Table of Contents

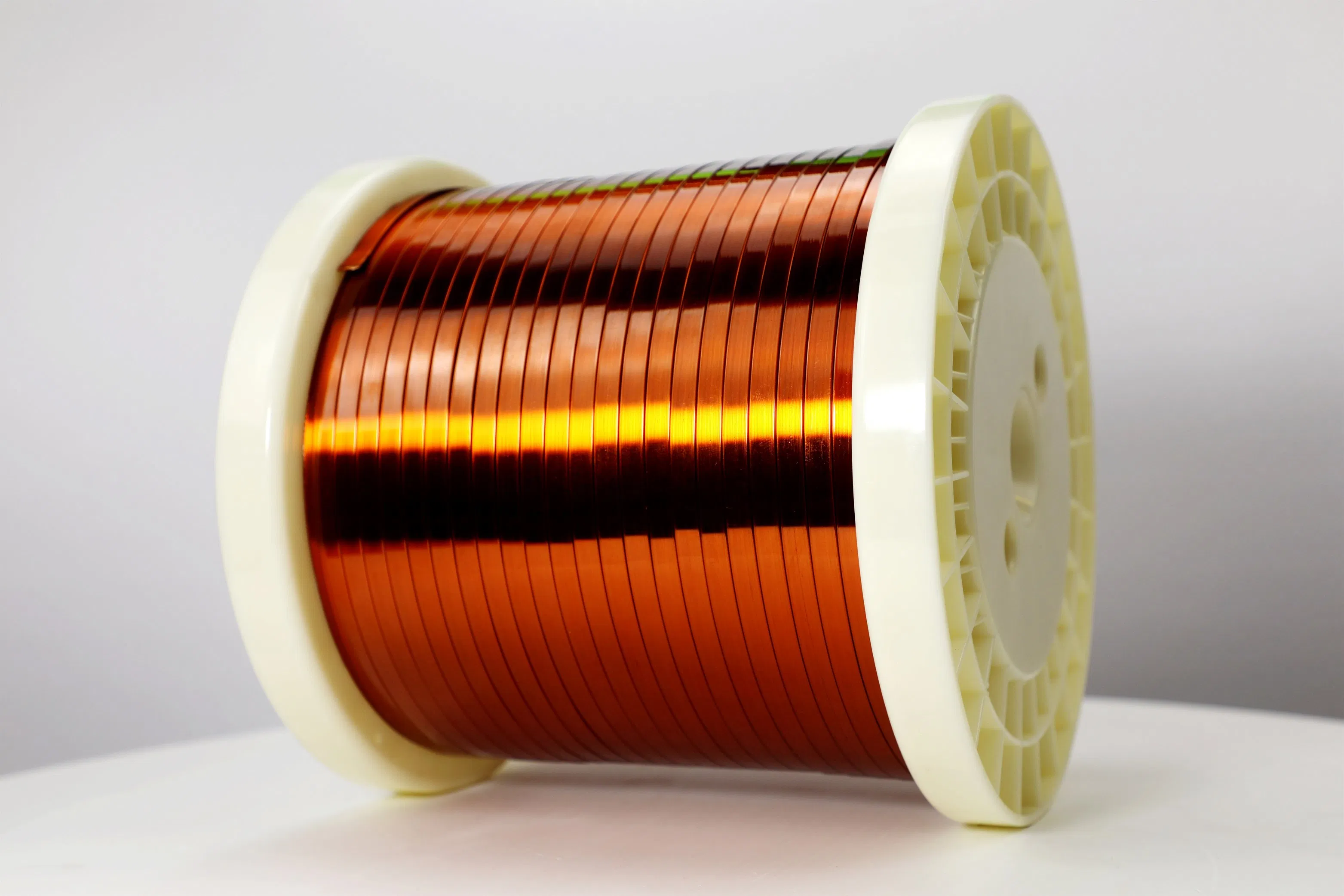

Market Insight: Rectangular Enamelled Copper Wire

Market Analysis: Winding Wire – Demand for Rectangular Enamelled Copper Wire in Transformers

The global demand for rectangular enamelled copper wire (RECW) continues to grow, driven primarily by advancements in power infrastructure, industrial automation, and renewable energy systems. Within the winding wire segment, RECW is a critical material in the manufacturing of high-efficiency transformers, particularly dry-type distribution and traction transformers used in urban power networks, rail transit, and industrial motor drives. Its rectangular cross-section enables superior space utilization in winding slots, resulting in higher fill factors and improved thermal conductivity compared to round wire alternatives. This geometric advantage directly enhances the power density and operational efficiency of transformer windings, making RECW an indispensable component in modern electrical engineering applications.

