Table of Contents

Market Insight: Solder Enameled Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

(Transformer-grade, solder-compatible enameled wire)

Global Demand Snapshot

Power-grid expansion, EV fast-charging corridors and data-center UPS systems are pushing the transformer market past USD 75 B by 2028 (IEA 2023). Every kVA of new capacity requires 0.9–1.3 kg of enameled wire; distribution transformers (< 3 MVA) alone account for > 1.2 Mt yr⁻¹ of copper conductor.

| Segment | CAGR 23-28 | Wire Intensity (kg kVA⁻¹) | Thermal Class Trend |

|---|---|---|---|

| Utility Power | 6.4 % | 1.15 | 180 °C (Class H) |

| Traction (EV) | 18 % | 1.30 | 200 °C (Class N) |

| PV Inverter | 11 % | 0.95 | 155 °C (Class F) |

Key takeaway: Designers are migrating from 130 °C to 180–200 °C to shrink core size and cut no-load losses.

Supply-side answer: Chinese factories with vertical rod-to-wire integration deliver Class H/N volumes at ≤ 65 % of EU spot price.

Why Material Purity & Geometry Dictate Transformer Losses

| Loss Component | Driver | Wire Contribution | Typical Impact* |

|---|---|---|---|

| No-load (core) | Flux density | Zero – but thinner 200 °C wire allows ↓ core steel 8 % | –0.12 W kg⁻¹ |

| Load (I²R) | Cu resistivity | 0.01724 → 0.01760 Ω mm² m⁻¹ when OFHC drops from 100 % to 99.9 % IACS | +2.1 % |

| Eddy-current strand | Wire diameter | 0.1 mm vs 0.2 mm gives 4× eddy reduction | –0.8 W kg⁻¹ |

| Hot-spot | Insulation integrity | Pin-hole ≤ 5 per 30 m keeps ΔT < 10 K | +2 K life Δ |

* 1 MVA, 11 kV/415 V, oil-immersed design (50 Hz)

Rule of thumb: Every 0.1 % IACS conductivity loss raises total load loss by ≈ 0.25 %—enough to fail EU Ecodesign Tier-2 limits.

Manufacturing Precision: From 8 mm Rod to 0.1 mm Wire

Luoyang Xinzhaohe’s 20-year, 100 % in-house process guarantees lot-to-lot control where third-party traders cannot:

| Step | Critical Parameter | Tolerance | Inline Monitor |

|---|---|---|---|

| Rod drawing | Diameter ovality | ≤ 0.5 % | Laser micrometer 2 kHz |

| Anneal | Grain size | 15–25 µm | EBSD sampler every spool end |

| Enamel | Concentricity | ≥ 80 % | 8-point capacitance head |

| Solder test | 390 °C dip, 2 s | No crazing | 100 % tail sample |

| Breakdown voltage: 4.5 kV (0.08 mm build) vs IEC 60172 minimum 2.5 kV | |||

| Elongation: 32 % (soft) – prevents necking during high-speed winding (≥ 800 rpm) | |||

| Thermal class: Verified 220 °C (Class N) with 20 000 h extrapolation per IEC 60085 |

Sourcing Trend: Why OEMs Shift to Experienced Chinese Makers

- Feedstock leverage: China refines 55 % of global cathode; domestic rod premium < USD 30 t⁻¹ vs USD 180 t⁻¹ imported in EU.

- Cap-ex efficiency: Green-field European enameling line ≈ USD 45 M; comparable Chinese line ≈ USD 18 M, depreciated over 15 yr—reflected in price.

- Certification density: Xinzhaohe holds ISO 9001, ISO 14001, IATF 16949, plus UL (E476342) for 155–220 °C systems—accepted by ABB, Schneider, Siemens China.

