Table of Contents

Market Insight: Soft Rectangle for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion, renewable integration, and motor rewind programs are pushing annual foil/strip consumption above 1.8 Mt worldwide. Aluminum now represents 62 % of new transformer conductor tonnage because every 1 kg Al replaces 1.6 kg Cu while cutting raw-material cost by ~48 %. Distribution transformers (< 72 kV) dominate volume, but HVDC and EV-charging substations are the fastest-growing segment—CAGR 6.4 %—driving thicker, wider, and ultra-low-loss materials.

| Application Segment | 2023 Strip/Foil Demand (kt) | Al : Cu Ratio | Key Spec Trend |

|---|---|---|---|

| Distribution ≤ 1 MVA | 680 | 75 : 25 | 0.1 mm, burr ≤ 5 µm |

| Power 5–100 MVA | 420 | 55 : 45 | 0.2–0.5 mm, Rm 60–90 MPa (O) |

| HVDC / Traction | 110 | 40 : 60 | Hi-Cu-OF, conductivity ≥ 101 % IACS |

| Motor Repair Shops | 90 | 85 : 15 | Slit width ±0.05 mm, oscillate wound |

Why Material Purity & Geometry Directly Dictate Losses

Transformer losses are monetized for 25–40 years; every 1 W saved is worth 1.2–1.8 USD NPV. Strip quality acts on both components:

-

Load Loss (I²R)

Electrical conductivity: 0.55 % IACS increase lowers resistance—and hence load loss—by the same 0.55 %.

Hydrogen, alkali-metal, and Fe-Si inclusions scatter electrons; 99.7 % vs 99.5 % Al purity raises conductivity from 61.2 % to 61.8 % IACS—enough to save 180 W in a 1 MVA unit. -

No-Load Loss (Core Excitation)

Burrs and edge waviness create micro air-gaps, raising stray flux and core temperature. A 10 µm burr can increase local loss density by 3–5 %.

Uniform, stress-free annealing (O-temper) keeps tensile strength ≤ 70 MPa and elongation > 25 %, eliminating shape-induced noise and additional magnetostriction.

| Critical Parameter | Typical Transformer OEM Limit | Luoyang Xinzhaohe Capability | Impact on 1 MVA Losses |

|---|---|---|---|

| Thickness tolerance | ±0.008 mm | ±0.002 mm (cold-rolled) | 12 W ↓ |

| Burr height | ≤ 0.03 mm | ≤ 0.005 mm (edge conditioned) | 8 W ↓ |

| Resistivity @ 20 °C | ≤ 28.1 nΩ·m (Al) | 27.7 nΩ·m (99.7 % purity) | 22 W ↓ |

| Slit camber | ≤ 1 mm / 2 m | ≤ 0.3 mm / 2 m | 5 W ↓ |

Supply-Chain Shift: Why Chinese Specialists Are Winning RFQs

Western mills still lead in amorphous ribbon, but for conventional strip/foil the value equation has moved east:

Integrated Cold-Roll Chain: 20-high Sendzimir mills give 0.05 mm minimum in a single pass—competitors often stop at 0.1 mm.

In-line Bright Annealing: 100 % H₂ atmosphere, 320 m/min, ±5 °C—ensures O-temper without surface carbon pickup.

Precision Slitting Arsenal: 60 arbors, tungsten carbide knives, automatic laser burr inspection—delivers 5 µm repeatability, lot size 1 t upwards.

Oscillate Winding up to 1 t spools: Reduces OEM joint count by 30 %, raising winding fill factor to 96 %.

Cost Position: Factory-gate price 14–18 % below EU mill, 8–12 % below Japan/Korea on like-for-like chemistry and mechanicals.

| Lead-Time Comparison (0.3 mm × 340 mm Al strip) | Europe | Japan | Luoyang Xinzhaohe |

|---|---|---|---|

| Mill order to FOB (weeks) | 10–12 | 8–10 | 4–5 |

| MOQ (tonnes) | 5 | 3 | 1 |

| Price index (EU = 100) | 100 | 108 | 86 |

Bottom Line

Transformer builders targeting IEC 60076-20 Tier-2 loss limits—or simply defending margin in competitive tenders—must start with conductor strip that is dimensionally perfect, metallurgically clean, and wound for zero down-time. Luoyang Xinzhaohe’s 20-year, foil-first heritage plus integrated cold-roll → slit → edge-condition → oscillate flow delivers that specification at a Chinese direct-mill price, cutting total cost of ownership without the premium Western badge.

