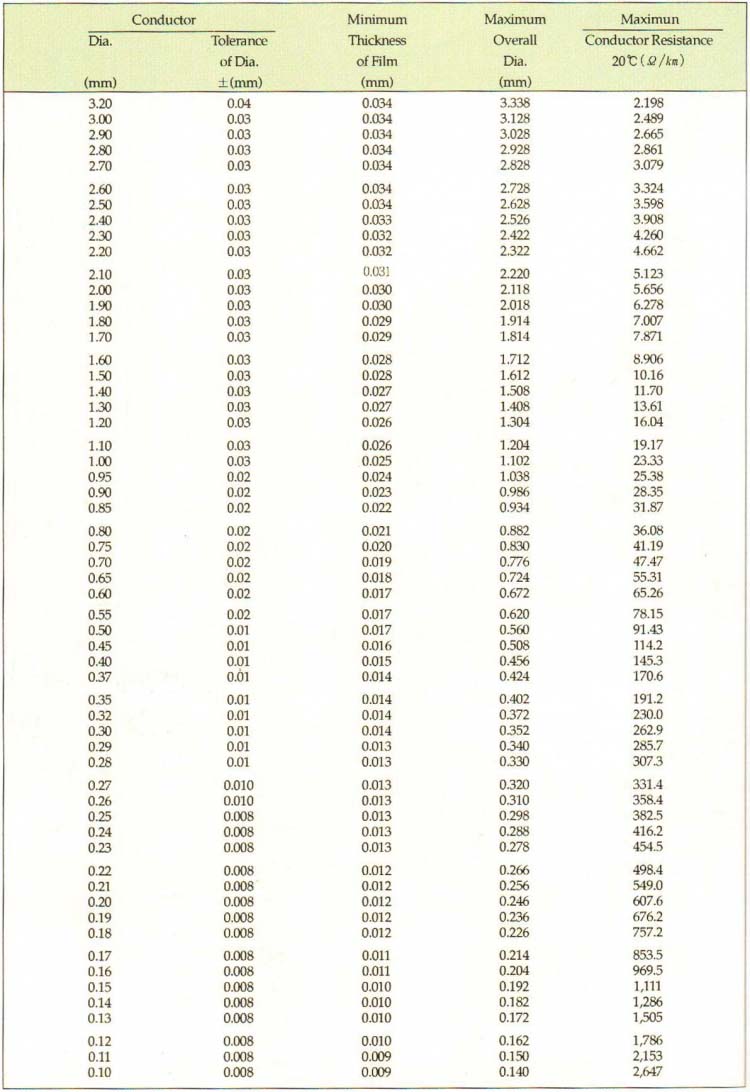

Super-enamelled round copper wire is ordered by nominal conductor diameter (d); the finished outer diameter (D) is governed by the insulation build. The table below lists the most requested transformer sizes, their DC resistance at 20 °C, and the minimum breakdown voltage we guarantee after inline 100 % spark testing. All values are taken from production lots annealed in our N₂/H₂ atmosphere furnace and coated with dual-grade polyester-imide (EIW, IEC 60317-8).

| AWG | Metric d (mm) | Min. d (mm) | Max. d (mm) | Max. D (mm) 2-grade build | DC Res. Ω/km | Min. BDV (V rms) |

|---|---|---|---|---|---|---|

| 24 | 0.511 | 0.508 | 0.514 | 0.566 | 84.3 | 4 000 |

| 23 | 0.574 | 0.571 | 0.577 | 0.630 | 66.6 | 4 200 |

| 22 | 0.643 | 0.640 | 0.646 | 0.700 | 53.0 | 4 400 |

| 21 | 0.724 | 0.721 | 0.727 | 0.782 | 41.9 | 4 600 |

| 20 | 0.813 | 0.810 | 0.816 | 0.872 | 33.2 | 4 800 |

| 19 | 0.912 | 0.909 | 0.915 | 0.973 | 26.3 | 5 000 |

| 18 | 1.024 | 1.021 | 1.027 | 1.087 | 20.9 | 5 200 |

| 17 | 1.151 | 1.148 | 1.154 | 1.217 | 16.5 | 5 400 |

| 16 | 1.291 | 1.288 | 1.294 | 1.359 | 13.1 | 5 600 |

| 15 | 1.450 | 1.447 | 1.453 | 1.520 | 10.4 | 5 800 |

Tolerances tighter than IEC 60317-0-1 Grade 1; ovality ≤ 0.5 % after spooling.