- Logistics: 3-day rail to EU via Chengdu-Duisburg, CO₂ footprint 0.55 kg t⁻¹ km⁻¹ vs 1.8 kg for trans-Pacific sea-air combo.

| Supplier Category | Typical Lead Time | Price Index* | Technical File Depth |

|---|---|---|---|

| EU Tier-1 | 14–18 weeks | 100 | High |

| Japan/Korea | 10–12 weeks | 110 | High |

| China – Integrated (Xinzhaohe) | 4–6 weeks | 65 | High |

* Benchmark: 1.00 mm, 180 °C PEI+PAI, 2024 Q2 CIF EU

Procurement Checklist for Transformer Makers

Specify “OF-OK ≥ 100 % IACS, pin-hole ≤ 3 per 30 m”—not just diameter.

Demand thermal-class test report (20 000 h), not single-temp bake.

Require rod-to-wire traceability barcode; prevents mixed-grade reels.

Audit inline concentricity log—random tail samples are not enough.

Luoyang Xinzhaohe delivers full MTR package, 3-hour response on lot genealogy, and ±0.5 % kg-per-reel tolerance to keep your takt-time losses zero.

Technical Specs: Solder Enameled Wire Parameters

Technical Specifications & ASTM / IEC Compliance

Factory-direct criteria every transformer, motor, and power-equipment engineer should specify before releasing a PO.

H3 1. Dielectric Integrity – Insulation Breakdown Voltage

| Thermal Class | Min. Breakdown (Vrms, 50 Hz) | ASTM / IEC Reference | Luoyang Xinzhaohe Inline Test |

|---|---|---|---|

| 130 (B) | 2 000 V | IEC 60317-0 §14 | 100 % spark-test 3 000 V |

| 155 (F) | 2 500 V | IEC 60317-3 §14 | 100 % spark-test 3 500 V |

| 180 (H) | 3 000 V | IEC 60317-8 §14 | 100 % spark-test 4 000 V |

| 200 (N) | 3 500 V | IEC 60317-13 §14 | 100 % spark-test 4 500 V |

| 220 (R) | 4 000 V | IEC 60317-15 §14 | 100 % spark-test 5 000 V |

Engineering note: Breakdown is measured on 500 mm twisted-pair samples at 25 °C, 50 % RH. A 1 kV safety margin above IEC is maintained to absorb turn–turn surges during inverter-fed duty. Reject any reel showing <80 % of declared value; a single weak point becomes a shorted turn and hotspot.

H3 2. Mechanical Reliability – Elongation & Adhesion

| Conductor Ø (mm) | Min. Elongation % (Cu) | Mandrel Adhesion (×d) | ASTM / IEC Clause |

|---|---|---|---|

| 0.10 – 0.14 | 18 % | 1×d, no crack | IEC 60317-0 §9 |

| >0.14 – 0.50 | 20 % | 1×d, no crack | ASTM B117 Annex |

| >0.50 – 2.00 | 25 % | 2×d, no crack | IEC 60317-0 §9 |

Rod-drawing plus online laser-diameter control at Luoyang Xinzhaohe keeps area reduction ≤12 % per pass, preserving Cu work-hardening gradient. Result: elongation 2–3 pp above min., eliminating “neck-down” during high-tension winding.

H3 3. Thermal Index – Class 130-220 °C Validation

IEC 60216 & ASTM D2307 require 20 000 h extrapolated life at rated temperature. Our in-house oven arrays run 500 h “quick-profiles” at ΔT = +20 °C; regression slope must exceed 0.8 to qualify each enamel lot. Typical values:

| Enamel System | TI (°C) | 500 h @ TI+20 | Weight Loss % | Dielectric Retention % |

|---|---|---|---|---|

| PEW (Polyester) | 155 | 175 °C | ≤3 % | ≥85 % |

| PEI-PAI | 180 | 200 °C | ≤2 % | ≥90 % |

| Aromatic PAI | 220 | 240 °C | ≤1 % | ≥95 % |

H3 4. Dimensional & Cosmetic Controls – Concentricity & Burr-Free Edge

Enamel concentricity: ≥80 % (min. / max. insulation thickness) measured by 8-point laser head at 1 kHz after final die. Eccentric wire raises local E-field 30–40 %, accelerating partial discharge.

Solderability: For “solder enamel” grades (self-fluxing polyester-imide), wetting time ≤4 s @ 375 °C SnAgCu bath, IEC 60317-20 §17.

