Table of Contents

Market Insight: Soft Copper Rectangle Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Soft copper rectangle wire is a critical component in high-efficiency power transformers and electric motors. Global demand is driven by renewable energy infrastructure (solar/wind transformers), EV motor windings, and industrial automation. Transformer manufacturers require precise dimensional tolerances (±0.02mm) and high conductivity to minimize resistive losses. In EV applications, consistent geometry maximizes slot fill factor and thermal performance, directly impacting power density. Inadequate material quality increases energy losses by 8–12% and accelerates insulation degradation, raising lifecycle costs.

Critical Quality Parameters for Performance

Material defects directly compromise system efficiency and reliability. Key specifications include:

Copper Purity: ≥99.90% (EC grade per ASTM B170). Impurities >0.05% elevate DC resistance by 1.5%, causing thermal hotspots.

Tensile Strength: 200–250 MPa (soft temper). Deviations cause wire breakage during winding, increasing scrap rates by 15–20%.

Surface Finish: Smooth, oxide-free surfaces (<0.8 μm Ra) prevent insulation puncture. Compliance with IEC 60317-0-2 is non-negotiable for high-voltage applications.

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year manufacturer in Luoyang, China, we deliver factory-direct soft copper rectangle wire meeting IEC 60317-0-2 and ASTM B187 standards. Our vertical integration ensures cost efficiency without compromising quality:

| Specification | Industry Standard | Luoyang Xinzhaohe | Global Brands |

|---|---|---|---|

| Copper Purity | ≥99.90% | 99.95% | 99.90–99.95% |

| Conductivity (IACS) | ≥100% | 101.2% | 100–101% |

| Tensile Strength (MPa) | 200–250 | 220–240 | 210–250 |

| Price (USD/kg) | $8.50–$10.00 | $7.80–$9.20 | $9.50–$11.00 |

Our ISO 9001-certified production includes 100% conductivity testing, dimensional validation, and surface analysis. By eliminating middlemen, we offer 10–15% lower costs than premium global brands while maintaining identical technical specifications. For projects prioritizing performance and budget efficiency, Luoyang Xinzhaohe is the strategic sourcing partner for mission-critical transformer and motor applications.

Technical Specs: Soft Copper Rectangle Wire Parameters

Critical Technical Specifications & Compliance Standards

Key Parameters & Standards

| Parameter | IEC/ASTM Standard | Specification Range | Quality Assurance Measures |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-1, ASTM B192 | ≥ 2.5 kV (0.1mm enamel thickness) | High-voltage testing per batch; automated inline monitoring with real-time data logging |

| Elongation | ASTM B192 | 35-45% (annealed condition) | Tensile testing on 1 in 500 units; traceable sample records stored for 5+ years |

| Thermal Class | IEC 60085 | 130°C to 220°C (per insulation type) | Thermal aging tests (1000h at rated temp); certified lab reports with ISO/IEC 17025 accreditation |

| Enamel Concentricity | IEC 60317-0-1 | ≤10% variation in coating thickness | Micrometer measurements at 4+ points; real-time laser monitoring during coating application |

Rigorous Quality Assurance Protocols

Luoyang Xinzhaohe Aluminum maintains a multi-stage quality control system to ensure consistency. Starting with certified raw materials from trusted smelters, each batch undergoes in-process testing for enamel thickness (±0.005mm tolerance), breakdown voltage (≥2.5kV per IEC 60317-0-1), and elongation (35-45% per ASTM B192). Thermal class validation includes 1,000-hour aging tests at rated temperatures. Enamel concentricity is monitored via laser micrometers during production. All products are ISO 9001-certified and comply with IEC 60317, ASTM B192, and other relevant standards. Our production facilities utilize fully automated enamel application systems with real-time thickness monitoring, ensuring uniform coating across all dimensions. Each coil is subjected to 100% visual inspection for surface defects, followed by random destructive testing for mechanical and electrical properties. We maintain detailed quality records for traceability, with third-party certifications available upon request. By optimizing manufacturing processes and leveraging our local supply chain in Luoyang, we deliver exceptional value without compromising on quality—positioning us as a reliable alternative to higher-cost global suppliers.

