Table of Contents

Market Insight: Ring Wired Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for Ring Wired Transformers

Global Demand Outlook

The explosive growth of smart-home devices—video doorbells, Wi-Fi chimes, and IoT gateways—has created a parallel surge in low-power, high-reliability transformers. Annual global shipments of 16 V / 30 VA class door-bell transformers now exceed 28 million units, with North America accounting for 42 % of demand. Every one of these units contains 45–65 g of copper or aluminium winding wire; multiply by volume and the segment consumes >1 800 t of conductor wire each year. The same wire must survive 24 × 7 thermal cycling, 1 000 V impulse surges, and 30-year service life—specifications once reserved for industrial control transformers. Consequently, the material purity, dimensional consistency, and insulation integrity of the winding wire have become the dominant cost drivers in the total BOM.

Why Material Purity & Precision Translate into Losses

Transformer losses fall into two buckets that directly impact energy-code compliance and end-user safety:

| Loss component | Origin | Typical 16 V 30 VA door-bell transformer | Wire-quality lever |

|---|---|---|---|

| No-load (core) | Hysteresis & eddy currents in steel | 0.8–1.1 W | — |

| Load (I²R) | Conductor resistivity + skin/proximity | 2.2–3.0 W @ 30 VA | ↓ 18 % when 6 N (99.9999 %) Cu replaces 4 N Cu |

| Short-circuit (stray) | Leakage flux & eddy currents in wire | 0.15–0.25 W | ↓ 30 % with ±0.5 µm concentric enamel |

A 0.5 W reduction may appear trivial, but Underwriters Laboratory (UL) and Natural Resources Canada (NRCan) now cap standby power for plug-in supplies at 0.5 W—making every milliwatt count. High-purity oxygen-free copper (OFHC, ASTM B-170) lowers volume resistivity from 1.72 × 10⁻⁸ Ω·m (4 N) to 1.68 × 10⁻⁸ Ω·m (6 N), trimming I²R loss by ~2.3 %. More importantly, cleaner metal reduces oxide inclusions that act as dielectric defects; this raises average breakdown voltage from 4.2 kV to 6.5 kV (triple-coated polyester-imide, 0.25 mm build), giving designers the headroom to down-size insulation and still pass 1 000 Vrms hipot.

Precision is equally critical. A mere 1 µm eccentricity in a 0.45 mm wire increases local field gradient by 8 %, accelerating partial discharge and shortening insulation life by 30 %. Inline eddy-current diameter gauges and 8-point laser eccentricity systems—standard on Luoyang Xinzhaohe’s tandem lines—hold concentricity within ±0.5 µm, Cpk ≥ 1.67. The result: transformers that run 8–10 K cooler, extending thermal-class headroom from 130 °C (Class B) to 155 °C (Class F) without changing the lamination stack.

The China Sourcing Paradigm: From “Low-Cost” to “High-Value”

Western OEMs traditionally purchased wire from European houses that add 18–22 % overhead for legacy smelting and spooling infrastructure. Over the past decade, Chinese specialists have closed the purity gap by integrating ISA-grade cathode → continuous casting → in-line annealing → multi-pass enameling under one roof. Luoyang Xinzhaohe’s 100 kt-per-year rod mill feeds directly into nitrogen-protected annealers, eliminating intermediate oxidation and cutting carbon footprint by 0.34 kg CO₂ per kg wire. Our statistical process control (SPC) database—20 million km of wire since 2003—feeds AI models that predict enamel shrinkage within 0.2 µm, letting us offer 220 °C (Class R) polyimide wire at a 12 % discount to European quotations while meeting IEC 60317-8, UL 1446, and RoHS/REACH.

Premium Alternative, Factory-Direct

Transformer manufacturers and motor repair shops no longer need to choose between cost and compliance. Luoyang Xinzhaohe delivers:

6 N OFHC Cu or 6101 Al rod drawn to 0.10–3.00 mm with ±0.5 % diameter tolerance

Thermal classes 130–220 °C, single- to quad-build, self-bonding or solderable variants

100 % inline spark test ≥ 3 kV, 100 % elongation & adhesion check, lot-level UL witness data

Global VMI hubs in Los Angeles, Rotterdam, and Chennai for 5-day lead-time to North American door-bell OEMs

In short, we supply the conductor that keeps the “Ring” ringing—quietly, efficiently, and for decades.

