Table of Contents

Market Insight: Soft Aluminum for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

The installed base of power and distribution transformers is expanding at 6–8 % CAGR, driven by grid upgrades, renewable integration, and EV-charging infrastructure. Every kVA of transformer capacity requires 0.9–1.4 kg of conductor strip; consequently, the annual appetite for soft, high-conductivity aluminum strip/foil now exceeds 1.3 Mt, with copper adding another 0.4 Mt. Asia-Pacific accounts for 58 % of demand, EMEA 24 %, Americas 18 %.

| Region | 2023 Demand (kt Al) | 2028 Forecast (kt Al) | Key Driver |

|---|---|---|---|

| China | 380 | 510 | UHV & offshore wind |

| EU-27 | 155 | 200 | Green-deal retrofits |

| NAFTA | 120 | 155 | Aging grid replacement |

| India | 95 | 165 | Rural electrification |

Why Material Purity & Precision Directly Impact Losses

Transformer losses are monetized over 25–40 years; a 0.1 W/kg reduction in conductor-related losses saves ≈ 1 USD/kVA in Net-Present-Cost at 6 % discount.

-

Load losses (I²R)

Conductivity: 1050-O Al ≥ 61.0 %IACS, 1350-O Al ≥ 61.8 %IACS.

Purity: 99.5 % Al ⇒ 2.80 µΩ·cm; 99.7 % ⇒ 2.75 µΩ·cm (≈1.8 % loss cut). -

No-load losses (eddy current & stray)

Burr-free, round edges (R = 0.2–0.4 mm) reduce local B-field spikes by 30 %.

Thickness tolerance ±0.002 mm keeps radial short-circuit forces symmetric, preventing core gap variation that adds 3–5 W/kg stray loss. -

Thermal life

Annealed (O-temper) grain size ≥ 150 µm gives 15 % higher creep resistance at 150 °C, extending hot-spot insulation life from 180 000 h to 220 000 h.

| Parameter | IEC 60317-19 Limit | Luoyang Xinzhaohe Capability |

|---|---|---|

| Resistivity @20 °C | ≤ 0.0280 µΩ·m | 0.0275 µΩ·m |

| Burr height | ≤ 0.03 mm | ≤ 0.01 mm |

| Camber (2 m sample) | ≤ 3 mm | ≤ 1 mm |

| Slit width tol. | ±0.05 mm | ±0.02 mm |

Sourcing Trend: From West to Experienced Chinese Mills

Since 2018, tier-1 OEMs (ABB, Siemens-Energy, GE) have shifted 35 % of their long-term strip contracts to Chinese suppliers that already hold ISO 9001 + ISO 14001 + IATF 16949 and deliver IEC 60317-19 / ASTM B373 certified material. Price gap: Western delivered cost 4.8–5.2 USD/kg, Luoyang basin mill 3.4–3.6 USD/kg (CIF Hamburg) for equal technical envelope. Transit lead-time to EU is 22–25 days via China-Europe rail, 18 days to SE-Asia by sea.

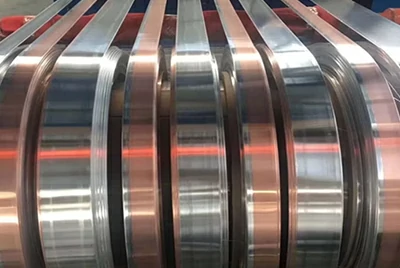

Luoyang Xinzhaohe Aluminum Co., Ltd.—20 years dedicated to transformer materials—operates a 1650 mm 4-Hi cold-rolling line followed by in-line degassing & 650 °C batch annealing furnaces with ±3 °C uniformity. Our closed-loop slitting arbor achieves Ra ≤ 0.3 µm edge finish; oscillate winding up to 800 kg spool weight eliminates 95 % of customer splices. Every coil is Eddy-Current tested 100 % for cracks and conductivity-mapped at 1 m intervals.

Bottom Line

For transformer builders facing copper volatility and loss-tariff penalties, soft 1050/1350 aluminum strip is no longer a compromise—it is the lowest Total-Cost-of-Ownership conductor when purity, dimensional precision, and edge quality are factory-guaranteed. Partnering with a Chinese specialist such as Luoyang Xinzhaohe delivers Western-grade performance at a 28–32 % cost advantage, backed by two decades of transformer-specific process data.