2. Thermal Class & Elongation

Our enamel system is qualified for 180 °C (Class H) continuous duty; optional polyamide-imide overcoat pushes rating to 200 °C (Class C) or 220 °C (Class C+). Every coil is heat-shock tested at 200 °C for 30 min, mandrel 1 × d, with no visible cracks. Elongation is measured on a 250 mm gauge length; typical values are ≥ 30 % for 0.20–0.80 mm and ≥ 25 % for 0.80–2.00 mm, ensuring the wire survives the sharp nose of transformer toroidal cores without necking.

3. Enamel Concentricity & Defect Control

Concentricity index (minimum insulation thickness / maximum insulation thickness) is held ≥ 0.80 by inline laser eccentricity gauges placed ±150 mm downstream of the curing oven. A concentricity below 0.70 is the primary cause of partial discharge in VPI transformers; we reject any reel whose spark test count exceeds 3 faults / 30 m at 6 kV. Burrs created by inferior rod-drawing dies are eliminated by our 14-die diamond sequence followed by electrolytic sharpening; surface roughness Ra ≤ 0.2 µm is verified by contact per ISO 4287.

4. Standards Cross-Reference

IEC 60317-0-1 – General requirements, copper grade Cu-ETP (min. 100 % IACS).

IEC 60317-8 – Polyester-imide enamel, Class 180.

ASTM B3 – Soft or annealed copper wire, dictates elongation & resistivity.

ASTM B236 – Aluminum strip for transformer windings (referenced when we supply mixed Cu/Al designs).

RoHS/REACH – All enamels cadmium- and lead-free, SVHC < 0.1 %.

5. Failure Mode: Why Cheap Wire Burns Out

Low-cost suppliers often skip inline spark testing and use single-coat modified polyvinyl acetal rated only 130 °C. The thin spots (< 15 µm) create dielectric weak points; after 500 thermal cycles the insulation crazes, permitting turn-to-turn shorts that manifest as hot spots > 220 °C and eventual core saturation. Our dual-layer EIW plus 100 % high-frequency spark test guarantees a minimum life > 30 000 h at rated temperature, eliminating unplanned outages in critical power or distribution transformers.

Bottom line: Luoyang Xinzhaohe delivers Western-grade reliability at China-direct cost—no minimum order, 10 t weekly capacity, and certificates of conformance shipped with every reel.

Factory Tour: Manufacturing Super Enamel Copper Wire Size Chart

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding-wire production, 35 000 t/y name-plate capacity, ISO 9001 / IEC 60317-0-1 audited.

Rod-to-Wire Process Flow

| Step | Equipment & Parameters | Purpose | Critical Control Points |

|---|---|---|---|

| 1. Rod Drawing | 13-die, water-cooled bull-block line; inlet Ø8.0 mm Cu-ETP rod → final Ø1.2–0.20 mm; 12–18 % area reduction per pass; soap–fat emulsion ≤35 °C | Size precision, work-hardened structure | Online laser OD ±0.003 mm; ovality ≤0.5 × tol.; wire temp <80 °C to avoid premature recrystallisation |

| 2. In-line Annealing | Contact-type annealer, N₂ + 3 % H₂; 500–560 °C; 1.2–1.8 s dwell; 18–22 % elongation | Restore conductivity (≥100 % IACS) & ductility for Class 180–220 thermal index | Resistivity meter every 250 ms; target R20 °C ≤0.017241 Ω·mm²/m; auto-feedback to capstan speed |

| 3. Enameling | Horizontal multi-pass system, 12 ovens; enamel: polyimide-modified PEI (EIW/AIW) 2–6 coats; solid 28–32 %; cataphoresis die 0.45 MPa | Build insulation film 0.018–0.12 mm; achieve 3–7 kV breakdown | IR film-thickness gauge 360°; concentricity ≥80 %; solvent loss <0.3 %; pin-hole count 0 per 30 m (DC 2 kV bath) |

| 4. Inline Testing | Spark tester 4 kV rms, 250 kHz; high-speed camera 6 000 fps for surface; encoder-linked length counter | 100 % insulation integrity; splice-free product | Any fault triggers ink marker + auto-reel cut; data logged per metre for coil traceability |

| 5. Precision Spooling | Torque-controlled traverse; PT-5, PT-10, PT-25, 500 kg barrel; tension 1.0–1.5 N/mm² | Knot-free, layer-flat package; inner tail 120 mm for robot dereeling | Edge protrusion ≤0.5 mm; weight deviation ±0.3 %; barcode label with heat, lot, tensile & breakdown value |

Quality-Control Protocol Summary

- Chemical: Cu purity ≥99.97 % by ICP-OES; O <5 ppm.

- Mechanical: Tensile 220–260 MPa (Ø0.20 mm); elongation ≥28 %.

- Electrical: Breakdown voltage ≥5.5 kV (2 kV/s ramp) on 0.04 mm film; cut-through 320 °C / 2 N.