Transformers serve as the backbone of electrical power transmission and distribution, and their performance is heavily influenced by the quality of materials used in construction. The use of high-purity electrolytic tough pitch (ETP) copper as the base conductor ensures low electrical resistivity, minimizing I²R losses and supporting energy-efficient operation. However, the insulation system—typically a multi-layer polymer coating such as polyurethane, polyesterimide, or polyamide-imide—is equally critical. These enamel coatings must exhibit excellent dielectric strength, thermal stability (rated up to Class 200°C or higher), mechanical robustness during winding, and long-term resistance to thermal cycling and environmental degradation. Inadequate insulation performance can lead to inter-turn short circuits, partial discharges, and premature transformer failure, especially under high-voltage or high-frequency operating conditions.

Quality control in RECW production is therefore non-negotiable. Dimensional precision—including tight tolerances on width, thickness, and corner radii—is essential to ensure uniform winding tension and prevent insulation damage during coil fabrication. Surface smoothness of the enamel layer reduces friction and abrasion during high-speed winding processes, while consistent coating thickness prevents weak spots that could compromise dielectric integrity. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced conductor manufacturing, we apply rigorous in-line monitoring and batch testing protocols to ensure compliance with international standards such as IEC 60317, GB/T 23312, and NEMA MW 1000. Our RECW products undergo continuous testing for breakdown voltage, thermal shock resistance, flexibility, and solderability to guarantee reliability under demanding service conditions.

The shift toward smart grids, electric mobility, and energy-efficient industrial equipment further intensifies the demand for high-performance transformers. As system voltages increase and footprint constraints tighten, the role of precision-engineered RECW becomes increasingly strategic. Manufacturers who prioritize material quality not only enhance transformer reliability and lifespan but also contribute to broader energy conservation goals. In this evolving landscape, sourcing RECW from technically capable and quality-focused suppliers is a decisive factor in maintaining competitive advantage and ensuring long-term operational success.

Technical Specs: Rectangular Enamelled Copper Wire

Technical Specifications: Rectangular Enamelled Copper Wire for Precision Winding Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and winding wire manufacturing expertise to deliver rectangular enamelled copper wire meeting stringent global industrial standards. This conductor geometry optimizes space utilization in stator/rotor windings, transformers, and inductors, directly enhancing power density and thermal efficiency versus round wire equivalents. Critical performance parameters must be rigorously controlled to ensure reliability under high-stress electromagnetic and thermal cycling conditions.

Insulation breakdown voltage is non-negotiable for electrical safety and longevity. Our wires undergo 100% testing per IEC 60851-5, with minimum AC breakdown voltages scaled to insulation thickness. For standard single-build insulation (0.05–0.12mm), breakdown exceeds 2.5 kV; double-build variants (0.10–0.25mm) achieve ≥4.5 kV. This performance is validated at 50 Hz, 60-second dwell time, ensuring dielectric integrity even with tight coil bends. Thermal class defines operational temperature limits and directly correlates with insulation polymer chemistry. We supply wires compliant with IEC 60317 classifications from 130°C (Class B) up to 220°C (Class R), utilizing advanced polyamide-imide, polyester-imide, or silicone-modified resins. Each class undergoes 20,000-hour thermal aging per IEC 60172 to confirm life expectancy at maximum continuous temperature.

Elongation (%) is critical for mechanical resilience during high-speed winding and thermal expansion cycles. Values are temper-dependent: hard-drawn wire maintains 2–4% elongation for dimensional stability, while soft-annealed grades reach 15–25% to accommodate complex coil geometries without cracking. All conductors adhere to IACS conductivity standards (≥100% IACS minimum), with resistivity strictly controlled at ≤0.017241 Ω·mm²/m at 20°C. Adhesion strength (tested via mandrel wrap to IEC 60851-3) ensures insulation remains intact during winding tension spikes.