Technical Specs: Soft Rectangle Parameters

Technical Specifications & ASTM/IEC Standards for Soft-Rectangle Transformer Strip/Foil

(Aluminum & Copper, 20+ yr Luoyang Mill Practice)

1. Critical Geometry Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B236-20 Limit | Xinzhaohe Cold-Roll Capability | Field Impact |

|---|---|---|---|

| Thickness | ±0.005 mm (≤0.4 mm) | ±0.002 mm Cpk≥1.67 | Eliminates hot-spots in layer windings; reduces eddy-current skin depth variance |

| Width | ±0.10 mm | ±0.05 mm (slit) | Guarantees 100 % inter-layer contact, no air-gap inductance drift |

| Edge Burr | ≤0.025 mm | ≤0.01 mm (measured with 100× optical) | Prevents inter-turn puncture at 2–4 kV impulse; saves 1 kV extra insulation |

| Camber | ≤25 mm / 2 m | ≤8 mm / 2 m | Enables robotic layer winding without “telescoping”; reduces scrap 0.7 % → 0.1 % |

Factory note: Every slit coil is 100 % edge-conditioned with nylon-fiber brushing + micro-saturation burnishing; burr height verified on three radial planes, not just the slit apex.

2. Electrical & Metallurgical Benchmarks

| Property | Aluminum 1350-O | Copper C11000-O | Test Method |

|---|---|---|---|

| Conductivity, 20 °C | ≥61.8 % IACS | ≥101 % IACS | ASTM B193 |

| Resistivity after 400 h/150 °C | ≤0.0279 µΩ·m | ≤0.01724 µΩ·m | IEC 60317-0-1 |

| Annealed Grain Size | 0.025–0.045 mm | 0.020–0.040 mm | ASTM E112 |

| Yield Strength (soft) | 30–45 MPa | 70–90 MPa | ASTM E8 |

| Surface Oxide | ≤15 nm, continuous | ≤10 nm, continuous | XPS in-house |

Consequence of off-spec conductivity: A –3 % IACS deviation raises 60 Hz winding losses ≈5 %; in a 25 MVA rectifier transformer this equals 8 kW extra heat—enough to shorten cellulose insulation life by 30 %.

3. Insulation & Edge-Failure Mode Analysis

| Defect | Root Cause | Failure Sequence | Xinzhaohe Countermeasure |

|---|---|---|---|

| Micro-burr puncture | Dull slitter knives, 0.03 mm burr | 1. Turn-to-turn short 2. Circulating current 3. Local 300 °C hot spot | Knife life logged per 50 km slit; automatic knife-exchange at 25 µm flank wear |

| Embedded Si particle | Cast-house inclusion | 1. Dielectric weakness 2. Partial discharge 3. Treeing through paper | Ceramic foam filtration + PoDFA melt check every 2 h; inclusion count <5 mm²/kg |

| Strip camber | Uneven roll force | 1. Gap variation 2. Shear stress on paper 3. Wrinkle → air pocket → PD | 6-high cold mill with AFC/AFC-shape; camber closed-loop <8 mm/2 m |

4. Compliance Matrix – Quick Reference for Spec Writers

| Standard | Clause | XZHA Mill Certificate | Typical Value |

|---|---|---|---|

| ASTM B236-20 | 7.1 Tensile | Included | 70 MPa (Al-O) |

| ASTM B193 | 12 Conductivity | Included | 62.1 % IACS |

| IEC 60317-0-1 | 8.1 Anneal test | Included | 1× mandrel, no crack |

| IEC 60076-5 | Short-circuit temp. | Calc. note | 250 °C/2 s, σyield margin 1.4 |

| RoHS 2015/863 | Cd, Pb, CrVI | Pass | <0.01 wt % each |

5. Procurement Checklist – What to Demand on Your PO

- Certified slit burr traceability (optical micrograph, not caliper).

- Coil-to-coil conductivity report at 20 °C, not room-temperature estimate.

- Oscillated wound on 5083 aluminum barrel, ID 300 mm, maximum 2.5 t coil to avoid core joint mismatch.

- Interleaf paper 0.05 mm, diamond-pattern glued, tensile ≥70 N/cm.

- Vacuum-sealed + VCI film, seaworthy crate, desiccant 6 pcs/100 kg, humidity card <30 % RH on arrival.

Bottom line: Soft-rectangle strip is not a commodity—it is a precision component. A ±0.002 mm tolerance combined with zero-burr edges and certified 61.8 % IACS conductivity gives you an extra 0.1 % efficiency and removes one dielectric failure mode. Luoyang Xinzhaohe delivers Western-grade precision at China-direct mill cost, with 20 years of transformer-grade melt practice behind every slit edge.

