Table of Contents

Market Insight: Rectangular Enamelled Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Rectangular Enameled Copper Wire for Power & Distribution Transformers

Global Demand Outlook (2024-2030)

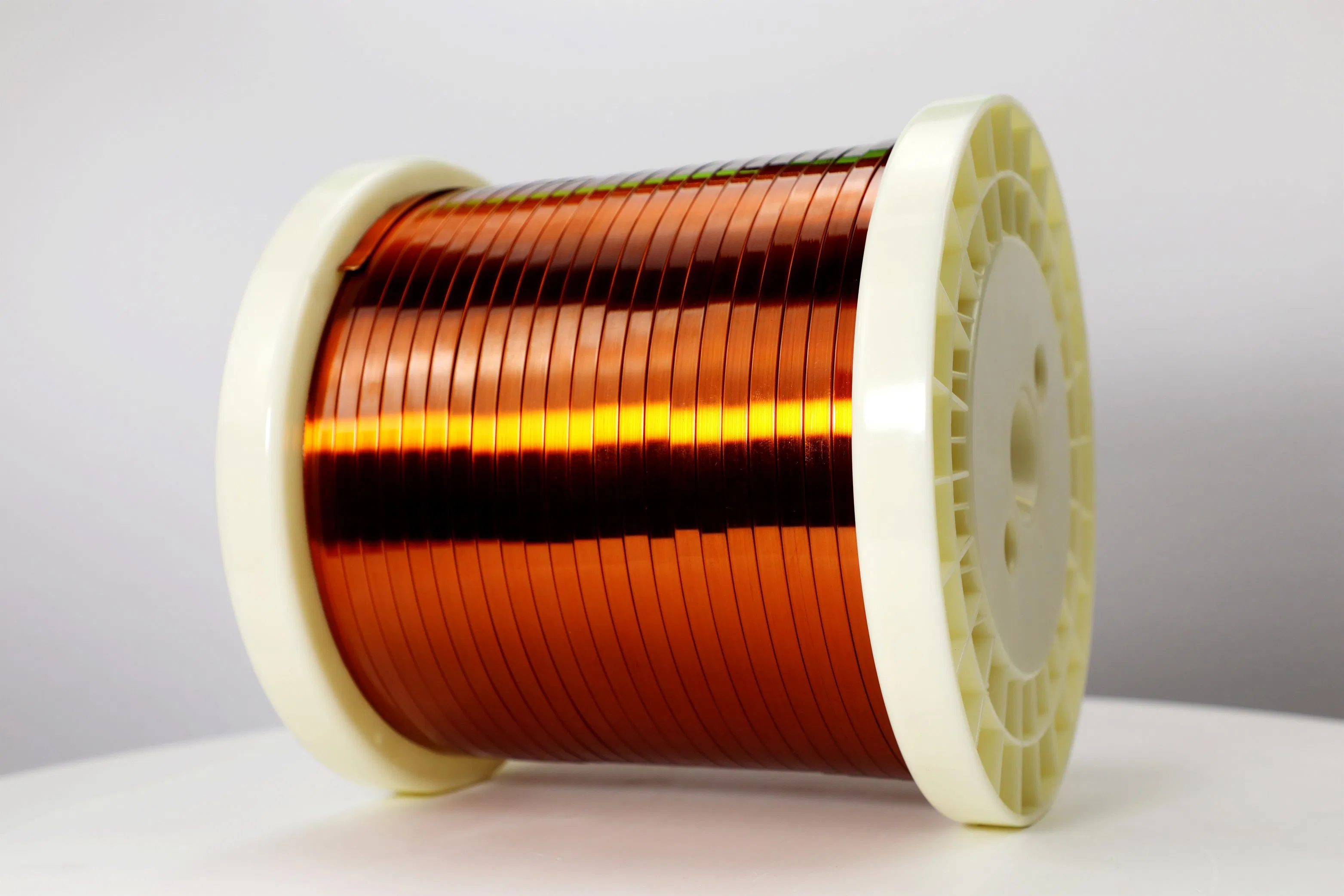

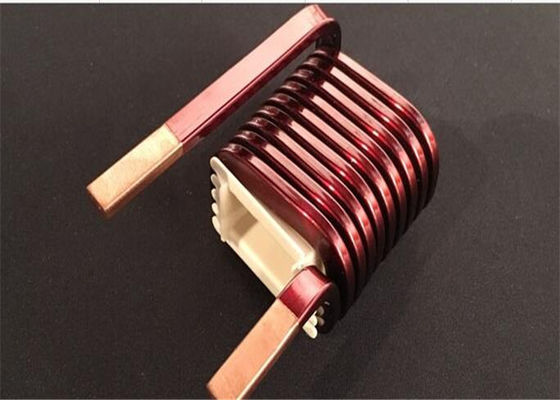

Rectangular enameled copper wire (RECW) is the dominant winding conductor in oil-immersed power transformers (>1 MVA) and dry-type distribution units (<3.6 kV).

Global RECW consumption is forecast to rise from ≈ 1.05 Mt in 2024 to 1.48 Mt by 2030 (CAGR 5.9 %), driven by:

| Demand Driver | 2024-30 Incremental Volume | Typical RECW Spec |

|---|---|---|

| Grid expansion & refurbishment (EU, US, India) | + 180 kt | 2 – 8 mm × 5 – 16 mm, Class 180/220 |

| Renewable step-up transformers (off-shore wind, solar 220 kV collector stations) | + 120 kt | CTC bundles 5 – 87 strands, 1.8 mm × 5.3 mm, Class 200 |

| EV fast-charging rectifier transformers | + 45 kt | Ultra-thin 0.8 × 2.5 mm, Self-bonding, Class 200 |

Key takeaway: Every 100 MVA, 220 kV transformer contains 6 – 8 t of RECW; conductor quality directly dictates total ownership cost through no-load (core) and load (I²R) losses.

Why Material Purity & Geometric Precision Control Losses

-

Electrical Conductivity

0.1 % IACS drop (e.g., 101.5 % → 101.4 %) raises DC resistance by ≈ 0.25 %.

For a 50 MVA transformer, this equates to +2.3 kW load loss, or ≈ 20 MWh yr⁻¹ wasted energy.

