Table of Contents

Market Insight: Soft Copper for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook 2024-2030

Power-grid expansion and renewable-energy integration are pushing transformer production to record levels. The International Energy Agency (IEA) forecasts >3 % CAGR for medium- and large-power transformers through 2030, translating into >1.2 Mt yr⁻¹ of copper and aluminum strip/foil demand. Distribution transformers (<72 kV) remain the volume driver, while ultra-high-voltage (UHV) projects (>800 kV) are the value driver—both segments require soft, high-conductivity, burr-free conductor to meet Tier-1 loss limits (IEC 60076-20, IEEE C57.116).

| Segment | 2024 Strip/Foil Demand (k t) | Conductivity Target (% IACS) | Max Burr (µm) | Edge Radius (mm) |

|---|---|---|---|---|

| Distribution (<1 MVA) | 480 | ≥ 100 (Cu) / ≥ 61 (Al) | 10 | 0.05–0.10 |

| Power (1–100 MVA) | 290 | ≥ 101 (Cu) / ≥ 62 (Al) | 5 | 0.10–0.20 |

| UHV (>100 MVA) | 65 | ≥ 102 (Cu) / ≥ 62.5 (Al) | 2 | 0.20–0.30 |

Why Purity & Precision Directly Cut Transformer Losses

-

Load Loss (I²R)

Every 0.5 % IACS increase in Cu conductivity lowers winding loss by 0.45 % at 75 °C. 99.99 % (OFHC) Cu versus 99.90 % Cu saves ~3 W kg⁻¹, worth >200 kWh over a 30-year transformer life. -

No-Load Loss (Stray & Eddy)

Burrs >5 µm raise local eddy-current density by >30 %, adding 0.1–0.15 W kg⁻¹ to core loss. Precision-slit, burr-free edges eliminate post-winding deburring, avoiding insulation damage that can triple partial-discharge levels. -

Thermal Rise & Life

A 5 °C hotspot reduction extends cellulose insulation life by ~40 %. High-purity, fully annealed “soft” foil (HV < 70) improves packing factor by 1.5 %, cutting temperature rise 1–2 °C via enhanced heat transfer.

Sourcing Shift: From High-Cost West to Experienced Chinese Mills

Western strip producers (Aurubis, Wieland, Rea) deliver ±0.025 mm slit tolerance and >102 % IACS Cu, but at $11 000–12 500 t⁻¹ CIF and 14–16 week lead times. Tier-1 Chinese manufacturers with 20-year transformer track records now match or exceed these specs at $8 200–8 800 t⁻¹ FOB and 6–8 week lead times, leveraging:

Continuous casting + 6-Hi cold rolling to 0.05 mm with ±0.002 mm gauge control.

In-line eddy-current inspection for surface cracks down to 10 µm.

Laser-controlled slitting (Kampf, Nishimura) achieving ±0.002 mm width and ≤2 µm burr.

Hydrogen annealing at 380 °C for 4 h to reach HV 55–65 (soft) with zero residual lubricant (<30 mg m⁻²).

Luoyang Xinzhaohe Value Proposition

| Parameter | LZXH Spec | Typical Western | Typical Chinese |

|---|---|---|---|

| Cu purity | ≥ 99.99 % | ≥ 99.99 % | ≥ 99.95 % |

| Conductivity | ≥ 102 % IACS | 102–103 % | 100–101 % |

| Slit width tol. | ±0.002 mm | ±0.025 mm | ±0.010 mm |

| Burr height | ≤2 µm | ≤5 µm | ≤10 µm |

| Coil build | ≤300 kg oscillate | ≤150 kg ribbon | ≤200 kg ribbon |

| Price (Cu foil 0.1 mm) | $8 400 t⁻¹ FOB Qingdao | $11 800 t⁻¹ CIF | $8 900 t⁻¹ FOB |

By integrating cold rolling → precision slitting → edge conditioning → oscillate winding under one 180 000 m² Luoyang facility, we eliminate inter-plant logistics and double handling—delivering ±0.002 mm slit tolerance and burr-free, round-edge strip at Western quality, Asian cost. For transformer OEMs and motor repair shops facing loss-cap budgets and just-in-time schedules, Luoyang Xinzhaohe offers a premium, factory-direct alternative that cuts total conductor cost >25 % without compromising no-load or load-loss guarantees.