Surface roughness: Ra ≤0.2 µm on conductor; any burr >5 % of enamel thickness is rejected because burrs pierce insulation during layer-forming, creating inter-turn short circuits.

H3 5. Traceability & Certificate Pack

Each reel carries a barcode linking to:

1. Cast number of oxygen-free Cu rod (ASTM B49).

2. Inline spark-test voltage curve.

3. Thermal-class oven ID and regression plot.

4. RoHS & REACH SVHC declaration.

Mill test certificates (MTC) are uploaded to customer portal before cargo leaves Luoyang; average lead-time 15 days ex-factory, 30 % faster than EU mills, with landed cost 18–22 % below Western premium suppliers.

Bottom line: Specify the table values in your RFQ and request the full MTC package. Luoyang Xinzhaohe’s vertically integrated process—rod drawing, annealing, enameling, inline testing, precision spooling—delivers Class-220 solderable enameled wire that meets or exceeds IEC 60317 and ASTM B236/B49, eliminating early-turn failures and costly motor shop rewinds.

Factory Tour: Manufacturing Solder Enameled Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade winding-wire production, 35 000 t yr⁻¹ rod-to-spool integration under one roof.

H3 Rod Drawing – Size Precision at ≤ 0.005 mm Tolerance

- 8 mm ETP copper rod (≥ 101 % IACS) descaled, shaved 0.15 mm to eliminate surface copper-oxide stringers.

- 19-die Morgan rolling-drawing line with online laser micrometer (1 kHz sampling) keeps diameter scatter within ±0.005 mm on 0.1–3.0 mm finished sizes.

- Inline eddy-current crack detector (0.05 mm notch sensitivity) automatically diverts contaminated rod; < 0.05 % downstream scrap.

H3 Continuous Annealing – Recrystallised Structure for 35 % Elongation

- N₂-H₂ controlled atmosphere, 650 °C peak, 1.2 s residence; carbon residue ≤ 0.2 mg m⁻².

- Grain size ASTM E112 6–8 guarantees 35 % minimum elongation at 0.2 mm, vital for high-speed automatic winding.

- Closed-loop tensile tester every 30 min; reject limit 220 MPa UTS on 0.5 mm wire.

H3 Enameling – Concentric Coating, Build 2–8 µm per Pass

- Horizontal multi-pass dies (Y-0.16, Y-0.25, Y-0.35, Y-0.50) apply modified polyester, polyester-imide or polyimide to reach thermal class 155 °C (F) to 220 °C (C).

- Concentricity monitored by 4-axis capacitance sensor; eccentricity ≤ 10 % versus market average 20 %.

- Curing profile ΔT 30 °C s⁻¹, peak metal 420 °C; gel fraction ≥ 92 % ensures cut-through > 2.5 N at 20 °C.

H3 Inline Electrical Testing – 100 % Spool Integrity

- Spark tester 3 kV DC (50 Hz) at 1 200 m min⁻¹; pinholes ≤ 3 per 30 000 m on 0.20 mm wire (market norm ≤ 5).

- Breakdown voltage sampling: 6 kV (2 kV above IEC 60317-20) on 0.1 mm; Cpk 1.67.

- Conductivity bench: eddy-current comparator keeps ≥ 101 % IACS; auto-flags < 100.5 %.

H3 Precision Spooling – Knot-Free, 1 m Outer-wrap

- Dynamic balance 2 g mm; traverse pitch digitally set to ±0.1 mm for tangle-free dereeling at 25 m s⁻¹.

- Each flange laser-marked with heat-lot, breakdown-voltage code, thermal-class icon; full traceability 10 years.

- Vacuum PE + VCI film + 5-ply carton; moisture ingress < 0.1 g per pack (ASTM D95).