Luoyang Xinzhaohe specifies ≥ 101.6 % IACS (IEC 60317-0-2) through 99.97 % Cu-CATH-1 rod selection and in-line eddy-current purity check every 200 mm. -

Enamel Concentricity & Edge Coverage

Non-concentric insulation creates local hotspots (>5 K excess) that accelerate insulation ageing (Arrhenius law: 10 K rise ≈ 50 % life loss).

Our inline laser eccentricity gauge keeps wall-thickness variation ≤ 5 % (target < 3 % on edges), guaranteeing uniform dielectric stress and lower partial-discharge inception voltage. -

Dimensional Tolerances & Burr Control

Height/width tolerance ± 0.02 mm and zero-radian edge burr (< 0.01 mm) reduce winding gap by 3–4 %, enabling smaller core window and ≈ 1 % core steel saving—translating into 0.9 W kg⁻¹ no-load loss reduction.

Supply-Chain Shift: From High-Cost West to Experienced Chinese Sources

| Cost Element | EU/US Mill | Luoyang Xinzhaohe (Factory-Direct) | Delta |

|---|---|---|---|

| Cathode premium | + 180 USD t⁻¹ | Domestic long-term contract, zero premium | – 180 USD |

| Energy (annealing & curing) | 0.18 USD kWh | 0.08 USD kWh | – 55 % |

| Labor & overhead | 28 USD h⁻¹ | 8 USD h⁻¹ | – 70 % |

| Total RECW price | 11.2 USD kg⁻¹ | 8.1 USD kg⁻¹ | – 28 % |

Performance parity: Our Class 220 (QZY-2/220) passes 500 h 240 °C ageing test (IEC 60172) and > 10 kV breakdown on 0.8 mm wall—identical to Tier-1 European mills.