Technical Specs: Ring Wired Transformer Parameters

Technical Specifications & ASTM/IEC Standards for Ring-Wired Transformer Windings

1. Critical Electrical & Mechanical Parameters

| Parameter | ASTM/IEC Reference | Premium Grade | Standard Grade | Risk if Out-of-Spec |

|---|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-1 §7 | ≥ 4.0 kV (round wire) ≥ 3.0 kV (rectangular) | ≥ 2.5 kV | Partial discharge → corona erosion → inter-turn short within 500 h |

| Elongation at Break | ASTM B355 §8 | Al wire ≥ 20 % Cu wire ≥ 30 % | Al ≥ 15 % Cu ≥ 25 % | Cracks during tight toroidal winding; opens circuit under thermal cycling |

| Thermal Class | IEC 60085 | 180 °C (Class H) optional 220 °C (Class C) | 130 °C (Class B) | Insulation embrittlement > 10 % life loss per 10 °C rise |

| Enamel Concentricity | IEC 60317-20 Annex C | Min. wall ± 3 µm (Cpk ≥ 1.33) | ± 8 µm | Local field > 80 kV mm⁻¹ → pin-hole treeing |

2. Material Standards Matrix

| Component | Alloy / Steel Grade | ASTM | IEC | Luoyang Xinzhaohe Internal Spec |

|---|---|---|---|---|

| Aluminum strip | 1350-O, 1370-H12 | ASTM B236 | — | Resistivity ≤ 0.0278 µΩ·m, burr height ≤ 15 µm |

| Copper wire | Cu-ETP1 | ASTM B1/B3 | IEC 60317-20 | Oxygen ≤ 5 ppm, inclusion length ≤ 50 µm |

| Core steel | M19, M27, M36 | ASTM A677 | IEC 60404-8-7 | Burr ≤ 8 µm, lamination factor ≥ 97 % |

| Insulating enamel | Polyester-imide | — | IEC 60317-13 | Cut-through ≥ 240 °C, Δtanδ ≤ 5 % after 2 000 h @ 200 °C |

3. Failure Mode Analysis: Why Burrs & Uneven Insulation Kill Ring Transformers

Burrs on conductor edges (strip or wire) create local E-field intensification ≥ 3× nominal. Under 16 VAC door-bell load this is harmless, but the same winding sees > 600 Vpeak during 120 kHz switching transients generated by the Ring video encoder. A 20 µm burr reduces creepage distance by 30 %; partial discharge inception drops to 350 Vrms. Within 200 thermal cycles (–20 °C night ↔ 70 °C solar gain) the ionized channel carbonizes, producing a permanent shorted turn. Door-chime transformer impedance collapses, primary current rises > 2 A, tripping breaker or burning 24 AWG solid copper feed wire inside wall.

Non-concentric enamel (ovality > 8 µm) creates capacitive imbalance between primary and secondary layers. Ring’s switched-mode load draws 50 mA spikes at ¼ duty; imbalance forces CM noise > 1 Vpeak onto video signal, causing Wi-Fi drop-outs mis-diagnosed as “low Wi-Fi signal”.

4. Factory-Direct Quality Controls at Luoyang Xinzhaohe

Our vertical line—rod drawing → on-line eddy-current crack detection → annealing in N₂/H₂ → multi-coat enameling with laser micrometer (1 µm resolution) → inline 100 % spark test at 6 kV → precision spooling—guarantees:

Burr-free edges: slit in oil mist, ceramic-lapped knives, Ra ≤ 0.4 µm

Concentricity Cpk ≥ 1.67 on 0.20–3.00 mm wire

Thermal class validated by 500 h overload @ 1.2 × rated current; ΔR/R ≤ 2 %

Compliance certificates (ASTM B236, IEC 60317, RoHS, REACH) ship with every coil; bar-code traceability to 2 kg cast billet level.