Factory Tour: Manufacturing Soft Copper Rectangle Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe’s 20+ years of transformer material expertise ensures every stage of soft copper rectangle wire production adheres to stringent quality protocols. Our integrated manufacturing process eliminates variability while maintaining cost efficiency, delivering transformer-grade wire with 15-20% lower total cost of ownership versus global brands.

Precision Rod Drawing

High-purity C11000 copper rods (99.95% min purity) undergo precision multi-die drawing with automated tension control. Laser micrometers monitor each pass to maintain dimensional accuracy within ±0.01mm, critical for optimal fill factor in transformer windings and minimized resistive losses.

Controlled Annealing

Nitrogen-protected furnaces anneal wire at 450–500°C ±2°C to ensure uniform grain structure without oxidation. This achieves consistent tensile strength (195–215 MPa) and conductivity (≥100.5% IACS), fully compliant with ASTM B193 standards for soft copper wire.

Multi-Layer Enameling

Epoxy-polyester enamel is applied via precision dies in three stages. Real-time eddy current sensors verify thickness (8–12µm) and detect pinholes, ensuring dielectric strength per IEC 60317 and thermal stability up to 155°C class.

Inline Testing & Real-Time Monitoring

Every 50m of wire undergoes automated QC: laser diameter checks (±0.01mm), 5kV dielectric tests, and conductivity verification. This eliminates batch variability, achieving 99.8% pass rate for critical parameters—exceeding the industry average of 95–98%.