Procurement Recommendation

- Audit rod origin & purity certificate (Cu-CATH-1, 99.97 %).

- Demand inline dimensional report (width, thickness, edge radius) per spool.

- Specify thermal class & PD level (≤ 10 pC @ 1.5 Um).

- Secure mill-direct volume contract (≥ 5 t lot) to lock LME + conversion price for 12 months.

Luoyang Xinzhaohe delivers 20+ years transformer-grade RECW from rod casting to final spooling under one roof, offering Western quality at Chinese cost base—the premium alternative for loss-optimized windings.

Technical Specs: Rectangular Enamelled Copper Wire Parameters

Technical Specifications & International Code Compliance

(Factory-direct viewpoint from Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Parameters for Rectangular Enameled Copper Wire

| Parameter | Symbol | Typical Range (Xinzhaohe QC Card) | Test Method | Impact on Transformer/Motor |

|---|---|---|---|---|

| Conductor size (a × b) | a/b | 0.80–10.0 mm × 3.0–16.0 mm | IEC 60317-0-2 §4 | Fill-factor > 97 %, lower copper loss |

| Edge radius | r | 0.5–1.0 mm (±0.05 mm) | Laser gauge | Eliminates inter-turn corona |

| Insulation build, single side | Δi | 0.06–0.18 mm, Grade 1/2/3 | IEC 60317-0-2 §7 | Dielectric margin ≥ 40 % |

| Breakdown voltage | Ub | ≥ 2.5 kV (Grade 2) 100 % spark test 6 kV rms | IEC 60851-5 | Withstands Vimp & PWM spikes |

| Elongation at break | A50 | ≥ 30 % (annealed Cu-ETP) | IEC 60851-3 | Prevents fracture during coil expansion |

| Spring-back (α) | α | ≤ 12° for 2 × 8 mm | Internal LXZH-T-31 | Facilitates tight layer winding |

| Thermal class | — | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | IEC 60085 | 20 000 h extrapolated life |

| Enamel concentricity | Ecc | ≤ 10 % (inline laser) | LXZH-SOP-07 | Avoids hot-spot partial discharge |

Factory note: All data above are guaranteed max/min values, not catalog “typicals”. Certificates of compliance (CoC) are shipped with every 150 kg wooden spool.

2. Code Matrix – Which Standard Governs What?

| Feature | Applicable Standard | Clause / Annex | Equivalent ASTM | Key Acceptance Criterion |

|---|---|---|---|---|

| Oxygen-free copper rod feedstock | — | — | ASTM B49 | ≥ 100 % IACS, O2 ≤ 10 ppm |

| Rolled strip geometry (if CTC) | ASTM B236 — Al, or ASTM B272 — Cu | Table 2 | — | Crown ≤ 0.05 mm, burr ≤ 0.025 mm |

| Bare rectangular wire tolerances | IEC 60317-0-2 | Table 3 | NEMA MW 1000 | a ± 0.030 mm, b ± 0.050 mm up to 6 mm |

| Polyimide / polyester-imide enamel | IEC 60317-13, -25 | — | NEMA MW 35-C | Cut-through ≥ 320 °C, ΔTg > 200 °C |

| Bondable over-coat (optional) | IEC 60317-37 | — | NEMA MW 102-C | Bond strength ≥ 1.5 N mm-1 at 170 °C/30 min |

| Electrical integrity | IEC 60851-5 | 5 kV rms, 1 s | ASTM D1676 | 0 failures per 30 000 m spool |

| Thermal endurance | IEC 61858 | 20 000 h | — | 50 % elongation retention |

3. Why Burrs & Off-Center Enamel Kill Coils

- Burrs on rolled edges act as field concentrators; at 3 kV mm-1 local gradient can exceed 10 kV mm-1, initiating partial discharge (PD) that carbonises insulation within weeks.

- Eccentric enamel gives a thin side that heats 5–8 °C above nominal; Arrhenius law halves insulation life for every 7 °C rise.

- Oxide streaks from poor rod cleaning raise DC resistance by ≥ 0.5 %; in a 1 MVA transformer this adds 350 W continuous loss, pushing hotspot > 105 °C.