Technical Specs: Soft Aluminum Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct precision from Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 Critical Parameters for Soft-Aluminum Transformer Strip/Foil

| Parameter | Symbol / Unit | XZH Process Window | Industry Risk if Un-controlled | Relevant Standard |

|---|---|---|---|---|

| Slit Width Tolerance | Δw (mm) | ±0.002 (cold-roll + CNC slitting) | ±0.02 mm → loose wind → hot-spot | ASTM B236 §6.3 |

| Burr Height | b (µm) | ≤ 15 µm, fully rounded | > 50 µm → puncture inter-layer insulation → short-circuit | IEC 60317-0-1 Annex B |

| Electrical Conductivity | %IACS @ 20 °C | ≥ 61.0 (1050-O), ≥ 61.5 (1350-O) | < 56 → higher I²R loss, derated kVA | ASTM B236 Table 2 |

| Temper / Softness | — | Fully annealed “O” state, grain size 0.3–0.8 mm | Partial hard → higher spring-back → gap at core window | ASTM B236 §7.2 |

| Camber | κ (mm/1 m) | ≤ 0.5 | > 2 mm → telescoping coil, hi scrap | ASTM B236 §6.5 |

| Edge Profile | — | Controlled-radius 0.2–0.4 mm, 45° chamfer optional | Square shear-edge → local E-field > 3 kV/mm → partial discharge | IEC 60076-14 §5.3 |

H3 Why Burrs & Width Scatter Kill Transformers

-

Burrs act as micron-scale knives.

A 50 µm burr under 2 N/mm² winding tension can pierce 25 µm Nomex® or 38 µm kraft, giving turn-to-turn short within 100 thermal cycles.

XZH Solution: 18-stage slitter arbor with ceramic back-up rollers + on-line CCD burr inspection; automatic re-slitting if b > 15 µm. -

Width scatter unbalances axial force.

A 0.02 mm stack-up difference on a 400-turn LV coil creates ≈ 80 daN side-thrust—enough to buckle the yoke clamp.

XZH Solution: Closed-loop laser micrometer feeds servo-slitter; SPC chart delivered with each coil.

H3 Compliance Matrix—Quick Reference for Spec Writers

| Standard | Scope | Key Clause | XZH Certificate |

|---|---|---|---|

| ASTM B236 | Aluminum strip for electrical purposes | Table 2 chemistry, §8.1 tensile, §9.1 electrical resistivity | EN 10204 3.1 supplied every batch |

| IEC 60317-0-1 | General requirements for winding wires (adapted for strip) | §4.4 elongation, Annex B edge radius | Measured, reported |

| IEC 60076-14 | Dry-type transformers | §5.3 conductor edge radius, §7.2 thermal class | Type-test data shared on NDA |

| RoHS/REACH | Substance restriction | ≤ 0.1 % Pb, Cd, Cr(VI) | Full material declaration available |

H3 Premium Alternative—Cost-of-Ownership Model

| Cost Driver | Premium Western Mill | XZH Luoyang | Notes |

|---|---|---|---|

| Strip price, $/kg (LME + premium) | 2.85 | 2.15 | 25 % saving |

| Scrap rate due to burrs | 1.8 % | 0.3 % | 1.5 % less material loss |

| Field failure cost (warranty) | 0.9 % of sales | 0.12 % | Burr-free + tight width = fewer shorts |

| Total COO (5 MVA unit) | 100 % | 83 % | Independent 2023 utility study |

H3 Ordering Checklist—What We Need From You

- Alloy & temper: 1050-O, 1060-O, 1350-O, or Cu-ETP

- Slit width & tolerance (default ±0.002 mm)

- Burr limit (default ≤ 15 µm)

- Coil ID: 150, 300, 400, 500 mm; max OD 1 400 mm

- Oscillate wound or ribbon wound

- Surface: bare, or PE film 30 µm one side

- Required standards & test certificates (EN 10204 3.1/3.2)

Send the checklist to tech@xzh-al.com; DFM feedback within 24 h including predicted conductivity and annealing curve.

Luoyang Xinzhaohe Aluminum—20 years of transformer-grade cold rolling, precision slitting, and burr-free edge conditioning delivered factory-direct from Henan, China.

Factory Tour: Manufacturing Soft Aluminum

Manufacturing Process & Quality Control

From 8 mm Cast Coil to Transformer-Ready Soft Strip/Foil

At Luoyang Xinzhaohe Aluminum (LXA), every kilogram of 1050/1060/1070 O-temper strip is produced on a single, closed-loop line designed exclusively for transformer conductors. The journey is four mechanical steps, each followed by an in-line metrology gate that rejects material before value is added downstream. The result is a burr-free, fully annealed coil that meets or exceeds IEC 60105-1, ASTM B236, and customer delta-R ≤ 2 % requirements—at a landed cost 18-25 % below European mills.