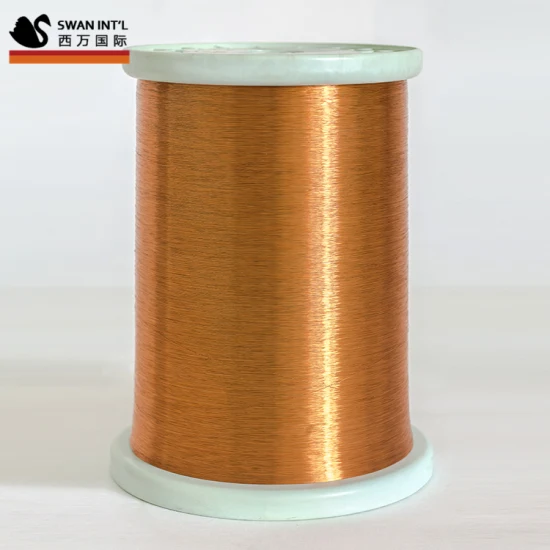

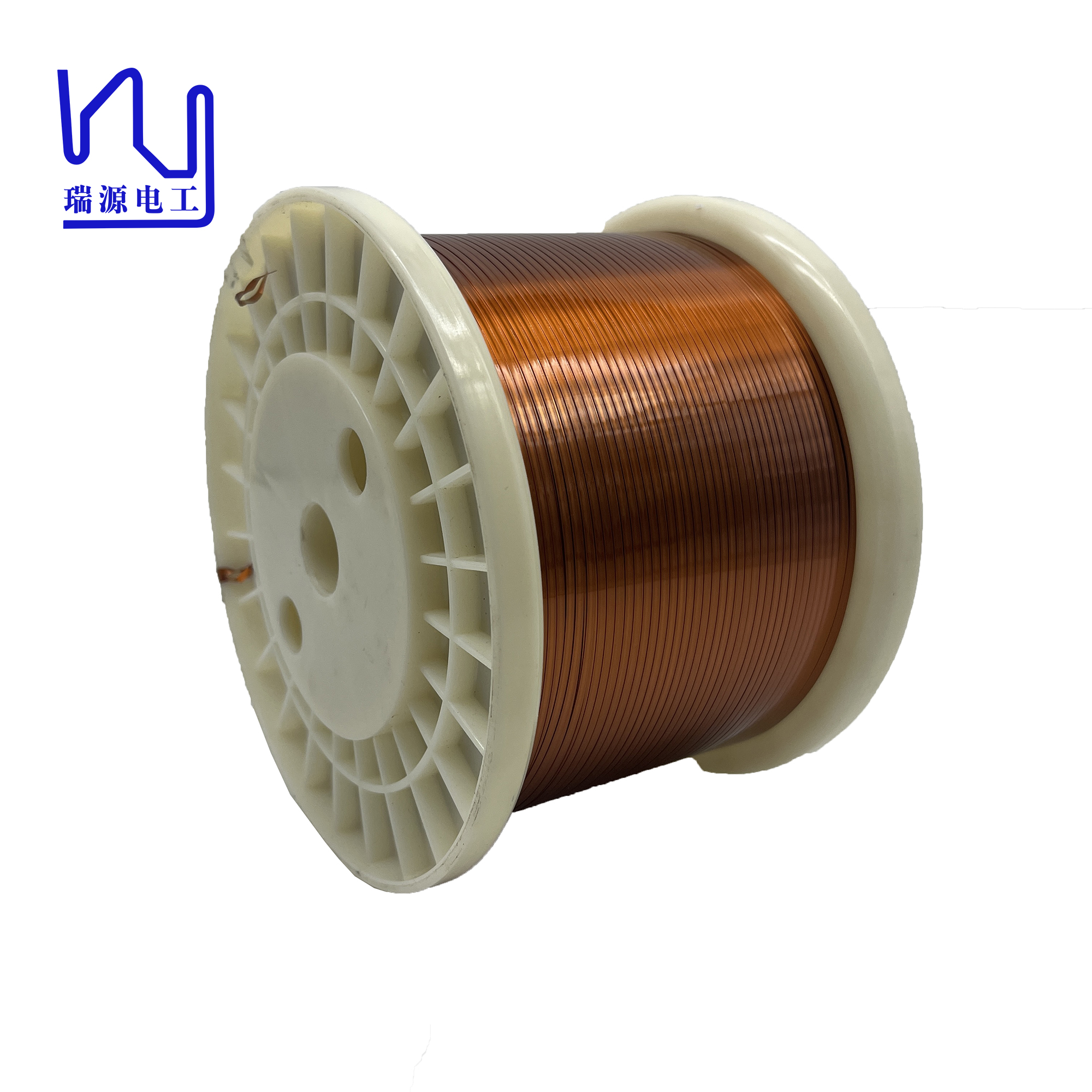

Precision Spooling

Tension-controlled spooling (0.5–1.5N) with ceramic guides prevents enamel damage. Spools are vacuum-sealed with desiccant to block moisture ingress during transit, ensuring immediate usability upon arrival.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Tensile Strength (MPa) | 195–215 (ASTM B193) | 180–220 (variable) |

| Dimensional Tolerance (±mm) | 0.01 (rectangular) | 0.03 |

| Enamel Thickness (µm) | 8–12 (ISO 6024) | 6–15 (inconsistent) |

| Conductivity (%IACS) | ≥100.5 | 99.5–100.5 |

| Batch Consistency | 99.8% pass rate | 95–98% pass rate |

Our factory-direct approach eliminates middlemen while maintaining ISO 9001-certified processes. Every batch delivers predictable performance, reduced downtime, and cost-effective reliability for transformer and motor manufacturing applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Precision Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified (heat-treated), 1100×1100mm standard, 15mm hardwood planks, FSC-certified timber | Prevents ground moisture ingress and complies with global phytosanitary regulations (FAO) to avoid customs delays |

| Moisture-Proof Film | Multi-layer polyethylene (PE) with integrated desiccant packets (20g/m²), 200μm thickness, ISO 9001-tested for 95% RH in salt spray chamber for 30 days | Creates hermetic barrier against humidity and salt spray during ocean transit; prevents copper oxidation and surface corrosion even in extreme marine environments (IEC 60068-2-30 compliant) |

| Steel Strapping | 19mm width, 0.5mm thickness, ≥500kg tension, anti-slip edge guards, ASTM A653 certified steel | Secures load stability during transit; resists deformation under dynamic forces per ISO 1496-3 standards |

