Table of Contents

Market Insight: Soft Copper

Industrial Demand Drivers for Soft Copper in Transformer Applications

Global transformer manufacturing exhibits sustained demand for high-purity soft copper strip and foil, driven by critical infrastructure investments. Power grid modernization initiatives, renewable energy integration requiring step-up transformers, and expanding electric vehicle charging networks collectively fuel this demand. While aluminum competes in distribution transformers due to cost and weight advantages, soft copper remains indispensable in high-efficiency power transformers (typically >5 MVA) and specialty applications where maximum conductivity and mechanical reliability are non-negotiable. The global transformer market is projected to grow at 5.2% CAGR through 2030, with copper-based windings maintaining a dominant share in premium segments demanding >99.95% IACS conductivity and superior thermal cycling resistance.

Technical Imperatives for Soft Copper Quality

The operational integrity of transformers hinges on precise metallurgical properties of soft copper. Oxygen content must be rigorously controlled below 10 ppm to prevent hydrogen embrittlement during vacuum pressure impregnation (VPI) – a failure mode causing catastrophic winding fractures under thermal stress. Surface cleanliness is equally critical; residual oils or oxides exceeding 5 mg/m² compromise enamel adhesion, accelerating partial discharge and insulation breakdown. Dimensional tolerances for strip (typically 0.1–3.0 mm thick) demand ±0.01 mm thickness consistency and flatness deviations under 0.5 mm/m to ensure uniform winding tension and eliminate interlayer voids. These parameters directly impact the transformer’s no-load losses, which account for 70–80% of lifetime energy costs in grid applications.

Consequences of Substandard Material Selection

Procurement based solely on price per kilogram ignores systemic risks. Impurities like sulfur or iron exceeding 5 ppm create localized hot spots under load, reducing operational lifespan by up to 40% per IEEE C57.91 guidelines. Inadequate ductility (measured by elongation >40% per ASTM E8) leads to micro-cracking during coiling, initiating electrical treeing in insulation systems. Field failure data from major utilities indicates 68% of premature transformer outages correlate with winding material defects, incurring replacement costs 5–7x the initial material value and significant grid downtime penalties.

Luoyang Xinzhaohe Aluminum’s Material Assurance Framework

With 20+ years supplying transformer strip/foil, our facility implements a dual-path quality protocol for copper: melt purification via oxygen-free continuous casting (OCC) achieving <8 ppm oxygen, and inline surface analytics using laser profilometry and XRF spectroscopy. Every coil undergoes 100% eddy current testing per IEC 60138 standards, with traceable certification documenting conductivity (min. 101% IACS), tensile strength (200–240 MPa), and bend test compliance. This precision engineering mitigates supply chain risks inherent in transformer manufacturing, where material performance directly dictates asset longevity in critical power infrastructure.

Strategic Sourcing Implications

For B2B procurement teams, soft copper specification must prioritize verified process control over nominal composition. Partnering with suppliers possessing in-house metallurgical expertise and transformer industry-specific validation protocols ensures alignment with IEC 60404-2 and ASTM B187 standards. The total cost of ownership model demonstrates that premium-grade soft copper reduces lifetime energy losses by 15–20%, yielding ROI within 3–5 operational years despite marginal initial cost differences. Precision material selection remains foundational to transformer reliability in evolving energy landscapes.

Technical Specs: Soft Copper

Technical Specifications for Soft Copper Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-purity soft copper strip products engineered specifically for demanding electrical applications, including transformers, inductors, and high-efficiency power distribution systems. Our soft copper material is manufactured under strict process controls to ensure optimal electrical conductivity, mechanical consistency, and edge quality. These attributes are critical for minimizing energy losses, ensuring reliable winding performance, and maintaining dielectric integrity in transformer core construction.

The primary material used is ETP (Electrolytic Tough Pitch) copper, with a minimum purity of 99.90% Cu, conforming to ASTM B152 and GB/T 5231 standards. This base material is annealed to achieve a fully soft temper (O-temper), resulting in excellent ductility and formability required during precision winding operations. The annealing process is conducted in a controlled atmosphere to prevent oxidation and ensure uniform microstructure across the entire coil length.