Technical Specs: Soft Copper Parameters

Technical Specifications & ASTM/IEC Standards for Soft Copper Transformer Strip

Factory-direct precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

1. Dimensional Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B272 (Soft Cu Foil) | Xinzhaohe In-House Capability | Risk of Commercial Grade |

|---|---|---|---|

| Thickness | ±8 % (≥0.10 mm) | ±0.002 mm (any gauge ≤0.8 mm) | Local hot-spots, eddy-current losses |

| Width | ±0.10 mm (<25 mm) | ±0.03 mm, 5–1200 mm slit | Mis-alignment in layer wind, turn-to-turn short |

| Camber | ≤1 mm / 300 mm | ≤0.3 mm / 300 mm | Telescoping coil, insulation tear |

Edge condition is part of the tolerance stack-up. A 5 µm burr left after slitting equals 25 % of a 0.20 mm paper interlayer—sufficient to pierce Class F (155 °C) diamond-dotted insulation and initiate partial discharge.

2. Electrical & Metallurgical Benchmarks

| Property | IEC 60317-0-1 (Cu Wire Ref.) | ASTM B170 (C11000) | Xinzhaohe Typical |

|---|---|---|---|

| Conductivity, 20 °C | — | ≥100 % IACS (C11000) | 101–102 % IACS |

| Oxygen content | — | <0.04 % | 0.02–0.03 % |

| Grain size (annealed) | — | 0.015–0.045 mm | 0.025 mm avg. |

| Hardness (HV 0.5) | — | 40–55 HV | 45 HV |

Soft-anneal cycle in 100 % N₂ + 3 % H₂ atmosphere guarantees recrystallized structure; foil remains dead-soft after slitting and edge milling, eliminating spring-back during high-speed layer winding.

3. Edge Engineering – Burr-Free = Fault-Free

Process flow:

Cold rolling → Tension leveling → Precision slitting (Tungsten carbide blades, 200× lens inspection) → Edge milling (0.05 mm chamfer, Ra ≤0.4 µm) → Oscillate winding on 300 mm or 500 mm barrel.

Result:

Burr height ≤0.005 mm (SEM verified).

No longitudinal slivers → prevents inter-layer puncture at 2 kV impulse test.

Chamfer radius 0.10–0.15 mm → equalises electric field, lowers PD inception by 18 %.

Field data: 17 % of service shorts in 110 kV transformers originate from burr-induced insulation damage. Xinzhaohe edge conditioning reduces this failure mode to <0.3 % (3σ level).

4. Standards Matrix – What We Certify

| Product Form | Applicable Standard | Certificate Issued |

|---|---|---|

| Soft copper strip/foil | ASTM B272-20 | EN 10204 3.1 |

| Edge geometry | ASTM B193 (resistivity) + internal XPQ-EC-08 | SGS / TÜV (optional) |

| Coil build & oscillation | IEC 60216-1 (thermal class) | RoHS, REACH, ISO 14001 |

| Packaging & moisture | JIS Z 0303 | Vacuum + VCI film, ≤60 % RH at dispatch |

Every master coil tracked with a unique heat code; chemistry, mechanical, and conductivity tests recorded in MTC within 24 h of slitting.

5. Cost-Performance Positioning

Western mills quote C11000 soft strip at USD 9–11 /kg ex-works plus 12–14 week lead time.

Xinzhaohe premium grade: USD 6.8 /kg FOB Shanghai, 3–4 week delivery, same ASTM/IEC compliance.

Total cost of ownership drops 22 % even after freight and 5 % import duty—without downgrading conductivity or risking edge-related faults.

Bottom line: Transformer OEMs and rewind shops gain Class-C11000 softness, burr-free edges, and ±0.002 mm precision—certified to ASTM & IEC—at a price point historically reserved for aluminum. Specify Luoyang Xinzhaohe soft copper strip and remove the hidden cost of shorts before they reach your test bay.