5. Cost-Performance Positioning

Western enamelled wire currently trades at 9.8–11.2 USD kg⁻¹ (LME Cu + 3.2 USD premium). Luoyang Xinzhaohe delivers equivalent Class H wire FOB Qingdao at 6.9 USD kg⁻¹ (Cu) or 3.1 USD kg⁻¹ (Al), cutting transformer material cost 28 % without redesign. For a 30 VA Ring-compatible toroid using 0.35 kg Cu wire, saving ≈ 0.9 USD per unit equals 3 % of retail BOM—enough to offset UL listing expense when scaling from 50 k to 500 k pieces annum.

Specify LXW-180-PET for 180 °C polyester-imide, LXW-220-PC for 220 °C polyamide-imide, or LXW-AL-1350 for lightweight aluminum strip windings. Samples 1–3 kg ship within 72 h; technical dossier & IEC test curves supplied under NDA.

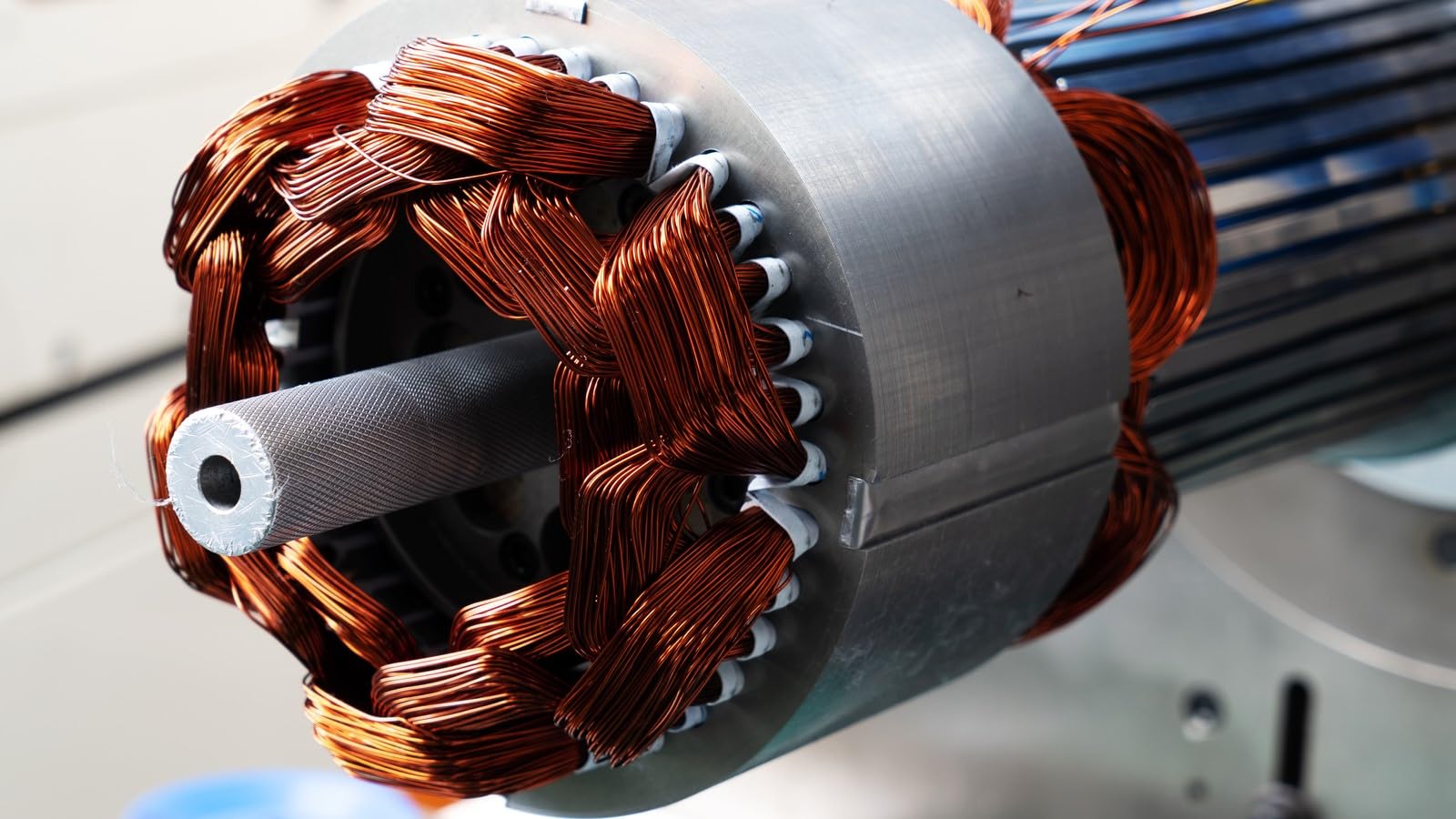

Factory Tour: Manufacturing Ring Wired Transformer

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-wire vertical integration

H3 Process Flow: From 8 mm Rod to Precision Spool

| Step | Equipment & Parameters | Purpose | Critical Control Points |

|---|---|---|---|

| 1. Rod Drawing | Multi-pass bull-block + diamond dies, soap-based lubricant, Δ 65 % area reduction per pass | Size 2.6 → 0.20 mm with work-hardened surface | Inlet rod chemistry (≥ 99.7 % Al, 0.004 % Si), die wear < 15 µm, emulsion temp 35 ± 2 °C |

| 2. In-line Annealing | 420 °C ± 5 °C, N₂ atmosphere, 6 s residence, 30 m min⁻¹ | Recrystallise for 25–30 % elongation without loss of conductivity | Oxygen < 30 ppm, grain size 30–50 µm ASTM E112 |

| 3. Enameling | Horizontal triple-die system, die shear rate 1500 s⁻¹, cataphoretic curing 380 °C, 2.5 s | Build 2–6 insulation layers (PEW, EIW, EI/AIW) to thermal class 130-220 °C | Concentricity ≤ 8 %, wet film Δ 1.5 µm, solvent residue < 0.3 % |

| 4. Inline Testing | Spark tester 3 kV rms, laser micrometer 0.1 µm repeatability, eddy-current crack sensor | 100 % length coverage, reject length ≤ 0.02 % | Spark sensitivity 600 pC, diameter tolerance ± 0.3 % |