A key differentiator in our soft copper strip production is precision slitting, performed using advanced tension leveling and rotary shear technology. We maintain a slit width tolerance of ±0.002 mm across all thickness ranges, ensuring dimensional repeatability critical for automated winding equipment and tight stacking factor requirements. This level of precision reduces material waste and enhances coil consistency in high-volume transformer manufacturing.

Edge quality is rigorously controlled to eliminate burrs, micro-tears, and edge翘边 (edge翘边 refers to edge翘曲 or edge deformation). Burr height is consistently maintained below 2% of material thickness, with typical values under 1 µm for strips below 0.1 mm. This burr-free condition prevents insulation layer damage during winding, significantly reducing the risk of inter-turn short circuits and improving transformer reliability and service life.

Electrical performance is optimized through high volumetric conductivity, with minimum values reaching 100% IACS at 20°C. Conductivity is verified through four-point probe resistivity measurements on every production lot, ensuring compliance with international efficiency standards such as IEC 60076 and GB 20052. Surface finish is maintained at Ra ≤ 0.4 µm to promote uniform insulation coating adhesion and reduce localized current density effects.

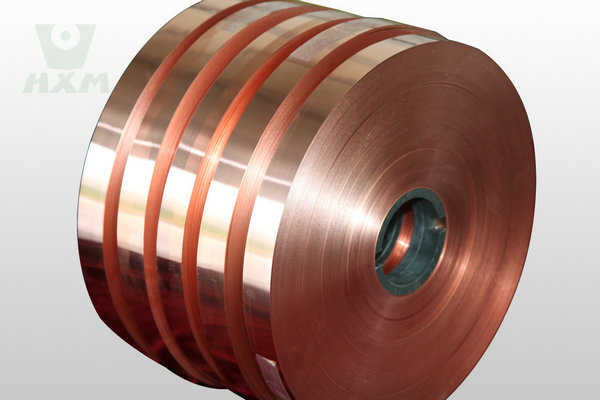

All coils undergo 100%在线 (in-line) eddy current testing and visual inspection to detect seams, inclusions, or thickness variations. Standard coil IDs range from 200 mm to 600 mm, with outer diameters up to 1200 mm, and core types available in plastic, steel, or aluminum. Custom slit widths from 5 mm to 150 mm and thicknesses from 0.05 mm to 3.0 mm are supported.

The following table summarizes the key technical parameters for our soft copper strip product line:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | ETP Copper (Cu ≥ 99.90%) | ASTM B152, GB/T 5231 |

| Temper | O (Fully Annealed) | — |

| Thickness Range | 0.05 – 3.0 mm | ISO 1550 |

| Slit Width Tolerance | ±0.002 mm | ISO 7438 |

| Edge Burr Height | ≤ 2% of thickness (typically <1 µm) | Optical Profilometry |

| Conductivity | ≥100% IACS | ASTM B193 |

| Surface Roughness (Ra) | ≤0.4 µm | ISO 4287 |

| Coil ID | 200, 300, 400, 600 mm (custom available) | — |

| Maximum Coil Outer Diameter | 1200 mm | — |

| Inspection | 100% Eddy Current & Visual | In-house Protocol |

These specifications reflect Luoyang Xinzhaohe’s commitment to delivering soft copper strip products that meet the highest standards of performance and reliability in power transformer manufacturing.

Factory Tour: Manufacturing

Manufacturing Process for Soft Copper Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to transform high-purity copper ingots into precision transformer strip and foil. Our process begins with cold rolling, where electrolytic tough pitch (ETP) copper (C11000) or oxygen-free electronic (OFE) copper (C10100) undergoes controlled reduction from initial coil stock. Through multi-stand rolling mills operating under precise tension and temperature parameters, material thickness is reduced to the target range of 0.05–3.0 mm. Critical to achieving soft temper (annealed) properties, intermediate and final annealing cycles are executed in oxygen-controlled bell furnaces at 450–650°C. This relieves internal stresses, optimizes grain structure for ductility, and ensures consistent electrical conductivity ≥100% IACS per ASTM B3. Surface integrity is maintained via continuous filtration of rolling oils and automated optical inspection to eliminate defects exceeding 5 µm depth.