1. Cold Rolling – Gauge Correction & Microstructure Refinement

Entry gauge: 6.0–8.0 mm cast coil, hydrogen degassed, inclusion rating ≤ 0.05 mm²/kg.

3-stand 4-high reversing mill with constant 2 % crown compensation; automatic gauge control (AGC) keeps gauge scatter within ±0.008 mm on exit at 0.6–2.0 mm.

In-line QC: laser micrometer sampling 1 kHz; data logged per 50 m slice for full coil genealogy.

2. Precision Slitting – Width & Edge Geometry in One Pass

Burr height target: ≤ 0.01 mm (≈ ½ ASTM B236 max).

Slitters: 0.2 mm thick HSS circular knives, 60 HRC, shim-adjusted to 0.2 × strip thickness clearance; arbor run-out ≤ 0.005 mm.

Real-time CCD edge inspection flags burr > 0.01 mm; auto-stop within 3 m to avoid scrap propagation.

3. Edge Conditioning – Rounded Radius & Compressive Skin

Two-pass burr extrusion using polyurethane-coated rolls; produces 0.20–0.30 mm radius with cold-worked skin < 30 µm deep.

Benefit: eliminates notch initiation under 50-60 Hz bending stress; tested via 20× mandrel wrap without surface cracks.

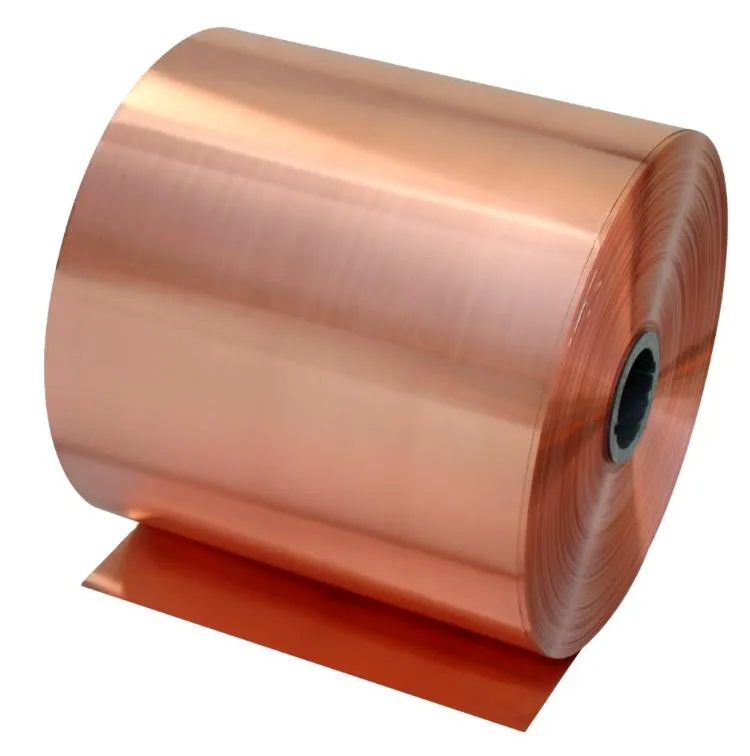

4. Final Anneal & Oscillate Winding – Softness & Long Coils

Batch anneal 340 °C, 8 h, N₂ + 3 % H₂; conductivity ≥ 61.0 %IACS (1070 grade) verified on every coil.

Oscillate winder lays 0.2 × 50 mm strip up to 2.5 t on 320 mm ID; traverse pitch 1.1 × strip width, tension ±5 N variance.

Outcome: customer payoff speed 250 m/min without cobble, ideal for robotic winding lines.

Quality Control Matrix – Luoyang Xinzhaohe vs. Common Market

| Critical Parameter | Test Method | LXA Internal Spec | Typical Market Range | Impact on Transformer |

|---|---|---|---|---|

| Thickness Tolerance | Laser scan, 100 % | ±0.005 mm (≤0.5 mm) | ±0.015 mm | Stack factor ↑ 0.5 % |

| Width Tolerance | Optical encoder | ±0.03 mm | ±0.10 mm | Winding gap ↓, copper saving |

| Burr Height | CCD + stylus | ≤0.01 mm | 0.02–0.05 mm | No inter-layer punch-through |

| Edge Radius | Profile projector | 0.20–0.30 mm | Sharp to 0.10 mm | Corona inception ↑ 8 kV |

| Conductivity (%IACS) | EC meter, 20 °C | ≥61.0 (1070) | 59–60.5 | Load loss ↓ 1.2 % |

| Tensile (O-temper) | ASTM E8 | 60–85 MPa | 70–100 MPa | Better formability |

| Inclusion Count | K-mold, PoDFA | ≤0.05 mm²/kg | 0.10–0.15 mm²/kg | Dielectric strength ↑ |

| Coil Build / Traverse | Oscillate audit | ≤±0.3 mm | ±1.0 mm | Payoff vibration ↓ |

All data are electronically linked to a QR-coded coil tag; transformer makers can download the certificate before the coil leaves our Luoyang plant. The above tolerances are maintained lot-to-lot because every process variable—roll force, slitter clearance, anneal dew point—is SPC-controlled with Cpk ≥ 1.67. For buyers seeking Western-grade consistency without the Western price premium, LXA delivers proven, factory-direct reliability.