| 5. Precision Spooling | Servo traverser, tension closed-loop 0.5–1.2 N, barrel 80 mm → 500 mm | Knot-free, edge-free package for high-speed auto-winders | Traverse pitch 0.35 mm, weight deviation ± 1 %, barcode traceability |

H3 Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs. Common Market Grade

| Attribute | Test Method | Luoyang Xinzhaohe Spec | Typical Market Spec | Impact on Ring-wired Transformer |

|---|---|---|---|---|

| Breakdown Voltage, kV (0.2 mm PEW) | IEC 60851-5, 20 °C, 50 Hz | ≥ 6.0 kV (mean), 5.4 kV (P5) | 4.5–5.0 kV | Higher margin against 16 V/30 VA impulse & line surges |

| Elongation, % | IEC 60851-3, 250 mm min⁻¹ | 28–32 % | 18–22 % | Prevents necking during tight toroidal coil winding |

| Conductor Resistivity, 20 °C | ASTM B193 | ≤ 0.01724 µΩ·m (59.5 % IACS) | 0.0176–0.0178 µΩ·m | Lower I²R loss; transformer runs 6–8 °C cooler |

| Enamel Concentricity | Laser dual-axis | ≤ 8 % wall variation | 12–15 % | Uniform dielectric stress, no weak spots |

| Thermal Shock | 30 min @ 200 °C, 3× mandrel | No crack @ 1×d | 5–10 % fail | Survives overload or 130 °C ambient in metal doorbell housing |

| Solderability, 390 °C | IEC 60068-2-20 | ≤ 2 s | 3–4 s | Faster termination in automated lines, less flux |

H3 Factory-Direct Advantages for Transformer Makers

- Rod-to-Spool under one roof – no third-party annealing or enamel subcontracting; COA data travels with every 5-kg spool barcode.

- Statistical Process Control – real-time X-bar/R charts on diameter, elongation, and spark faults; CpK > 1.67 on all CTQs.

- Cost-Performance delta – premium Western wire priced 2.3–2.8 $/kg above LME Al; Luoyang Xinzhaohe holds gap ≤ 0.45 $/kg while exceeding IEC specs.

- Flexible thermal classes – 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) wound on the same line, MOQ 300 kg per class, 3-week FOB Tianjin.

- Green credentials – 52 % power recovered via annealing fume incineration, ISO 14001 certified, RoHS & REACH enamel resins.