Key Technical Parameters for Rectangular Enamelled Copper Wire

| Parameter | Value Range | Test Standard | Notes |

|---|---|---|---|

| Conductor Dimensions | Width: 1.0–8.0 mm; Thickness: 0.5–3.0 mm | IEC 60122 | Tolerance: ±0.02 mm (width/thickness) |

| Thermal Class | 130°C (B) to 220°C (R) | IEC 60317 | Polyamide-imide base for ≥180°C |

| Breakdown Voltage (AC) | ≥2.5 kV (single-build) | IEC 60851-5 | Per 0.1 mm insulation thickness |

| ≥4.5 kV (double-build) | |||

| Elongation | 2–4% (hard-drawn) | IEC 60851-4 | Optimized for high-speed winding |

| 15–25% (annealed) | For complex coil geometries | ||

| Conductor Resistivity | ≤0.017241 Ω·mm²/m @ 20°C | IEC 60468 | ≥100% IACS conductivity |

| Adhesion | Pass (no flaking/delamination) | IEC 60851-3 | Mandrel diameter = 4x wire thickness |

All specifications are validated under controlled atmospheric conditions (23°C, 50% RH) per IEC 60028. Consistency in cross-section uniformity (verified via laser micrometry) prevents localized heating in high-current applications. Our production integrates real-time metallurgical process control to eliminate micro-voids in copper and ensure enamel cohesion. For mission-critical applications, we recommend thermal class 180°C (H) or higher with double-build insulation to mitigate partial discharge risks in inverters and traction motors. Contact our engineering team for custom temper profiles or hybrid insulation systems meeting UL 1446 or GB/T 6109 requirements.

Factory Tour: Manufacturing

Manufacturing Process of Rectangular Enamelled Copper Wire

The production of rectangular enamelled copper wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment and real-time quality monitoring to deliver high-performance winding wire suitable for demanding applications in motors, transformers, and high-efficiency electrical systems.

The process begins with high-conductivity electrolytic tough pitch (ETP) copper rod, conforming to IEC 60086 and ASTM B3 standards. The rod is first subjected to precision rod drawing, where it is reduced in diameter through a series of diamond or tungsten carbide dies under controlled tension and lubrication. This cold working process transforms the round rod into a rectangular cross-section with tight tolerances on width, thickness, and edge radius. Dimensional consistency is maintained through laser micrometer feedback systems that continuously monitor profile geometry and adjust drawing parameters in real time.

Following drawing, the rectangular wire undergoes a continuous annealing process in a controlled atmosphere furnace. The annealing stage restores ductility lost during cold drawing by recrystallizing the copper microstructure. Our inline induction-heated annealing system operates under a nitrogen-hydrogen atmosphere to prevent oxidation and ensure a clean, oxide-free surface—critical for optimal enamel adhesion. Temperature profiles are precisely regulated to achieve uniform metallurgical softening, resulting in a final temper that meets IEC 60172 requirements for fully annealed (soft) copper.

The annealed wire then proceeds to the enameling line, where multiple layers of polymer insulation are applied via dip-coating or die-coating methods. Depending on the insulation class (e.g., Class 130, 155, 180, or 200), formulations may include polyurethane, polyesterimide, polyamide-imide, or hybrid systems. Each coat is immediately cured in a series of high-temperature ovens with precisely controlled residence times and temperature gradients to ensure complete cross-linking and eliminate volatile residues. Up to four enamel layers can be applied in succession to achieve the required build thickness and dielectric strength.

Throughout the enameling process, inline testing systems continuously monitor critical parameters. These include spark testing at 3 kV to detect pinholes, diameter measurement via laser gauges, and tension control to prevent deformation. Additional quality control checkpoints include adhesion testing (tape test), thermal shock resistance, and dielectric breakdown voltage verification. Final samples undergo batch-level testing for elongation, springback, and solderability to confirm compliance with international specifications.

This integrated approach to manufacturing ensures that each meter of rectangular enamelled copper wire produced meets the highest standards of performance, consistency, and reliability required in modern electromagnetic winding applications.

Packaging & Logistics

Export Packaging Specifications for Rectangular Enamelled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for rectangular enamelled copper wire to ensure product integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our methodology addresses the dual threats of mechanical stress and moisture ingress inherent in sea freight. All shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, knot-free coniferous timber. These pallets feature a minimum load-bearing capacity of 2,500 kg and dimensions standardized at 1,200 mm × 1,000 mm to optimize container space utilization while preventing deformation under stacked loads. Each pallet undergoes anti-corrosion treatment and is fitted with chamfered edges to eliminate wire abrasion risks during handling.

The core moisture protection system employs a triple-layer barrier strategy. Wire reels are first sealed within 125μm-thick, metallized polyester moisture-proof film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/day at 38°C and 90% RH. This film is heat-sealed under vacuum conditions to expel ambient humidity, followed by the strategic placement of silica gel desiccants calculated at 10% of the cargo’s net weight. A secondary outer wrap of polyethylene stretch film provides puncture resistance against container handling impacts. Critical to this process is the verification of seal integrity via dew point testing, ensuring internal relative humidity remains below 30% throughout voyages exceeding 45 days.