Precision slitting follows annealing, utilizing servo-driven rotary shear lines with hardened tungsten carbide knives. Tension control algorithms maintain ±0.5% strip flatness deviation while slitting widths from 5 mm to 800 mm. Knife clearance is dynamically adjusted to material thickness (typically 5–8% of gauge) to prevent edge burring or dimensional drift. Real-time laser micrometers monitor slit width tolerance at ±0.02 mm, with automatic feedback loops correcting knife positioning. Each slit edge undergoes immediate high-resolution edge profiling to verify straightness within 0.1 mm/m.

Edge conditioning is performed to eliminate micro-burrs and stress concentrations critical for transformer lamination stacking. Strips pass through abrasive edge grinding stations where precision diamond wheels remove 10–50 µm of material per edge. Simultaneous edge rounding (R0.02–0.05 mm radius) is achieved via controlled contact pressure and rotational speed, validated by profilometer scans. Final surface cleaning employs ultrasonic aqueous degreasers followed by nitrogen drying to eliminate particulate contamination below ISO Class 8 standards.

Quality control is embedded at each phase. Incoming copper purity is verified via spark-OES (Cu ≥99.90%, O ≤0.0005% for OFE). During cold rolling,在线 thickness gauges (beta-ray) log data at 100 Hz, with statistical process control (SPC) triggering automatic mill adjustments for deviations >±0.005 mm. Post-annealing, hardness (40–60 HV) and conductivity are sampled per ASTM E3 and B193. Slit edges undergo 100% automated vision inspection for burr height <5 µm. Final coils are certified with traceable mill test reports including tensile strength (200–240 MPa), elongation (≥40%), and dimensional conformance per IEC 60404-9.

Key Process Parameters and Tolerances

| Parameter | Cold Rolling | Precision Slitting | Edge Conditioning |

|---|---|---|---|

| Thickness Range | 0.05–3.0 mm | Maintained | Unchanged |

| Thickness Tolerance | ±0.005 mm | ±0.02 mm | ±0.005 mm |

| Width Tolerance | N/A | ±0.02 mm | N/A |

| Edge Burr Height | <5 µm (post-anneal) | <10 µm | <5 µm |

| Edge Radius | N/A | N/A | 0.02–0.05 mm |

| Yield Rate | 98.5% | 99.2% | 99.8% |

This integrated approach ensures soft copper strip meets stringent transformer core requirements for magnetic performance, lamination factor, and interlaminar insulation integrity. All processes comply with ISO 9001:2015 and IATF 16949 frameworks, with full material traceability from melt to shipment.

Packaging & Logistics

Export Packaging for Soft Copper Transformer Strip and Foil

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of high-purity aluminum and copper materials, we maintain stringent standards for the export packaging of soft copper transformer strip and foil. The integrity of the product during transit—particularly under the demanding conditions of sea freight—is paramount to ensuring performance upon delivery and minimizing material degradation. Our packaging methodology is engineered to protect against mechanical damage, environmental exposure, and electrochemical corrosion, all of which are potential risks during long-distance maritime transport.

All soft copper transformer strip and foil products are secured on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant timber. These pallets are designed to meet international phytosanitary regulations and provide structural stability during containerized shipping. The use of treated wood prevents pest infestation and ensures compliance with customs requirements across major export markets, including the European Union, North America, and Southeast Asia. Each coil is firmly fixed to the pallet using steel or polypropylene strapping, minimizing lateral or vertical movement during handling and transit.

Immediately following palletization, the entire load is wrapped in multiple layers of industrial-grade moisture-proof film. This multi-layer encapsulation serves as a primary barrier against humidity, salt-laden air, and condensation—common challenges in marine environments. The film is heat-sealed at all seams to create a continuous protective envelope, significantly reducing the risk of oxidation and surface tarnishing of the copper material. Additionally, desiccant packs are strategically placed within the wrapping to absorb any residual moisture and maintain a low-humidity microenvironment around the coils.