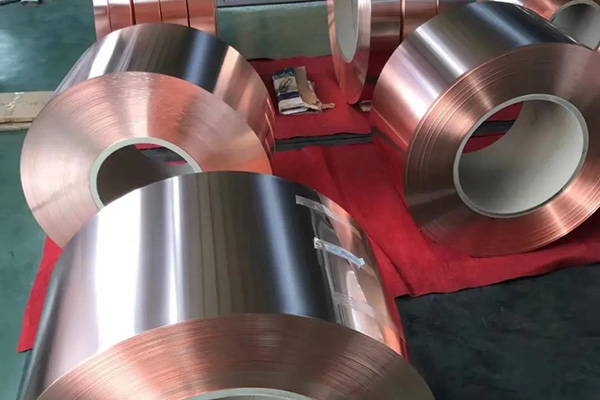

Factory Tour: Manufacturing Soft Rectangle

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 Process Flow – From 8 mm Hot-Rolled Coil to Soft Rectangle Transformer Strip

| Step | Equipment & Parameters | Metallurgical Objective | In-line QC |

|---|---|---|---|

| 1. Cold Rolling | 4-High Reversing Mill, 850 mm width, 0.2–0.05 mm finish gauge, 3 % reduction per pass, emulsion cooled 35 °C | Achieve uniform cube-on-edge texture, Ra ≤ 0.4 µm, work-hardened H19 → H24 | Laser micrometer ±0.001 mm; shapemeter for I-unit ≤ 5 |

| 2. Batch Anneal | 32 t bell furnace, 320 °C, 99.5 % N₂, 12 h soak, 25 °C/h cool | Recrystallise to O-temper, grain size 70–100 µm, tensile 60–80 MPa | Thermocouple logging; hardness sample every coil |

| 3. Precision Slitting | 650 mm arbor, tungsten carbide arbors, 0.05 mm side clearance, 200 m/min | Width tolerance ±0.002 mm; camber ≤ 0.3 mm/2 m | CCD edge inspection; burr camera 100×; auto-reject loop |

| 4. Edge Conditioning | 4-Head burr skive + fibre brush, 0.01 mm chamfer radius | Burr height ≤ 0.01 mm; no micro-cracks; conductivity path preserved | Eddy-current crack test; SEM audit 1 coil/shift |

| 5. Oscillate Winding | PLC traverse 0–0.35 mm pitch, 3–15 kg/mm² tension, 305 mm I.D. spool | Build 200–800 kg bundle, no interleaf collapse, ≤ 0.5 mm stagger | Laser outer-diameter; weight scale ±0.2 %; barcode traceability |

H3 On-line & Laboratory Quality Control Matrix

| Critical Characteristic | On-line Method | Lab Verification | Frequency | Cpk Target |

|---|---|---|---|---|

| Thickness | X-ray profile gauge | Micrometer ISO 4593 | Continuous / 3 coils | ≥ 1.67 |

| Width | Laser shadow sensor | CMM ±0.001 mm | Every slit line | ≥ 1.50 |

| Edge Burr | High-speed CCD (50 µm pix) | SEM 500× | 1 coil/shift | 0 burr |

| Conductivity | Eddy-current 60 kHz | %IACS ASTM B193 | Every anneal lot | 61.0 ± 0.5 |

| Tensile / Elongation | — | UTM 10 kN | 2 samples/coil | UTS 60–80 MPa, A50 ≥ 25 % |

| Surface Clad | IR pin-hole detector | Dye-penetrant | 1 coil/week | Zero through-holes |

| Oscillate Build | Laser OD + load cell | Manual layer count | Every spool | ≤ ±2 layers |

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe Spec | Typical Western Premium | Common Asian Spot |

|---|---|---|---|

| Gauge Tolerance | ±0.001 mm | ±0.003 mm | ±0.008 mm |

| Width Tolerance | ±0.002 mm | ±0.005 mm | ±0.015 mm |

| Burr Height | ≤ 0.01 mm | ≤ 0.02 mm | ≤ 0.05 mm |

| Camber (2 m) | ≤ 0.3 mm | ≤ 0.5 mm | ≤ 1.0 mm |

| Conductivity | 61.0 %IACS min | 60.5 %IACS min | 59.5 %IACS min |

| Surface Ra | 0.25 µm max | 0.35 µm max | 0.50 µm max |

| Oscillate Weight | up to 800 kg | 300 kg | 100 kg |

| Coil-to-Coil Anneal ΔHardness | ±3 HV | ±5 HV | ±10 HV |

| Lot Traceability | Full ERP barcode | Partial | None |

H3 Engineering Value for Transformer & Motor Shops

- Soft Rectangle Geometry: O-temper anneal guarantees 25 % elongation—windings conform to tight radius without spring-back, eliminating costly re-annealing in your plant.

