Table of Contents

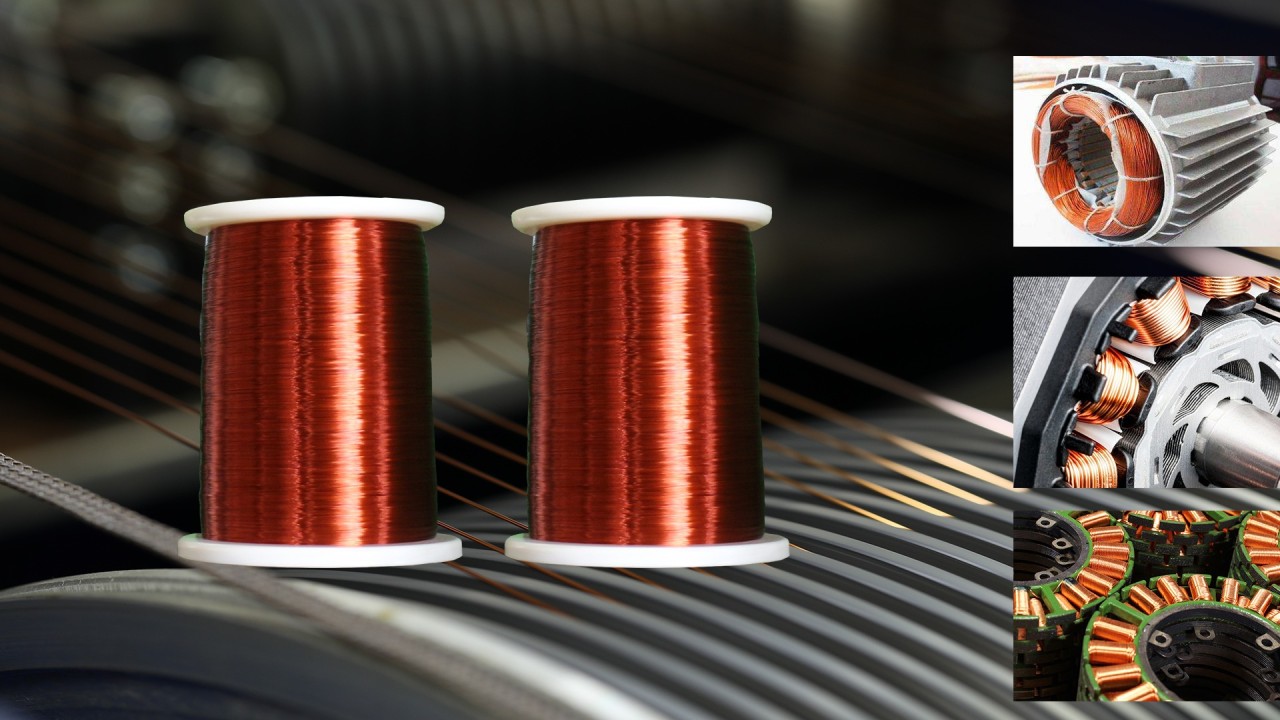

Market Insight: Soft Wire

Market Analysis: Winding Wire Demand and Quality Imperatives in Transformer Applications

The global demand for high-purity annealed aluminum soft wire, specifically designated for transformer windings, continues robust expansion driven by critical energy infrastructure developments. Core demand stems from the worldwide acceleration of electrical grid modernization, renewable energy integration requiring step-up transformers at solar/wind farms, and the escalating deployment of electric vehicle charging networks necessitating distribution transformers. Emerging economies, particularly across Asia and Africa, represent significant growth vectors as they expand grid access and capacity. China’s State Grid Corporation investment exceeding RMB 500 billion annually underscores the scale of this infrastructure push, directly fueling demand for reliable winding materials. Crucially, aluminum soft wire has gained substantial market share against copper due to its superior weight-to-conductivity ratio and cost efficiency, especially in distribution and power transformers above 500 kVA, where material volume significantly impacts total landed cost.