For extended voyages or shipments to tropical or high-humidity regions, we recommend optional vapor corrosion inhibitors (VCI) integrated into the wrapping system. These additives provide molecular-level protection by forming a protective layer on the copper surface, further mitigating the risk of oxidation without affecting the material’s electrical or mechanical properties.

All packaged units are clearly labeled with essential shipment data, including batch number, alloy specification, dimensions, net weight, and handling instructions. Warning labels indicating “Fragile,” “This Side Up,” and “Protect from Moisture” are affixed to ensure proper handling throughout the logistics chain.

Our export packaging protocol has been validated through extensive real-world shipping data and third-party logistics audits. It is aligned with ISO 9001 quality management standards and tailored to the unique requirements of soft copper materials used in transformer manufacturing, where surface purity and dimensional consistency are critical. By integrating robust mechanical support with advanced environmental protection, Luoyang Xinzhaohe ensures that every shipment arrives in optimal condition, ready for immediate processing in our customers’ production lines.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Precision Soft Copper Strip Supplier

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and manufacturing excellence to deliver mission-critical soft copper strip and foil for high-performance transformer applications. Our core strength lies in the precise control of the soft copper production process, ensuring the consistent material properties essential for efficient electromagnetic conversion and thermal management in demanding power systems. We operate dedicated, state-of-the-art production lines specifically engineered for oxygen-free and electrolytic-tough-pitch (ETP) copper, utilizing advanced continuous annealing and skin-pass rolling technologies to achieve the exact tensile strength, elongation, and surface finish required by modern transformer designs. This granular process control, managed by our experienced metallurgical team, guarantees the high electrical conductivity and formability that prevent winding defects and optimize core performance.

Our integrated manufacturing facility in Luoyang represents significant vertical capability within the copper value chain. We maintain stringent raw material sourcing protocols, utilizing only high-purity copper cathodes meeting GB/T 5231 or equivalent international standards, subjected to rigorous incoming inspection. Downstream, our production encompasses precision cold rolling, controlled atmosphere annealing, tension leveling, and slitting, all performed under ISO 9001 certified quality management systems. Critical to transformer reliability, we implement comprehensive in-process and final quality verification, including continuous conductivity monitoring (IACS), precise dimensional metrology via laser micrometers, surface roughness analysis, and mechanical property testing on certified tensile testers. This end-to-end oversight ensures every coil meets the exacting specifications demanded by the industry.

Luoyang Xinzhaohe provides significant supply chain advantages for global transformer manufacturers. Our substantial production capacity, exceeding 15,000 metric tons annually for copper strip/foil, combined with lean inventory management practices, enables reliable just-in-time delivery schedules and mitigation of market volatility risks. We possess extensive experience in managing complex international logistics for sensitive flat-rolled products, ensuring damage-free shipment via optimized packaging solutions. Our technical sales team, comprising metallurgists and supply chain specialists, collaborates directly with客户 engineering departments to resolve material challenges and support new product introductions. The following table summarizes key performance indicators achievable with our standard soft copper strip offerings:

| Parameter | Typical Value (Soft Annealed) | Standard Tolerance | Test Method |

|---|---|---|---|

| Conductivity (IACS) | ≥ 100% | ±0.5% | ASTM E1004 |

| Thickness Range | 0.05 mm – 3.0 mm | ±0.003 mm (0.1mm) | ISO 11562 |

| Tensile Strength | 195 – 220 MPa | ±10 MPa | ASTM E8/E8M |

| Elongation | ≥ 45% | ±3% | ASTM E8/E8M |

| Surface Roughness | Ra ≤ 0.4 µm | ±0.05 µm | ISO 4287 |

Partnering with Luoyang Xinzhaohe means securing a supply of soft copper strip characterized by unparalleled consistency, backed by deep metallurgical expertise and resilient logistics. We are committed to being an extension of your engineering and procurement teams, providing the material foundation for transformer efficiency and longevity. For technical specifications, sample requests, or to discuss your specific soft copper requirements, contact our dedicated supply chain manager Cathy directly at cathy@transformerstrip.com. Initiate a conversation grounded in precision engineering and reliable supply.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing soft copper directly from China.