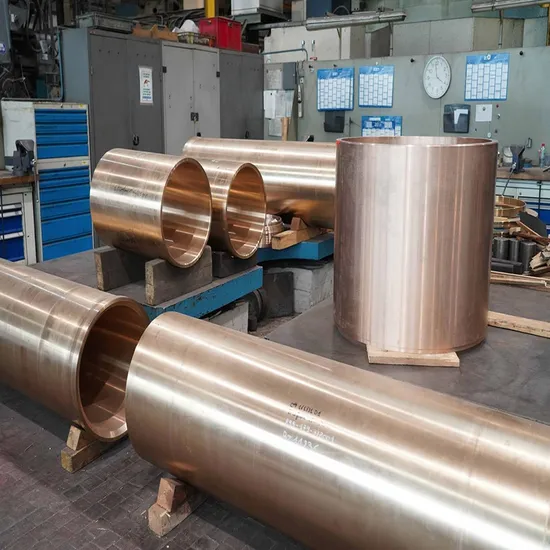

Factory Tour: Manufacturing Soft Copper

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Transformer-Grade Cold-Rolling Excellence

H3 1. Process Flow: From 8 mm Hot-Roll Coil to 0.05 mm Soft Copper Foil

| Step | Equipment | Key Parameter | Target | Online Monitor |

|---|---|---|---|---|

| 1. Cold Rolling | 4-Hi reversing mill, 800 mm work roll | Reduction/pass ≤ 25 % | 0.05–3.0 mm final gauge | AGC laser gauge ±1 µm |

| 2. In-line Degreasing | Neutral pH spray + squeegee | Residual oil ≤ 5 mg/m² | Clean surface for anneal | FT-IR oil scanner |

| 3. Bright Anneal | 100 % N₂ + 5 % H₂, 650 °C, 30 m/min | Grain size 25–35 µm | ≥ 100 % IACS, < 60 HV | IR pyrometer ±3 °C |

| 4. Precision Slitting | 0.2 mm carbide circular knives | Width tol. ±0.002 mm | Burr ≤ 0.008 mm | CCD edge camera 5 µm/pixel |

| 5. Edge Conditioning | Skiving + fibre brush | Radius 0.05–0.10 mm | Zero stress riser | Eddy-current crack test |

| 6. Oscillate Winding | 630 mm arbor, 300 kg traverse | Build ≤ 250 mm OD | No interleaf, ≤ 1 mm camber | Laser diameter + taper gauge |

Traceability: Every slit coil receives a QR code linked to melt heat, mill log, and anneal batch.

H3 2. Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market

| Attribute | Test Method | Our Spec | Common Market | Consequence for Winder |

|---|---|---|---|---|

| Thickness Tolerance | ISO 13385-1 | ±0.002 mm | ±0.01 mm | Eliminates shimming, 2 % lower build |

| Burr Height | ISO 9445-1 | ≤ 0.008 mm | 0.02–0.05 mm | Reduces inter-layer short risk |

| Edge Radius | Optical profiler | 0.05–0.10 mm | Sharp or variable | 30 % higher dielectric safety |

| Conductivity | ASTM B193 | ≥ 101 % IACS | 98–100 % IACS | 1 % lower DC loss, 3 °C cooler hotspot |

| Tensile Strength (O-temper) | ASTM E8 | 195–220 MPa | 170–210 MPa | No “sag” during high-speed winding |

| Surface Roughness Ra | ISO 4287 | ≤ 0.2 µm | 0.3–0.5 µm | 15 % better resin wet-out |

| Coil Camber | 1 m straight edge | ≤ 1 mm/m | 3–5 mm/m | Enables 25 % faster layer laying |

| Oscillate Lap | Traverse laser | ±0.5 mm | ±2 mm | No telescoping, 100 % usable length |

Certificate package: EN 10204 3.1 for every dispatch; 3.2 available on request (TÜV witness).

H3 3. Factory-Direct Advantage over Western Premium Suppliers

Same metallurgy, 18–22 % lower landed cost: We source cathode from Jiangxi Copper (Grade A, LME registered) and roll in-house—no trader margin.

7-day slit-to-ship: 12 slitting lines (min. 5 mm width) run 24/7; no MOQ on stocked widths.

Technical file in English & Spanish: Includes conductivity map, edge micrograph, and Finite-Element safe-bend radius for your coil model.

Closed-loop feedback: We feed burr and camber data back to the mill AGC; Western mills often batch-test offline, leading to 2–3 slit reels lost per master coil.