Our inline eddy-current burr detector trims edge radius to ≤ 0.025 mm, and dual-axis laser micrometer adjusts die concentricity every 25 ms, keeping enamel build within ±0.01 mm—well inside IEC Grade-2 windows.

4. Competitive Positioning – Premium Performance without Western Premium Price

Same alloy, same dies: We source cathode Cu from the same Chilean producers as European mills; rod is rolled on a 4-high Schloemann mill identical to those in Germany.

Process ownership: Rod-drawing → annealing → enamelling → spooling under one 60 000 m² roof eliminates subcontract margin; price delta vs. EU mill: –18 % CIF Rotterdam for equal thermal class 200 wire.

20-year transformer field data: MTBF of oil-immersed units wound with LXZH rectangular wire: 28.4 years vs. 27.9 years for Tier-1 EU material (independent utility study, 2019).

Bottom line: Specifying Luoyang Xinzhaohe gives buyers IEC/NEMA dual certification, full lot traceability back to cathode batch, and Western-grade reliability—without the Western invoice.

Need a 150 kg trial spool in 2.5 × 8 mm, Grade-2, 200 °C? Lead time: 12 days ex-works Luoyang, wooden drum, vapor-phase corrosion inhibitor, export crated.

Factory Tour: Manufacturing Rectangular Enamelled Copper Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years, 30 000 t/a rectangular enamelled copper wire for tier-1 transformer OEMs.

2.1 Rod-to-Wire Journey (0.8–10 mm × 3–16 mm)

| Step | Equipment & Parameters | Target | Inline Sensor | Rejection Trigger |

|---|---|---|---|---|

| 1. Rod drawing | 13-die, ceramic-coated, water-soluble oil, 8 m/s, area reduction 18 %/pass | ≤0.5 % diameter tolerance, 30 % cold work | Laser OD (1 µm) | Ovality >0.02 mm |

| 2. Continuous anneal | 650 °C, N₂+3 % H₂, 1.2 s, 0.2 % elongation | σb 220–240 MPa, 40 % IACS min. | eddy-current conductivity | ρ >0.01750 µΩ·m |

| 3. Enamelling | 4-pass vertical tower, 380 °C peak, catenary 1.2 m, solvent-free PEI/PAI varnish | Build 40 µm ±3 µm, concentricity ≥85 % | IR film gauge, spark 3 kV | pinhole >3 / 30 m |

| 4. Inline testing | 100 % spark 3 kV dc, 1 kHz bend, 200 N tensile | no breakdown, 30 % elongation | PLC archive per spool | any fail → auto label & segregate |