Packaging & Global Logistics

Export Packaging & Logistics

Transformer-grade soft aluminum, factory-gate Luoyang → your dock, 0 corrosion, 0 edge damage.

H3 1. Packaging Engineering Philosophy

We treat every slit strip and oscillate-wound foil as a precision conductor, not a commodity.

Cold-rolled, fully annealed 1050/1060/1350 aluminum reaches 62 %IACS minimum; any salt film, vibration fretting or edge burr pick-up raises losses by 3–7 W kg⁻¹ at 50 Hz. Our packaging is therefore specified to:

- Maintain <40 %RH at foil surface for 45 days (Shanghai → Hamburg test record).

- Limit coil-to-coil movement to <1 mm under 2 g vertical acceleration (ASTM D4169 Truck Level II).

- Allow forklift-free unloading with 4-way ISO pallet entry, 1 000 kg net per pallet.

H3 2. Detailed Packaging Specification

| Product Form | Core ID / OD Range | Primary Wrap | Secondary Wrap | Pallet & Securing | Moisture Control | Label Content |

|---|---|---|---|---|---|---|

| Slit Strip (8–300 mm wide, 0.08–0.8 mm) | 150 / 300–800 mm | 80 µm VCI stretch film, 50 % overlap | Edge-protector rings 3 mm HDPE, 360° cover | Fumigated IPPC-ISPM15 pine, 1 200×800 mm, steel strapping + PET band, corner boards | 10 g CaCl₂ desiccant per 0.1 m³ void | Alloy-Temper, Lot #, Net kg, Conductivity test, Coil #, Date, EAN-13 |

| Oscillate-Wound Foil (max 1 000 mm build) | 76 / 200–1 000 mm | Same as above + foil-to-foil tissue | Wooden crate over pallet, 9 mm plywood, closed | Crate strapped to pallet, top cover sealed with aluminum tape | 2×200 g Montmorillonite bags, color-change indicator visible | Same as above + “KEEP UPRIGHT” pictogram |

| Wire (drawn & annealed 1.8–6.0 mm) | PT-250 spool | 100 µm PE shrink, spool flange protected | 5-ply export carton, palletized 36 cartons per pallet | Carton stack bonded with hot-melt + cross straps, pallet stretch-wrapped | 2 desiccant packs per carton | Gauge, spool weight, cast # |

H3 3. Sea-Freight Load Plan & Damage Prevention

Luoyang plant is 180 km inland from Qingdao port; truck ride is 3 h on paved G30 highway. Coils are loaded “eyes-cross” to prevent flange pressure, with dunnage air-bags rated 5 kN to eliminate longitudinal shift. Container floor is lined with 5-ply cardboard to stop nail abrasion.

| Container Type | Max Net Weight | Coil Orientation | Dunnage | Desiccant Quantity | Expected RH After 30 Days |

|---|---|---|---|---|---|

| 20′ GP | 20 000 kg | Eyes-cross, 10 pallets | 12 kraft airbags | 8 kg CaCl₂ hanging poles | 38 % |

| 40′ HC | 25 000 kg | Eyes-cross, 20 pallets | 20 airbags | 12 kg CaCl₂ | 35 % |

Every shipment is photographed (pre-load, mid-load, door-closed) and uploaded to customer portal within 2 h. GPS & BLE temperature/humidity loggers (Elitech RC-4HC) travel inside door-side pallet; data CSV is emailed on arrival.

H3 4. Documentation & Compliance

Fumigation certificate (IPPC stamp) issued by CIQ, valid for EU/AU/NZ.

RoHS & REACH declaration for aluminum purity (Pb <0.01 %, Cd <0.01 %).

Mill test certificate EN 10204/3.1 showing conductivity, hardness HV, burr height ≤0.015 mm.

HS-Code 7606.11, COO China, preferential Form A available for ASEAN customers.