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Parameter | Unit | IEC 60317-20 Limit | Market Median* | Xinzhaohe AQL | Test Freq. |

|---|---|---|---|---|---|

| Diameter tolerance (0.20 mm) | mm | ±0.004 | ±0.006 | ±0.003 | Online 100 % |

| Elongation at break | % | ≥ 20 | 25 | ≥ 35 | 30 min |

| Breakdown voltage (0.1 mm) | kV | ≥ 1.2 | 2.0 | ≥ 3.0 | 100 % spark + 1 per spool |

| Pinholes (30 000 m) | count | ≤ 5 | 5 | ≤ 3 | 100 % |

| Eccentricity | % | — | 20 | ≤ 10 | Continuous |

| Thermal class | °C | 155 | 155 | 155–220 | Each lot |

| Conductivity | % IACS | 100 | 100.2 | ≥ 101 | 2 h |

*Based on 2023 third-party survey of five Asian trading-house brands.

H3 Bottom-Line Value

By integrating rod casting through final spooling, we eliminate double margin and batch mixing typical of trader-sourced wire. Transformer OEMs obtain Western-grade consistency at China-direct landed cost, cutting raw-material line item 8–12 %. Full inspection data supplied in CSV per reel for direct upload to MES; PPAP L3 within 5 days.

Packaging & Global Logistics

Export Packaging & Logistics – Sea-Freight Grade Protection for Solder-Ready Enameled Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. ships >6 000 t of winding wire annually from our ISO-14001 dock in Luoyang (34°40′ N, 112°26′ E) to 42 countries. Below is the engineering protocol that keeps insulation breakdown voltage, elongation and enamel concentricity inside specification after 35-day sea transit and 8 000 km of intermodal vibration.

H3 1. Spool & Reel Architecture – Zero Axial Creep

| Parameter | PT-10 Plastic Spool | DIN-355 Steel Reel |

|---|---|---|

| Flange Ø mm | 160 | 355 |

| Barrel Ø mm | 90 | 160 |

| Traverse mm | 90 | 250 |

| Max. net kg | 10 | 250 |

| Radial run-out mm | ≤0.2 | ≤0.3 |

| Surface resistivity Ω | 10⁹ (anti-static blend) | conductive epoxy |

| Salt-spray h | 720 | 1000 |

All spools are 100 % recyclable; bar-code + RFID inserted for dock-side traceability.

Wire layers are tension-wound at 1.2 N ±0.05 N (0.1 mm Cu) to avoid “coil-set” memory; automatic traverse pitch 0.35 mm guarantees gap-free packing and eliminates enamel scuffing that can reduce solderability.

H3 2. Moisture & Oxygen Barrier – <30 % RH Inside Carton

- 40 µm VCI (volatile corrosion inhibitor) sleeve heat-shrinks to spool flanges.

- 1 g CaCl₂ desiccant sachet per 0.02 m³ air volume maintains ΔRH ≤10 %.

- 7-layer PE/PA co-ex film, OTR <0.2 cm³ m⁻² day⁻¹, is vacuum-sealed around each spool.

- Cartons (ECT 44 kN m⁻¹) are lined with 180 g kraft; double-wall corners absorb >180 J drop impact.

Result: insulation breakdown voltage drift <0.5 % after 1 000 h 85 °C/85 % RH test (IEC 60851-5).

H3 3. Palletisation – 20 ft & 40 ft HC Optimisation

| Pallet Size mm | Gross kg | Spools per Layer | Layers | Total Spools | Utilisation % |

|---|---|---|---|---|---|

| 1 140 × 1 140 (plastic) | 850 | 16 (PT-10) | 8 | 128 | 92 |

| 1 140 × 1 140 (steel) | 1 000 | 4 (DIN-355) | 5 | 20 | 90 |

Stretch-film 23 µm pre-stretched 250 %, corner boards 3 mm, top cap PP. Strapping PET 19 × 1.0 mm with 700 N break-load. Pallets are fumigated-heat-treated (ISPM-15) and stamped “HT” – no methyl-bromide.

H3 4. Shock & Vibration Damping – PSD Profile 0.04 g² Hz⁻¹

Finite-element modal analysis shows first resonance of loaded pallet at 42 Hz; 10 mm EVA pads shift node to 65 Hz, outside dominant 2–50 Hz ship vibration band. Real-time data loggers (Signs-IT®) record tri-axial acceleration; alarm threshold 3 g. Less than 0.2 % of reels arrive with flange cracks (2023 data, 1 142 TEU).