Quality consistency in aluminum soft wire is non-negotiable for transformer performance, longevity, and safety. The annealing process must achieve precise metallurgical homogeneity to ensure the wire possesses the required soft temper (typically O-temper per ASTM B548) without surface oxidation or residual stresses. Inconsistent annealing leads to variable elongation and tensile strength, causing winding deformation during coil formation or catastrophic failure under short-circuit electromagnetic forces. Electrical conductivity must consistently meet or exceed 61.0% IACS (International Annealed Copper Standard), as deviations directly increase resistive (I²R) losses, elevating operating temperatures and reducing transformer efficiency by measurable percentage points over its 30+ year lifespan. Impurities, even at trace levels (e.g., Fe > 0.12%, Si > 0.08%), critically degrade conductivity and accelerate intergranular corrosion under thermal cycling, a primary failure mode in fielded units. Luoyang Xinzhaohe Aluminum’s two decades of specialized production focus on controlling melt chemistry, continuous casting parameters, and precision annealing profiles ensures the grain structure and surface integrity required for reliable high-voltage insulation adhesion and thermal stability.

Substandard soft wire manifests in transformer failures through multiple mechanisms. Microscopic surface defects act as initiation sites for partial discharges under operational voltage stress, progressively degrading solid insulation. Variations in diameter tolerance exceeding ±0.02 mm disrupt precise layer winding, creating localized hot spots and mechanical instability. Most critically, inadequate conductivity or inconsistent softness increases no-load and load losses, violating global efficiency standards (e.g., DOE 2016, EU EcoDesign) and incurring substantial lifetime energy cost penalties for utilities. Field data correlates even minor conductivity deviations below 60.8% IACS with a 15-20% acceleration in thermal aging of cellulose insulation. Sourcing from suppliers with rigorous in-process metallurgical testing—verifying conductivity, tensile properties, elongation, and surface quality per batch—is therefore a fundamental risk mitigation strategy. The initial material cost differential is insignificant compared to the lifecycle cost of premature failure or chronic inefficiency in critical power assets. Partnering with an experienced aluminum wire specialist ensures the metallurgical precision demanded by modern transformer design.

Technical Specs: Soft Wire

Technical Specifications for Soft Wire – Winding Wire Product Line

Luoyang Xinzhaohe Aluminum Co., Ltd. has over two decades of expertise in the production and supply of high-performance soft wire for industrial winding applications. Our soft wire solutions are engineered to meet the rigorous demands of motors, transformers, generators, and other electromagnetic equipment where reliability, thermal stability, and mechanical integrity are paramount. This section outlines the core technical parameters that define the performance of our soft wire products, with emphasis on insulation breakdown voltage, elongation characteristics, and thermal class ratings.

Insulation breakdown voltage is a critical performance indicator for soft wire, determining the dielectric strength of the insulation layer under high electrical stress. Our soft wire products are manufactured with precision-coated insulation systems designed to withstand operating voltages while preventing electrical leakage or short circuits. The minimum insulation breakdown voltage is tested under standardized conditions (IEC 60317 and GB/T 6109) and varies depending on wire diameter and insulation thickness. Typical breakdown voltages range from 3,000 V to 6,000 V AC, ensuring robust performance in high-voltage environments. Each batch undergoes 100% spark testing during production to guarantee insulation integrity.

Elongation, or tensile ductility, is another essential mechanical property, especially during coil winding operations where the wire is subjected to bending and tension. Our soft wire exhibits controlled elongation values between 30% and 50%, depending on alloy composition and temper condition. This range ensures optimal formability without cracking or insulation damage during high-speed winding. The elongation is verified through uniaxial tensile testing per ASTM E8, with results traceable to certified material test reports.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Our soft wire portfolio supports thermal classes ranging from 130°C to 220°C, aligning with global standards such as NEMA MW 1000 and IEC 60085. Higher thermal classes utilize advanced insulation materials such as polyimide, aromatic polyamide, or ceramic coatings, offering superior thermal endurance and long-term reliability in demanding environments. All thermal class ratings are validated through thermal endurance testing (Arrhenius plotting) and thermal index determination.

The following table summarizes the key technical parameters for our standard soft wire offerings:

| Parameter | Test Standard | Typical Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, GB/T 6109 | 3,000 – 6,000 V AC (rms) | Depends on wire diameter and insulation build |

| Elongation | ASTM E8 | 30% – 50% | Measured on bare conductor; depends on temper |

| Thermal Class | IEC 60085, NEMA MW | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system and thermal index |

| Conductor Material | GB/T 8170 | Aluminum (1350, 8030), Copper (ETP) | Custom alloys available |

| Diameter Tolerance | GB/T 7899 | ±0.01 mm to ±0.03 mm | Depends on nominal diameter |

These specifications reflect Luoyang Xinzhaohe Aluminum Co., Ltd.’s commitment to precision engineering and consistent quality. All products are subject to in-process and final quality inspections, with full documentation available for traceability and compliance.