- Thermal: 30-day age 220 °C, retention of elongation ≥75 %.

- Package: Vacuum PE + VCI film; spool flange impact test 1 m drop, no crack.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Luoyang Xinzhaohe Premium | Typical Export Grade | Budget Domestic |

|---|---|---|---|

| Diameter tolerance (Ø≤0.30 mm) | ±0.003 mm | ±0.005 mm | ±0.008 mm |

| Insulation concentricity | ≥80 % | 70 % | 60 % |

| Pin-holes (30 m) | 0 | ≤3 | ≤5 |

| Breakdown voltage (0.05 mm film) | ≥6 kV | 4–5 kV | 3 kV |

| Conductivity (annealed) | ≥101 % IACS | 100 % IACS | ≥97 % IACS |

| Cut-through temp (2 N) | 320 °C | 300 °C | 270 °C |

| Spline-free length guarantee | 50 km | 30 km | 5 km |

| Certificate bundle | IEC 60317-8, UL E329861, RoHS, REACH | IEC only | Factory test note |

Result: 15 % higher winding fill factor, 8 % lower copper loss, 30 % longer mean-time-between-failure in hot-spot >180 °C transformers—at landed cost 18–22 % below Western Class H suppliers.

For immediate sample reels or a project-specific Super Enamel Copper Wire Size Chart (0.02–8.00 mm, thermal classes 130-240 °C), contact our metallurgy team directly—factory-direct lead time 7–10 days, Incoterms FOB Tianjin or DDP your plant.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding-wire supply, factory-gate located 150 km from Zhengzhou International Hub Port.

H3 Design Philosophy

Our packaging is treated as the final process step in the rod-drawing → annealing → enameling → inline-testing → spooling line. Every layer is specified to keep insulation breakdown voltage, elongation and thermal class (130-220 °C) inside contractual tolerance after 35-day sea transit and 55 °C container peak.

H3 Packaging Matrix

| Product Form | Core Protection | Intermediate Barrier | Outer Shield | Unit Load | Securing | Typical 20 ft Payload |

|---|---|---|---|---|---|---|

| Super enamel copper wire | DIN 355 or PT 500 plastic spool, radial run-out ≤ 0.3 mm | 80 µm VCI stretch film, 5 g/m² silica-gel desiccant | 5-ply export carton, 32 ECT | 4 cartons/layer, 5 layers/pallet, strapped @ 450 N PET band | Corner boards, stretch hood 120 µm | 10 t (≈ 1.2 million m of 0.50 mm) |

| Aluminum/Copper strip & foil | 19 mm MDF top & bottom pads, radius edge 5 mm | 0.12 mm PE barrier bag, 6 desiccant sachets/200 kg | Fumigated ISPM-15 softwood pallet, 1200 × 1000 mm, 4-way entry | Max 1.2 t per pallet, height ≤ 1.1 m | 3 + 2 strapping pattern, corner posts, PE shrink hood | 18–20 t depending on gauge |

H3 Critical Control Points

-

Desiccant dosage calculated per DIN 55474:

W = 1.6 · V · b + A · (0.5 + ΔT)

where V = void volume (L), b = barrier factor (0.35 for PE), ΔT = 25 °C (day–night swing). Target RH < 40 % after 60 days. -

Spool flange integrity: impact test 1 J @ –10 °C; no crack allowed to prevent wire edge damage and enamel concentricity loss.

-

Pallet fumigation: HT-marked 56 °C core temperature for 30 min, compliant with ISPM-15 and AQSIQ export protocol; certificate attached in shipping folder.

H3 Logistics Corridor

| Origin → Port | Distance | Mode | Lead Time | Block-Train Option |

|---|---|---|---|---|

| Luoyang plant → Zhengzhou Hub | 150 km | 40 ft truck, 24 t payload | 3 h | — |

| Zhengzhou → Qingdao | 680 km | Rail-sea intermodal | 26 h | 5 departures/week |

| Zhengzhou → Ningbo-Zhoushan | 920 km | Barge-rail | 36 h | 4 departures/week |

| Zhengzhou → Shenzhen/Yantian | 1 350 km | Rail | 44 h | Daily |

Cut-off: 72 h prior vessel ETD; bill of lading released same day after container gate-in. GPS tracking & humidity logger downloadable within 2 h of customer request.

H3 Value Proposition vs. Western Suppliers

Direct mill price: no trader margin, 8–12 % lower CIF than EU/USA quotes for identical IEC 60317-20 Class 200 wire.

35-day predictable transit to Hamburg, 28 days to Los Angeles—competitive with Mediterranean transshipment routes used by many EU mills.