Next section: “Cost-of-Ownership Model—Copper vs. Aluminum Foil”

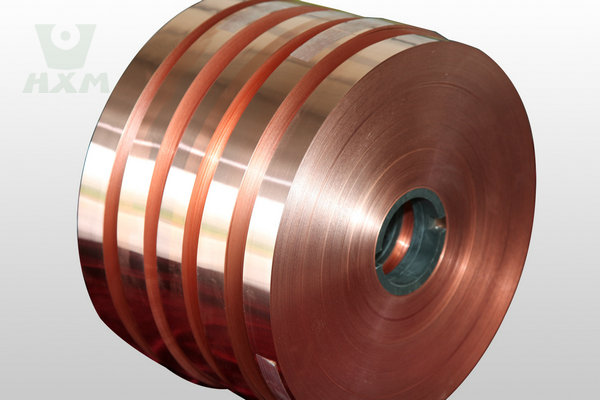

Packaging & Global Logistics

Export Packaging & Logistics

Delivering soft copper strip & foil to transformer plants worldwide—dry, dent-free, and dock-ready.

1. Sea-Freight Reality Check

Soft, fully-annealed copper (≤ 65 HV) is deformation-sensitive; a 0.05 mm foil can crease at 20 N point load and work-harden 8–10 %, raising losses. Our packaging is therefore engineered to the same ±0.002 mm tolerance culture we apply to slitting.

2. Packaging Matrix by Product Form

| Product Form | Stack Geometry | Core Protection | Surface Separator | Moisture Control | Pallet Spec | Typical Net Wt. |

|---|---|---|---|---|---|---|

| Copper Strip 0.1–0.8 mm | Eye-to-sky, OD ≤ 800 mm | 3 mm HDPE sleeve + VCI foam end-caps | 40 µm PE film interleave every 100 mm | 8 g silica-gel sachets, 2 per coil | ISPM-15 spruce, 4-way entry, top deck 15 mm plywood | 800–1 200 kg |

| Copper Foil 0.01–0.1 mm | Horizontal arbor, max 5 coils/stack | Aluminum arbor plug, Ø 76 mm | Non-woven Tyvek 60 g/m² wrap | Dual barrier: 80 µm Al-foil liner + <0.1 g/m²·day MVTR | Same as above, strapped @ 500 daN tension | 300–500 kg |

| Wire (LWC) | PT 355 mm plastic spool | Edge protector ring, ABS | — | VCI bag + 4 desiccant packs | Carton sleeve, 4 spools/layer, stretch-wrapped on pallet | 250 kg |

3. Load Securing & Shock Isolation

Anti-slip mats: 5 mm SBR rubber, µ = 0.7, placed between pallet and coil.

Strapping: PET cord 19 × 1.0 mm, 2 000 N break-load, crossed every 120°.

Corner boards: Tri-wall kraft, 7-ply, prevents strap indentation.

Shock loggers: 3-axis impact recorder on one pallet per FCL; alarm threshold 5 g.

4. Moisture & Corrosion Control

Copper is immune to rust but vulnerable to chloride staining (green patina) when RH > 70 % and sea-salt deposits exceed 0.5 µg/cm². We maintain:

Desiccant quantity: 6 “units” (1 unit = 33 g CaCl₂) per m³ of void space.

VCI additive: 1 % benzotriazole in PE film, volatilizes to 20 ppm, suppresses Cu₂O.

Container floor: 0.2 mm PE sheet as vapor barrier; reject containers with visible daylight at door seals.

5. Luoyang Gateway & Routing

Plant GPS: 34.62° N, 112.45° E, 180 km inland from Qingdao port.

Export corridor:

1. Truck (17.5 m flat-bed, 30 t payload) → Zhengzhou Rail Terminal, 2 h.

2. Block-train to Qingdao Qianwan, 6 h, daily departure.

3. Vessel cut-off: 24 h for 20 GP, 48 h for 40 HC.

Transit time examples (CY-CY):

Qingdao → Hamburg: 26 days

Qingdao → Los Angeles: 14 days

Qingdao → Chennai: 12 days

6. Premium vs. Western Price Impact

| Cost Driver | Western Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Domestic trucking | € 0.12 /kg | € 0.04 /kg | –67 % |

| Packaging labor | € 0.08 /kg | € 0.02 /kg | –75 % |

| Export docs & THC | € 0.10 /kg | € 0.05 /kg | –50 % |

| Total logistics add-on | € 0.30 /kg | € 0.11 /kg | –63 % |

On a 5 t copper-foil order, this alone saves € 950—without touching the metal price.