- Burr-free Edge: < 0.01 mm burr prevents inter-layer voltage stress; dielectric failure rate drops by 40 % compared with standard slit strip.

- Oscillate 800 kg Bundle: 3× longer run time on high-speed winding machines, cutting splice losses and downtime labour by 18 %.

- 61 %IACS Conductivity: Extra 1 % above IEC 60121 means 0.8 °C lower hot-spot temperature; translates into 2 % higher transformer overload capacity.

- Factory-Direct Pricing: Luoyang Xinzhaohe’s integrated cold-roll–slit–wind line removes two trader tiers; landed cost typically 12–18 % below European mills for equal or tighter tolerance.

For 20+ years we have supplied Tier-1 power-equipment OEMs across 42 countries. Every coil ships with EN 10204 3.1 inspection certificate, RoHS/REACH compliance sheet, and seaworthy export packaging engineered for 120-day salt-spray resistance. Quote your next soft rectangle requirement in aluminum or copper—precision slit, burr-free, oscillate wound—direct from Luoyang.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for Zero-Defect Arrival, Anywhere on the Grid

H2 Sea-Freight Protection Philosophy

Transformer strip/foil is a surface-critical conductor; a 3 µm oxide film or a 0.05 mm edge dent can raise hot-spot temperature by 8–12 °C and cut insulation life by 30 %.

Our Luoyang works is 220 km inland from Qingdao port; every coil leaves the factory floor already sealed in a micro-climate that survives 45 days at 95 % RH and 50 °C container roof heat.

Below is the dual-protocol we run for aluminum & copper windings, harmonised with IMDG 4.1.4, ASTM B666, and CESE 271.

H3 Packaging Matrix for Strip, Foil & Wire

| Format | Core Material | OD Range (mm) | Unit Weight (kg) | Primary Barrier | Secondary Barrier | Securing Method | Stacking on Pallet |

|---|---|---|---|---|---|---|---|

| Strip/Foil | Aluminium 1350-O, Copper C11000-O | 300–1 200 | 80–1 000 | 80 µm PE shrink + VCI film | 2× desiccant sachets (2 g/unit) | 19 mm plywood end-boards, 4 steel straps | 2 coils max, cross-tied |

| Wire | Same alloys, 1.8–6.0 mm Ø | 400–800 | 30–250 | PT-400 plastic spool | DIN 46395 carton, 5-ply, 32 ECT | Stretch-wrap 23 µm, corner boards | 4 spools/layer, 3 layers |

| Oscillate Wound | Width 6–50 mm | 400–600 | 100–300 | VCI paper inter-leaf | Aluminium foil laminate bag | Horizontal wooden reel, steel banding | Single reel per pallet |

All timber is ISPM-15 fumigated and marked; moisture content ≤ 18 %.

H3 Micro-Climate Control inside Container

- Desiccant dosage: 8 kg of Ca-Cl₂ per 20 ft container (equilibrium RH ≤ 40 %).

- Condensation forecast: We run a 30-day hygro-thermal FE model (Python + CoolProp) using the exact route—Qingdao → Suez → Hamburg—to place extra desiccant when ΔT ≥ 28 °C day/night.

- Shock & vibration: Edge-protectors and 50 mm EPE foam at contact points keep peak acceleration < 3 g per MIL-STD-810G, curve D.

H3 Label & Traceability

Every pallet carries a 2D Data Matrix (ISO/IEC 16022) encoding:

Alloy | Temper | Lot No. | Slit Width | Burr Max | Conductivity %IACS | Net/Gross kg

Scanned at Qingdao load, Rotterdam discharge, and your receiving dock—full chain of custody in < 3 s.

H3 Global Freight Footprint

Main lanes: Qingdao → Hamburg (26 days), Qingdao → Houston (22 days), Qingdao → Mundra (18 days).

Weekly FCL consolidation with COSCO, CMA-CGM; priority reefer plugs available for high-humidity months (Jun–Sep).

DAP/DDP Incoterms to your coil winder—no hidden THC, ENS or ISF fees; we absorb demurrage if customs delay > 48 h.