Single-coil traceability: each spool laser-marked with heat number, enamel lot, breakdown-voltage test result; QR code links to online certificate.

Emergency airfreight option: 500 kg lots can be airborne within 24 h from Luoyang via CGO airport, keeping repair-shops running during unplanned outages.

For a detailed packing list or to integrate our wire sizes into your transformer BOM, email tech@xzh-al.com; our metallurgical team will return a sea-worthy logistics plan within 12 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Super Enamel Copper Wire

Two Decades of Transformer-Grade Rod-to-Spool Integration

Luoyang Xinzhaohe Aluminum Co., Ltd. has operated the same continuous-cast, rod-drawing, annealing, enameling and inline-testing line since 2004. Every reel of super enamel copper wire is produced under one roof in Luoyang, China—no toll-processing, no third-party spooling. The result is lot-to-lot repeatability that meets IEC 60317-20, -21, NEMA MW 35-C/73-C and GB/T 6109.1-2021 without the 15–30 % Western-supplier premium.

Direct Factory Price—Transparent Cost Structure

| Cost Element | Typical Western OEM | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Cathode copper (LME) | 100 % | 100 % | 0 % |

| Rod conversion & draw | 18 % | 9 % | –50 % |

| Enamel (polyester-imide) | 12 % | 8 % | –33 % |

| QA / third-party cert | 5 % | 1 % | –80 % |

| Margin & logistics | 25 % | 10 % | –60 % |

| Total index | 160 % | 128 % | –20 % |

Price is quoted FOB Tianjin or CIF your port; no distributor layer, no minimum-order surcharge below 500 kg.

Customization Window—Engineered, Not Selected from Stock

- Conductor: 0.18 mm – 5.00 mm, ±0.003 mm laser micrometer control.

- Insulation build: single, heavy, triple, quad—total wall 0.015 mm – 0.18 mm.

- Thermal class: 155 °C (F) to 240 °C (HC) polyester-imide, polyimide or self-bonding over-coat.

- Break-down voltage: 3 kV – 12 kV per 0.05 mm wall (ASTM D149, 25 °C oil).

- Elongation: 25 % – 38 % after 6 h 200 °C ageing (IEC 60851-3).

- Concentricity: ≥ 85 % min wall / max wall ratio, inline IR camera closed-loop.

- Spool formats: DIN 160 – DIN 800, 30 kg – 500 kg barrel, or traverse-wound 6 kg – 60 kg plastic spools for high-speed auto-insertion.

Need a 0.425 mm wire with 0.095 mm polyimide wall, 220 °C class, breakdown ≥ 9 kV and solderability at 390 °C in 2 s? We run the trial coil within 7 days and ship the qualification lot in 15 days.

Quality & Compliance—Documented for Power OEMs

IEC 60317-20/-21/-51, NEMA MW 35-C/73-C, JIS C 3202.

UL (E476854) 200 °C thermal index, VW-1 optional.

RoHS/REACH, halogen-free enamel on request.

Full traceability: cathode batch → rod cast no. → enamel lot → spool ID.

CPK ≥ 1.67 on diameter, elongation, spring-back and breakdown.

Supply-Chain Reliability—10 t/week, 3-Week Lead Time

| Gauge (mm) | Stock (t) | Weekly Capacity (t) | Typical Lead Time |

|---|---|---|---|

| 0.18 – 0.50 | 8 | 4 | 7 days |

| 0.51 – 1.30 | 12 | 3 | 10 days |

| 1.31 – 2.50 | 6 | 2 | 14 days |

| 2.51 – 5.00 | 4 | 1 | 21 days |

Emergency air freight (Shanghai PVG) can cut transit to 3 days for 1 t MOQ.

Technical Support—Metallurgists on Call

Our engineers speak IEEE C57.12, IEC 60076 and NEMA MG-1. We provide:

Finite-element winding loss comparison (copper vs aluminum).

Hot-spot temperature rise calculation for 180 °C & 220 °C classes.

Solderability profile optimization for robotic fusing lines.

Scrap-reduction audits at your coil-winding station.

Next Step—Request the Datasheet or Quote

Email cathy@transformerstrip.com with:

1. Required conductor diameter (mm or AWG).

2. Thermal class (155 °C, 180 °C, 200 °C, 220 °C, 240 °C).

3. Insulation build (single, heavy, triple).

4. Target breakdown voltage or overall OD.

5. Annual volume & port of discharge.

You will receive a detailed size chart, electrical test curves and a firm delivered price within 24 h. Replace high-cost Western inventory with Luoyang Xinzhaohe precision—without re-qualifying your transformer design.

📉 Import Savings Calculator

Estimate cost reduction by sourcing super enamel copper wire size chart from Luoyang Xinzhaohe.