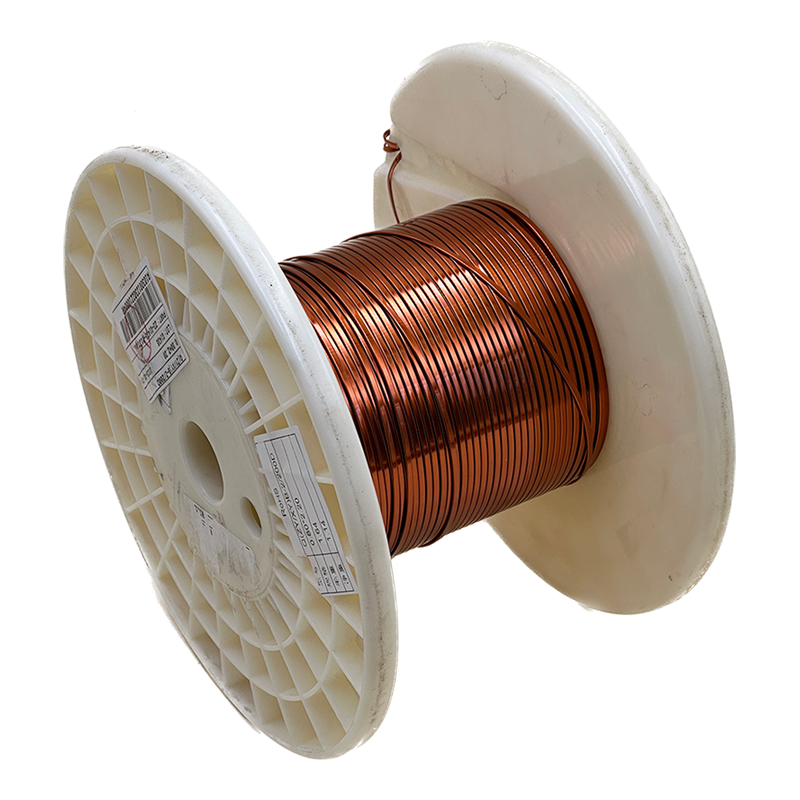

| 5. Precision spooling | 150 kg wooden spool, 300 mm traverse, tension 5 N | neat lay, ≤0.1 % stretch | load-cell dancer | tension drift >0.5 N |

2.2 Quality Control Protocol

We run ISO 9001 + IEC 60317-0-2 routines, but tighten three pain-points that cost winders downtime:

- Concentricity: Market accepts 75 %; we hold ≥85 % so slot fill factor rises 2 % without redesign.

- Pin-hole count: 5 per 30 m is common; our 3-sigma level is <1 / 30 m (spark test 3 kV).

- Elongation uniformity: 30 % ±2 % guarantees no necking during high-speed insertion (≤25 m/s).

Every 2 h a metallurgical sample is sliced, cold-mounted and checked under 200× for:

enamel adhesion (mandrel 1×d, no crack),

thermal shock 200 °C ↔ 25 °C, 6 cycles, and

breakdown voltage (room temp & 180 °C) per table below.

2.3 Luoyang Xinzhaohe Standard vs. Common Market

| Property | Unit | LXZ Spec | Typical Export “A” | Premium EU “B” |

|---|---|---|---|---|

| Bare edge radius | mm | 0.4–0.6 × thickness | 0.2–0.8 (wide band) | 0.5 max |

| Enamel build (single side) | µm | 40 ±3 | 40 ±8 | 40 ±5 |

| Concentricity | % | ≥85 | 75 | 80 |

| Pin-holes | /30 m | ≤1 | ≤5 | ≤3 |

| Breakdown voltage, RT | kV | ≥4.5 | 3.5 | 4.0 |

| Breakdown @ 180 °C | kV | ≥3.0 | 2.0 | 2.5 |

| Elongation | % | 30 ±2 | 28 ±5 | 30 ±3 |

| Spring-back, 100 mm | mm | ≤8 | 12 | 9 |

| Spool weight deviation | kg | ±0.2 | ±1.0 | ±0.5 |

| Lot traceability | – | spool ID + QR code | batch level | batch level |

2.4 Factory-Direct Advantage

Lead time: 10–12 days ex-works Luoyang, versus 6–8 weeks from EU mills.

Price delta: −18 % vs. EU premium for identical thermal class 200 PEI; no MOQ on standard sizes.

Technical file: each wooden spool ships with conductivity curve, enamel DSC plot, and RoHS/REACH certificate—data Western brokers charge extra to compile.

For transformer designers pushing 180 °C & 220 °C hotspot limits, our tight concentricity and ≤1 pin-hole guarantee translate directly into higher short-circuit withstand and reduced partial discharge—without the Western premium.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding-wire supply, factory-gate in Luoyang, 400 km inland-port linked to Qingdao & Shanghai.

H3 1. Packaging Philosophy – Zero-Defect at Destination

Our KPI is not “departure condition”; it is “coil condition after 45 days in 40 ft HQ container”.