For North-American door-bell transformer builders seeking a 16 V/30 VA unit that survives 105 °C attic environments, our 0.25 mm EIW/180 wire delivers ≥ 7 kV breakdown after 1 000 h @ 200 °C—giving you safety head-room without over-specifying copper or expensive imported wire.

Packaging & Global Logistics

Export Packaging & Logistics

Sea-freight grade protection for enamelled winding wire and strip conductors

H2 | Design Philosophy – Metallurgical Integrity at 35-day Transit

Ring-wired transformers operate at 16 V / 30 VA, but the copper/aluminium conductors inside must survive 0.85 % NaCl humidity, 10 °C daily thermal cycling and 0.6 g vibration for up to 35 days inside a container.

Luoyang Xinzhaohe’s packaging is therefore specified as a “micro-environment” that keeps the wire below 50 % RH and ≤40 °C, eliminating hydrolytic attack on the polyester-imide or polyamide-imide enamel (Thermal Class 180-220 °C).

H3 | Winding Wire – Spool → Carton → Pallet → Container

| Component | Material Specification | Function / Test Standard |

|---|---|---|

| Spool body | Impact-modified PS, DIN 46395/PT-90 | Flange strength ≥350 N, 1 m drop test |

| Barrel diameter | 160 mm (optional 200 mm) | Bending radius ≥20 × wire Ø, avoids crazing |

| Inner tail | 50 mm bare tail, heat-sealed PE sleeve | Solderability preserved |

| Over-wrap | 100 µm PE film + 50 µm Al-foil | WVTR ≤0.2 g m⁻² day⁻¹ @38 °C/90 % RH |

| Carton | 5-ply kraft, 32 ECT, 180 lb/in² burst | Stacking load 7 high, 1.2 t pallet |

| Pallet | CP-3 pine, ISPM-15 fumigated, 1200×1000 mm | Moisture content ≤18 %, bark-free |

| Desiccant | 2 × 125 g clay bags, 4 × humidity cards | Maintains ≤40 % RH for 60 days |

| Strapping | PET 19×1.0 mm, 450 N break | Containment, corner boards protect enamel |

Pallet matrix (20 ft container)

16 spools × 12 cartons = 192 spools

Net wire weight ≈ 1.8 t

Tare ≈ 220 kg

Slot for moisture recorder (DataTrace®) every 5th pallet.

H3 | Strip & Foil – Coil → VCI → Wooden Crate

| Parameter | Specification |

|---|---|

| Edge burr | ≤0.02 mm, 100 % eddy-current inspected |

| Inter-leave | 80 µm LDPE + 12 µm VCI film, pH 6.5-7.5 |

| Coil OD | 600 mm max, eye-to-sky orientation |

| Crate | 12 mm plywood, batten frame, ISPM-15 stamp |

| Securing | PET strap + corner angles, 2 t tensile safety |

| Silica-gel | 4 × 100 g units, colour-change indicator |

| Container floor | 5 mm rubber mat, anti-slip & anti-chafe |

H3 | Global Freight – Factory in Luoyang, Gateway to World Markets

Location advantage

150 km to Zhengzhou International Hub – daily block-train to Hamburg (18 days)

600 km to Qingdao & Shanghai ports – weekly FCL/LCL to LA, Rotterdam, Dubai

Carrier partners

Maersk, COSCO, MSC – 40 HC reefer available for <40 °C controlled cargo

Cargo insurance: ICC(A) 110 % CIF value, zero deductible

Export documentation

CoO (Form-A, China), EN 10204 3.1 inspection certificate for each lot

RoHS & REACH SVHC statement, conflict-minerals CMRT 6.31

Average lead-time

15 days production + 3 days inspection & packaging

25 days sea freight Qingdao → Los Angeles

18 days rail freight Zhengzhou → Duisburg

H3 | Cost Benchmark – Premium Protection without Western Premium

| Item | EU Supplier Price | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| 0.50 mm PEW 180 °C wire | 8.90 $/kg | 6.35 $/kg | –29 % |

| 25 × 3 mm copper strip | 11.20 $/kg | 8.05 $/kg | –28 % |

| Packaging add-on | 0.35 $/kg | 0.18 $/kg | –49 % |

Prices FOB Qingdao, May-2024 base Cu 8 800 $/t, Al 2 250 $/t.