Maritime safety is further enhanced through dynamic load stabilization. Palletized units are secured using steel strapping at 800 kgf tension, anchored to container floors via anti-slip rubber mats and cross-braced with timber dunnage. This configuration mitigates lateral movement during vessel roll, validated through ASTM D4169 vibration testing simulating Pacific and Atlantic routes. Our protocol explicitly prohibits direct contact between wire reels and container walls to prevent condensation transfer, a common cause of enamel delamination in polyurethane-imide insulated grades.

Xinzhaohe’s packaging framework aligns with IMO MSC/Circ.1046 guidelines for hazardous cargo prevention, though copper wire shipments fall under non-hazardous classification. All documentation includes moisture barrier certification, desiccant placement logs, and pallet treatment certificates to expedite customs clearance. Field data from 500+ shipments confirms a 99.8% integrity rate for enamel insulation layers, directly attributable to this system. Clients receive digital moisture logs via IoT sensors upon request, providing real-time RH monitoring from factory to port discharge. This end-to-end control eliminates the hygroscopic degradation risks that compromise dielectric strength in improperly packaged winding wire, safeguarding your downstream manufacturing yield.

For extended transits exceeding 60 days, we recommend optional nitrogen purging within the primary film layer—a solution deployed in 30% of our Southeast Asian shipments to counter monsoon humidity. Xinzhaohe’s packaging is not merely compliant but engineered to exceed IEC 60317-0-7 environmental resilience benchmarks, ensuring your rectangular enamelled copper wire arrives with unimpaired electrical and mechanical properties.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Rectangular Enamelled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the design, production, and supply of precision winding materials, including high-grade rectangular enamelled copper wire. As a trusted partner in the global electrical manufacturing supply chain, we combine advanced metallurgical engineering with rigorous quality assurance to deliver products that meet the exacting demands of transformers, motors, generators, and high-efficiency inductors.

Our production facility is equipped with fully integrated wire drawing, annealing, and enamel coating lines, enabling end-to-end process control from copper rod to finished rectangular wire. We utilize oxygen-free copper (OFC) with a minimum purity of 99.99%, ensuring optimal electrical conductivity and mechanical ductility. The rectangular profile is precision-drawn using multi-stage dies calibrated to maintain tight dimensional tolerances—typically within ±0.02 mm on width and thickness—critical for high fill factor in winding applications. Each wire batch undergoes continuous monitoring via laser micrometers and automated diameter feedback systems to guarantee consistency across production runs.

The enamel insulation system is applied using a multi-layer solvent-based coating process, typically comprising a base layer of polyurethane (PU) or polyamide-imide (PAI), with optional overcoats of polyesterimide (PEI) for enhanced thermal endurance. Our standard insulation withstands temperatures up to 200°C (Class F) and can be customized to meet Class H (180°C) and higher specifications. Dielectric strength is routinely tested to exceed 4 kV AC per layer, with pinhole density maintained below 0.3 defects per meter. All coatings exhibit excellent adhesion, thermal shock resistance, and compatibility with varnish impregnation and vacuum pressure infiltration (VPI) processes.

Quality assurance is embedded at every stage. Our in-house laboratory conducts routine testing on tensile strength, elongation, springback, and thermal aging performance in accordance with IEC 60317, ASTM B354, and GB/T 23311 standards. Full traceability is maintained through batch coding and material certification, with options for third-party inspection and SGS reports upon request.

With an annual production capacity exceeding 8,000 metric tons and a flexible manufacturing setup capable of handling cross-sections from 1.0 mm × 3.0 mm up to 6.0 mm × 16.0 mm, we support both high-volume OEM contracts and specialized project-based orders. Our supply chain is optimized for reliability, with strategic raw material reserves and partnerships with certified copper suppliers ensuring stable lead times even under market volatility.

For engineering teams and procurement managers seeking a technically capable, responsive, and scalable partner in winding wire solutions, Luoyang Xinzhaohe offers proven performance and industrial-grade consistency. We invite you to leverage our metallurgical expertise and manufacturing precision to enhance your product reliability and production efficiency.

Contact us today at cathy@transformerstrip.com to discuss your rectangular enamelled copper wire requirements.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing rectangular enamelled copper wire directly from China.