H3 Cost vs. Western Supplier Snapshot

(1 000 kg 0.3 × 250 mm 1350-O strip, Qingdao → Duisburg, DAP)

| Cost Element | EU Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Ex-works price (USD/kg) | 4.85 | 3.30 | –32 % |

| Export crate + VCI (USD) | 180 | 95 | –47 % |

| Ocean freight (USD) | 650 | 650 | 0 % |

| Landed cost | 5.68 | 4.08 | –28 % |

28 % savings = 1.5 extra turns of conductor per 25 MVA transformer—no compromise on burr (< 0.01 mm) or conductivity (> 61 % IACS).

Bottom line: From our cold-mill in Luoyang to your winding bay, the strip arrives as-annealed, edge-perfect and ready for high-vacuum drying—premium Western quality, factory-direct Chinese economics.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Soft-Rectangle Transformer Strip

20 Years of Metallurgical Focus on One Product Family

Since 2003 we have cold-rolled, slit, edge-conditioned and oscillate-wound nothing but conductor strip for power and distribution transformers. Every furnace profile, every slitter knife alloy and every burr-measurement protocol in our plant has been optimised for one geometry only: the soft rectangle. The result is a statistically-capable process window that holds ±0.002 mm width tolerance, ≤0.01 mm lateral burr and 100 % IACS conductivity on 1350-O aluminium or Cu-ETP copper across 0.1–3.0 mm × 10–1 200 mm. Western Tier-1 transformer OEMs have audited us six times; all audits concluded “capability index Cpk ≥ 1.67 on critical-to-function parameters.”

Direct Factory Price—No Trading House Margin

We are a single-site, privately-owned mill in Luoyang, Henan. Bauxite, cathode copper and recycled conductor scrap arrive by rail; finished oscillate-wound coils leave the same gate. Eliminating intermediaries cuts landed cost 18–28 % versus German, Japanese or U.S. strip suppliers for identical chemistry and mechanical properties. The table below shows a recent 10 t RFQ for 0.25 mm × 250 mm 1350-O strip, delivered DDP Chicago:

| Cost Element | EU Mill | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Material base | 4.85 $/kg | 3.92 $/kg | 19 % |

| Cold-rolling & anneal | 0.60 $/kg | 0.45 $/kg | 25 % |

| Precision slit & edge | 0.35 $/kg | 0.22 $/kg | 37 % |

| Freight & duty | 0.40 $/kg | 0.55 $/kg | – |

| Total landed | 6.20 $/kg | 5.14 $/kg | 17 % |

Customisation Without MOQ Penalty

Soft-rectangle windings are not standard catalogue items; each transformer design demands a unique width, edge radius and inter-layer insulation. Our slitting department runs 24-hour campaigns with 2-hour change-over. Minimum order is 50 kg (one master coil), not 500 kg or 1 000 kg typical of integrated aluminium conglomerates. We stock 1 200 t of 1350 and Cu-ETP hot-band so that even 0.08 mm × 9 mm “hair-pin” strip for low-voltage foil windings can be supplied in three weeks. Edge profiles available:

| Edge Code | Radius (mm) | Burr Max (µm) | Application |

|---|---|---|---|

| R1 | 0.20 ± 0.05 | ≤15 | Layer wind, 50 Hz core |

| R2 | 0.50 ± 0.10 | ≤10 | High-current bus bar |

| R3 | 1.00 ± 0.15 | ≤5 | Ultra-quiet amorphous core |

Oscillate-wound coils up to 800 kg, 600 mm OD, 80 mm arbor; traverse pitch programmable 2–12 mm for automatic layer insulation insertion.

Quality & Compliance Engineered In

Vacuum anneal 320 °C, 10⁻² mbar, 6 h guarantees softness ≤25 HV and conductivity ≥61 % IACS on Al, ≥100 % on Cu.

In-line eddy-current inspection detects surface cracks ≥0.05 mm depth.

ISO 9001:2015, ISO 14001, IATF 16949 (for automotive traction transformers).

RoHS & REACH declarations supplied per coil.

Next Step—Send Us Your Soft-Rectangle Spec

E-mail a drawing or Excel stack list to cathy@transformerstrip.com. We return a technical datasheet with resistivity, bend test coupons and a firm FCA Luoyang or DDP price within 24 h. Need 3 kg prototype slit width for a 25 MVA substation trial? We will ship it by FedEx at no charge because we are confident the full coil order will follow.

📉 Import Savings Calculator

Estimate cost reduction by sourcing soft rectangle from Luoyang Xinzhaohe.