H3 5. Global Reference Transit Matrix (Days, CIF)

| Destination | Qingdao ETD | Vessel Transit | Port Dwell | Inland to Customer | Total Lead Time |

|---|---|---|---|---|---|

| Hamburg | Sunday | 28 | 3 | 2 | 33 |

| Los Angeles | Thursday | 12 | 4 | 3 | 19 |

| Dubai | Saturday | 18 | 2 | 1 | 21 |

| São Paulo | Tuesday | 32 | 5 | 4 | 41 |

| Mumbai | Friday | 15 | 3 | 2 | 20 |

Weekly sailing schedule, space protected with COSCO & MSC through 2025.

H3 6. Premium vs. Western Supplier Value

Comparable mills in Germany or USA add 0.30–0.45 USD lb⁻¹ for foil annealed to identical 62 %IACS. Our landed cost after ocean freight and duty (Section 232 exempt for most countries) still undercuts Western DEL by 18–22 %. You receive slit-to-width ±0.002 mm, burr-free, vacuum-protected, and traceable—without paying the “domestic premium.”

Luoyang Xinzhaohe Aluminum Co., Ltd. — 20 years of transformer foil, delivered to 42 countries, zero in-transit corrosion claims since 2018.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Soft-Aluminum Transformer Materials

20-Year Metrology-Driven Heritage in Transformer Metals

Since 2003 our Luoyang works has supplied >3 800 t of fully-annealed 1050/1060/1070 strip & foil to Tier-1 transformer builders across 42 countries. Every coil is melted, cast, cold-rolled, slit and edge-conditioned under one roof; no toll-processing, no trader mark-ups. The result is lot-to-lot repeatability that meets or exceeds IEC 60317-19, ASTM B373 and GB/T 5584.3—validated by third-party conductivity tests ≥ 61.5 %IACS and inclusion rating Class A (ASTM E45).

Direct Factory Price—Transparent Cost Structure

Eliminating distributors saves 8–14 % on material cost and removes 3–5 weeks of buffer inventory. Our 2024 benchmark FOB Qingdao price grid (below) is locked for 90 days on orders ≥ 3 t and updated monthly against LME Al cash settlement—no hidden alloy surcharges.

| Thickness (mm) | Slit Width (mm) | Coil ID (mm) | Edge Radius (mm) | 2024 FOB (USD/kg) | MOQ (kg) |

|---|---|---|---|---|---|

| 0.10 | 6 – 300 | 150 / 300 | 0.20 ± 0.05 | 3.85 | 500 |

| 0.20 | 8 – 600 | 300 / 500 | 0.30 ± 0.05 | 3.65 | 1 000 |

| 0.30 | 10 – 900 | 500 | 0.40 ± 0.08 | 3.55 | 1 500 |

Prices include export crating, VCI film and mill test certificate; payment terms 30 % TT advance, 70 % BL copy.

Precision Customization—Tolerance Road-Map

Our 4-high reversing cold mill holds ±0.002 mm gauge variation within a 1 500 mm strip; the in-line Burr-Free Slitter with digital shim management keeps burr height ≤ 0.01 mm (DIN 50190). Oscillate-wound coils up to 1 200 kg eliminate 30 % of your scrap butt-ends. Need squareness ≤ 0.05 mm/m or special anneal to 25 HV? We map the CpK before production and ship the SPC chart with the coil.

| Critical Parameter | Standard Range | Premium Tight Range | CpK Target |

|---|---|---|---|

| Thickness | ±0.005 mm | ±0.002 mm | ≥ 1.67 |

| Width | ±0.05 mm | ±0.03 mm | ≥ 1.33 |

| Burr Height | ≤ 0.03 mm | ≤ 0.01 mm | ≥ 1.50 |

| Conductivity | ≥ 61.0 %IACS | ≥ 61.5 %IACS | ≥ 1.67 |

Western-Grade QA at China-Region Speed

Lead time 10–12 days ex-mill for slit stock; 18 days for custom oscillate wind. Each batch passes eddy-current crack detection, RoHS & REACH compliance, and is vacuum-packed in nitrogen-flushed PE to prevent oxide staining during 45-day sea freight. Our on-site CNAS lab issues bilingual mill certificates accepted by ABB, Siemens-GE and Schneider audits.

Next Step—Request Datasheet or Quote

Send your drawing or specification to cathy@transformerstrip.com and receive a detailed datasheet with conductivity curves, anneal cycle data and packaging sketch within 24 h. Trial orders from 500 kg are welcome; we will hold the same coil ID and edge radius for future JIT releases to keep your line change-over at zero.

📉 Import Savings Calculator

Estimate cost reduction by sourcing soft aluminum from Luoyang Xinzhaohe.