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Aluminum Soft Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to produce precision aluminum soft wire for demanding electromagnetic winding applications. Our integrated manufacturing process ensures consistent electrical conductivity, mechanical formability, and enamel adhesion, critical for motor and transformer performance. The sequence begins with high-purity aluminum rod (minimum 99.7% Al) sourced under strict supplier protocols, subjected to rigorous incoming inspection for chemical composition and surface integrity.

Rod Drawing Process

The rod undergoes multi-pass cold drawing through precision tungsten carbide or diamond dies within a controlled lubrication system. This reduces the diameter to the final wire specification while maintaining roundness and surface smoothness. Critical process parameters including reduction ratio per pass, lubricant viscosity, and capstan speed are continuously monitored and adjusted via PLC systems. In-process quality control mandates 100% diameter verification using laser micrometers at defined intervals, ensuring tolerances within ±0.003mm. Surface defect detection via high-resolution cameras occurs inline, automatically flagging sections for rejection.

Annealing Treatment

Following drawing, the wire enters a continuous annealing furnace operating under a precise hydrogen-nitrogen reducing atmosphere. This critical thermal treatment eliminates work hardening induced during drawing, restoring optimal ductility and electrical conductivity. Temperature profiles and residence time are meticulously calibrated based on wire gauge and target mechanical properties. The table below outlines key annealing parameters for standard grades:

| Parameter | Typical Range | Target Conductivity | Verification Method |

|---|---|---|---|

| Annealing Temp | 380°C – 420°C | ≥61.0% IACS | Online conductivity meter |

| Atmosphere H₂ % | 3% – 5% | Gas chromatography | |

| Line Speed | 8 – 15 m/min | Encoder monitoring |

Post-annealing, every spool undergoes 100% electrical conductivity testing against IACS standards and tensile strength/elongation verification per ASTM B355.

Enameling Application

The annealed wire proceeds to the enameling line where one or multiple layers of thermosetting polymer resin (typically polyester-imide or polyamide-imide) are applied via precision die or nozzle systems. Film thickness is controlled within microns through resin viscosity management, coating die geometry, and curing oven profiles. Multiple curing stages with precisely controlled temperature zones ensure complete polymer cross-linking without thermal degradation. In-process checks include continuous wet-film thickness measurement and visual inspection for bubbles or streaks.

Integrated Inline Testing & Final QC

Comprehensive electrical validation occurs during rewinding. The primary test is high-voltage spark testing at 3kV to 15kV DC (depending on wire gauge and insulation class), detecting pinholes or thin spots with millisecond response. Simultaneously, optical sensors monitor diameter consistency and surface defects. Final quality assurance requires destructive testing on representative samples from each production lot, including mandrel wrap tests per NEMA MW 1000, thermal shock evaluation, and adhesion testing. Only wire meeting all dimensional, electrical, and mechanical specifications documented in the Mill Test Report is released for shipment, ensuring unwavering performance in the customer’s winding operations. This closed-loop process control system, refined over 20 years, guarantees the reliability demanded by global electrical component manufacturers.

Packaging & Logistics

Export Packaging for Soft Wire – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum winding wire, we recognize that reliable export packaging is a critical component in preserving product integrity throughout international logistics. Our soft wire products, designed for precision applications in transformers, motors, and electrical systems, require packaging solutions that mitigate environmental and mechanical risks during prolonged sea transportation. To this end, we implement a robust, standardized export packaging protocol centered on wooden pallets and moisture-proof barrier protection.

All soft wire reels are systematically mounted onto high-strength wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are engineered to support the full static and dynamic load of coiled aluminum wire, typically ranging from 200 kg to 2,000 kg per shipment unit. The structural rigidity of the pallet ensures dimensional stability during stacking and crane handling, minimizing deformation or reel displacement during container loading and unloading. Reinforced corner braces and calibrated nail spacing enhance load distribution, reducing the risk of pallet failure under maritime freight conditions.