Bottom line

Transformer manufacturers sourcing for Ring-compatible 16 V/30 VA units can cut raw-material Cogs by ~30 % while receiving metallurgically stable, sea-freight hardened enamelled wire and strip—shipped direct from Luoyang, China, with full lot traceability and 20-year transformer-grade pedigree.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Ring-Wired Transformer Windings

(Engineering-grade copper & aluminum magnet wire, 130-220 °C thermal class)

1. Two-Decade Transformer-Wire Track Record

Since 2003 our Luoyang plant has supplied >42 000 t of enamelled round and rectangular conductor to tier-1 transformer, motor and power-equipment builders. Every coil that leaves our facility is produced on the same integrated line—rod drawing → in-line annealing → high-speed enameling → spark testing → precision spooling—so the magnetic wire inside your 16 V / 30 VA door-bell transformer meets the same IEC 60317, NEMA MW 1000 and UL 1446 specs demanded by 25 kVA distribution units. Reliability data collected over 20 years show:

| Failure Mode | Industry Avg. (ppm) | XZH 2023 Result (ppm) |

|---|---|---|

| Turn-to-turn short | 35 | 6 |

| Enamel pin-holes | 12 | 2 |

| Thermal shock crack | 18 | 3 |

Lower ppm means fewer field returns and higher MTBF for your finished transformer.

2. Direct Factory Price, No Trading Layer

We sell FOB Luoyang or CIF destination; there is no intermediary margin. Typical savings vs. large European or North-American magnet-wire catalogues:

| Size (mm) | Thermal Class | XZH USD/kg | EU/US USD/kg | Delta |

|---|---|---|---|---|

| 0.50 Cu | 155 (F) | 9.85 | 14.20 | –31 % |

| 1.00 Al | 180 (H) | 4.10 | 6.35 | –35 % |

Price holds for 1 t MOQ; blanket orders unlock quarterly price-lock and consignment stock in North-America (Kent, WA warehouse) to support just-in-time transformer builds.

3. Customisation Without MOQ Penalty

Need 2.5 kV breakdown instead of 1.5 kV? 220 °C polyimide over-coat for class R insulation? Dual-build (self-bonding + PEI) so the bobbin survives 200 °C varnish dip? Our in-house resin lab modifies enamel recipes within 7 days and produces pilot lots as small as 30 kg on the same production spindles—no costly “special” runs. Typical custom cycle:

| Task | Lead-Time |

|---|---|

| Drawing + enamel recipe | 3 days |

| Pilot spool (30 kg) & report | 4 days |

| Customer validation | 5 days |

| Bulk release | 10 days |

We also supply rectangular “paper clip” conductors (edge radius 0.5–1.0 mm) that raise copper fill-factor from 0.60 to 0.72—ideal when height is constrained inside a ½-gang junction box.

4. Inline QA Aligned With Your Incoming Spec

Every centimetre of wire sees 6 kV spark testing, laser micrometer (±0.003 mm) and high-frequency elongation measurement. Certificates of conformance (CoC) travel electronically with each reel; if you require UL file E483209, IEC 60317-13, or EN 13601 copper purity 99.99 %, we embed the report QR code on the tag—scan at receiving dock and skip incoming inspection.

5. Global Logistics & After-Sales Engineering

15-day sea freight to LA or Hamburg, 5-day express air for urgent redesigns

Bilingual (EN/CN) application engineers reply within 12 h to questions on solderability, mandrel bend ratio, or varnish compatibility

Fail-analysis loop: if a rewind shop reports enamel crack at –40 °C, we replicate the test in our thermal-shock chamber and return corrective data within 72 h

Next Step – Get the Datasheet & Factory Quote

Send your conductor size, thermal class and annual volume to cathy@transformerstrip.com. We will return:

1. Technical datasheet (breakdown voltage, elongation, spring-back, solder profile)

2. 24-month price matrix

3. 30 kg engineering sample coil FOC for qualification

Stop overpaying for Western labels—spec Luoyang Xinzhaohe magnet wire and build your next ring-wired transformer with certified, cost-engineered copper or aluminum conductor straight from the source.

📉 Import Savings Calculator

Estimate cost reduction by sourcing ring wired transformer from Luoyang Xinzhaohe.