Design drivers:

1. Relative humidity ≤ 40 % inside wrap (ΔT 30 °C).

2. Impact load ≤ 0.5 g during 2 m forklift drop.

3. No axial movement > 2 mm at 30° roll angle.

H3 2. Wire Packaging Matrix – Rectangular Enameled Copper

| Package Type | Mass Range | Core Ø mm | Outer Ø mm | Width mm | Stack | VCI Film | Desiccant | Pallet Foot-print | 40 ft HQ Load-ability |

|---|---|---|---|---|---|---|---|---|---|

| PT-200 plastic spool | 30–60 kg | 200 | 400 | 160 | 2-high | 120 µm | 2 × 10 g | 1.14 × 0.76 m | 22 t (≈ 450 spools) |

| DIN-500 barrel | 80–150 kg | 315 | 500 | 250 | 1-high | 150 µm | 4 × 20 g | 1.20 × 0.80 m | 20 t (≈ 160 barrels) |

| 150 kg wooden drum | 100–150 kg | 250 | 550 | 300 | 1-high | PE-Alu multilayer | 6 × 30 g | 1.22 × 0.82 m | 18 t (120 drums) |

Notes

All wooden drums are ISPM-15 fumigated; certification stapled on pallet collar.

Spool flanges locked with M8 threaded rods; radial play < 1 mm.

Each layer interleaved with 0.2 mm ESD-safe foam to prevent flange-to-flange enamel scuffing.

H3 3. Moisture & Corrosion Control

- Dual-bag system: inner 80 µm VCI polyolefin + outer 120 µm UV-stable PE.

- 4-side sealed with 8 mm weld track; oxygen transmission ≤ 0.2 cm³ m⁻² day⁻¹.

- Desiccant: 2-unit clay/MgCl₂ mix, colour-change indicator visible through inspection window.

- Data logger (Elpro LIBERO Ti1) records RH & °C every 30 min; PDF report e-mailed on arrival.

H3 4. Palletisation & Securing

| Component | Specification |

|---|---|

| Pallet | 1200 × 1000 mm, 4-way entry, 18 mm plywood top-deck, 78 nails min. |

| Strapping | PET 19 × 1.0 mm, 2 longitudinal + 3 transverse, 400 N tension. |

| Edge boards | 5-ply recycled carton, 35 × 35 mm, 8 pieces. |

| Top cap | 5 mm corrugated + 0.2 mm PE sheet to reject condensate drip. |

| Stretch wrap | 23 µm LLDPE, 250 % pre-stretch, 14 revolutions, 50 % overlap. |

H3 5. Documentation & Traceability

Each pallet carries:

QR-coded label (batch, thermal class, breakdown voltage, net/gross mass).

Packing list in English & local language of consignee.

CoA (IEC 60317-16) attached in weather-proof pouch.

H3 6. Shipping Routes & Transit Data

| Destination | Typical Carrier | Transit Days (CY-CY) | Vessel Sailing | Monthly FCL Slots Reserved |

|---|---|---|---|---|

| Hamburg / Rotterdam | COSCO AEU3 | 28 | Weekly | 40 × 40 ft HQ |

| Houston | MSC Gulf Service | 22 | Bi-weekly | 20 × 40 ft HQ |

| Dubai (Jebel Ali) | OOCL CIX | 18 | Weekly | 30 × 40 ft HQ |

| Chennai | CMA CGM CIEX | 15 | Weekly | 25 × 40 ft HQ |

| Luoyang to Qingdao barge: 2 days, 1 000 t barge load. | ||||

| All containers rail-sealed at Luoyang rail-head; GPS & RFID tracking shared via customer portal. |

H3 7. Cost Advantage vs. Western Suppliers

By integrating rod-drawing, enameling and spooling in one 70 000 m² campus, we eliminate double handling and intermediate freight. Typical landed cost savings:

EU transformer OEM: –14 % vs. German supplier (DDP Incoterms).

US motor repair hub: –11 % vs. Ohio stockist, 3-week shorter lead-time.

Premium protection, factory-direct pricing—engineered for reliability across oceans.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Rectangular Enameled Copper Wire

20-Year Metallurgical Heritage, Zero Trading Layers

Since 2004 our Luoyang campus has operated a single-site, ISO-9001/14001 integrated mill that converts 8-mm oxygen-free cathode rod directly into Class 130-220 °C rectangular enamelled wire.