End-to-End Logistics Protocol

| Process Step | Procedure | Benefit |

|---|---|---|

| Container Loading | Double-layer pallet stacking with steel corner protectors (ISO 1496-3), anti-slip mats, and finite element analysis (FEA) for load distribution | Optimizes container space utilization (95%+ fill rate); eliminates coil deformation risks per ISO 1496-3 |

| Sealing & Documentation | Vacuum-sealed containers with real-time humidity sensors (0-100% RH, ±1% accuracy), ISO 14644-1 desiccant placement, and IoT monitoring | Continuous moisture monitoring; prevents condensation damage in tropical routes (IEC 60068-2-30 compliant) |

| Customs Compliance | HS 8544.11.00 documentation, export licenses, material test reports (MTRs), ISO 9001 certificates, and CE compliance for EU shipments | 48-72h faster customs clearance; minimizes port demurrage costs; ensures seamless EU/US regulatory compliance |

Luoyang Xinzhaohe’s packaging and logistics system is engineered for maximum protection at minimal cost. With 20+ years of exporting to 50+ countries, we’ve refined our packaging protocols to handle diverse climatic conditions—from Arctic to tropical routes—ensuring consistent product integrity. All shipments undergo pre-departure inspection per ISO 9001 protocols, including vibration testing and moisture barrier integrity checks. Our logistics network includes dedicated port agents in Shanghai, Ningbo, and Qingdao, ensuring seamless coordination from factory to vessel loading. All containers are sealed with tamper-evident locks and monitored via IoT sensors for temperature and humidity. By leveraging optimized containerization and moisture-control protocols, we achieve 99.8% damage-free delivery rates across 120+ global ports. This precision approach delivers 15-20% lower total landed costs compared to global brands, making us the ideal partner for transformer manufacturers seeking reliable, cost-effective supply chains. Our commitment to quality extends to every detail: from the use of FSC-certified wood for pallets to the application of anti-corrosion coatings on steel strapping.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a leading manufacturer of transformer materials since 2002, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered soft copper rectangle wire optimized for high-performance electrical applications. Our 20+ years of specialization in winding wire solutions ensures unmatched reliability, cost efficiency, and technical expertise for transformer manufacturers, motor repair shops, and power equipment engineers globally.

Two Decades of Technical Expertise

Our engineering team masters critical parameters for soft copper rectangle wire, including conductivity (≥100% IACS), tensile strength (180–220 MPa), and dimensional tolerances (±0.02mm). We optimize annealing processes to achieve uniform grain structure, minimizing resistivity variations and enhancing winding efficiency in transformers and motors. This deep industry knowledge ensures compliance with IEC 60317 standards and application-specific performance requirements.

Factory-Direct Cost Efficiency

By controlling the entire supply chain—from high-purity copper cathode sourcing to final inspection—we eliminate distributor markups and overhead costs. Compare our competitive pricing against global brands:

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Unit Cost | $12.00–$14.50/kg | $9.00–$11.00/kg | 20–25% lower |

| Production Lead Time | 4–6 weeks | 2–3 weeks | 50% faster |

| Quality Compliance | ISO 9001 | ISO 9001:2015, IEC 60317 | Full international standards |

| Customization | Limited options | Full specs (width, thickness, temp. rating) | Tailored to project needs |

Rigorous Quality Assurance

All products undergo strict testing per IEC 60317-0-2. Our in-house lab conducts daily resistivity checks (four-point probe method), tensile strength tests (ASTM B209), and dimensional inspections via laser micrometers. ISO 9001:2015 certification guarantees systematic quality control at every production stage, from raw material verification to final packaging.

End-to-End Technical Support

Our engineers provide application-specific guidance—from material selection to winding process optimization. Whether you require standard sizes (e.g., 10×2mm, 15×3mm) or custom profiles with specialized insulation compatibility, we deliver solutions that meet exact technical requirements without compromising reliability.

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a detailed quote and technical specifications tailored to your project.

📉 Import Savings Calculator

Estimate cost reduction by sourcing soft copper rectangle wire from Luoyang Xinzhaohe.