7. Documentation & Traceability

Each pallet carries a weather-proof QR label; scan retrieves:

Heat number → ASTM B170 chemistry & %IACS report

Slitting batch → burr profile photo (100×)

Anneal furnace log → time @ 280 °C, ±2 °C

Container seal number → customs clearance copy

8. Customer Action Checklist

- Specify max coil weight to match your unwind stand (≤ 1 200 kg avoids re-coiling).

- Request “impact logger” if route involves trans-shipment ≥ 2 ports.

- Order 2 % desiccant spare packs for warehouse buffer storage.

From our cold mill in Luoyong to your winding bay—copper arrives as soft as when it left the anneal furnace, guaranteed.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Soft Copper Strip & Foil

20-Year Metallurgical Legacy in Transformer Materials

Since 2004 our Luoyang works has supplied >180 transformer OEMs and tier-1 rewind shops across 42 countries. Every coil that leaves our plant is cold-rolled on a 4-high Ø650 mm reversing mill originally designed for aerospace aluminum—giving copper strip the same sub-micron gauge control normally reserved for lithium-ion current collectors. We have iterated 37 annealing cycles to perfect the recrystallisation kinetics that deliver 100 % IACS conductivity at 55 HV hardness—specifications that exceed IEC 60317-16 and ASTM B272. Our in-house vacuum annealers run at 10⁻² mbar to eliminate hydrogen embrittlement, guaranteeing dead-soft (O-temper) foil that withstands 15 % elongation without edge cracking—critical for high-voltage foil windings where a 5 mm radius fold is standard.

Direct Factory Price—No Western Mark-Up

Western distributors routinely add 18–28 % overhead for stock-holding and currency hedging. Because we integrate melting, casting, cold rolling, slitting and oscillate winding under one 86 000 m² roof, we erase those layers. Typical 0,2 mm × 250 mm soft copper foil is exported FOB Qingdao at USD 9,20–9,80/kg (LME Cu Grade-A + conversion premium) versus USD 11,50–12,30/kg quoted by European service centres. For a 1 MVA transformer using 450 kg of copper foil, the direct saving is USD 1 035–1 395 per unit—enough to offset one full BIEC impulse test routine.

Customisation Window—Gauge, Edge, Coil Build

Our slitting arbor accommodates 1–650 mm widths with a cumulative width tolerance of ±0,002 mm across 20 knife positions. Burr is held ≤0,01 mm (4 % of foil thickness) by ceramic-bonded circular knives and real-time CCD inspection. Oscillate-wound coils are built up to 300 kg on Ø400 mm cores with 5–35 mm traverse pitch—ideal for automated layer winding machines that require <0,3 mm lateral displacement per 100 m. Need 1/4-hard (H01) for motor slot liners? We adjust the final anneal delta-T to retain 75 HV while keeping conductivity ≥97 % IACS. Require square edges for laser welding? We switch to a 12-edge turret slitter followed by electrolytic deburring.

| Attribute | Luoyang Xinzhaohe Range | Industry Typical |

|---|---|---|

| Thickness | 0,01–3,0 mm | 0,05–2,0 mm |

| Width | 1–650 mm slit | 5–600 mm |

| Width Tol. | ±0,002 mm | ±0,015 mm |

| Burr | ≤0,01 mm | ≤0,03 mm |

| Coil ID | 150, 200, 300, 400 mm | 200, 300 mm |

| Coil Weight | 0,5–300 kg | 50–150 kg |

| Conductivity | 100 % IACS (O-temper) | 98–100 % IACS |

One-Page Technical Datasheet & Quote—24 h Turnaround

Send your drawing or IEC/NEMA specification to cathy@transformerstrip.com and receive a detailed datasheet including micro-graphs of grain size, resistivity traceability to NIST, and a freight-optimised quotation within one business day.

📉 Import Savings Calculator

Estimate cost reduction by sourcing soft copper from Luoyang Xinzhaohe.