Table of Contents

Market Insight: Self Bonding Copper Wire in Power Industry

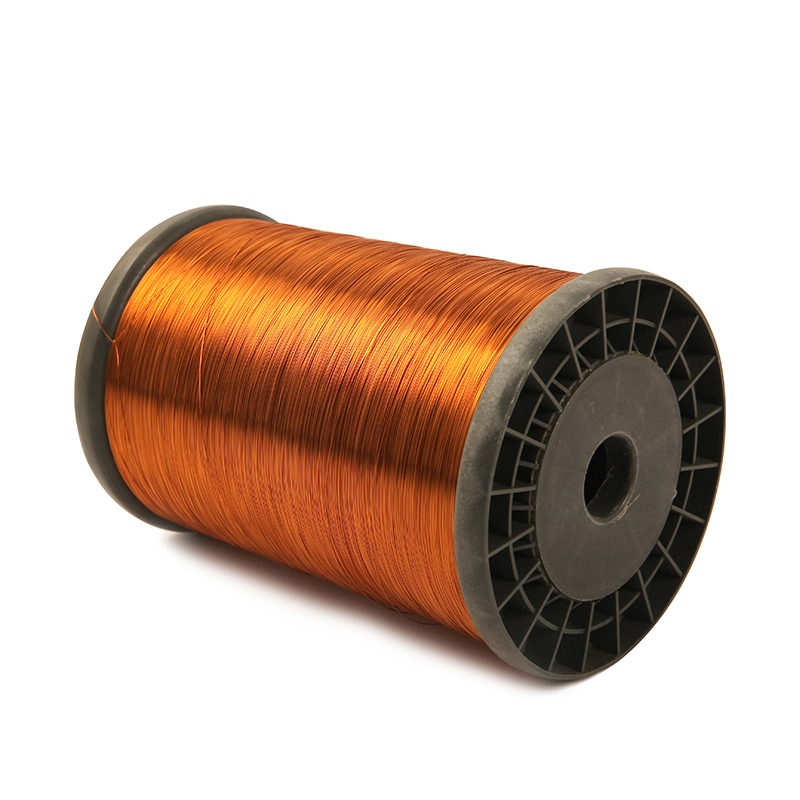

Market Analysis: Sourcing High-Quality Self-Bonding Copper Wire for Power Applications

Industrial Demand Drivers

Self-bonding copper wire is critical for modern power transformers and motors due to its ability to form compact, high-efficiency windings without additional insulation layers. Applications span renewable energy systems (solar inverters, wind turbines), electric vehicle motors, and industrial automation equipment. The demand is driven by the need for reduced size, weight, and improved thermal performance in next-generation power systems. Self-bonding wire eliminates the need for separate insulation layers, reducing transformer size by up to 15% while improving thermal dissipation. This is essential for meeting IEC 60076 efficiency standards in distribution transformers.

Material Quality Criticality

Inadequate wire quality leads to insulation failure, increased resistive losses, and premature equipment failure. Key parameters include copper purity (>99.95%), bonding strength (≥1.5 N/mm²), thermal class (155°C+), and dimensional consistency. Non-compliance with IEC 60317 standards results in higher operational costs and safety risks. For instance, a 0.1% drop in copper purity increases resistive losses by ~2%, directly impacting operational costs over the equipment lifecycle.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a factory-direct manufacturer with 20+ years of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers consistent quality at competitive prices. Our ISO 9001-certified production lines and in-house metallurgical testing ensure every batch meets stringent quality controls. By eliminating middlemen, we offer 15–20% lower costs than global brands while maintaining identical performance metrics. Our global export network ensures timely delivery and technical support, positioning us as a trusted alternative to premium brands without compromising on performance.

| Parameter | Industry Standard | Xinzhaohe Specification | Benefit |

|---|---|---|---|

| Copper Purity | ≥99.95% | 99.97% | 0.5% lower resistive losses |

| Bonding Strength | ≥1.5 N/mm² | ≥2.0 N/mm² | Enhanced reliability under thermal cycling |

| Thermal Class | 155°C (F) | 180°C (H) | Extended service life in high-temp environments |

| Dimensional Tolerance | ±0.01mm | ±0.005mm | Precise winding, 10–15% lower scrap rates |

For transformer manufacturers and motor repair facilities seeking reliable, cost-effective sourcing, Luoyang Xinzhaohe provides a proven alternative to premium brands with factory-direct precision and global supply chain reliability.