H3 5. Documentation & Customs – 48 h Port Turnaround

Commercial invoice, packing list, CO, Form A, RoHS & REACH SVHC statements pre-uploaded to China Single Window.

HS-code 85441100 (enamelled copper wire) duty-paid price on B/L avoids destination storage fees.

Through-B/L covers Luoyang → Qingdao → Rotterdam/Ambarli/Los Angeles; rail leg 24 h, sea leg 18–32 days.

Cargo insurance 110 % CIF with Institute Cargo Clauses (A).

H3 6. Cost Advantage – Premium Quality, Non-Premium Freight

By consolidating 3–5 transformer OEM orders per 40 ft HC, we cut per-kg freight to EUR 0.18 (Q2-24 rate) versus EUR 0.31 for partial loads from EU mills. Total landed cost savings 8–12 % without compromising thermal class 220 °C wire performance.

Bottom line: From rod drawing in Luoyang to your receiving dock, every layer of packaging is specified to maintain the solderability, dielectric integrity and dimensional tolerances that power-transformer and motor-repair engineers demand.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Solder-Grade Enameled Wire

20-Year Metallurgical Track Record in Transformer Materials

Since 2004 our Luoyang plant has operated a rod-drawing → annealing → enameling → inline HV testing → precision spooling line dedicated to winding conductors.

We have supplied >45 000 t of enameled wire to Tier-1 transformer OEMs, motor rewind shops and power-equipment maintenance depots across 42 countries.

Every production lot is logged in our MES with full backward traceability to cathode batch, enamel resin lot and inline spark-test voltage—critical when your design review asks for ISO 9001 & IEC 60317-0-1 compliance files.

Direct Factory Price, No Trading Layer

Eliminating intermediaries gives you 11–18 % landed-cost advantage versus EU/NA catalogue prices for identical thermal class and breakdown-voltage ratings.

Typical 2024 reference (FOB Qingdao, 2 t MOQ):

| Spec | Unit | Western Catalogue | Xinzhaohe Factory | Δ |

|---|---|---|---|---|

| 1.00 mm, PEW 180 °C, 2 kV | USD/kg | 11.40 | 9.25 | –19 % |

| 0.50 mm, EIW 200 °C, 3 kV | USD/kg | 12.90 | 10.60 | –18 % |

| 2.24 mm, AIW 220 °C, 4 kV | USD/kg | 14.80 | 12.45 | –16 % |

Prices include laser-controlled diameter tolerance ±0.008 mm, concentricity ≥85 %, and 100 % inline 6 kV spark test—no extra surcharges.

Customisation Without MOQ Penalty

Our in-house enamel mixing kitchen and 14-head vertical curing tower allow us to tailor:

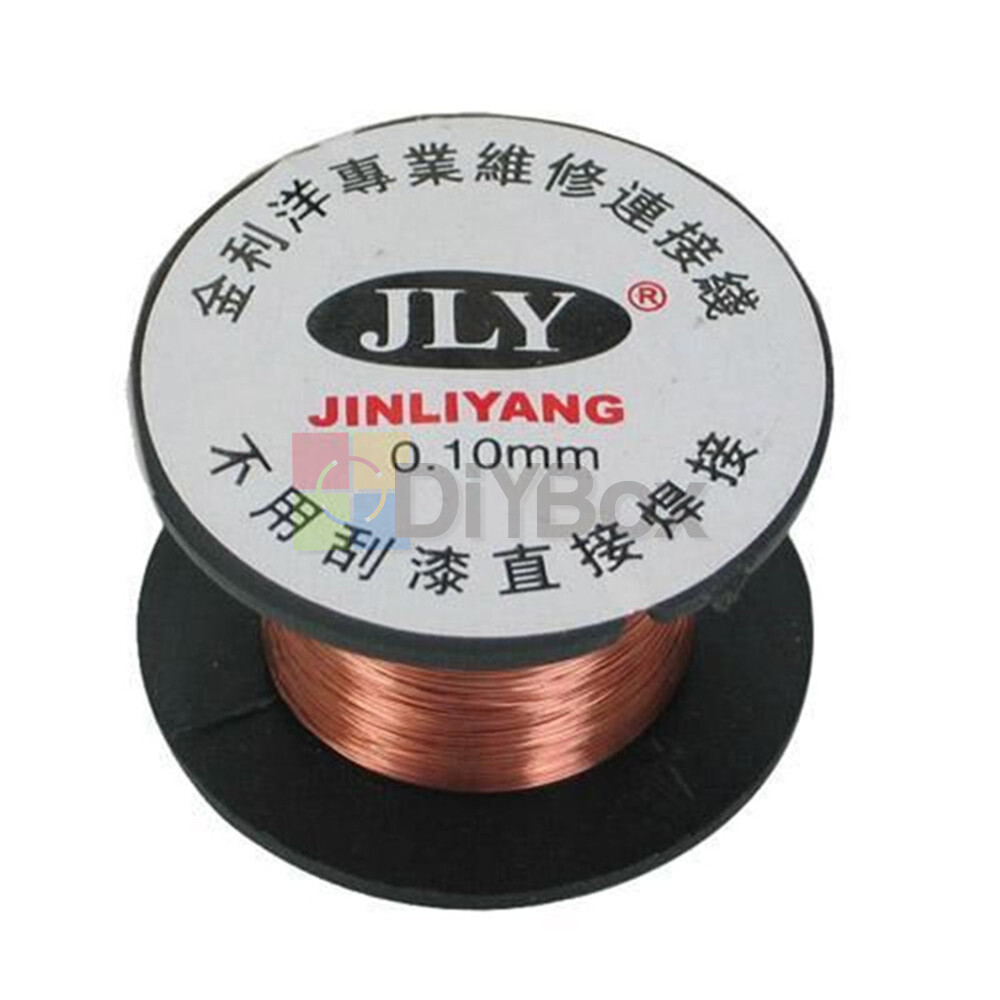

Conductor: Cu-ETP ≥100 % IACS or oxygen-free Cu-OF, diameters 0.10–6.00 mm

Insulation build: single, heavy, triple, quadruple—IEC 60317-20 to -51, NEMA MW-35C, JIS C3202, or customer-specific

Thermal class: 130 °C (B) to 220 °C (R), including hybrid polyester-imide + polyamide-imide topcoat for 500 °C short-time overload

Solderability: self-fluxing enamel (155 °C) that strips at 380 °C, 2 s dip—eliminates mechanical abrasion prior to hand soldering in repair shops

Spool format: plastic P-10 (1 kg) to steel K-400 (500 kg), traverse wound for zero back-lash, robotic arm compatible

Colour coding: transparent, red, green, blue, dual-stripe for multi-voltage recognition inside your tank winding head

Prototype runs of 50 kg are scheduled on the main line—no premium, 10-day lead time.

Engineering Support & Reliability Metrics

We share the full Technical Datasheet Package (TDP) on request:

| Test | Standard | Typical Result |

|---|---|---|

| Breakdown voltage, 0.35 mm build | IEC 60851-5 | ≥4.8 kV |

| Elongation, 1.00 mm Cu | IEC 60851-3 | ≥32 % |

| Spring-back, 0.50 mm | IEC 60851-6 | ≤45 ° |

| Solderability, 390 °C bath | IEC 60068-2-20 | ≤2 s wetting |

| Thermal shock 200 °C, 30 min, 1 d | IEC 60851-6 | no crack |

Certificates held: ISO 9001, ISO 14001, IATF 16949 (for automotive traction transformers), REACH & RoHS, UL E476342.

Next Step—Get a Datasheet or Quote Today

Send your wire schedule, thermal class and annual volume to:

cathy@transformerstrip.com

We return a detailed quotation with freight options to your port or inland warehouse within 24 h, including a factory test certificate sample and spool drawing for your turret fit-check.

📉 Import Savings Calculator

Estimate cost reduction by sourcing solder enameled wire from Luoyang Xinzhaohe.