Once secured on the pallet, each wire reel is fully encapsulated using multi-layer moisture-proof laminated film. This film combines low-density polyethylene (LDPE) with aluminum foil interlayers to create a vapor transmission rate (VTR) of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. This barrier effectively prevents salt-laden marine atmospheres from inducing surface oxidation or hydrolytic degradation of the wire’s insulation coating. The wrapping process is performed in a climate-controlled environment to eliminate internal condensation, followed by heat-shrink sealing at all seams to ensure continuity of the protective envelope.

Additional safeguards include the application of desiccant packs affixed within the film enclosure, typically at a dosage of 500 g per ton of wire, to absorb residual humidity. Pallets are further labeled with moisture-sensitive indicators and orientation arrows to guide proper handling. For containerized shipments, we recommend the use of 20-foot or 40-foot dry van containers with verified door seals, loaded under tarpaulins when exposed to open yards. Each pallet is secured using steel or composite strapping anchored to the container floor, preventing lateral movement during vessel transit.

Our packaging methodology aligns with international maritime safety standards, including the CTU (Cargo Transport Unit) Code and ISO 1496 for freight containers. It has been validated through accelerated aging tests simulating 60-day ocean voyages under tropical and temperate conditions. This systematic approach ensures that soft wire arrives at destination ports with maintained electrical performance, surface quality, and reel geometry.

Luoyang Xinzhaohe Aluminum Co., Ltd treats packaging not as a logistical afterthought but as an extension of metallurgical quality control. By integrating structural resilience with environmental isolation, we guarantee that our soft wire meets the exacting demands of global supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Aluminum Soft Wire Manufacturer

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver premium annealed aluminum winding wire, specifically engineered for demanding electrical applications. Our core strength lies in deep vertical integration and process mastery, ensuring unparalleled consistency and performance in every coil of soft wire produced. We control the entire value chain from high-purity aluminum billet sourcing through precision casting, homogenization, hot rolling, cold rolling, and the critical final annealing stage. This integrated approach eliminates supply chain vulnerabilities and guarantees material traceability from raw input to finished product, a non-negotiable requirement for critical components like transformer windings and motor coils.

Our manufacturing capability is defined by technical precision and scale. We operate state-of-the-art continuous annealing lines specifically calibrated for aluminum soft wire production. These lines enable exact control over annealing temperature profiles, dwell times, and cooling rates, directly influencing the wire’s final mechanical and electrical properties. This precision results in consistently achieving the target tensile strength range of 40-60 MPa and elongation exceeding 35%, essential for high-speed winding operations without breakage. Crucially, our process optimization ensures electrical resistivity remains at or below 0.028264 Ω·mm²/m at 20°C, meeting or exceeding international conductivity standards (IACS ≥ 61.0%). We produce soft wire across a comprehensive dimensional spectrum, from 1.0mm to 6.0mm diameter, with tight tolerances on ovality and surface finish critical for layer-to-layer insulation integrity.

Quality assurance is rigorously embedded within our production system, not an endpoint. We implement real-time monitoring of key parameters including diameter, ovality, surface defects, and mechanical properties during drawing and annealing. Every production batch undergoes comprehensive final inspection per ASTM B233 and IEC 60122 standards, with full material certification including chemical composition analysis (ensuring Al content ≥ 99.70% with controlled Fe+Si levels) and mechanical test results. Our ISO 9001 certified quality management system provides documented traceability for every coil, offering complete confidence in material pedigree and process control. This systematic commitment minimizes defect rates and ensures batch-to-batch uniformity vital for high-yield manufacturing in our customers’ facilities.

Partnering with Luoyang Xinzhaohe means securing a reliable source of technically superior aluminum soft wire backed by metallurgical authority and industrial-scale manufacturing discipline. We understand the exacting demands of transformer and inductor manufacturers where material performance directly impacts end-product efficiency, reliability, and lifespan. Our engineering team collaborates closely with clients to tailor wire specifications to unique application requirements, providing technical support from prototype to high-volume production. For sourcing managers and design engineers seeking a strategic partner with proven capability in aluminum soft wire, contact our technical sales team directly. Reach out to Cathy at cathy@transformerstrip.com to discuss your specific requirements, request detailed technical documentation, or initiate a formal quotation process. Let Luoyang Xinzhaohe become your trusted provider of precision-engineered aluminum winding solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing soft wire directly from China.