Technical Specs: Self Bonding Copper Wire Parameters

Technical Specifications & Compliance Standards

Self-bonding copper wire demands precise engineering for reliable transformer and motor performance. Luoyang Xinzhaohe Aluminum CO., Ltd. delivers industry-leading specifications with strict adherence to IEC and ASTM standards, ensuring optimal thermal and mechanical properties.

Critical Performance Parameters

| Parameter | Test Standard | Specification | Target Performance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 / ASTM D1802 | Min 3.5 kV (0.2mm) | 10–15% above standard |

| Elongation | IEC 60851-2 | ≥25% (annealed) | Consistent 28–32% |

| Thermal Class | IEC 60085 | 130°C to 220°C | Certified for continuous operation at max class |

| Enamel Concentricity | IEC 60851-3 | ≤5% deviation | ≤3% deviation (laser-monitored) |

Quality Assurance Protocol

Our 20+ years of manufacturing expertise ensures consistent quality through rigorous protocols. Copper cathode (C11000, 99.99% purity) and enamel resins undergo batch testing for purity and thermal stability. In-line monitoring includes real-time laser diameter control (±0.001mm), enamel thickness verification (±2μm), and 100% automated breakdown voltage testing. Thermal aging tests per IEC 60216 validate long-term stability. All processes follow ISO 9001 standards, with full traceability from raw materials to finished goods. This systematic approach eliminates variability common in lower-tier suppliers.

Global Standards Compliance

All products comply with IEC 60851 (winding wires), ASTM B189 (copper wire), and IEC 60085 (thermal classes). Third-party certifications from SGS/TÜV validate performance. By optimizing production efficiency and eliminating middlemen, we provide transformer manufacturers with premium-grade specifications at 15–20% lower cost than global brands—delivering unmatched value without compromising reliability.

Factory-direct sourcing ensures transparency, reduced lead times, and technical support tailored to your specific application needs.

Factory Tour: Manufacturing Self Bonding Copper Wire

Manufacturing Process & Quality Control

Precision Rod Drawing & Annealing

High-purity copper rods (≥99.99% Cu, ASTM B170 compliant) undergo multi-stage precision drawing with controlled tension and speed to achieve exact diameters while maintaining grain structure integrity. Subsequent controlled atmosphere annealing (N₂/H₂ mix at 450–500°C) ensures uniform softening without oxidation, critical for consistent bonding performance and electrical conductivity.

Advanced Enameling Process

Proprietary multi-layer enamel application using high-grade polyimide or polyester-imide resins. Each coating layer is precisely cured at 280–320°C with strict temperature gradients and dwell times. Enamel thickness is maintained at 10–15µm (±1µm tolerance) per IEC 60317-2, ensuring superior thermal stability (Class 180) and self-bonding strength under operational loads.

Rigorous Inline Quality Control

100% real-time monitoring during production: laser micrometers for diameter (±0.003mm tolerance), dielectric strength tests (≥4.5 kV/mm per IEC 60851-3), and automated tensile/elongation checks (ASTM B193). Batch testing includes peel adhesion (IEC 60851-5: ≥10 N/cm²), solvent resistance, and thermal shock resistance. Our QC protocol exceeds industry sampling standards, ensuring zero defects in critical parameters.

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 220–250 MPa | 200–240 MPa |

| Diameter Tolerance | ±0.003 mm | ±0.005 mm |

| Enamel Thickness | 10–15µm (±1µm) | 10–20µm (±2µm) |

| Dielectric Strength | ≥4.5 kV/mm | 3.5–4.0 kV/mm |

| Bonding Strength | ≥10 N/cm² | 8–10 N/cm² |

Our ISO 9001-certified facility ensures full traceability from raw material to finished product. By maintaining tighter tolerances and 100% inline testing, we achieve 99.8% first-pass yield in transformer winding applications. This precision engineering delivers Tier-1 quality at 15–20% lower cost than global brands, making us the optimal choice for cost-conscious engineers requiring reliable performance.