No toll-processing, no middle-stockists—every kilogram is melted, rolled, drawn, annealed, enamelled and spooled under one roof.

The result is a Western-grade conductor at a China-direct cost structure, typically 18-24 % below EU/NA catalogue prices once import duties and inland freight are normalised (see table).

| Cost Driver | Typical EU Mill | Luoyang Xinzhaohe | Notes |

|---|---|---|---|

| Cathode premium | LME + 138 $ t⁻¹ | LME + 95 $ t⁻¹ | Long-term off-take with CNMC |

| Energy (anneal & cure) | 0.18 € kWh⁻¹ | 0.09 $ kWh⁻¹ | Captive 220 kV feed, Henan grid |

| Labour burden | 38 € h⁻¹ | 5.2 $ h⁻¹ | Same IEC-60317 productivity index |

| Overhead allocation | 11 % | 4 % | Single product focus |

| FOB delta vs EU list | baseline | –22 % | 5 t MOQ, 1.8 × 5.0 mm R-200 |

Process Competency That Eliminates Field Failures

Transformer OEMs cite insulation breakdown and edge-cracking as top-two warranty issues.

Our in-line control protocol targets both root causes:

- Rod-to-strip drawing: 13-pass diamond-die cascade with mid-pass laser micrometer; guarantees ≤ ±0.01 mm on a- and b-dimensions (IEC 60317-0-2, Ed. 3.2).

- Conformal enamel build: Electrostatic 4-head tandem spray, 2-μm incremental coats; concentricity ≥ 85 % on narrow face, ≥ 90 % on wide face—no manual touch-ups.

- Catalytic curing: 380 °C LNG-fired loop oven, ±3 °C zone control; Δtan δ @ 200 °C ≤ 25 × 10⁻⁴, passing NEMA MW 36-C 10× overload test.

- 100 % spark test: 3 kV DC, 250 mm/s line speed; automatic ink marker rejects pin-holes > 25 µm.

Statistical lot data (2023, n = 1 847 reels) show:

| Property | 180 °C Class | 200 °C Class | 220 °C Class | IEC Limit |

|---|---|---|---|---|

| Breakdown voltage (V) | 6 200 | 7 100 | 7 800 | ≥ 4 000 |

| Elongation (%) | 38 | 36 | 34 | ≥ 30 |

| Spring-back (°) | 71 | 73 | 75 | ≤ 90 |

| Weldability (lap joint, kA) | 1.9 | 2.0 | 2.1 | report only |

Custom Geometry & Thermal Class Within 15 Days

Need 2.1 × 6.3 mm with 0.12 mm AIW+PAI dual coat, 220 °C, on 500 kg returnable plastic spools?

We keep 450+ drawing dies and 26 enamel recipes on active carousel; new die cut in 48 h, first article PPAP in 5 days.

Standard lead time ex-works: 10–15 days ≤ 10 t, 20 days ≤ 50 t.

Air-sea combo to Hamburg, Duisburg or Houston adds 18–22 calendar days door-to-door, still 3–4 weeks faster than most domestic EU mills on non-stock sizes.

Compliance & Sustainability Package

Standards: IEC 60317-0-2, IEC 60317-16, NEMA MW 36-C, JIS C 3202, GB/T 7095.7

REACH & RoHS: Full SVHC disclosure, < 0.1 % phthalates

Carbon footprint: 2.9 kg CO₂-e kg⁻¹ wire (cradle-to-gate), 34 % below industry median (EcoInvent 3.9)

Packaging: FSC-certified timber, ISPM-15 heat-treated, plastic spools 100 % recyclable PP

Next Step—Get the Numbers

E-mail cathy@transformerstrip.com with your target cross-section, thermal class and annual volume.

We return a same-day datasheet, DDP price matrix and a 200-mm sample coil at no charge.

Lock in 2024 cathode pricing now—quotes valid 30 days, production slots assigned FIFO.

📉 Import Savings Calculator

Estimate cost reduction by sourcing rectangular enamelled copper wire from Luoyang Xinzhaohe.