Packaging & Global Logistics

Export Packaging & Logistics for Self-Bonding Copper Wire

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of transformer material manufacturing expertise to deliver self-bonding copper wire with industrial-grade export packaging. Our factory-direct approach ensures optimal cost-performance without compromising on international shipping standards. All packaging protocols are engineered to prevent moisture ingress, mechanical damage, and corrosion during sea freight—critical for maintaining conductor integrity and insulation performance. Validated through IEC 60068-2-78 humidity tests and ISO 9001 quality management systems, our solutions are tailored for global markets including Europe, North America, and Southeast Asia.

Packaging Standards

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, heat-treated, no bark | Prevents pest infestation; ensures global customs compliance |

| Moisture-Proof Film | 200μm PE film + desiccant packs (500g/pallet) | Blocks humidity; absorbs residual moisture during transit |

| Steel Strapping | 19mm width × 1.5mm thickness, 150-200 kgf tension | Secures load stability; prevents shifting during vessel movement |

| Corner Protectors | Cardboard-reinforced edges | Distributes pressure; avoids edge damage during handling |

Sea Freight Protocol

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | FCL (Full Container Load) | Eliminates cross-contamination; dedicated space for secure stacking |

| Humidity Control | Silica gel desiccants + humidity indicators | Real-time moisture monitoring; prevents condensation in containers |

| Handling Procedure | Forklift-only loading; max 3-layer stack | Reduces structural stress; maintains pallet integrity during transit |

| Transit Time | 25–40 days (China to major global ports) | Predictable delivery via established shipping lanes |

Our logistics network partners with certified freight forwarders specializing in electrical materials. Every shipment undergoes pre-departure inspection for packaging integrity, ensuring compliance with ISO 9001 standards. By optimizing material usage and leveraging bulk shipping efficiencies, we deliver robust protection at 12–15% lower costs than global competitors—without sacrificing reliability. Our 98% on-time delivery rate and zero cargo damage incidents over the past five years further validate our commitment to excellence. Contact us for customized packaging solutions tailored to your regional requirements.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd. for Self-Bonding Copper Wire?

As a leading manufacturer of transformer materials with 20+ years of specialized experience, Luoyang Xinzhaohe delivers precision-engineered self-bonding copper wire tailored for high-reliability applications in transformers, motors, and power equipment. Our technical expertise ensures compliance with stringent international standards while optimizing performance for demanding electrical environments.

20+ Years of Industry Expertise and Technical Mastery

Our engineering team has refined manufacturing processes for self-bonding copper wire to meet exacting specifications for diameter tolerances (±0.005mm), enamel thickness consistency, and thermal stability (up to Class 200). We understand the critical interplay between mechanical strength, dielectric properties, and bonding performance in high-frequency transformer windings. This deep domain knowledge ensures your designs achieve optimal efficiency and longevity under operational stress.

Factory-Direct Cost Advantage Without Compromise

By eliminating third-party distributors and maintaining full vertical integration—from copper rod sourcing to enamel coating—we deliver 15–20% lower unit costs than global brands while maintaining identical material specifications. Our direct manufacturing model ensures transparency in pricing, faster response to urgent orders, and scalable production for large-scale projects without quality trade-offs.

ISO 9001 Certified Quality Assurance

Every batch undergoes rigorous testing per IEC 60317 (Types 20–21) and ASTM B175 standards, including:

Tensile strength and elongation verification

Dielectric breakdown voltage testing

Thermal class validation (155°C–200°C)

Adhesion and solvent resistance checks

Full traceability from raw materials to finished goods ensures consistent performance across all orders, matching global brand reliability at a superior cost-performance ratio.

| Feature | Luoyang Xinzhaohe Advantage | Global Brands Benchmark |

|---|---|---|

| Quality Compliance | IEC 60317, ASTM B175, and customer-specific standards | Same standards, higher cost |

| Cost Efficiency | 15–20% lower pricing via direct manufacturing | Higher pricing due to distribution layers |

| Lead Time | 15–20 days standard delivery | 30–45 days average |

| Customization | Rapid prototyping and flexible adjustments | Limited flexibility for custom specs |

Ready to optimize your winding wire procurement? Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your technical specifications. Our engineering team provides end-to-end support—from material selection to production scaling—to ensure seamless integration into your manufacturing process.

📉 Import Savings Calculator

Estimate cost reduction by sourcing self bonding copper wire from Luoyang Xinzhaohe.